Load grippers | 03/19/2017

Pulley hoists are a system formed by movable and fixed blocks that are connected to each other by rope (less often, chain) transmissions. Known back in ancient times, pulley blocks are still a device without which lifting and transport equipment cannot function. In fact, the components of this mechanism have not changed much over the millennia. Pulley hoists, their purpose and design are issues that are important for the effective use of all designs of lifting mechanisms.

The design of the pulley and its operating conditions

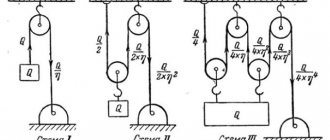

The main area of application for pulley blocks is jib mechanisms of cranes. The whole variety of pulleys can be reduced to two requirements: either increase the force (power pulleys) or increase the speed (high-speed pulleys). In cranes, the former are more often used, and in hoists, the latter. Thus, the schemes of high-speed and power pulleys are mutually inverse.

The chain hoist includes the following components:

- Blocks with fixed axes

- Blocks with moving axes.

- Bypass blocks.

- Stroke drums.

All of the above elements are located predominantly in a vertical layout, and the location of the drum depends on the presence of bypass blocks: on top, if such blocks are absent, and below, if present.

The number of blocks with fixed axes is always one less than with moving ones. In this case, the total number of blocks determines (for power pulleys) the multiplicity of the increase in the total force on the mechanism. The number of bypass blocks is determined by the size of the unit: with an increase in the number of such blocks, the force also increases.

Power pulleys, the purpose and design of which are characterized by several parameters, the most important of which is the load developed in the lifting mechanism. It increases with the increase in the calculated load capacity of the crane, the multiplicity of the device (the number of rope branches on which the load is suspended) and the efficiency of the block. Efficiency takes into account friction losses in axial supports, as well as losses determined by the rigidity of the rope or chain.

There can be several pulley blocks, then the total load on the block is proportionally reduced. Single chain hoists are structurally simpler, but also the least effective. In them, one end is fixedly fixed on a stationary element, and the other on the drum. In this case, the angle of deflection is very limited due to the danger of the rope coming off the block. The presence of a bypass block significantly improves the operating conditions of the mechanism: the load becomes symmetrical, which reduces rope wear and increases the permissible speed of rotation of the blocks. The stability of the pulley block also depends on the distance between the bypass and main blocks. With an increase in this parameter, the reliability of the pulley as a functional unit increases, although at the same time its complexity increases (due to the presence of a connecting axis). Other chain hoist schemes used in practice are:

- Double three-fold, when the circuit contains three working units and two bypass units;

- Double triple, equipped with a leveling beam. This option is used in lifting equipment, which is operated in difficult and especially difficult conditions.

Classification of models according to different characteristics

There are many executions of one idea - a system of blocks connected by rope. They are differentiated depending on the method of application and design features. Get to know the different types of lifts, find out what their purpose is and how the device differs.

Classification depending on the complexity of the mechanism

Depending on the complexity of the mechanism, there are

- simple;

- complex;

- complex chain hoists.

Example of even models

A simple chain hoist is a system of series-connected rollers. All movable and fixed blocks, as well as the load itself, are combined by one cable. Even and odd simple pulleys are differentiated.

Even lifting mechanisms are those whose end of the cable is attached to a fixed support - a station. All combinations in this case will be considered even. And if the end of the rope is attached directly to the load or the place where the force is applied, this structure and all its derivatives will be called odd.

Odd chain hoist diagram

A complex pulley system can be called a pulley system. In this case, not individual blocks are connected in series, but entire combinations that can be used on their own. Roughly speaking, in this case one mechanism sets in motion another similar one.

The complex chain hoist does not belong to one or the other type. Its distinctive feature is rollers moving towards the load. The complex model can include both simple and complex chain hoists.

Combining a two-fold and six-fold simple chain hoist gives a complex six-fold version

Classification according to the purpose of the lift

Depending on what they want to get when using a chain hoist, they are divided into:

- power;

- high-speed.

