R6M5 is a high-speed tool steel of domestic production. It is used to produce metal-cutting tools for drills, machine tools, cutting machines and hand tools.

In the material:

- Main characteristics of the alloy

- What tools are made from R6M5 steel? Drills R6M5

- Taps R6M5

- R6M5 dies

- R6M5 cutters

- R6M5 canvas

- R6M5 cutters

- Other products made from R6M5 steel

Alloy Application

The given qualities of this steel determined its direct place in production. It is mainly used for cutting other materials under extremely high temperature conditions. It is much more practical to use a quick cutter for these tasks than any stainless alloys. A characteristic feature of R6M5 is its excellent edge retention due to its high hardness.

This beautiful metal also withstands shock loads very well, which makes it in demand in the manufacture of cranes, drills and reamers.

Knife blade made of R6M5 steel.

R6M5 with its properties is dynamically used for the production of knives. Due to the widespread use and production of this tool, there are many well-known manufacturers, for example, the same Rapid.

Numerous experiments are being carried out using knives made of P6M5. They are effective at cutting the following objects with increased strength: thick ropes, wood, bones, etc. The most spectacular successful test was cutting an iron plate with a knife made of P6M5, which was several mm thick - not without difficulties, but it was successful.

When P6M5 is used to make knives, it is usually hardened to HRC 60-62, although sometimes this parameter is brought to HRC 66-67.

Benchmade is one of the largest companies producing knives using P6M5 steel. This alloy is unique in its composition, it contains large amounts of molybdenum and tungsten, but the result is a very fine-grained steel, ideal for creating blades.

GOST and TU steel R6M5

Information about R6M5 steel is available simultaneously in several GOSTs and TUs. All contain products and their technological parameters. Despite the redirection of rolled metal to hard alloys, due to its properties, R6M5 is still very popular in many industries.

Standards regulating the quality of rental products

Rolled P6M5 is presented in several versions, each of them is regulated by its own standard:

- GOST 2590-88 – hot-rolled wheels;

- GOST 7417-75 – calibrated rods;

- GOST 19265-73 – rods and strips;

- GOST 14955-77 – circles with special surface finishing.

The listed products are actively used in Russia and abroad. Despite the ongoing popularization of hard alloy rolled products, it continues to hold its position.

Circle R6M5

Decoding - what the marking symbols mean

Elements of equipment and devices have a high strength index, the material has excellent viscosity. Steel ensures long-term performance, both in product components and in blades or finished tools.

Such markings are a legacy of the Soviet era:

- The letter "P" is an indicator of high-speed steels. The expression comes from the translation of the English “rapid” - “swift”.

- The sign after “P” indicates the presence of tungsten in the composition as a percentage. For this particular metal it is in the range of 6% with minor deviations.

- This is followed by the letter “M”, meaning cash in the molybdenum mark. The next indicator is the percentage of presence of the element in the total mass.

- In addition to M, high-speed steels can include the following designations in their markings: “K” - cobalt, “T” - titanium, “F” - vanadium, “C” - zirconium.

Considering the designation “P6M5”, decoding can also include other letters. If the steel was smelted by electroslag remelting, an addition appears in the form of “Ш” (Р6М5-Ш). With the introduction of the latest technologies into the production process, the following wording now appears - P6AM5. This means adding nitrogen to the overall composition.

Determining the type of drill by the color of its surface

The color of a drilling tool is an important feature that allows us to draw appropriate conclusions about its quality and durability. Different types of gimlet colors have different strength characteristics, the choice of which should be based on the frequency of use of the tool, its accuracy and the requirements for the quality of the finished hole.

Gray drills are short-lived and the least reliable due to the complete absence of any protective coating, which makes them susceptible to changes in mechanical properties for the worse under the influence of high temperature or force loads. Such drills have a low cost, but their use will be one-time.

Black metal drills, compared to gray ones, are of better quality. The manufacturing technology of black gimlets involves treatment with high-temperature steam, which increases their strength and resistance to wear. Drilling products with a black surface also have a low cost, which attracts the attention of many craftsmen.

