04.09.2020 Author: VT-METALL

Issues discussed in the material:

- Description of structural steel

- Classification of structural steels

- Areas of application of structural steel

- Advantages and disadvantages of structural steels

- How to choose structural steel by its markings

Structural steel is in great demand today. It is indispensable in the manufacture of industrial mechanisms and the construction of building structures, as it has high strength, ductility and resistance to destruction.

This material is also used in other areas of human activity. For example, it is used to produce parts for various types of machine tools, hot-rolled ordinary products, springs, leaf springs, small fasteners and much more. However, when choosing structural steel, keep in mind that it comes in different types, each with its own physical and chemical characteristics.

Alloy structural steels

Structurally alloy steel contains several chemicals in its composition. These include manganese, nickel, and chromium. But they may not contain all three components, but only one chemical indicator. That is why the division occurred: into low-alloy steel, where the number of various additives did not exceed 2.5%; to medium alloy steel, where the impurity indicator can only be increased to 10%, high alloy steel, in which additional elements can be over 10%.

Steel is the most popular material in mechanical engineering

As you know, steel is obtained by alloying iron with a number of chemical elements - carbon (2%), silicon, sulfur, manganese, phosphorus, etc. - they are present in smaller quantities.

The material is reliable, wear-resistant, durable and relatively cheap, so it is not surprising that it is in great demand in mechanical engineering. Unlike its closest “competitor” cast iron, steel has:

- high hardness;

- malleability;

- viscosity;

- great strength.

It is very important that it is well processed by cutting, forging, rolling, stamping and is excellent at welding. Steel is also capable of changing mechanical properties as a result of heat treatment. This occurs during the process of heating, holding and cooling in a special mode format. It should be taken into account that the greater the amount of carbon present in the alloy, the greater the hardness it has after quenching. But steel, where the inclusion of carbon up to 0.3% is physically not amenable to hardening.

Low alloy structural steel

Low-alloy steel has found its application in the production of cars, rolling stock, locomotives, and in equipment for agricultural and industrial purposes. Any products made from low-alloy steel can withstand very large and heavy loads. They don't have any restrictions.

For alloy steel, the markings can be as follows: two numbers (carbon content), letters without numbers (alloying element), a letter and a number (alloying element as a percentage) and a letter at the end of the marking (an indicator of very high quality steel).

Specifics of using steels in heavy engineering

Construction group materials

Materials of the structural group are used for the manufacture of:

- machine parts;

- machine tools;

- engineering structures, etc.

Such steels are subject to high requirements for strength, toughness and ductility. An example of products in this direction is spring steel. It is used for the manufacture of elastic elements - springs, springs, membranes, etc. Among other things, technical characteristics such as corrosion resistance and non-magneticity are also expected from such a material.

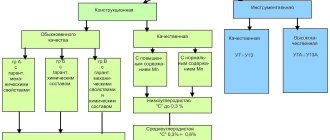

Products made from tool steels

Special tools are produced from tool steels:

- cutting;

- measuring;

- drilling rig, etc.

They are extremely hard and durable, which is achieved through additional heat treatment. Taking into account quality indicators, tool steels are divided into carbon (GOST 1435-99), alloy (GOST 5950-2000) and high-speed - including die steel (GOST 19265-73). By the way, alloying elements that are included in the component formula of steel determine its name. Hence: nickel, chromium-nickel, chromium-manganese, etc.

Products made from boron steels

Boron-containing steel is used to manufacture machine parts for industrial and agricultural purposes. It is from this material that the following are made:

- track chains;

- grader knives;

- crushing plants;

- knives and cutting blades;

- harrow discs;

- plows, etc.

Boron steel is an alloy of iron, carbon and other components, where boron plays the role of an alloying additive. In certain quantities, it has a positive effect on the formation of the microstructure of the material, increasing its strength properties.

Steel without boron and steel with boron

Carbon structural steels

Carbon structural steel can also be divided into several conventional varieties: automatic, construction and boiler. Fasteners are made from automatic steel. It is not suitable for welding work, and all parts are processed on special machines. Boiler steel is needed for the production of boilers, vessels and other containers that are designed to withstand extremely high temperatures. Engineering steel is used in the production of automotive equipment.

Carbon steel may have the following marking: art. (steel designation), SP/PS/KP (degree of deoxidation), letter G (manganese - high content). An example is steel 08PS, St2ps, St3sp5, St20, St35, St40, St45, St3ps and others.

