09.06.2019

Today's equipment and technical equipment helps to create aesthetic and versatile paintings both with your own hands and with the help of special devices. In the article we will analyze what metal engraving is, how and with what it is done, types, techniques and methods of applying drawings. This method transforms an everyday item into a striking and original creation that makes an excellent gift or keepsake.

What is the procedure

Engraving is one of the ancient methods of finishing metal surfaces. Initially, it was used to add sophistication to household items, after which things were passed on from generation to generation. Despite the fact that this is an ancient art, today it is actively used for both personal and public purposes (decorating streets, city monuments, etc.).

Previously, painting was carried out exclusively by hand, without the help of special equipment. Now, for this purpose, various devices and devices are used that make it possible to create any pattern, inscription or picture. Depending on what is used to engrave on metal and how exactly to engrave (choice of technique), different results are obtained. Therefore, it is worth familiarizing yourself with the available methods, since each of them has its own characteristics.

Mordants used for steel

Usually solutions are multicomponent, but not always. Acids can be used as a base or additive:

- Nitrogen.

- Tartar.

- Salt.

- Vinegar.

- Sulfuric (for cast iron).

The auxiliary components are:

- Water.

- Alcohol.

Glyphogen is prepared on their basis, but you can buy it already prepared. The part is kept in it for etching for the first time - a few minutes is enough. It is then washed and dried before being placed into the final solution.

Description of technologies

The rapid development of this craft has led to the fact that there are several different ways of applying an image to a metal surface. If initially only the hands of a master and simple improvised means were used to realize fantasies, today engraving machines and even lasers are used for this.

Manual

This type is often called artistic, since it is extremely difficult to engrave metal by hand. This is a labor-intensive and time-consuming process that requires the master to have special skills, knowledge and patience. To create the required design or inscription, only a cutting steel tool is used - a graver. This is a special cutter for drawing lines and points of various indentations, which are later turned into a picture. Such work is considered exclusive, and therefore is of particular value to people who want to get a unique thing of its kind or a creation by a famous master.

Mechanical

Mechanical engraving on metal is popular because it is particularly durable - it is almost impossible to remove or erase the design. It is realized with a sharply sharpened rotating cutter by cutting material that has an exclusively flat surface. The cutter is located inside the engraving machine, which allows you to obtain three-dimensional and relief designs. The result depends on the depth of penetration of the drill, the use of various cliches (taking into account the characteristics of the cutter) and the skill of the person. The main advantages of this type are:

- Guarantee of high accuracy and obtaining the desired result while achieving the desired realism.

- Long service life. The created drawings do not lose their original appearance even after several decades and under unfavorable external conditions.

- Ability to create three-dimensional images.

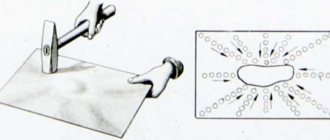

A subtype of the mechanical method is the diamond method, which has some differences. In it, the cutter performs striking movements on the surface, as a result of which a certain ornament is formed. After pressing the diamond needle, microscopic dots are formed, due to which the resulting product receives a specific shine. A diamond cutter can cope with even complex tasks, but a perfectly flat surface is a prerequisite.

Sandblasting

This type has another name - abrasive processing. Engraved inscriptions or other images on metal are applied by etching the top layer of the product with sand or other abrasive powdery substances. They are sprayed with a powerful air flow, resulting in a matting effect. The use of special stencils allows you to obtain not only patterns, drawings or inscriptions, but even photographs.

This type of image application requires sandblasting systems, a mask and an air compressor. Most professionals prefer medium-sized closed units because they filter dust. Also, implementing this technology will require a lot of free space, since engraving on metal using the sandblasting method is only possible with an air compressor, which takes up a lot of space and makes a lot of noise.

Laser sublimation

This type involves the use of a color printer, special cartridges, sublimation paper and a heat press for coloring metal materials. To get the desired image, first of all, you need to print it. The resulting transfer is placed on top of the product, after which the latter is exposed to high temperatures, which promote coloring and the transition of substances from a solid to a gaseous state.

Deep laser engraving on metal is characterized by productivity and practicality, which is especially important for business, for example, for souvenirs when applying photographs. It simultaneously combines high speed, mass production, accuracy, low cost and excellent quality. This technique involves the use of a focused laser beam. It allows you to adjust the laser power, which gives the image a different tonality and relief. In addition, the resulting pattern is preserved for many years and does not deform under the influence of water or moisture.

Different laser powers for metal engraving allow you to create sophisticated and complex patterns that have the required depth. Laser engraving involves removing the outer layer of the metal surface, which is important to consider during the work process. Laser contour engraving stands out separately, implying the drawing of exclusively contours. In most cases, this technique is used for processing coins, awards and other souvenirs. The main advantages of the laser are:

- Ability to work on finished products.