Drills with a light yellow coating have a very good safety margin. Internal stresses in such products are eliminated by thermal tempering even at the stage of their manufacture, due to which high strength of the tool is created. For their manufacture, they resort to the use of high-quality high-speed tool steel. Despite all their advantages, pale gold drills are inferior in their characteristics to brighter specimens.

The bright yellow drill bits are made of high-strength steel coated with titanium nitride. Products with a similar color when making holes experience minimal frictional force, which has a positive effect on their service life. The cost of such gimlets is quite high, but they fully pay for themselves due to their long service life.

Chemical composition

The chemical composition of R6M5 includes, in addition to the carbon and molybdenum listed above, the following components:

- carbon (C) 0.82 - 0.90%;

- manganese (Mn) 0.20 - 0.50%;

- chromium (Cr) 3.8 - 4.4%;

- silicon (Si) 0.20 - 0.50%;

- molybdenum (Mo) 4.8 - 5.3%;

- vanadium (V) 1.7 - 2.1%;

- cobalt (Co) 0.5%;

- nickel (Ni) 0.4%;

- phosphorus (P) 0.03%;

- sulfur (S) 0.025%;

- tungsten (W) 5.5 - 6.5%.

An alloy with cobalt additives has been used since the beginning of the twentieth century. It is used to produce devices for cutting acid-resistant metals that are resistant to high temperatures. Processing such metals with devices from a different brand requires additional costs. This steel is characterized by high hardness and heat resistance.

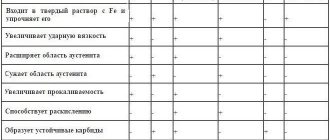

The influence of alloy elements on the properties of steel

High heat resistance of high-speed steel grades is provided by tungsten and molybdenum. On their basis, carbides are formed, which partially pass into solid solution. After heat treatment, the martensite structure is ensured. Tungsten, molybdenum, and vanadium slow down its decomposition. This is what provides the necessary red fastness. For a long time, high-speed steel alloyed only with tungsten was used. However, due to the scarcity of this metal, they began to partially replace it with molybdenum. This element also has a positive effect on the tendency of tungsten steel grades to carbide heterogeneity. Vanadium forms the hardest carbide. However, the carbon content must be sufficient for greater saturation of the solid solution. The more vanadium is introduced, the more carbon there should be in the alloy. The main task of chromium is to impart high hardenability to steel. Cobalt also increases red resistance.

High-speed steel (hardness when alloyed with this element increases to 70 HRC) in this case will have reduced strength. It is worth noting that the introduction of chromium is not widely used due to the high cost of the element.

Main characteristics

The basic parameters of steel of this grade are: high toughness, excellent wear resistance, and a good level of grindability. This grade is used in the production of many types of blades and cutting equipment for working with structural strength steels.

Knife with a blade made of steel R6M5.

A tungsten-molybdenum alloy is the second name of this brand, which can retain its characteristic qualities even under extreme temperature changes. Moreover, its bending strength reaches 4700 MPa. Its combination with impact strength gives it a noticeable superiority over many of its peers.

Manufacturing method R6M5

Of course, like any other alloy, R6M5 is manufactured in various assortments. So, in some workshops, high-speed hot steel is poured into ingots. At another production facility, it is hot rolled. To do this, heated ingots are compressed between the shafts of a rolling mill. Its resulting shape will depend on the shape of the shafts themselves.

Steel grade R6M5 is widely used for parts operating at high temperatures. For this reason, powder steel has become a very popular method of making steel lately.

When hot steel is poured into ingots, carbides are released very quickly from the melt. In some areas they form uneven areas of accumulation, which subsequently become the site of crack initiation.

In powder manufacturing, a special powder is used, which contains all the necessary components. It is sintered in a special vacuum container under high temperature and pressure. This helps ensure that the material is homogeneous.

Difficulties in hardening high-speed steel

Heat treatment of P6M5 contains a number of specific features associated with the characteristics of this brand, as well as a long heating time for hardening. To reach 1230 degrees Celsius (hardening temperature according to GOST), 25 percent more working time is spent than for a similar grade P18. First, a vacation period is made at 200 and 300 degrees for an hour. Further processing is carried out in 3 stages:

- 690 degrees -3 minutes;

- 860 - also 3 minutes;

- 1230 - 1.5 minutes.

Then the steel is cooled. In further processing, a three-time vacation period at 560 degrees for 1.5 hours is used. During tempering periods, the alloy is supplemented with alloying additives that form carbides, which increases the strength of the final metal. Previous annealing of steel helps eliminate high brittleness with a high strength index.

Metal cost

It is relatively easy to purchase this steel in finished form, but the cost is quite high. For example, a tool wheel, depending on the thickness, costs from 600 to 1350 rubles per kilogram. The instrumental strip is sold for 620 rubles.

Prices can vary over a fairly wide range. But the high cost of such steel allows it to be sold at a fairly high price in the future. The secondary price for products made of high-speed steel is higher than analogues of standard metal grades. Structures that have expired can be used as business scrap with increased value.

Features of steel sharpening

Any product is subject to wear, and if it is a blade, to loss of sharpness. R6M5 steel, due to its special manufacturing method and chemical composition, is difficult to sharpen.

Electrocorundum grinding wheels are not able to cope with such a problem. The blade being sharpened will remain uneven, and the cutting qualities will be far from working. Therefore, to restore a product to its factory sharpening, it must be processed on CBN wheels, which are not available at every specialized sharpening machine.

An example of proper knife sharpening.

Buying and selling quick cutters

Do you need a reliable supplier of high-quality high-speed steel? It offers its services, operating in Lyubertsy. We offer cooperation on the most favorable terms.

Our services

High-speed steels are widely used in the production of cutting tools. If you are looking for where to buy quick cutters P6M5 P18, etc., we can offer a wide range of rolled metal products of this type. Our assortment includes the following brands:

- P18 is a universal option, suitable for the manufacture of cutting tools of various types;

- R6M5 is a brand perfectly suitable for the production of thread-cutting tools;

- R6M5K5 is the best choice if you need to produce rough and semi-rough tools;

- other brands (R9K5, R6M5F3, R18F2, R18F2K8M, R9K5, R9M4K8, R12F2K8M3, etc.);

- tool steels of the following grades: (9ХС, ХВГ, 95Х18, Х12МФ, Х12М, Х12Ф1, 4Х5МФС,

- 3Х2В8Ф, 5ХНМ, 3Х3М3Ф, 4Х5В2ФС, 4Х4ВМФС, (DI22), 6ХВ2С, 5ХВ2С, Х6ВФ), etc.

Rolled metal is supplied in the form of:

- sheets;

- stripes;

- circles;

- squares.

Sales of high-speed steels are not the only area of our activity. The scope also includes:

- steel purchase. By contacting us, you can sell quick cutters P6M5 P18, etc., as well as tool steels of various grades;

- chemical analysis of the composition of metals and alloys. Our specialists travel within Moscow and the surrounding Moscow region. To perform the analysis, a modern portable XRF analyzer DELTA (OLYMPUS) is used, which makes it possible to obtain the most accurate information about the composition of the samples.

Why ZIRCON LLC?

ZIRCON LLC has been operating in the high-speed steel market since 2009. During its work, the company has excellently established itself as a conscientious supplier, which can offer customers a number of important advantages:

- high quality rolled metal. Quick cutters must undergo strict quality control. It meets the requirements of GOST 19265-73 and TU;

- optimal prices. Our company has the ability to deliver from State Reserve bases, making the cost of rolled metal as profitable as possible. Special conditions and special offers apply to regular suppliers;

- large warehouse. Rental is sold from a warehouse located in Lyubertsy. ZIRCON LLC can guarantee its availability and prompt daily updating of the list of warehouse balances on the website.