A – power version, B – high-speed

The power option is used more often. As the name suggests, its task is to ensure a gain in strength. Since significant gains require equally significant losses in distance, losses in speed are also inevitable. For example, for a 4:1 system, when lifting a load one meter, you need to pull 4 meters of cable, which slows down the work.

The high-speed chain hoist, by its principle, is a reverse power design. It does not give a gain in strength, its goal is speed. Used to speed up work at the expense of the applied effort.

Multiplicity is the main characteristic

The main indicator that people pay attention to when organizing cargo lifting is the multiplicity of the pulley. This parameter conventionally indicates how many times the mechanism allows you to win in strength. In fact, the multiplicity shows how many branches of the rope the weight of the load is distributed over.

Kinematic ratio

The multiplicity is divided into kinematic (equal to the number of kinks in the rope) and force, which is calculated taking into account the cable’s overcoming the friction force and the non-ideal efficiency of the rollers. The reference books contain tables that display the dependence of the power factor on the kinematic factor at different block efficiencies.

As can be seen from the table, the force multiplicity differs significantly from the kinematic one. With a low roller efficiency (94%), the actual gain in strength of a 7:1 pulley will be less than the gain of a six-fold pulley with a block efficiency of 96%.

Schemes of pulleys of different multiplicities

Performance characteristics of chain hoists and their selection

The effectiveness of pulley blocks, their purpose and design in a particular mechanism are influenced by the following factors:

- Load capacity of the main mechanism in which these units operate.

- Number of bypass blocks: as their number increases, friction losses increase.

- Deflection angles of ropes from the middle plane of the drum.

- Block diameters.

- Rope diameter/chain height.

- Rope material.

- The nature of the supports (in rolling or sliding bearings).

- Conditions for lubrication of all axes of the pulley block.

- Speed of rotation of blocks or movement of traction ropes (depending on the purpose of the device).

The greatest losses in pulleys are associated with friction conditions. In particular, the efficiency of the mechanisms under consideration, which operate in sliding bearings, depending on their operating conditions, is:

- With unsatisfactory lubrication and at elevated temperatures - 0.94...0.54;

- With rare lubrication - 0.95...0.60;

- With periodic lubrication - 0.96...0.67;

- With automatic lubrication - 0.97...0.74.

Smaller values correspond to pulleys with the highest possible multiplicity. Friction losses for units that operate in rolling bearings are much lower and amount to:

- With insufficient lubrication and high operating temperatures - 0.99...0.83;

- At normal operating temperatures and lubrication - 1.0...0.92.

Thus, by using modern antifriction coatings on the contact surface of blocks, friction losses can be virtually eliminated.

The angles of deflection of the rope located on the pulley block/blocks determine not only the wear of the ropes and blocks, but also the safety of the production personnel of the lifting device. This is explained by the fact that if the permissible values are exceeded, the rope coming off the block is fraught with an industrial accident. This parameter is influenced by the material of the ropes, the profile of the drum groove, as well as the direction of winding. The most common types of rope materials are TLK-O according to GOST 3079, LK-R according to GOST 2688 and TK according to GOST 3071. The third type has the lowest rigidity (no more than 1.7), which has a positive effect on the maximum permissible angle of deflection of the rope on the pulley. Accordingly, for the first two types of ropes, the stiffness reaches 2.

Normal angles of deviation from the pulley axis are considered to be angles of 7.5...2.50 (smaller values are accepted for maximum ratios of the block diameter to the rope diameter). In general, when designing these devices, they always try to choose this ratio in the range of values 12...40. The permissible angle of deflection of ropes made of low-rigid materials is less: up to 6.5...20.

GOST allows an increase in the maximum deviation, compared to the recommended one, by no more than 10...20% (depending on the operating mode of the lifting equipment). On the equalizing block, the permissible deviation angles can increase, but not more than 1.5 times.

To reduce the deflection angles, profile grooves are made on the pulley drums, and the angle of their direction depends on the winding direction. Therefore, drums in mechanisms of modern design are always made with a cross profile, suitable for both types of winding.

How to make a lift with your own hands

In construction, during installation work, it is not always possible to fit a crane. Then the question arises of how to lift the load with a rope. And here a simple chain hoist finds its application. To make it and fully operate, you need to make calculations, drawings, and choose the right rope and blocks.

Different schemes of simple and complex lifts

Preparation of the base - diagram and drawing

Before you start building a chain hoist with your own hands, you need to carefully study the drawings and choose a suitable scheme for yourself. You should rely on how it will be more convenient for you to place the structure, what blocks and cable are available.

It happens that the lifting capacity of the pulley blocks is not enough, and there is no time or opportunity to build a complex multiple lifting mechanism. Then double chain hoists are used, which are a combination of two single ones. This device can also lift the load so that it moves strictly vertically, without distortions.

Drawings of a dual model in different variations

How to choose a rope and block

The most important role in building a chain hoist with your own hands is played by the rope. It is important that it does not stretch. Such ropes are called static. Stretching and deformation of a flexible connection causes serious losses in work efficiency. For a homemade mechanism, a synthetic cable is suitable; the thickness depends on the weight of the load.

The material and quality of the blocks are indicators that will provide homemade lifting devices with the calculated load capacity. Depending on the bearings that are installed in the block, its efficiency changes and this is already taken into account in the calculations.

But how can you lift a load to a height with your own hands and not drop it? To protect the load from possible reverse movement, you can install a special locking block that allows the rope to move only in one direction - the desired direction.

Roller along which the rope moves

Step-by-step instructions for lifting a load through a block

When the rope and blocks are ready, the diagram has been selected, and the calculations have been made, you can begin assembly. For a simple double pulley you will need:

- roller – 2 pcs.;

- bearings;

- bushing – 2 pcs.;

- clip for block – 2 pcs.;

- rope;

- hook for hanging cargo;

- slings - if they are needed for installation.

Carabiners are used for quick connection

Step-by-step lifting of the load to a height is carried out as follows:

- Connect the rollers, bushing and bearings. They combine all this into a clip. Get a block.

- The rope is launched into the first block;

- The clip with this block is rigidly attached to a fixed support (reinforced concrete beam, pillar, wall, specially mounted extension, etc.);

- The end of the rope is then passed through the second block (movable).

- A hook is attached to the clip.

- The free end of the rope is fixed.

- They sling the lifted load and connect it to the chain hoist.

The homemade lifting mechanism is ready to use and will provide double the strength benefits. Now, to raise the load to a height, just pull the end of the rope. By bending around both rollers, the rope will lift the load without much effort.

Is it possible to combine a chain hoist and a winch?

If you attach an electric winch to the homemade mechanism that you build according to these instructions, you will get a real do-it-yourself crane. Now you don’t have to strain at all to lift the load; the winch will do everything for you.

Even a manual winch will make lifting the load more comfortable - you don’t need to rub your hands on the rope and worry about the rope slipping out of your hands. In any case, turning the winch handle is much easier.

Pulley hoist for winch

In principle, even outside a construction site, the ability to build a basic pulley system for a winch in field conditions with a minimum of tools and materials is a very useful skill. It will be especially appreciated by motorists who are lucky enough to get their car stuck somewhere in an impassable place. A hastily made pulley will significantly increase the performance of the winch.

It is difficult to overestimate the importance of pulley hoists in the development of modern construction and mechanical engineering. Everyone should understand the principle of operation and visually imagine its design. Now you are not afraid of situations when you need to lift a load, but there is no special equipment. A few pulleys, a rope and ingenuity will allow you to do this without using a crane.

Pulley hoists are a system formed by movable and fixed blocks that are connected to each other by rope (less often, chain) transmissions. Known back in ancient times, pulley blocks are still a device without which lifting and transport equipment cannot function. In fact, the components of this mechanism have not changed much over the millennia. Pulley hoists, their purpose and design are issues that are important for the effective use of all designs of lifting mechanisms.