Application

Typically, a chain hoist is part of the mechanisms for lifting and changing the boom reach of cranes and rigging devices

The pulley on its own is used for lifting (lowering) small loads (for example, boats on ships). Double chain hoists are widely used in the lifting mechanisms of many cranes - overhead, cantilever, gantry and others, where constant pressure on the drum supports during lifting or lowering of the load is important to ensure uniform loading of the bridge metal structure under both rails. Pulley hoist in mountaineering. In mountain tourism and mountaineering, pulley blocks are used to tension railings and crossings, and to lift a victim (for example, someone who has fallen into a crack)

A system of two gripping units or mechanical clamps, such as jumars, is used. In industrial mountaineering, the same principle is used in rigging work when lifting structures. An original solution for a specific climbing pulley is the so-called Munter pulley. Power pulleys are used in the electrification of railways to tension the wires of the contact network. Small pulleys are used for tensioning overhead communication and power cables, as well as supporting cables during the construction of overhead lines on poles and on the roofs of houses: human muscular strength usually does not allow pulling a large span of cable strongly enough. A chain hoist can be used to pull out a car stuck in the ground if there is no winch.

Block system - theory ↑

The invention of the chain hoist gave a huge impetus to the development of civilizations. The block system helped build huge structures, many of which have survived to this day and puzzle modern builders. Shipbuilding also improved, and people were able to travel great distances. It's time to figure out what it is - a chain hoist and find out where it can be used today.

Simplicity and efficiency of the mechanism

A classic chain hoist is a mechanism that consists of two main elements:

- pulley;

- flexible connection.

The simplest diagram: 1 – movable block, 2 – fixed, 3 – rope

A pulley is a metal wheel that has a special groove for a cable along its outer edge. An ordinary cable or rope can be used as a flexible connection. If the load is heavy enough, ropes made of synthetic fibers or steel ropes and even chains are used. To ensure that the pulley rotates easily, without jumping or jamming, roller bearings are used. All elements that move are lubricated.

One pulley is called a block. A pulley block is a system of blocks for lifting loads. The blocks in the lifting mechanism can be stationary (rigidly fixed) and movable (when the axis changes position during operation). One part of the pulley is attached to a fixed support, the other to the load. Movable rollers are located on the load side.

Fixed block

The role of the stationary block is to change the direction of movement of the rope and the action of the applied force. The role of the mobile is to gain strength.

Movable block

The operating principle of a pulley block is similar to a lever: the force that needs to be applied becomes several times smaller, while the work is performed in the same volume. The role of the lever is played by the cable

In the operation of a chain hoist, the gain in strength is important, so the resulting loss in distance is not taken into account

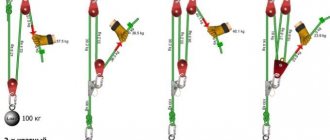

Depending on the design of the pulley, the gain in strength may be different. The simplest mechanism of two pulleys gives approximately a twofold gain, of three - threefold, and so on. The increase in distance is calculated using the same principle. To operate a simple pulley, you need a cable twice as long as the lifting height, and if you use a set of four blocks, then the length of the cable increases in direct proportion to four times.

Operating principle of the block system

A chain hoist is a faithful assistant in a warehouse, in production, and in the transport sector. It is used wherever force needs to be used to move all kinds of loads. The system is widely used in construction.

Despite the fact that most of the heavy work is performed by construction equipment (cranes), the chain hoist has found a place in the design of load-handling mechanisms. The block system (pulley block) is a component of such lifting mechanisms as a winch, hoist, and construction equipment (various types of cranes, bulldozer, excavator).

