Paints in powder form are distinguished by the creation of a particularly durable and stable coating. But in order to distribute it over the surface, you need to work using special technology. Powder painting equipment is required. The features of the process and the rules for choosing a gun and other devices for painting will be discussed in detail below.

Advantages and disadvantages of powder coating

The demand for powder compositions for painting work is the creation of a durable coating that can withstand negative environmental factors and last a long time. At the same time, painting material is saved, and the product is environmentally friendly. This is due to the fact that the composition does not contain harmful substances, such as thinners, and consumption is also slow. Particles of powder that fall off during painting can be collected and reused.

The following advantages of this material can be highlighted:

- There is no untidy smell;

- The dry composition does not have the property of spontaneous combustion;

- If you don’t like the result, the layer can be repainted without difficulty;

- You need to apply one layer;

- The composition is distributed evenly over the base;

- No priming required;

- They do not rust and withstand changes in temperature.

The technical process also has some disadvantages:

- Not suitable for wood and plastic;

- To coat large items, a large drying oven is needed;

- It is difficult to create a thin coating;

- High price.

There are no harmful substances such as thinners in the composition, and consumption is also slow.

Surface preparation

This stage is considered the most important. The technology of powder painting of metal products involves complete cleaning of the surface from rust and dirt. If there are even the smallest traces of corrosion, the coating will simply crumble.

The surface should be cleaned with sandpaper or a metal brush until it shines, so that not even the smallest rusty speck remains. To remove a significant layer of corrosion, etching with hydrochloric or sulfuric acid is used. The old layer of paint or blackening is also completely removed. For this purpose, a special wash is used.

After complete stripping, the metal must be degreased with a solvent. Next, to increase adhesion (adhesion to paint), the surface is primed. The last stage is passivation, that is, treatment with a mixture of sodium and chromium nitrate to protect against corrosion.

Methods of working with powder paint

Powder painting equipment can be used in different ways. So there are several ways to apply an unusual coloring composition to a surface. The following work options can be distinguished:

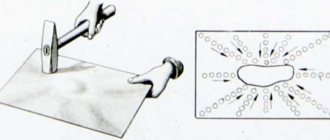

- Typically, the electrostatic application technique is used; in a special apparatus, the powder particles are charged, and the base that will be painted remains neutral. This is how an electric field is generated so that the particles attach to the surface and a reliable adhesion is created. Then the object should be heated to 200 degrees in a special oven; under the high-temperature influence, the top layer of the base melts, and the paint is reliably absorbed into it. The charge gradually disappears;

- The second option begins with heating the base until the powder particles are transferred to the metal. Their contact with a heated surface leads to melting, sometimes it is necessary to reheat the base. This depends on the paint chosen;

- Another method is used for thermoplastic paints. Powder coating equipment that contains a propane burning chamber. Powder particles are heated in advance and released onto the base, clinging securely to it. The method is considered new, for this reason it is rarely used.

The first method is more common since there are different types of powder painting equipment, and they can be used at home. For the second method, you need to set the heating temperature correctly, the third is still little known.

Powder painting equipment can be used in different ways.

Design Feature

The design varies depending on the type of equipment used, since tribostatic guns generally have fewer components. This is a working handle, a tank or funnel, a nut, the inner rod of the tribostatic barrel and the body of this barrel. The gun itself is connected to the compressor. Electrostatic guns are somewhat more complex in their design, since there is a housing with a control panel, a paint tank, a converter with a power supply, a spark gap, an electrode with a nozzle, and cables.

Important. For electrostatic guns, it does not matter what type of powder paint is used.

It can be polyurethane or polyester powder. The painting efficiency will be the same.

Criterias of choice

An important step is the selection of a dye; the construction market offers a large number of options from various manufacturers; the chosen paint determines the quality that will be obtained after painting.

The following criteria must be taken into account when choosing:

- Resistance to mechanical stress;

- Temperature resistance, the layer must withstand high temperatures and heating processes;

- Electrical insulating characteristics, often polymer-based products are considered dielectrics, and they are used as a protective layer against electrical influences;

- Resistant to chemicals if detergents, gasoline, etc. are used on the metal base. facilities;

- Resistant to corrosion, so exposure to chemicals and water is required.

There may be other differences in the appearance of the coating:

- A smooth layer is created by most compositions;

- Textured, you can get different textures, an example is orange peel;

- Colorless, used to protect the base;

- Tinted, with their help you can create the effect of a different material - bronze, metal, etc.;

- Coatings of different gloss levels, glossy or semi-gloss, etc.

