There are a great variety of welding machines. They vary in functions, dimensions and many other criteria. But one of the most important technical indicators is the type of welding current obtained at the output during the welding process. There are only two such types: constant and variable.

Correct AC welding electrodes are the key to quality welder work. They have their own characteristics and precise technical characteristics.

What is alternating current in welding

Is it good or bad, which current is better? Variable or constant? No one will give you a definite answer.

Welding classification.

To begin with, it is better to understand the features of processes with alternating current, they are as follows:

- The behavior of the arc leaves much to be desired: with alternating voltage it is the most unstable.

- The welding seam is not of the highest quality due to deviation from the axis of the welding arc.

- If the arc goes out, its combustion can only be resumed when the voltage increases.

- The metal is splattered to a large extent.

Despite all these complexities, the equipment required for AC welding is simple and inexpensive. These are, first of all, transformers - devices that are still very popular among welding masters.

It would seem that electrodes for alternating current should gradually lose their relevance: after all, many rectifiers have appeared on the market - inexpensive and with small dimensions convenient for use. However, these consumables are still in demand in many industries and handicraft workshops.

Most of the brands are universal, which is also extremely suitable for older generation domestic welders.

If you look at it, the best consumables for “change” have and show very serious production advantages. First of all, this concerns the resulting electric arc: its durability and easy ignition. Another feature of such electrodes is the low level of metal spattering during welding.

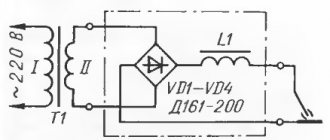

Welding transformer

Electrode diameter and steel thickness.

To carry out welding using a transformer, the following mandatory structural elements are required:

- Windings primary and secondary. The primary is made of a special insulated wire; there is no insulation on the secondary winding.

- Magnetic wire.

- Screw for controlling the position of two windings and changing the distance between them.

- Protective housing for the entire unit.

- Screw handle, running nut.

- Fan and other elements depending on the transformer model.

Despite the fact that many welding professionals regard transformers as equipment of the “outgoing generation,” they are presented on the market in the form of a wide range of models of very different values and for wallets of any thickness.

Transformers differ according to the following criteria:

- dimensions and weight;

- output current strength;

- output voltage level at idle;

- volume of electricity consumed;

Welding generator

It is assessed as an independent device, necessary for operation if there is no full-fledged network electricity.

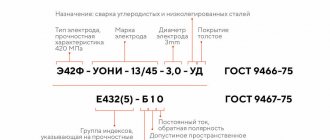

Electrode markings.

The generator design includes the required structural elements:

- The most important part - the converter consists of an electric generating element with an alternating voltage motor. They provide changes in current indicators.

- Drive internal combustion engine.

- Indicator for monitoring and recording current strength.

- Mode switches.

- Special circuit breaker.

- Regulators for current and arc behavior.

- Terminals for connecting cables and 230V outlets.

These types of generators are available in two versions:

- Collector generators.

- Valve generators.

The main advantages of a gas generator in comparison with other welding machines are:

- Compact and therefore highly mobile.

- Convenience, relative cheapness, noiselessness.

- Wide functionality and high reliability.

- Quite high technical characteristics.

Summarize

From this article you learned about the differences between models for alternating current and electrodes for welding with direct current, the pros and cons of the models, and the criteria for selecting certain models depending on the tasks.

In order not to worry about the quality of the electrodes you purchase, you should first turn to reputable manufacturers such as ESAB or Continent.

Chasing the lowest price can undo all your work. We wish you success in your work

AC electrodes

Electrodes for alternating current have an interesting feature: they are universal, that is, they are suitable for working with both alternating and direct voltage. Let us immediately note that electrodes for direct current do not in any way possess such versatility.

AC electrodes are used where transformers and generators are used as welding machines. Like the devices themselves, these electrodes are in great demand, since these methods can only be used during recess.

Both units and consumables are significantly cheaper than welding technologies based on the use of constant voltage. So the popularity and demand for “change” is not going to decrease.

Electrode markings for different types of coatings.

Advantages of AC electrodes:

- The use of alternating consumables does not require rectifiers in addition to the transformer.

- The weld pool is not exposed to the harmful effects of nitrogen and oxygen from the air.

- The versatility of this type of consumables.

Disadvantages of variable consumables:

- The main disadvantage is that the quality of the welds is lower than when using constant voltage.