In addition to the construction industry, pulleys are widely used in organizing rescue operations. The principle of operation remains the same, but the design is slightly modified. Rescue equipment is made of durable rope and carabiners are used

For devices of this purpose, it is important that the entire system is quickly assembled and does not require additional mechanisms

Pulley hoist as part of a crane hook

Stationary gear hoists (HADEF, Germany)

| Manual chain gear hoist HADEF 8/12, lifting capacity from 0.25 to 2 tons (OPI) |

| Stationary gear hoist of the professional line HADEF (Germany), type 8/12. Load capacity from 250 kg to 2 tons. |

| Manual chain gear hoist HADEF 8/12, lifting capacity from 3 to 5 tons (OPI) |

| Stationary gear hoist of the professional line HADEF (Germany), type 8/12. G/p 3 and 5 tons. |

| Manual chain gear hoist HADEF 8/12, lifting capacity 10 tons (OPI) |

| Stationary gear hoist of the professional line HADEF (Germany), type 8/12. G/p 10 tons. |

| Manual chain gear hoist HADEF 9/12, lifting capacity from 0.5 to 2 tons (OPI) |

| Stationary gear hoist premium line HADEF (Germany), type 9/12. Load capacity from 500 kg to 2 tons. |

| Manual chain gear hoist HADEF 9/12, lifting capacity from 3 to 5 tons (OPI) |

| Stationary gear hoist premium line HADEF (Germany), type 9/12. G/p 3 and 5 tons. |

| Manual chain gear hoist HADEF 9/12, lifting capacity from 10 to 20 tons (OPI) |

| Stationary gear hoist premium line HADEF (Germany), type 9/12. G/p 10 and 20 tons. |

Types of pulleys

All chain hoists can be divided into two categories:

power;

high-speed.

Based on the name, the purpose of each type is determined. The first is the most common and is used for lifting loads, exactly as it was invented. The high-speed option is a modified design where great efforts are aimed at increasing the speed of transportation. This principle is used to create cable cars at ski resorts.

In addition, the difference lies in the number of rollers and working branches, as well as other modifications. An electric drive and a stopper can be connected to the structure. Another difference lies in the material of the rope, because it can be presented in the form:

ropes;

metal rope;

iron chain;

electrical cable.

In construction equipment, the second option is most often used due to the strength of the material. Rope ropes are most often used in tourism, rescue operations and so on. The use of an iron chain can be found very rarely; these are narrowly targeted varieties for certain jobs.

Lift with at home

Sometimes in everyday life there is a need to lift a heavy load, but not all people have the opportunity to drive a construction crane to the threshold, which requires them to get out of it. And this is where the block system can come to the rescue. Pulley hoists, the purpose and design of which may seem quite complicated to design, but with proper preparation, creating such a design at home will not be a problem. Everything is done in four stages:

Calculations. They are produced taking into account your goals and objectives, namely, the parameters of the working room, the presence of restrictions in it, the weight of the cargo and the distance over which it needs to be transported. It is necessary to record all these data to draw up a drawing and select a design.

Creating a drawing. If you have no experience in this matter, then it is better to contact a person with experience and engineering education who can reduce the time for creating a model on paper. If you can’t get help from anywhere, then it’s better to go online and look at working drawings of basic structures. Each type will be effective under certain conditions, which you will measure earlier.

Selection of materials. The selection should begin already in the first stages, namely, starting from the things you already have and those that can be purchased. It depends on your drawing and calculations what parts will be needed and what material is best to use. Buy according to your budget and with a reserve for future use. You shouldn’t save much, otherwise the design may fail at the most crucial moment.

Construction. This step is the simplest of all, because here you just need to follow the plan and do it conscientiously.