An important step is the selection of a dye; the construction market offers a large number of options from various manufacturers.

Polymerization

The use of an oven for polymerization cannot be ruled out, because the paint and varnish material simply will not be able to adhere to metal parts.

The stove is the most expensive piece of equipment on the entire list, but you don’t have to buy it; you can easily make an analogue yourself if you have the right tools and suitable materials.

The essence of technology

Technologically, the use of this type of paintwork material differs from standard painting, when brushes and rollers are used. The composition is applied in the form of a dry mixture, and not in liquid form. So, to understand the essence of the work, two main stages of painting will be considered:

- The powder coating is transferred to the base;

- The effect is permanent.

When a charged powder is sprayed using equipment for polymer painting. It is applied to the base with a different type of charge. This is how the coloring matter settles on the surface.

However, such a distribution is not enough to ensure reliable coverage. A consolidation step is required. A heating method is used to make the paint “boil” on the base. A special camera is required for this purpose. As a result of melting, the layer is firmly fixed to the base.

A heating method is used to make the paint “boil” on the base.

Camera

Carrying out the work will be impossible without a special camera. This is where most of the entire process is performed. The powder coating chamber is needed for air purification (recovery process), in addition, it is due to it that the material can be reused. Here, paint that does not reach the surface being treated is sent to filters and then discarded.

Such equipment can have different sizes. Which one to choose should be decided individually in each case, having previously determined which products you plan to work with.

Powder painting equipment: selection and self-production

Some of the equipment can be made with your own hands, but this is often too difficult and time-consuming. For this reason, it is still better to purchase some devices ready-made rather than try to create homemade versions.

Some of the equipment can be made with your own hands, but this is often too difficult and time-consuming.

Spray

The application stage is the most important; the final result depends on how the layer is laid. Therefore, it is recommended to use ready-made guns to obtain a beautiful and reliable coating. The electrostatic gun is popular; it allows you to cover any type of surface, the product consumption is low.

There is also a tribostatic type, but its use requires more paint, and it is difficult to regulate the temperature required to start the application process.

All devices must be grounded.

Therefore, it is recommended to use ready-made guns to obtain a beautiful and reliable coating.

Painting chamber

The camera can be replaced by an ordinary space, which must be clean, the entrance must be covered with a film covering. But this option is for one-time use. If painting will be done frequently, then more thorough equipment will be made:

- A suitable frame structure is being welded;

- Iron sheets are installed on the outer walls; the inside walls are covered with heat-insulating sheets;

- To make it easier to collect the remaining paint after work, it is advisable to make a lattice floor covering;

- Forced ventilation is created.

If painting is done frequently, then more thorough equipment will be made.

Bake

The oven must reach high temperatures to a certain level. You can do it yourself, but the process is complex and requires skill and the availability of many materials. Therefore, it is better not to resort to such a solution.

The oven must reach high temperatures to a certain level.

Powder coating lines: automatic and semi-automatic

Lines for powder coating are automatic, manual and semi-automatic. The latter are cheaper compared to automatic ones, but they are more difficult to work with, although the effect is good.

The automatic option, as the name implies, allows you to minimize manual labor, but they will be expensive.

Lines for powder coating are automatic, manual and semi-automatic.

Business organization

These works in specialized centers today are quite expensive. If you want to try yourself in this business, then if you have financial resources, you can start. Of course, not everyone can afford a powder coating line (automated system), but thanks to our recommendations, you will be able to replace some elements with other tools at first.

Start with small items. These can be plaster figurines, ceramic dishes and much more. Try painting something in your home first (start with something you don't mind ruining). Gradually you will develop the necessary skills and dexterity, then you will be able to accept orders from friends. However, you shouldn’t expect much income if you rely only on one-time orders from individuals.

The best case scenario involves the presence of large start-up capital. In this case, you can immediately purchase the necessary equipment and hire workers. Clients should be sought among enterprises engaged in the production of metal products. Only the presence of such customers will allow your business to exist and develop.

What to look for when choosing powder coating equipment

Powder coating installations can often require a lot of space to be fully applied, which is why it is important to estimate the size before purchasing a line. The following points are also taken into account:

- The type of products that will be painted, if they are small, then the use of large equipment will not be required;

- The choice between a gas and electric oven is not fundamental; it is made based on the preferences of the master;

- An electrostatic spray gun is preferable for large objects, and a tribostatic one for small ones.

Before purchasing a line, you need to estimate the size in advance.

To apply modern powder paint, you will need several devices. They should be selected based on the volume of work, financial capabilities and working conditions.