Heat-resistant and spring

Heat-resistant compounds are used in power engineering. Steam heaters and steam pipelines, boilers, and vessels are made from it. The operating temperature of such material can reach 650 °C. In the manufacture of parts for power units, alloys alloyed with vanadium, chromium, and molybdenum are in demand.

Spring steel must provide high resistance to deformation. Only in this case can the material ensure the reliability and strength of the spring, as well as constant torque.

Today it is possible to order materials for products with individual parameters. Thanks to the improvement of the chemical composition, the product can have certain qualities at the request of the customer, if this was taken into account during the manufacture of raw materials.

Types of structural steels by type of purpose

All structural steels will be divided into machine-building and reinforcing types. Reinforcing steels are especially popular and are in great demand due to the fact that their welding is reliable, easy and simple. You can hear in circles that reinforcing steel is also called construction steel. This is due to their active use in construction and large-scale production work. Alloys are divided into general purpose and special types.

When producing any type of structural steel, various chemical elements and components are necessarily added to its alloy. Very often, some grades of steel may contain compounds that are considered harmful and dangerous. First of all, hazardous elements include chemical components: sulfur, phosphorus. It is this that makes steel products too malleable and brittle.

Scope of application

Structural steels are widely used in the construction of instruments, machines and units. Each brand is intended for the manufacture of certain structures, which will then be involved in the assembly of a machine or unit. Alloy alloys are used for the production of:

- springs, spring bands and coil springs - grade 60С2(A);

- critical springs and springs operating at elevated temperatures – 50ХФА (ХГФА);

- large and heavily loaded springs and springs - 60C2XA;

- splined rollers, bushings, spindles, couplings – 40Х-50Х;

- parts operating at high speeds and under heavy loads - 18ХГТ, 20ХГР;

- wear-resistant, high-strength and critical elements - 40ХС, 40ХФА;

- turbines, shafts, fasteners operating at elevated temperatures - 35ХМ.

These are examples of the use of specific grades of alloys. Separation into groups also helps to determine which structural compositions are used for what.

Mechanical engineering types

General Purpose Specifications

General purpose structural alloys are divided into two main groups. The first is medium-alloyed and low-alloyed. The second group is medium-carbon and low-carbon.

When producing a general purpose alloy, it is subject to strict testing. Products are monitored and tested for many indicators. Particular attention is paid to the ductility of the material, strength and reliability are checked, and the material is tested for impact strength. Depending on the classification of the metal and the scope of its application, other equally important indicators may be taken into account. There are a lot of them and they are also tested for some important characteristics and properties.

If we consider the first group of medium-alloy and low-alloy, then they are manufactured for machine builders. Such alloys are classified as hypoeutectoid pearlitic steels. For viscosity, these grades use nickel and molybdenum. Such steels include 40KhN2SMA, 40KhGT, 40KhGR, 30Kh3MF, 45KhN2MFA, 25Kh2GNTRA, ZOKHGSN2A, 08Kh15N5D2T

Structural alloys that are produced for the engineering industry can be divided depending on the method of their hardening. Thus, such graded steel can be divided into an alloy with hardening of the top layer, without treatment and with hardening throughout the entire volume.

Many structural steels are used without heat treatment. That is, they are produced and sold to consumers in ordinary sheets of metal. For such products there is one important condition - a minimum amount of carbon and silicon. It is a small amount of silicon and carbon that provides excellent screeding to the material when cold. That is, structural steel easily lends itself to the desired deformation. Among these steels, such grades as St3sp5, 08ps, 08Yu, St20, St30, St40 and others are common.

If high-quality long steel is produced, then in turn it must undergo several heat treatment options: hardening, after which the product can be tempered, standard metal hardening with mandatory tempering (the most effective welding of the finished product), and the last option, normalization.

Definition and labeling

Such materials are used to make parts of structures. Steels used in construction and mechanical engineering must contain no more than 1.3% carbon.

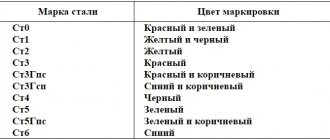

Ordinary alloys are marked with the letters St and a number from 0 to 6, which indicates the grade - this is not the average carbon concentration. Although as this figure increases, the carbon concentration increases.

The most in demand and widespread are steels with an average carbon content according to this marking - the technical characteristics of St3 structural steel allow it to be used for load-bearing, non-load-bearing, welded and non-welded structures. Its versatility makes it widely used.