With a certain skill and preparedness, you can get a very high-quality working model that will not be inferior to construction analogues. But if the tasks are not too ambitious, then this will not require significant expenses. For reliability, you can use ready-made parts from construction pulleys.

operating principle of a pulley block.

| How a chain hoist works - we get a gain in strength |

| Click to view | A little theory. A visual video tutorial on how a chain hoist works. Would you like to know how you can use… |

| Tags: |

| Galileo. Experiment. Block system |

| Click to view | No. 534 from #Galileo #GalileoEk experiments block system. How it can be used to easily lift heavy… |

| Tags: |

| 7th grade Block and block system |

| Click to view | We consider such a simple mechanism as a block. It is shown what gains in strength are given by mobile and stationary... |

| Tags: |

| Polyspast 5:1. The first video about chain hoists. |

| Click to view | A pulley for pulling a rope or lifting a load. Pulley hoists are used both in mountaineering, when... |

| Tags: |

| Click to view | Making a homemade pulley block. |

| Tags: |

| Blocks. "The Golden Rule of Mechanics" |

| Click to view | You can download this video for your work using the link: ... |

| Tags: |

| How to pull a car out of the mud / A pulley is power |

| Click to view | We were looking for a picturesque place to set up a trolley descent. Specifically, stuck in the mud, help push... |

| Tags: |

| How does a chain winch work and what does it consist of? |

| Click to view | Operating principle and components of a lifting chain winch. |

| Tags: |

| Pulley hoist, we pulled the car out of the snowdrift. |

| Click to view | How to pull a car out of a snowdrift, mud or swamp if you are stuck and have no one to call for help. Using rope... |

| Tags: |

| Click to view | Homemade block lifting device for use in the garage. when installing the engine, transfer case,... |

| Tags: |

| Manual mini crane - homemade lifting device, chain hoist |

| Click to view | A short training video on how to assemble a simple chain hoist. Everything you need can be ordered… |

| Tags: |

| Assembly of the chain hoist |

| Click to view | A pulley block is a system of several movable and fixed blocks and a cable passing through them... |

| Tags: |

| Pulley and Rollers (winch reinforcement unit). Let's deal with misconceptions. Let's learn to use it. |

| Click to view | Help me make my dream come true, no matter how much I feel sorry for “I want to buy a metal lathe”! Requisites:. .. |

| Tags: |

| Explanation! The principle of operation of the hoist! |

| Click to view | Where did you buy it? Our YouTube channel... |

| Tags: |

| Click to view | Statics. A simple task with basic explanations. For beginners . In the frame at the blackboard is student Pyotr Gorshkov. |

| Tags: |

| Click to view | The sequence of actions when eliminating play in the boom section extension pulley and tensioning... |

| Tags: |

| Adjusting the boom extension and retraction pulley |

| Click to view | You can watch a detailed description of the video experience on our website: ... |

| Tags: |

| Click to view | How it works! “Polyspato system in” |

| Tags: |

| The Pulley Systems Learn from a Pro Use them to To |

| Click to view | Pulley hoist - pulled by many ropes or cables, a lifting device consisting of an assembly ... |

| Tags: |

| Construction chain hoist, manual winch (how to lift a heavy load) |

Chain hoists of general industrial design with normal construction height

| Chain hoist HADEF AK410 |

| Electric chain hoist HADEF, AKE66/04 series, lifting capacity 1 ton. |

| Chain hoist HADEF AK1010 |

| Electric chain hoist HADEF, AKE66/04 series, with a lifting capacity of 10 tons, with increased lifting speed. |

| Chain hoist HADEF AK910 |

| Electric chain hoist HADEF, AKE66/04 series, with a load capacity of 10 tons. |

| Chain hoist HADEF AK906 |

| HADEF electric chain hoist, AKE66/04 series, with a load capacity of 6.3 tons. |

| Chain hoist HADEF AK850 |

| Electric chain hoist HADEF, AKE66/04 series, with a load capacity of 5 tons. |

| Chain hoist HADEF AK832 |

| Electric chain hoist HADEF, AKE66/04 series, with a lifting capacity of 3.2 tons, with an increased lifting speed. |

| Chain hoist HADEF AK732 |

| Electric chain hoist HADEF, AKE66/04 series, with a load capacity of 3.2 tons. |