By contacting us, you will acquire an executive supplier who will never let you down!

Analogs

Foreign analogues of the alloy:

| USA | Germany | Japan | France | England | Italy | Spain | China | North Korea |

| T11302 M2 | 1.3343 HS6-5-2 S6-5-2 S6-5-2S SC6-5-2 X82WMoCrV6-5-4 | SKH51 | HS6-5-2 HS6-5-2HC X85WMoCrV6-5-4 Z85WDCV | 3343 BM2 | HS6-5-2 X82WMoV6-5 | 6-5-2 EM2 HS6-5-2 | W6Mo5Cr4V2 | SKH51 |

Previous

KnivesPhrases for engraving on knives

Next

KnivesSteel M390: characteristics and properties

OTHER MATERIALS USED IN THE PRODUCTION OF KNIVES (EXCEPT STEEL):

Cobalt-Stellite 6K. This is a flexible material with very high wear resistance, most often resistant to corrosion. Stellite 6K is a cobalt alloy. David Boye uses cobalt to make submariner knives. Titanium. The latest titanium alloys can have a hardness of up to 50 units, and this allows them to be used for the manufacture of cutting parts. Titanium is incredibly resistant to corrosion and is also non-magnetizable. Widely used in expensive submarine knives due to the fact that military marines use it to work with mines that detonate when metal approaches. Titanium is also used in survival knives. Tygrys produces knives with a steel core covered with layers of titanium. Ceramics. The blade on some knives is actually made of ceramic. Most often, these blades are very fragile and cannot be sharpened on their own. However, they hold the factory sharpening well. Such knives are made by Boker and Kyocera companies. Kevin McClung recently released a composite knife using ceramic that is much more durable than other ceramic knives and is quite suitable for most general jobs, and can also be sharpened at home and still holds an edge well.

Steel R6M5K5 – Vladresurs company

| Brand: | R6M5K5 |

| Classification: | High-speed tool steel |

| Addition: | The steel has an increased tendency to decarburization, good toughness, increased wear resistance, and good grindability Products offered by advertisers: No data. |

Chemical composition in % of the material R6M5K5

GOST 19265 – 73

| C | Si | Mn | Ni | S | P | Cr | Mo | W | V | Co | Cu |

| 0.86 – 0.94 | 0.2 – 0.5 | 0.2 – 0.5 | up to 0.6 | up to 0.03 | up to 0.03 | 3.8 – 4.3 | 4.8 – 5.3 | 5.7 – 6.7 | 1.7 – 2.1 | 4.7 – 5.2 | up to 0.25 |

Temperature of critical points of the material R6M5K5.

| Ac1 = 840, Ac3(Acm) = 875, Ar3(Arcm) = 805, Ar1 = 765 |

Mechanical properties at T=20oC of the material R6M5K5.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| – | mm | – | MPa | MPa | % | % | kJ/m2 | – |

| 850 | 510 | 12 | 14 | 180 | Delivery status |

| Hardness Р6М5К5 after annealing, GOST 19265-73 | HB 10 -1 = 269 MPa |

Physical properties of the material R6M5K5.

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 2.2 | 8200 | 458 | |||

| 100 | 27 | |||||

| 200 | 28 | |||||

| 300 | 29 | |||||

| 400 | 30 | |||||

| 500 | 32 | |||||

| 600 | 36 | |||||

| 700 | 34 | |||||

| 800 | ||||||

| 900 | 29 | |||||

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

Foreign analogues of the material R6M5K5

Attention! Both exact and closest analogues are indicated

| USA | Germany | Japan | France | England | European Union | Italy | Spain | China | Sweden | Bulgaria | Hungary | Poland | Czech | Austria | South Korea | ||||||||||||||||

| – | DIN,WNr | JIS | AFNOR | B.S. | EN | UNI | UNE | G.B. | SS | BDS | MSZ | PN | CSN | ONORM | KS | ||||||||||||||||

|