Welding equipment from Resanta company

The Resanta company was created by Latvian engineers in 1993 to produce voltage stabilizers. Later, production was expanded and production of welding equipment began. The choice was made in favor of inverter models.

Currently, thanks to reliability, convenience and beautiful design, Resanta inverters have conquered the markets of many countries. It’s no wonder that they are made in China and are tested before shipping.

Resanta welding machines

The welding inverter Resanta SAI 190 in various designs is most often used in everyday life. This choice is explained very simply:

- Typically, welders use electrodes with a thickness of 3 mm. To ignite them, it is enough to set 140 A, but a current reserve is required, since you cannot cook at the maximum load; when cutting metal, the load increases, and power is lost when using an extension cord.

Resanta with a maximum current of 190 A has the necessary reserve.

In addition, a welding machine with a higher current value has a higher cost.

- Thanks to special modes, it is easy to master all the subtleties of welding work. These include: accelerated ignition when touching the seam and easy removal of a stuck electrode.

Inverter Resanta SAI 190

Also check out these articles

- Choosing a good sofa for your home

- Printer repair and maintenance

- Advantages of horizontal blinds in apartment interior design

- Mezzanines for closets are an indispensable attribute of small apartments and spacious apartments

Video review of the welding machine:

For reliable welding of metal workpieces with an electric arc, the Resanta SAI 190 welding inverter was developed, which has the following technical characteristics:

- Power supply 220 V.

- Peak load 5 kW.

- Fast recovery after overheating (duty cycle – 70%).

- There are ways to instantly ignite and prevent electrode sticking.

Positive user reviews from using the Resanta SAI 190 inverter:

- Easy setup and operation.

- In the event of a power failure, the inverter remains operational for some time.

- High-quality protection against overheating. For cooling, two fans are installed. One cools the block of IGBT transistors, and the other cools the block of diodes. The indicator promptly notifies you of overheating.

- Unlike other models, an automatic switch is installed that trips when overloaded.

Among the shortcomings, the following points were noted:

- Short welding cables.

- It is difficult to set the exact current value, since the regulator has increased sensitivity.

- There are restrictions on operation and storage due to the electronic filling.

Resanta brand SAI 190 K

Video review of the welding machine:

The next in the line is the Resanta SAI 190 K inverter, which has the following characteristics:

- Highly compact.

- Supply voltage 220 V/50 Hz.

- The highest electricity consumption is 5 kW.

- Thanks to special modes, the electrode quickly ignites and is protected from sticking.

- In case of overheating, rapid recovery is provided (PV - 70%).

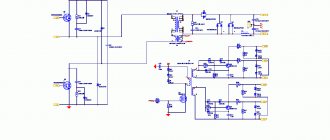

- Use of IGBT transistors in an electronic circuit.

Positive user reviews about the welding inverter Resanta SAI 190 K:

- High-quality protection against overheating. For cooling, forced ventilation of the unit is used. The indicator promptly notifies you of overheating.

- To carry out welding, basic knowledge and a little practice are enough.

- Convenient carrying strap.

Negative user reviews:

- The board is not filled with compound. If metal dust gets on it, it burns.

- Insufficient length of welding cables.

- Due to the electronic filling, strict storage conditions. It is not recommended to store in a cold room in winter.

- Welding cables are made of aluminum, so they heat up at high currents.

- There is no screen to control the current value. It is difficult to make correct adjustments in the dark.

Inverter welding machine Resanta SAI 190PN

We have installment plans without interest and overpayments through Tinkoff Bank and Post Bank.

Are there really no overpayments?

An installment plan is the same as a bank loan, we (the store) just pay all the interest for you. You pay only the amount for the product itself, divided by the number of months for which you took the installment plan (6 months).

How can I apply for an installment plan?

On the product page, in the block under the price and delivery information there will be a button “In installments for...”. Click on this button.

The installment selection window will open. At the moment there are two options - Tinkoff Bank or Post Bank. A detailed description of installment plans through each bank will be in this window.

When you choose where you would like to take out the installment plan, click on the green “Select” button at the bottom of this window. A new window will open where you will need to fill in information about you.

Just try it - it's really not difficult!

A little about installments through Tinkoff Bank

Ideal for cities with a population of 300 thousand or more or Tinkoff Bank clients.

Fill out all the information required for installment payments directly on our website. After a few minutes, the bank gives an answer - whether it can give you an installment plan or not.

If the installment plan is approved, it must be signed. Online signing (via SMS) is available for Tinkoff Bank clients. If you are not a Tinkoff Bank client, they will call you within a day and arrange a meeting to sign documents. They usually meet in a convenient public place, such as a shopping center, and can often even come to your home.

A little about installments through Post Bank

Ideal option for small towns.

Fill out a short application form on our website for installment plans through Post Bank. During the day, they call you back from Post Bank, clarify (if necessary) the remaining data and tell you the result of the installment plan (whether they are ready to issue it or not).

If the installment plan is approved for you, you must sign it. This can be done at the nearest branch of Post Bank or Russian Post.

Installment plans may not be approved?

Yes, sure. An installment plan is the same as a loan, we (the store) just pay the interest for you. But for the bank there is still a risk that you will not pay the “body” of the installment plan - which means they will not issue installment plans to everyone.

This depends on salary, credit history and current credit load.

My installment plan was not approved, what should I do?

Try placing an order through the Shares service (see below). In this case, you will have to pay 25% of the order value immediately, and the next 25% every 2 weeks.

Yes, this will result in an installment plan for a shorter amount of time and there is a down payment.

But approval is 99%, everything is completely online, without signing documents.

Resanta SAI 190 PN

We recommend reading our other articles

- The best entrance doors for a cottage, how to choose?

- Features of the use of cylinders for pipe installation

- The main advantages of professional adjustment of metal-plastic doors

- LED screens in advertising

Video review of the welding machine:

The welding inverter Resanta SAI 190 PN has the following technical characteristics:

- Mains power 140 - 240 V.

- Maximum power consumption 5 kW.

- The device does not overheat if seven minutes of welding alternate with three minutes of “rest”.

- There are ways to improve the quality of the seam. This includes accelerated ignition of the electrode and protection against sticking.

Positive user reviews about the Resanta SAI 190 PN inverter:

- Rarely does the device overheat. Convenient control over overheating. An overheat indication is displayed on the front panel.

- The front panel has a plastic cover that reliably protects from dust, dirt, and welding drops.

- The length of the welding cable allows you to comfortably weld at a distance from the inverter.

Disadvantages of the model according to users:

- The switch on the rear panel is not suitable for use with gloves.

- Increased sensitivity of the current regulator, so it may go astray.

- Aluminum welding cables are heated in steel mating connectors located on the block.

Low voltage welding machine SAI-190PN

Description

Main advantages

- The Resanta SAI-190 PN low-voltage welding machine

is endowed with all the capabilities that allow high-quality, smooth and precise welding work of almost any complexity. - The welding current generated by the product does not change the qualitative composition of the metal in the elements being connected.

- The control panel of the unit is protected by a transparent cover and contains light indicators and a digital display, and the handles allow you to easily and smoothly adjust the parameters for operation.

- The device is reliably protected from overheating and is able to smooth out significant differences in the supply voltage.

- The device is equipped with useful functions “Anti Stick”, “Hot Start” and “Arc force”, which facilitate the work of the welder and ensure uninterrupted arc performance.

- IGBT technology was introduced into the system, which made it possible to reduce its external dimensions, weight and freely operate even in relatively inconvenient places.

- The unit is easy to set up, does not require special professional skills, and can be easily carried manually or using a convenient shoulder strap.

general description

The design of the Resanta SAI-190 PN product is based on advanced inverter technologies based on a rectifier with pulse-modular regulation and a current stabilizer. The device is powered by a conventional single-phase 220 V power supply. This inverter welding machine has become a fairly common tool for creating the strongest possible connection of metal parts in private households, workshops and other professional or domestic situations. Using this fairly compact device, you can ensure high quality and accuracy of the weld formed by an electrode using direct current. The delivery set includes a meter cable with a special convenient electrode holder, as well as a cable with a fastening device that ensures the circuit is closed.

The inverter operating principle of the welding machine, together with the use of IGBT transistors, made it possible to make the device lightweight (about 6.9 kg) and fit it into small dimensions. This significantly increased the convenience and versatility of the device. The operator can easily carry it manually or using a shoulder strap, and can also be positioned to work in inconvenient and hard-to-reach places. This quality will definitely be appreciated by experienced welders who have had to work with heavy and bulky welding machines based on a conventional transformer.

With the use of modern technologies in the production of the Resanta SAI-190 PN device, it was possible to ensure that this small and lightweight product contains serious practical qualities. The welding current is quite significant (10-190 A), and the welding current voltage of 80 V makes it easy to maintain the arc and use electrodes up to 5 mm in diameter. The load duration (LOD) of the system reaches 70%. That is, out of a time period of 10 minutes, the device can continuously cook for as long as 7 minutes, and only 3 minutes are required for rest.

The viability of a working device is maintained by an effective forced heat removal system that prevents the device from overheating. In addition, the temperature control sensors of the device will promptly, through a light indicator, notify you of the need to take a break and give the device additional rest to recover.

The design of the welding unit Resanta SAI-190 PN is such that even a beginner in this matter can now perform high-quality welding, since the unit has become the bearer of a number of useful functions:

— “Anti Stick” – automatic reduction of the operating current, facilitating easy tearing of the electrode if it gets stuck on the surface to be welded. After the electrode is torn off, the operating parameters of the system are immediately restored.

- “hot start” (Hot Start) – a pulsed short-term increase in the operating current at the moment of contact of the electrode with the surfaces being welded, easily igniting the electric arc and facilitating the start of the welding process.

- “Arc force” – allows you to adjust the depth of penetration (arc rigidity) and control the parameters of the metal at the welding point. This function is controlled manually.

In addition, the equipment of the unit allows you to smooth out unstable supply voltage within fairly significant limits (from -30% to +10%). Thus, the device ensures stable operation and uniform penetration in the range of supply voltage fluctuations from 140 to 240 V.

Design and functionality

The Resanta SAI-190 PN inverter welding machine is a rectangular body (300x170x300 mm), assembled from a steel sheet coated with a dielectric compound that protects it from corrosion. There are special slots in the housing designed for free access of cooling air. A durable handle is attached to the top for manual transportation, and there is also a shoulder strap that frees the operator’s hands. The bottom of the case is flat and therefore holds the device firmly on the surface. The electrical safety of the housing is IP21. This means that the device is not recommended for use in high humidity (more than 90%) or during rain.

On the rear panel of the case there is a network switch and a power cord with a plug for a regular outlet.

The front panel became the location of the unit's control panel. Here, under a folding transparent cap made of durable polymer, there is a handle for continuously adjusting the welding current (10-190 A), an arc adjustment handle (0-100%), light indicators for network and emergency overheating, as well as a digital display showing the current setting . Below the control panel there are receiving ports for attaching work cables (ground cable and cable with electrode holder).

The main working element of the device is located inside the housing and is protected by it. This is a special transformer with an inverter conversion system based on pulse frequency modulation. The purpose of this component is to create a welding current with optimal operating parameters. First, the network current with a frequency of 50 Hz and a voltage of 220 V is rectified to constant, but with an increased voltage (400 V). Then this current turns into an alternating current of high frequency and is rectified again, having an output voltage of 80 V. This voltage simplifies the start of the welding process.

The workload on the welding machine leads to increased heat generation in its main operating components. Removing excess heat and preventing the temperature from rising to emergency levels is a primary task for such systems. In this case, to increase cooling efficiency, the heating surfaces of the components are equipped with finned aluminum plates, and their forced air flow is provided by a built-in electric fan.

The welding process occurs due to the fact that a closed loop of working current is created with the help of working cables. At the point in the circuit where the electrode touches the surfaces being welded, an electric arc occurs, melting the electrode and the edges being welded. When burning, the flux that coats the electrode creates a protective gas environment that prevents accelerated oxidation and the formation of slag in the melt.

Preparing for work

The welding inverter Resanta SAI-190 PN is simple in design and is almost always ready for work. You just need to connect the working cables, make the appropriate settings, turn on the power and the machine is ready to perform welding work. Necessary preparatory operations should include a detailed study of the technical instructions on safety precautions, setup and methods of working with the welding machine. Such instructions, as a rule, are an integral part of the delivery kit.

A working welding machine creates conditions under which sparks and sometimes drops of molten metal can fly in different directions from a local point of increased heating. Thus, the device may be a source of increased fire hazard. This should be taken into account when assessing the location of the upcoming work. In addition, the gases released during the welding process are harmful to the operator’s body, so the work area must be well ventilated. The welder himself must use his own protective equipment (special clothing, a special welding shield for the eyes and face, gauntlet gloves, a hat and thick leather shoes).

The manufacturer of the inverter welding machine Resanta SAI-190 PN has established a warranty period of 24 months for its product. However, by observing the basic standards for the intended operation of such a unit, it is possible to make its operation practically indefinite.