| Chain hoist HADEF AK620 |

| Electric chain hoist HADEF, AKE66/04 series, lifting capacity 2 tons. |

| Chain hoist HADEF AK1025 |

| Electric chain hoist HADEF, AKE66/04 series, with a lifting capacity of 25 tons, with increased lifting speed. |

| Chain hoist HADEF AK820 |

| Electric chain hoist HADEF, AKE66/04 series, with a lifting capacity of 2 tons, with an increased lifting speed. |

| Chain hoist HADEF AK610 |

| Electric chain hoist HADEF, AKE66/04 series, lifting capacity 1 ton, with increased lifting speed. |

| Chain hoist HADEF AK1020 |

| Electric chain hoist HADEF, AKE66/04 series, with a lifting capacity of 20 tons, with increased lifting speed. |

| Chain hoist HADEF AK1012 |

| Electric chain hoist HADEF, AKE66/04 series, with a lifting capacity of 12.5 tons, with increased lifting speed. |

| Chain hoist HADEF AK925 |

| Electric chain hoist HADEF, AKE66/04 series, with a load capacity of 25 tons. |

| Chain hoist HADEF AK920 |

| Electric chain hoist HADEF, AKE66/04 series, with a load capacity of 20 tons. |

| Chain hoist HADEF AK915 |

| Electric chain hoist HADEF, AKE66/04 series, with a load capacity of 15 tons. |

| Chain hoist HADEF AK905 |

| Electric chain hoist HADEF, AKE66/04 series, with a lifting capacity of 5 tons, with increased lifting speed. |

How to make a lift with your own hands ↑

In construction, during installation work, it is not always possible to fit a crane. Then the question arises of how to lift the load with a rope. And here a simple chain hoist finds its application. To make it and fully operate, you need to make calculations, drawings, and choose the right rope and blocks.

Different schemes of simple and complex lifts

Before you start building a chain hoist with your own hands, you need to carefully study the drawings and choose a suitable scheme for yourself. You should rely on how it will be more convenient for you to place the structure, what blocks and cable are available.

It happens that the lifting capacity of the pulley blocks is not enough, and there is no time or opportunity to build a complex multiple lifting mechanism. Then double chain hoists are used, which are a combination of two single ones. This device can also lift the load so that it moves strictly vertically, without distortions.

Drawings of a dual model in different variations

The most important role in building a chain hoist with your own hands is played by the rope

It is important that it does not stretch. Such ropes are called static

Stretching and deformation of a flexible connection causes serious losses in work efficiency. For a homemade mechanism, a synthetic cable is suitable; the thickness depends on the weight of the load.

The material and quality of the blocks are indicators that will provide homemade lifting devices with the calculated load capacity. Depending on the bearings that are installed in the block, its efficiency changes and this is already taken into account in the calculations.

But how can you lift a load to a height with your own hands and not drop it? To protect the load from possible reverse movement, you can install a special locking block that allows the rope to move only in one direction - the desired direction.

Roller along which the rope moves

When the rope and blocks are ready, the diagram has been selected, and the calculations have been made, you can begin assembly. For a simple double pulley you will need:

- roller – 2 pcs.;

- bearings;

- bushing – 2 pcs.;

- clip for block – 2 pcs.;

- rope;

- hook for hanging cargo;

- slings - if they are needed for installation.

Carabiners are used for quick connection

Step-by-step lifting of the load to a height is carried out as follows:

- Connect the rollers, bushing and bearings. They combine all this into a clip. Get a block.

- The rope is launched into the first block;

- The clip with this block is rigidly attached to a fixed support (reinforced concrete beam, pillar, wall, specially mounted extension, etc.);

- The end of the rope is then passed through the second block (movable).

- A hook is attached to the clip.

- The free end of the rope is fixed.

- They sling the lifted load and connect it to the chain hoist.

The homemade lifting mechanism is ready to use and will provide double the strength benefits. Now, to raise the load to a height, just pull the end of the rope. By bending around both rollers, the rope will lift the load without much effort.

