Since people discovered metal, they have learned to use it in almost all areas of life. Moreover, each application requires specific characteristics from the metal. Therefore, in the modern world there are thousands of types of metals and alloys. One of the well-known and commonly used grades is C345 steel.

Chemical composition

The chemical composition of steel C345 according to heat analysis of a ladle sample must comply with the standards given in table. 1 (Table 1-2 GOST 27772-88).

Chemical composition of steel according to heat analysis of ladle sample

| carbon | manganese | silicon | sulfur | phosphorus | chromium | nickel | copper | arsenic |

| Mass fraction of element, %, no more | ||||||||

| 0,15 | 1,30-1,70 | 0,80 | 0,035 | 0,040 | 0,30 | 0,08 | ||

| Maximum deviations by mass fraction of elements, % | ||||||||

| ±0,020 | ±0,100 | ±0,050 | +0,050 | ±0,050 | — | |||

Note: When smelting steel from Kerch ores, the mass fraction of arsenic is no more than 0.15%, phosphorus is no more than 0.030%.

The addition of aluminum and titanium is allowed based on obtaining a mass fraction of titanium in rolled products of 0.01-0.03% (clause 2.8 of GOST 27772-88).

At the consumer's request, the mass fraction of phosphorus should be 0.030%, sulfur - no more than 0.035% (clause 2.9 of GOST 27772-88).

It is allowed to treat steel with synthetic slags, vacuum degassing, blowing with argon, modifying steel with calcium and rare earth elements based on the introduction of no more than 0.02% calcium and 0.05% rare earth elements into the metal (clause 2.10 of GOST 27772-88).

It is permissible for the manufacturer not to conduct a chemical analysis of steel for chromium, nickel, copper, and arsenic content. The required chemical composition is guaranteed by the manufacturer. In steel smelted from Kerch ores, the determination of arsenic is mandatory (clause 2.13.1 of GOST 27772-88).

The weldability of steel is guaranteed by the manufacturer (clause 2.18 of GOST 27772-88).

Mechanical properties

The mechanical properties of shapes and sheets made of steel C345 in tension, impact strength, as well as bending test conditions must meet the requirements of Table 2 (Table 3-4, clause 2.7 of GOST 27772-88).

Mechanical properties of rolled steel C345

| Thickness, shelves, mm | Mechanical characteristics | Bending until the sides are parallel (a is the thickness of the sample, d is the diameter of the mandrel) | Impact strength KCU, J/cm² (kgf m/cm²) | |||||

| Yield strength σ t, MPa (kgf/mm²) | Tensile strength σв, MPa (kgf/mm²) | Relative elongation δ5, % | at temperature, °C | after mechanical aging | ||||

| −20 | −40 | −70 | ||||||

| no less | no less | |||||||

| Mechanical properties of shaped steel | ||||||||

| From 4 to 10 incl. | 345 (35) | 490 (50) | 21 | d=2a | — | 39 (4,0) | 34 (3,5) | 29 (3) |

| St. 10 to 20 incl. | 325 (33) | 470 (48) | 34 (3,5) | 29 (3) | ||||

| From 20 to 40 incl. | 305 (31) | 460 (47) | — | |||||

| Mechanical properties of sheet and wide universal rolled products | ||||||||

| From 2 to 3.9 incl. | 345 (35) | 490 (50) | 15 | d=2a | — | — | ||

| From 4 to 10 incl. | 21 | 39 (4,0) | 34 (3,5) | 29 (3) | ||||

| St. 10 to 20 incl. | 325 (33) | 470 (48) | 34 (3,5) | 29 (3) | ||||

| From 20 to 40 incl. | 305 (31) | 460 (47) | ||||||

| From 40 to 60 incl. | 285 (29) | 450 (46) | ||||||

| From 60 to 80 incl. | 275 (28) | 440 (45) | ||||||

| From 80 to 160 incl. | 265 (27) | 430 (44) | ||||||

Impact strength standards are given for rolled products with a thickness of 5 mm or more (clause 2.22 of GOST 27772-88).

It is allowed to reduce the impact strength value on one sample by 30%. In this case, the average value of the test results must not be lower than the standards in Table. 2 (clause 2.23 GOST 27772-88).

Rolled steel C345 is produced in categories 1, 2, 3 and 4 depending on the requirements for impact bending tests. Standardized impact strength indicators for rolled products of various categories specified in the order are given in Table 3 (Table 5, clause 2.24 of GOST 27772-88).

| Standardized characteristic | Category | |||

| 1 | 2 | 3 | 4 | |

| Impact strength at: | ||||

| -40°С | + | — | + | — |

| -70°С | — | + | — | + |

| Impact strength after mechanical aging | — | — | + | + |

The calculated resistances in tension, compression and bending of sheet, wide-band universal and shaped rolled products made of steel grade C345 in accordance with GOST 27772–88 for steel structures of buildings and structures should be taken according to table. 4 (Table 51 Appendix 1 SNiP II -23-81)

Calculated resistance of rolled steel C345

| Rolled thickness¹, mm | Design resistance², MPa (kgf/cm²), rolled | |||

| sheet, broadband universal | shaped | |||

| Ry | Ru | Ry | Ru | |

| From 2 to 10 | 335 (3400) | 480 (4900) | 335 (3400) | 480 (4900) |

| St. 10 to 20 | 315 (3200) | 460 (4700) | 315 (3200) | 460 (4700) |

| St. 20 to 40 | 300 (3050) | 450 (4600) | 300 (3050) | 450 (4600) |

| Over 40 to 60 | 280 (2850) | 440 (4500) | – | |

| St. 60 to 80 | 270 (2750) | 430 (4400) | ||

| St. 80 to 160 | 260 (2650) | 420 (4300) | ||

- The thickness of the shaped steel should be taken as the thickness of the flange (its minimum thickness is 4 mm).

- The values of the calculated resistances were obtained by dividing the standard resistances (yield strength and tensile strength according to GOST 27772–88) by the reliability factor for the material γm = 1.025 (clause 3.2 of SNiP II -23-81), rounded to 5 MPa (50 kgf/cm²) .

Production

Carbon steel

When manufacturing, say, tubular products, the workpiece must be heated to the required temperature, and then cut

. The prepared blank fragment is heated, after which it is pierced using a two-roll mill with axial feed. As a result, it is possible to create a pipe characterized by the presence of approximate external and internal dimensions.

After this, it is time to perform continuous rolling between the mill rolls. The created pipe is distinguished by the presence of a perfectly flat surface. Having completed the calibration operation, the workpiece is processed in order to clean it from end irregularities. After waiting for it to cool completely, the pipe is placed on a straightening mill, where it is straightened. Thanks to this cycle, the cross-section, which has an oval shape, acquires the necessary characteristics.

It is worth noting that, regardless of the profile of the rolled product being manufactured, the density of the steel used should be 7850 kg/m 3

. By using a reduction mill, the pipe can be given the required diameter, after which it is subjected to electromagnetic and ultrasonic testing, which is designed to identify signs of internal defects and measure the wall thickness.

Analogs of steel grade C345

Carbon steel C345 according to GOST 27772-88 corresponds to low-alloy carbon steels of increased strength of the following grades:

- 09G2S according to GOST 19281 (Appendix 1 GOST 27772-88, Appendix 3 GOST 19281-89 and Appendix 4 GOST 19281-89)

- 12G2S according to GOST 19281 (Appendix 1 GOST 27772-88)

- 10G2S1 , 10KHNDP , 15HSND and 15GF according to GOST 19281 (Appendix 3 GOST 19281-89 and Appendix 4 GOST 19281-89)

- 17GS , 17G1S and 14HGS according to GOST 19281 (add. 4 GOST 19281-89)

- 14G2 and 15HSND according to GOST 19282-73 (Table 51b appendix 1 SNiP II -23-81)

- 12G2S-1 according to TU 14-1-4323–88 (Table 51b appendix 1 SNiP II -23-81)

- 09G2-2 , 09G2S-1 and 14G2-1 according to TU 14-1-3023–80 (Table 51b appendix 1 SNiP II -23-81)

- 390 according to TU 15-15-146-85 (Table 51b appendix 1 SNiP II -23-81)

- VStTPs according to GOST 14637–79 (Table 51b, Appendix 1, SNiP II -23-81)

We manufacture the following standard metal products:

Flight stairs, platforms, stepladders and their guards according to series 1.450.3-7.94.2:

Flight stairs, landings, stepladders and their railings according to series 1.450.3-3.2:

Steel stepladders for wells according to:

If you are interested in our metal structures

You can send us a message by filling out the following form:

Source of the article: https://www.gran-stroi.ru/stal-S345-GOST-27772-88.php

Steel C345, low-alloy carbon, high-strength manganese

C345 steel is produced mainly in sheets, which are used for the construction of building structures. This alloy is also used to make channels used for the construction of frames, vertical structures, columns, to increase the rigidity of floors, and in the construction of hangars and supports. High demand is also observed for metal corners, intended both for strengthening and for decorating a building. Good density and lightness, combined with an affordable price, have increased the popularity of this steel.