- Unlimited number of processed copies.

- Low price of service and excellent quality.

- There is no need to install supports and foundations.

- The ability to apply sketches even to hard-to-reach parts of the product.

- High precision, thanks to which the products are distinguished by realism and excellent reproduction of even small patterns.

Colored engraving on metal

The transfer of images of different colors occurs using a glassograph made in the form of a pencil or ink. After engraving, the workpiece is coated with colorless varnish in order to preserve the resulting effect in its original form for a long time. To ensure clarity, oil-based paints are used on the metal product. To achieve a rich black shade, you don’t have to resort to professional equipment. For this purpose, you can use a mixture of potassium carbonate and sulfur in a 1:2 ratio. These substances are heated over low heat with constant stirring. After the composition has noticeably blackened, it is removed from the heat and the mixture is ground in a mortar. How to engrave on black metal:

- Mix the composition with water in a ratio of 1:9.

- Place the desired item into a previously prepared container.

- Heat the parts until black (you should get the desired color shade).

Main stage

When the design has already been applied to the metal product, you can proceed directly to etching. To protect surrounding areas, a “barrier” is made of plasticine. They paste over the adjacent areas so that they do not come into contact with the liquid. The pickling solution should contain ½ teaspoon of salt for every 50 ml of water.

General technology

The main engraving techniques are manual and mechanical, which are also divided into volumetric and line type. Since it is impossible to engrave metal with 3D designs without the use of special equipment, surface treatment is carried out using a three-dimensional method. Line technology is used when performing surface actions. The work is carried out in several successive stages: drawing contour processing lines and removing a section of the metal surface with line movements.

For further manipulations, good sharpening of the stichel is required. To ensure high quality, the working apparatus is ground with a fine-grained sharpening stone and then rubbed with a piece of leather. When working with small parts, prepare a special pillow. It is made in the following way: blanks of the same size are sewn together, and the resulting cover is filled with sand. During work, when changing the direction of the pattern, the pillow, together with the workpiece, turns in the required direction, which ensures the convenience of applying the pattern.

Image application methods

Laser engraving easily adapts to automatic control. Working according to the program algorithm eliminates the possibility of subjective errors. When engraving by hand, the human factor does not eliminate the risk of making a mistake.

The image is applied according to control programs and is carried out using two methods - raster and vector.

Raster

With the raster method, the laser head moves discretely in one direction of the engraving area, and then moves down/up/down in the smallest possible increments. By sequentially processing the surface with such points, we obtain the required image. In this way, images such as photographs and pictures are engraved.

Interesting: Review of laser machines for metal cutting

Vector

With the vector method, the laser moves along the direction of certain lines. This method is usually used to engrave inscriptions and other images in the form of lines. This method is much more productive than the raster method, but if you need to change the thickness of the lines, you cannot do without raster engraving.

How to engrave metal using CNC machines

CNC milling machines are actively used to create memorable metal souvenirs. They make it possible to significantly increase productivity and speed up the workflow. Stainless steel is especially popular because it is durable, aesthetically pleasing, affordable, resistant to corrosion and temporary wear. The machines used have special fastening systems for workpieces of non-standard dimensions.

Today, metal engraving on CNC machines is in high demand in the restaurant business. The presence of a logo on cutlery gives status and leaves a pleasant impression on guests of the establishment. The process of applying an image on a milling machine occurs in several stages:

- Preparing a drawing in a special program.

- Drawing up a route for the cutter. At this stage, you need to pay special attention to the selection of the cutter and its rotation frequency. They also select the area on which the sketch of the future painting or inscription will be located.

- Fixing the workpiece on the machine. If necessary, a special lubricant is applied on top to ensure better results.

- Fastening the cutter in the spindle using a collet having the required diameter.

- Checking the fluid level in the mechanism.

- Loading the machine control program and completing automated work.

There are many ways to apply images to souvenirs and gift products. However, metal engraving has enjoyed success for many years.

In addition to creating such masterpieces with the hands of a master, you can use high-tech devices that provide high accuracy and excellent quality of the printed image. They are able to create any inscriptions and even real artistic paintings that are beyond the control of human skills. The automated system independently sets the correct depth and also determines what laser power is needed for engraving metal and applying photos (using the laser technique).

To get an original, high-quality drawing, contact. Our specialists will create a unique product for you in the shortest possible time using a laser engraving machine in exact accordance with your wishes.

Tools and materials

Engraving involves the use of various equipment. You can find specialized metal engraving machines on sale. They are used to decorate jewelry, tokens, bracelets, and pendants. A milling machine with special cutters is suitable for engraving. It is desirable that they have diamond coating on them.

However, it is better to use a laser machine. This is expensive equipment that allows you to quickly create beautiful drawings.

How to choose equipment

When choosing laser equipment for metal engraving, you need to pay attention to a number of factors: