Step-up voltage transformers are devices that are used in electrical circuits to change the voltage levels of electricity and increase them.

The basis of any voltage transformer is the operating principle based on electromagnetic induction. The iron core is found in insulating oils that do not allow electricity to pass through. The design contains two coils with different numbers of windings. The first coil will have more turns of data than the second.

Where did he come from

At the beginning of the 19th century, scientists studied the properties of the magnetic field. And it was experimentally shown that an alternating magnetic field is capable of creating a current: it was recorded by instruments on a conductor. However, for a long time no one measured its value.

By the middle of the same century, the properties of ferromagnets and the parameters of the magnetic field were studied, and even a prototype of a transformer appeared - the Ruhmkorff coil. Finally, in 1876, the Russian scientist P. N. Yablochkov patented the world's first rod transformer.

A little later, the first transformers with a closed core began to be produced in England, which became the prototype of almost all modern devices of this type. All further work was carried out in the direction of improvement, and they were based on studying the operational properties of this device. Thus, cores made of laminated material and oil cooling were introduced. In the USSR, the spread of transformers went along with the electrification of the entire country, from the late 20s of the last century.

Transformer types

As with any technical device, step-up transformers can be of various types, differing in power ratings, scope of use, etc.

Let's consider each type of this device in more detail:

- The autotransformer has only one winding with a pair of end terminals. As a rule, these are single-phase type transformers, in which there are primary and secondary coils.

- Current transformers have a larger number of windings compared to the previous type. In addition, the design of such devices uses a magnetic core, resistors and optical sensors responsible for adjusting the voltage frequency.

- A power-type unit is a special device that transmits current between circuits through the process of electromagnetic induction.

- The anti-resonance type unit is a cast device that has an almost completely closed structure. Both three-phase and single-phase devices are available for sale. In many ways, these devices are similar to power units, but have more compact dimensions.

- Grounded devices differ from others in the special structure of the windings, which are connected to each other by a zigzag or star.

- Peak transformers are used to separate AC and DC current. These devices have become quite widespread in computer technologies and radio communications.

- Home separation devices are used as a transmitter of electricity from an AC source to the device itself. Household devices with a power of 220 volts are used as a protective measure against the effects of electric current and to prevent interference in the operation of various devices.

What is idle mode

One of the most used electrical devices is the transformer. This equipment is used to change the magnitude of electrical voltage. Let's consider the features of the transformer no-load mode, taking into account the rules for determining characteristics for various types of devices.

The transformer consists of primary and secondary windings located on the core. When voltage is applied to the input coil, a magnetic field is formed, inducing a current in the output winding. The difference in characteristics is achieved due to the different number of turns in the input and output coils.

The idle mode is understood as the state of the device in which, when an alternating current is supplied to the input coil, the output coil is in an open state. This situation is typical for a unit connected to the mains, provided that the load to the output circuit has not yet been turned on.

Short circuit mode

During the experiment you can find:

- no-load electric current (measured with an ammeter) - usually its value is small, no more than 0.1 of the rated current of the first winding;

- power lost in the magnetic circuit of the device (or in other words, losses in steel);

- voltage transformation indicator - approximately equal to the value in the primary circuit divided by that for the secondary (both values are data from voltmeters);

- Based on the results of measurements of current, power and voltage of the primary electrical circuit, the power factor can be calculated: the power is divided by the product of two other quantities.

Manufacturing workflow of coil frames

Transformer coil.

When using a round core, it is first wrapped with tape insulation and then the wire begins to be wound directly onto it, distributing the required number of turns throughout the entire ring.

After the winding of the primary winding is completed, it is covered with 3-4 layers of varnished cloth and then the turns of its secondary part begin to be wound on top. When using conventional magnetic cores, the coil frame is made as follows:

- a sleeve pattern is made with cuffs on the sides of the ends;

- cheeks are cut out of cardboard;

- roll the coil body along the marked lines into a small box and seal it;

- put the upper parts (cheeks) on the sleeve and, bending the flaps, glue it.

After this, the wire is covered with tape insulation, having previously brought the ends of the windings out.

How to connect

Connecting transformers in parallel operation is allowed only if all the listed conditions are met. It is possible to operate devices with different groups of windings:

- in groups with a difference of 4 hours (120 degrees), a circular rearrangement of the windings is performed;

- groups with a difference of 6 hours (180 degrees), for example 0, 4, 8 and 6, 10, 2, are connected after changing the places of the beginning and end of the winding of one of the transformers;

- in odd groups, two phases on the high and low voltage windings are swapped.

In all cases, the windings are re-phased.

All installation and switching work is carried out in the absence of high voltage.

Tips for choosing

Before purchasing a voltage stabilizer, you need to decide whether it is needed or not, but for preventive purposes it is still worth installing, since the voltage in electrical networks often varies.

When choosing a mini-transformer, the following characteristics are taken into account:

- Number of phases.

- Output power.

- Weight of the device.

- Transformer dimensions.

- Operational life.

- Operating voltage range.

- Speed of reaction to power surges.

The load of specific devices must be clarified. Single-phase transformers are purchased for low-power household appliances, three-phase stabilizers are purchased for a large number of devices that require load distribution.

One of the most popular and sought-after transformers is the Resanta ASN, a single-phase digital stabilizer with an affordable price of 2,600 rubles. This transformer is mounted on the wall.

A more expensive and reliable model is the Shtil stabilizer. Its approximate cost is 4,000 rubles. The Shtil stabilizer is optimally suited for protecting electronic equipment and household appliances at alternating voltage.

Maintenance and repair

Step-up transformers are technically complex devices, so self-correction of breakdowns is highly discouraged .

The only thing that can be done with your own hands is rewinding the windings of the device .

Let us take as an example the type that uses multiple windings. This unit contains a magnetic core, which is common to all three inductors. As a rule, one coil is a step-down coil and the other a step-up coil in this device.

It would be a good idea to learn the procedure for checking transformers, which will help you avoid potential problems in the future. Let's look at the whole procedure step by step :

- First you need to inspect the entire block. As a rule, overheating of the system provokes the appearance of some bulges or irregularities, which indicate deformation of some parts.

- We determine the input and output of the device. The first circuit must be connected to the first coil of the device, where the magnetic field itself is formed. The second part, which acts as a receiver of energy from the magnetic field, must be connected to the secondary winding.

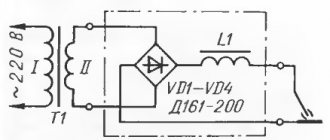

- Then you need to determine the filtering of the output signal. It is noteworthy that it is identical for the diodes and capacitors on the second coil of the device.

- Next, you need to remove some parts of the case so that you have full access to the device’s microcircuits. This is necessary so that voltage readings can be determined using a multimeter.

- If the obtained indicators are significantly less than expected (less than 80% of optimal), then the probable cause of the breakdown lies in the entire circuit that connects around the primary winding. To correct the causes, you should disconnect the first coil from the electricity supply to it.

- Next you need to check the secondary output. If there is no filtering, then you need to use power from a multimeter. If you notice that the optimal voltage is not achieved, then the reason may be in the transformer itself, or in the output terminals.

In general, it is better to entrust all these manipulations to the appropriate specialist , who will not only correctly disassemble and assemble the device, but also check the voltage frequency indicators in individual sections of the primary and secondary winding circuits.

Parameter calculations

On a simple transformer the primary winding has 440 turns for 220 volts. It turns out 1 volt for every two turns. Formula for counting turns by voltage:

It will be interesting➡ Tesla coil (Transformer) self-assembly on your own

N = 40-60 / S, where S is the cross-sectional area of the core in cm2. The constant 40-60 depends on the quality of the core metal. Let's make a calculation for installing the windings on the magnetic circuit. In our case, the transformer has a window 53 mm in height and 19 mm in width. The frame will be textolite. Two cheeks at the bottom and top 53 - 1.5 x 2 = 50 mm, frame 19 - 1.5 = 17.5 mm, window size 50 x 17.5 mm.

- The winding of a simple high voltage transformer is 2.18 x 450 = 981 turns.

- Low voltage for filament 2.18 x 5 = 11 turns.

- Low voltage filament 2.18 x 6.3 = 14 turns.

We calculate the required diameter of the wires. The power of the transformer core with your own hands is 170 watts in size. On the network winding the current is 170 / 220 = 0.78 amperes. Current density is 2 amperes per mm2, standard wire diameter according to the table is 0.72 mm. The factory winding is made of 0.5 wire, the factory saved money on this.

The assembled magnetic core, together with the components and connecting elements, forms the core of the transformer. The part on which the windings are wound is the rod. The area of the system intended to complete the circuit and not carrying any turns of the circuit is called the yoke. The arrangement of the rods in space serves to divide the system into the following types.

Types of arrangement of rods.

Read also: Registration of temporary residence permit, residence permit and Russian citizenship

Number of turns of the primary winding

We take a wire of 0.35 mm, 50 / 0.39 x 0.9 = 115 turns per layer. Number of layers 981 / 115 = 8.5. It is not recommended to draw conclusions from the middle of the layer to ensure reliability. Let's calculate the height of the frame with windings.

Primary of eight layers with 0.74 mm wire, 0.1 mm insulation: 8 x (0.74 + 0.1) = 6.7 mm. It is better to shield the high-voltage winding from other windings to prevent high-frequency interference. In order to wind the transformer, we make a screen winding from one layer of 0.28 mm wire with two layers of insulation on each side: 0.1 x 2 + 0.28 = 0.1 x 2 = 0.32 mm.

The process of winding a transformer coil.

The primary winding will take up space: 0.1 x 2 + 6.7 + 0.32 = 7.22 mm. Step-up winding of 17 layers, thickness 0.39, insulation 0.1 mm: 17 x (0.39 + 0.1) = 6.8 mm. On top of the winding we make layers of insulation 0.1 mm. It turns out: 6.8 + 2 x 0.1 = 7 mm. Height of the windings together: 7.22 + 7 = 14.22 mm. 3 mm left for filament windings.

You can calculate the internal resistance of the windings. To do this, the length of the turn is calculated, the length of the wire in the winding is taken, the resistance is determined, knowing the resistivity from the table for copper.

Technological connection to electrical networks

- Required power calculator - an approximate calculation of the need for electrical power to submit an application for technological connection;

- Cost calculator - approximate calculation of the cost of technological connection to electrical networks, depending on the type of connection (existing or new);

- Connection stages - a detailed description of the main stages required for technological connection to electrical networks;

- Answers of JSC Lenenergo to frequently asked questions on the technological connection of additional capacity or new capacity and the conclusion of an energy supply agreement.

Other types

In accordance with the performance characteristics, the presented equipment differs in several ways. Depending on the number of circuits, there are single-phase (domestic) and three-phase (industrial) designs.

Various substances are used as a cooling system. There are oil and dry varieties. In the first case, the equipment costs less. Oil is a flammable substance. When used, high-quality protection against accidents is provided. Dry units are filled with a non-flammable substance. They are more expensive, but the requirements for their installation are fair.

Coolant circulation in the system can be forced or natural. There are designs that combine these methods. The variety of types allows everyone to choose the optimal type of device.

Manufacturing of windings

The coil is placed on a wooden block with the dimensions of the magnetic core. A hole for the winding rod is pre-drilled in it. This part is inserted into the machine, and the winding manufacturing process begins:

- 2 layers of varnished fabric are wound on the reel;

- one end of the wire is fixed on the cheek and the handle of the machine begins to slowly rotate;

- the coils must be laid tightly, isolating each wound layer from the adjacent one with varnished cloth;

- after the primary winding coil is wound, the wire is cut and its second end is fixed on the cheek next to the first.

Insulating tubes are put on both terminals, and the outside of the winding is covered with insulation. The secondary winding coil is wound in the same sequence.