Steel welding can be carried out without preheating and heat treatment. The seams will be very tight and will be able to withstand serious external influences. All such items must comply with the rules of GOST, from which you can also find out a detailed description and options for this rolled metal. It should be noted that the following rules apply to the 345 model:

- the addition of aluminum and titanium is allowed;

- at the request of the consumer, 0.030% phosphorus and 0.035% sulfur can be added;

- analysis for the presence of chromium, nickel, arsenic and copper is allowed;

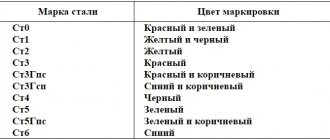

The manufacturing plant is obliged to strictly comply with all state requirements, and the products must apply the appropriate markings to the rental.

Description of steel C355

The description of steel C355 cannot ignore the analogues of the brand - C355-5, C355-6 and steel of other categories. It is naturally worth analyzing the characteristics of this alloy itself and its interpretation. You will also need to study the calculated resistance and density according to GOST.

Character traits

When C345 is exposed to a temperature of 20 °C, the steel is endowed with a short-term strength of 490 MPa, a fluidity of 345 MPa and an elongation at break of 15%. And the thicker the alloy, the lower these indicators will be. However, the elongation will increase to 21%. Rolled metal itself can be produced in 4 classifications, each of which has certain test indications: 1st and 3rd have impact strength at T = -40 °C, but at T = -70 °C such properties disappear. The 2nd and 4th categories are endowed with opposite indicators. As for viscosity after mechanical aging, they can only be observed in grades 4 and 3 of steel.

Such characteristics make it possible to produce complex building structures that can withstand extreme loads. The lowest alloy ingot can be used to make fences and enclosures of any size, water pipes for various liquids, tanks for storing emulsions and other products for typical applications. Also, due to its resistance to aggressive factors, steel is often used in mechanical engineering to create elements of cranes, rails, and power line supports.

What can be replaced?

Category C345 can be replaced by many alternative alloys, for example, 09G2S. Items from both brands have identical composition, but the latter has up to 0.08% (As) arsenic. This analogue is often used in industry for servicing metal structures operating under high pressure or at T = from -70 to +425 °C. The name contains the sign “G”, which means manganese, and the number 2 indicates its percentage (2%). Indicator 09 indicates total carbon (0.9%).

As for the hardness of 09G2S, its value can reach up to 490 Brinell pascals, which also increases the demand for this product. The materials are also capable of withstanding work in severe climatic conditions. The sheets themselves, the impact strength of which reaches 49KCU, can undergo hardening and heat treatment.

Also on the modern metallurgical market you can find German, Japanese, Bulgarian, Romanian versions of the C345, which will differ slightly in options and composition. However, objects can function freely with each other and under the same factors.

Source

Chemical elements and manufacturing technology

Each spare part contains many chemical components, the proportions of which will determine the quality of the future workpiece. If we talk about C345, then it includes 10 components, each of which plays an important role:

- Carbon (C) – no more than 0.15. It is added to any low-alloy ingot to increase strength. This effect occurs due to the release of carbides; however, an increase in hardness negatively affects the ductility and weldability of the object.

- Silicon (Si) – up to 0.8%. It is the main deoxidizing agent, the content of which will determine the quality of the finished product. Si also provides better hardenability of objects.

- Manganese (Mn) – 1.3-1.7%. It is added to the joint of almost any ingot to remove oxygen. Its properties have a beneficial effect on the future weldability of parts.

- Nickel (Ni), Chromium (Cr), Copper (Cu) – about 0.3%. These three elements protect the plane from rust and increase the elasticity of the metal as the thermal state increases.

- sulfur (S) – 0.04%. It has a negative effect on weldability, but this component is necessary for further mechanized finishing.

- Phosphorus (P) – 0.035%. Reduces ductility, but increases resistance to brittleness at low temperatures.

- Nitrogen (N) – 0.012%. Increases resistance to scale, and is mixed into heat-resistant workpieces.

- Iron (Fe) – 96%. The main component.

Equal-flange steel angle C345

All components are added during further melting. At the first stage, the recycled iron is collected in a large container, where it is heated to extreme temperatures and kept for several hours. Then the substance goes into a molten state, and additional components float to the surface. The result is steel without impurities. And at the last stage, the hot iron is poured into another tank, where it is cooled and given new compounds.

Decoding steel

Steel grade C345 belongs to the group of high-strength steel for welded building metal structures. The chemical composition and strength characteristics are regulated by the state standard GOST 27772 of 1988. According to it, the “C345” marking is deciphered as follows:

- Carbon up to 0.15%. For steels, carbon is an integral component along with iron. Its main purpose is to strengthen the metal structure due to the formation of iron carbides. Hardness and strength are directly proportional to the quantitative carbon content in the composition. The other side of the coin of such alloying is a decrease in manufacturability: ductility and weldability.

- Silicon (up to 0.8%) is introduced for deoxidation. It increases the strength of steel while maintaining its toughness value. In addition, this element helps to increase C345’s resistance to scale formation and improves weldability. Alloying with silicon also has a beneficial effect on the elasticity of the alloy.

- Manganese (1.3 -1.7%), like the previous element, belongs to the group of deoxidizers. A small amount of manganese in the alloy has a positive effect on hardness and strength. It is worth noting that such an increase in mechanical characteristics does not in any way affect the ductility of the metal. In addition to all of the above, alloying with manganese gives the alloy greater resistance to impact loads.

These elements, along with iron, are basic for c345. But GOST 27772-88 also allows the inclusion of the following components:

- Nickel (up to 0.3%) increases the alloy’s resistance to corrosion, hardenability and heat resistance.

- Chromium (up to 0.3%) significantly increases the ability of steel to harden under the influence of temperature. Increases the corrosion resistance of metal due to the formation of dense chromium oxides on its surface. Makes steel more resistant to abrasive wear.

- Copper (up to 0.3%) prevents corrosion under the influence of an aggressive environment.

It’s worth mentioning right away that the content of the above elements in c345 is insignificant. For this reason, their influence on properties is not so significant.

Just like any alloy, S345 steel contains harmful impurities. Among them, the most common are sulfur (up to 0.04%), phosphorus (up to 0.035%) and arsenic (0.08%). Their penetration into steel is due to the inaccuracy of the chemical composition of the starting materials - the charge. The error in the temperature regime of the melting equipment also has a significant impact.

A discrepancy between the amount of impurities and the above standards leads to significant losses in metal strength and leads to the formation of an effect such as brittleness. An increase in phosphorus by 0.01% can reduce tensile strength by 25%. Sulfur also increases the susceptibility of steels to red brittleness, i.e., the formation of cracks during hot pressure treatment.

Symbol meaning and classification

The name of any product contains important characteristics. And if we consider this variety, then its decoding has the following meaning: The symbol “C” says that the object belongs to the construction category. The following figures indicate the turnover of rental products. That is, the maximum stress at which plastic deformation of this material begins to appear reaches 345 MPa.

Steel grade C345 is mainly produced in accordance with GOST 27772-2015, and can be in the form of sheets, bent profiles, wide-band and shaped types. Rolled metal products belonging to this standard can have a wide range of applications. In some cases, compaction by heat treatment and the addition of impurities from other models are allowed. But all manufacturing methods must be discussed in advance with the customer, and the corresponding mark must be placed in the documents. In this case, the buyer will be provided with a quality guarantee.

Application

Structural steel, lightly alloyed with silicon and manganese, turns out to be a very attractive solution for many companies. It is used very widely - in mechanical engineering, in the energy sector, in bridge construction, in metallurgy, and in other areas. Based on steel C355, a variety of rolled metal products can be made, including sheets of different thicknesses. It is also possible to produce pipes and I-beams, channels and squares.

On the basis of such metal, good steel angles can also be created. This rolled product is also suitable for producing:

- heat exchange devices;

- pumps;

- flange components;

- industrial fans;

- important supports in industry and construction;

- transport containers;

- general purpose tanks (use under standard operating conditions);

- pipes used in gas and oil pipelines.