If you attach an electric winch to the homemade mechanism that you build according to these instructions, you will get a real do-it-yourself crane. Now you don’t have to strain at all to lift the load; the winch will do everything for you.

Even a manual winch will make lifting the load more comfortable - you don’t need to rub your hands on the rope and worry about the rope slipping out of your hands. In any case, turning the winch handle is much easier.

Pulley hoist for winch

In principle, even outside a construction site, the ability to build a basic pulley system for a winch in field conditions with a minimum of tools and materials is a very useful skill. It will be especially appreciated by motorists who are lucky enough to get their car stuck somewhere in an impassable place. A hastily made pulley will significantly increase the performance of the winch.

It is difficult to overestimate the importance of pulley hoists in the development of modern construction and mechanical engineering. Everyone should understand the principle of operation and visually imagine its design. Now you are not afraid of situations when you need to lift a load, but there is no special equipment. A few pulleys, a rope and ingenuity will allow you to do this without using a crane.

Electric chain hoists produced by Skladova Tekhnika (Bulgaria)

| Suspended two-speed electric chain hoist, B031M (Bulgaria) |

| Suspended chain electric hoist with a load capacity of 125 kg with two speeds. Production: Warehouse equipment (Bulgaria). |

| Mobile two-speed electric chain hoist, B091M (Bulgaria) |

| Electric chain hoist with a load capacity of 125 kg and two speeds. Production: Warehouse equipment (Bulgaria). |

| Suspended two-speed electric chain hoist, B032M (Bulgaria) |

| Suspended chain electric hoist with a load capacity of 250 kg with two speeds. Production: Warehouse equipment (Bulgaria). |

| Suspended two-speed electric chain hoist, chain hoist 2/1, B041M (Bulgaria) |

| Suspended chain electric hoist with a load capacity of 250 kg with two speeds, chain hoist 2/1. Production: Warehouse equipment (Bulgaria). |

| Mobile two-speed electric chain hoist, B092M (Bulgaria) |

| Mobile chain electric hoist with two speeds with a load capacity of 250 kg. Production: Warehouse equipment (Bulgaria). |

| Mobile two-speed electric chain hoist, pulley 2/1, B101M (Bulgaria) |

| Mobile chain electric hoist with a 2/1 chain hoist and two speeds with a load capacity of 250 kg. Production: Warehouse equipment (Bulgaria). |

| Suspended two-speed electric chain hoist, pulley block 2/1, B042M (Bulgaria) |

| Suspended chain electric hoist with a load capacity of 500 kg with two speeds, chain hoist 2/1. Production: Warehouse equipment (Bulgaria). |

| Suspended two-speed electric chain hoist, B033M (Bulgaria) |

| Suspended chain electric hoist with a load capacity of 500 kg with two speeds. Production: Warehouse equipment (Bulgaria). |

| Mobile two-speed electric chain hoist, pulley 2/1, B102M (Bulgaria) |

| Mobile chain electric hoist with a 2/1 chain hoist and two speeds with a load capacity of 500 kg. Production: Warehouse equipment (Bulgaria). |

| Mobile two-speed electric chain hoist, B093M (Bulgaria) |

| Mobile chain electric hoist with two speeds with a load capacity of 500 kg. Production: Warehouse equipment (Bulgaria). |

| Suspended two-speed electric chain hoist, chain hoist 2/1, B043M (Bulgaria) |

| Suspended chain electric hoist with a lifting capacity of 1 ton with two speeds, pulley 2/1. Production: Warehouse equipment (Bulgaria). |

| Mobile two-speed electric chain hoist, pulley 2/1, B103M (Bulgaria) |

| Mobile chain electric hoist with a 2/1 pulley and two speeds with a lifting capacity of 1 ton. Manufacture: Warehouse equipment (Bulgaria). |

| Suspended two-speed electric chain hoist, chain hoist 2/1, BY044M (Bulgaria) |

| Suspended chain electric hoist with a lifting capacity of 2 tons with two speeds, pulley 2/1. Production: Warehouse equipment (Bulgaria). |

| Mobile two-speed electric chain hoist, pulley 2/1, BY104M (Bulgaria) |

| Mobile chain electric hoist with a 2/1 pulley and two speeds with a lifting capacity of 2 tons. Manufacturer: Warehouse equipment (Bulgaria). |

| Mobile two-speed electric chain hoist, chain hoist 3/1, BY105M (Bulgaria) |

| Mobile chain electric hoist with a 3/1 pulley and two speeds with a lifting capacity of 3 tons. Production: Warehouse equipment (Bulgaria). |

In what areas is the device used?

The chain hoist is used for lifting and moving loads in cases where only human physical strength and the smallest number of auxiliary mechanisms can be used. Also, the chain hoist is the most important component of winches, cranes and other mechanization equipment.

For this reason, these devices are used in practically all areas where lifting and transport mechanisms are used in any way: from household tasks to heavy industry.

So, on what principle does a chain hoist operate? The operation of this device is based on the law of leverage: if you gain in strength, you lose in distance. Since this principle is very simple, making a chain hoist with your own hands will not be difficult. To do this, you only need two single-roller blocks.

To lift a load of a certain mass using a pulley, you need to make an effort that is half its mass. We should not forget about the length of the rope used. It should be twice the height to which the load will be lifted. It should be noted that pulleys with the simplest design are called “two-to-one pulleys,” since they double the applied force. The design with three blocks, accordingly, gives a threefold increase in strength.

Mobile gear hoists (HADEF, Germany)

| Manual chain gear hoist HADEF 240/12 HR+HH with trolley, lifting capacity from 0.5 to 5 tons (OPI) |

| Mobile gear hoist of the professional line HADEF (Germany), type 240/12 HR+HH. Load capacity from 500 kg to 5 tons. |

| Manual chain gear hoist HADEF 21/12 HR+HH with trolley, lifting capacity from 0.5 to 10 tons (OPI) |

| Mobile gear hoist premium line HADEF (Germany), type 21/12 HR+HH. Load capacity from 500 kg to 10 tons. |

| Manual chain gear hoist HADEF 24/12 HR+HH with trolley, lifting capacity from 0.5 to 10 tons (OPI) |

| Mobile gear hoist premium line HADEF (Germany), type 24/12 HR+HH. Load capacity from 500 kg to 10 tons. |

| Manual chain gear hoist HADEF 26/12 HH with trolley, lifting capacity from 5 to 25 tons (OPI and VBI) |

| Premium mobile gear hoist of the HADEF line (Germany) with ultra-low height, type 26/12 HH. G/p from 5 to 25 tons. |

| Manual chain gear hoist HADEF 27/12 HR+HH with trolley, lifting capacity from 0.5 to 10 tons (OPI and VBI) |

| Premium mobile gear hoist from HADEF line (Germany), type 27/12 HR+HH. Load capacity from 500 kg to 10 tons. |

Performance characteristics of chain hoists and their selection

The effectiveness of pulley blocks, their purpose and design in a particular mechanism are influenced by the following factors:

Load capacity of the main mechanism in which these units operate. Number of bypass blocks: as their number increases, friction losses increase. Deflection angles of ropes from the middle plane of the drum. Block diameters. Rope diameter/chain height. Rope material. The nature of the supports (in rolling or sliding bearings). Conditions for lubrication of all axes of the pulley block. Speed of rotation of blocks or movement of traction ropes (depending on the purpose of the device).

The greatest losses in pulleys are associated with friction conditions. In particular, the efficiency of the mechanisms under consideration, which operate in sliding bearings, depending on their operating conditions, is:

- With unsatisfactory lubrication and at elevated temperatures - 0.94...0.54;

- With rare lubrication - 0.95...0.60;

- With periodic lubrication - 0.96...0.67;

- With automatic lubrication - 0.97...0.74.

Smaller values correspond to pulleys with the highest possible multiplicity. Friction losses for units that operate in rolling bearings are much lower and amount to:

- With insufficient lubrication and high operating temperatures - 0.99...0.83;

- At normal operating temperatures and lubrication - 1.0...0.92.

Thus, by using modern antifriction coatings on the contact surface of blocks, friction losses can be virtually eliminated.

The angles of deflection of the rope located on the pulley block/blocks determine not only the wear of the ropes and blocks, but also the safety of the production personnel of the lifting device. This is explained by the fact that if the permissible values are exceeded, the rope coming off the block is fraught with an industrial accident. This parameter is influenced by the material of the ropes, the profile of the drum groove, as well as the direction of winding. The most common types of rope materials are TLK-O according to GOST 3079, LK-R according to GOST 2688 and TK according to GOST 3071. The third type has the lowest rigidity (no more than 1.7), which has a positive effect on the maximum permissible angle of deflection of the rope on the pulley. Accordingly, for the first two types of ropes, the stiffness reaches 2.

Normal angles of deviation from the pulley axis are considered to be angles of 7.5...2.50 (smaller values are accepted for maximum ratios of the block diameter to the rope diameter). In general, when designing these devices, they always try to choose this ratio in the range of values 12...40. The permissible angle of deflection of ropes made of low-rigid materials is less: up to 6.5...20.

GOST allows an increase in the maximum deviation, compared to the recommended one, by no more than 10...20% (depending on the operating mode of the lifting equipment). On the equalizing block, the permissible deviation angles can increase, but not more than 1.5 times.

To reduce the deflection angles, profile grooves are made on the pulley drums, and the angle of their direction depends on the winding direction. Therefore, drums in mechanisms of modern design are always made with a cross profile, suitable for both types of winding.

https://youtube.com/watch?v=OVVkLuirvQg%3F

Pneumatic hoists with manual drive for movement, incl. nosocomial infection

| Pneumatic mobile hoist with manual drive, HADEF AP 405 TI8 |

| Chain mobile pneumatic hoist type 70/06 APR + APH, capacity 500 kg. Manufacturer: HADEF (Germany). |

| Pneumatic mobile hoist with manual drive, HADEF AP 410 TI8 |

| Chain mobile pneumatic hoist type 70/06 APR + APH, lifting capacity 1000 kg, pulley multiplicity 2. Manufacturer: HADEF (Germany). |

| Pneumatic mobile hoist with manual drive, HADEF AP 610 TI15 |

| Chain mobile pneumatic hoist type 70/06 APR + APH, capacity 1000 kg. Manufacturer: HADEF (Germany). |

| Pneumatic mobile hoist with manual drive, HADEF AP 716 TI25 |

| Chain mobile pneumatic hoist type 70/06 APR + APH, capacity 1600 kg. Manufacturer: HADEF (Germany). |

| Pneumatic mobile hoist with manual drive, HADEF AP 620 TI15 |

| Chain mobile pneumatic hoist type 70/06 APR + APH, lifting capacity 2000 kg, pulley multiplicity 2. Manufacturer: HADEF (Germany). |

| Pneumatic mobile hoist with manual drive, HADEF AP 820 TI35 |

| Chain mobile pneumatic hoist type 70/06 APR + APH, capacity 2000 kg. Manufacturer: HADEF (Germany). |

Classification of models according to different characteristics ↑

There are many executions of one idea - a system of blocks connected by rope. They are differentiated depending on the method of application and design features. Get to know the different types of lifts, find out what their purpose is and how the device differs.

Depending on the complexity of the mechanism, there are

- simple;

- complex;

- complex chain hoists.

Example of even models

A simple chain hoist is a system of series-connected rollers. All movable and fixed blocks, as well as the load itself, are combined by one cable. Even and odd simple pulleys are differentiated.

Even lifting mechanisms are those whose end of the cable is attached to a fixed support - a station. All combinations in this case will be considered even. And if the end of the rope is attached directly to the load or the place where the force is applied, this structure and all its derivatives will be called odd.

Odd chain hoist diagram

A complex pulley system can be called a pulley system. In this case, not individual blocks are connected in series, but entire combinations that can be used on their own. Roughly speaking, in this case one mechanism sets in motion another similar one.

The complex chain hoist does not belong to one or the other type. Its distinctive feature is rollers moving towards the load. The complex model can include both simple and complex chain hoists.

Combining a two-fold and six-fold simple chain hoist gives a complex six-fold version

Depending on what they want to get when using a chain hoist, they are divided into:

A – power version, B – high-speed

The power option is used more often. As the name suggests, its task is to ensure a gain in strength. Since significant gains require equally significant losses in distance, losses in speed are also inevitable. For example, for a 4:1 system, when lifting a load one meter, you need to pull 4 meters of cable, which slows down the work.

The high-speed chain hoist, by its principle, is a reverse power design. It does not give a gain in strength, its goal is speed. Used to speed up work at the expense of the applied effort.

The main indicator that people pay attention to when organizing cargo lifting is the multiplicity of the pulley. This parameter conventionally indicates how many times the mechanism allows you to win in strength

In fact, the multiplicity shows how many branches of the rope the weight of the load is distributed over.

Kinematic ratio

The multiplicity is divided into kinematic (equal to the number of kinks in the rope) and force, which is calculated taking into account the cable’s overcoming the friction force and the non-ideal efficiency of the rollers. The reference books contain tables that display the dependence of the power factor on the kinematic factor at different block efficiencies.

As can be seen from the table, the force multiplicity differs significantly from the kinematic one. With a low roller efficiency (94%), the actual gain in strength of a 7:1 pulley will be less than the gain of a six-fold pulley with a block efficiency of 96%.

Schemes of pulleys of different multiplicities

Stationary pneumatic hoists, incl. nosocomial infection

| Stationary pneumatic hoist, HADEF AP 405 TI8 |

| Chain stationary pneumatic hoist, capacity 500 kg. Manufacturer: HADEF (Germany). |

| Stationary pneumatic hoist, HADEF AP 410 TI8 |

| Chain stationary pneumatic hoist, type 70/06 APS, lifting capacity 1000 kg, pulley ratio 2. Manufacturer: HADEF (Germany). |

| Stationary pneumatic hoist, HADEF AP 610 TI15 |

| Chain stationary pneumatic hoist, type 70/06 APS, capacity 1000 kg. Manufacturer: HADEF (Germany). |

| Stationary pneumatic hoist, HADEF AP 716 TI25 |

| Chain stationary pneumatic hoist, type 70/06 APS, lifting capacity 1.6 t. Manufacturer: HADEF (Germany). |

| Stationary pneumatic hoist, HADEF AP 620 TI15 |

| Chain stationary pneumatic hoist, type 70/06 APS, lifting capacity 2 tons, pulley ratio 2. Manufacturer: HADEF (Germany). |

| Stationary pneumatic hoist, HADEF AP 820 TI35 |

| Chain stationary pneumatic hoist, type 70/06 APS, capacity 2 tons. Manufacturer: HADEF (Germany). |

| Stationary pneumatic hoist, HADEF AP 732 TI25 |

| Chain stationary pneumatic hoist, type 70/06 APS, lifting capacity 3.2 t, pulley ratio 2. Manufacturer: HADEF (Germany). |

Purpose and use of the chain hoist

In modern construction, pulley blocks are used very widely. The crane hooks of a complex design with jaws are immediately designed for them.

The pulley design can be blocked if it is not necessary. The use of a chain hoist as an independent hydraulic lifting mechanism is limited by only one factor - the lack of a brake, which is vital in lifting machines.

Many specialized companies sell chain hoists. Before buying a chain hoist, make sure that the selected characteristics are correct for your needs and if in doubt, contact a professional.