- Spattering of metal during welding.

- Low viscosity is under attack.

Four types of electrode coating:

- An acidic coating with the marking letter A, containing a high proportion of oxygen. This is a typical “station wagon”; such consumables can also be used on direct current.

- “Basic” coating marked with the letter B. They have a high ionization potential, which is why it is better not to work with them on alternating current.

- Rutile coating usually consists of half a special rutile concentrate, and it is very loyal to alternating current.

- Cellulose electrodes are suitable for direct current operation.

Of all the possible coating options, the most popular for work with alternating current is rutile coating.

AC Electrode Rating

Types of electrodes for welding with alternating and direct current.

The type of current is indicated in all markings of consumables - this is always the last digit. The main thing is to remember that if the last place in the marking is 0, then the electrode is not suitable for welding with alternating current.

- OZS – 12 with rutile coating. The most common type of electrodes for welding with alternating current, which is used on almost all Russian-made machines. Excellent welding of carbon steel parts, suitable for connections of critical structures. Significant advantages of these electrodes are the ability to work in any position in space, the absence of pores in the seam, a stable arc, and a completely acceptable dose of toxic gases released during the welding process.

- MP – 3 are designed for welding low-carbon steels. The advantages are similar: excellent arc stability, acceptable metal spatter. The slag crust comes off very easily. With these consumables you can cook even rusty, damp and poorly cleaned workpieces.

- ANO – 4 are also used for carbon steels. Excellent arc that ignites quickly and easily. You can cook wet and rusty products. There are no pores or cracks during seam formation. Easy separation of slag crust. There is virtually no metal spattering.

- MP-3C are distinguished by their high versatility: they are suitable for both low-alloy and carbon steels. The arc is ignited easily and instantly, the seam is protected from slag and oxides due to the rutile coating. The seams are smooth and durable, they can withstand significant loads. You can work with them in any position in space.

- ANO – 6 are used for connecting parts made of low-carbon steels. They are not afraid of rust, scale and dirt. The arc is stable and easily ignited, the seam is formed correctly.

- OZS – 4 for carbon steels, can be welded in any spatial position. The arc ignites easily. You can weld metal workpieces with edges of medium and large thickness at high temperatures. Attention! Doesn't like dirt on the surfaces being welded - they stop working.

- ANO – 21 are also intended for steels with carbon additives and low-alloy alloys. They are very easy to handle, can be worked in any position, and are also used in conjunction with an inverter and a semi-automatic transformer. The metal hardly splashes during operation, and the slag in the form of a crust is easily separated. An arc with excellent qualities - stable and soft.

- OZS – 6 are intended for carbon steels. They are characterized by a high throughput speed, which gives high labor productivity with a welding seam of excellent quality. Capable of welding oxidized surfaces.

How to properly use an inverter welding machine

In experienced hands, an inverter can produce a good seam; you need to follow three rules:

- set the optimal current strength;

- choose the correct electrode diameter;

- take into account the thickness of the parts being welded.

Diameter is the main guarantee of a high-quality seam, and the current density also depends on it. The density cannot be higher, because the arc will be unstable, which means the metal will not be welded as well and the seam will be wider.

Of course, this will not affect the quality, but if aesthetics are important, then it is better to avoid it. If you need to cook thin products, it is better to use a semi-automatic machine.

Inverter welding will produce an unreliable seam, and when choosing thick welding rods, pores will appear in the joint, which will reduce its strength.

To find out the optimal current strength when working with the selected rods, just look at the markings on the packaging. It is not recommended to deviate from this parameter.

DC Electrode Rating

Differences in welding with different current polarities.

Types of electrodes used for DC welding:

- UONI - 13/55 - famous electrodes of their kind for direct current, applicable for steel alloys - with low doses of alloying elements and with the addition of carbon. They have significant advantages: the welding seam is very plastic and tough for mechanical stress, very durable. Almost no impurities and gases are formed. The arc is easily ignited. A wire of parameters Sv-08 or Sv-08A is placed in the rod.

- UONI - 13/45 are also used for joining workpieces made of carbon and low-alloy steels. The seam is not inclined to form cracks - neither hot nor cold. It is very ductile and tough, with ideal tightness, which makes it a suitable option for welding containers that will subsequently be subject to high pressure. Seams made with these electrodes do not age much longer.

- OZL – 6 are distinguished by their narrow focus: they are used in working with heat-resistant steels. Pores and cracks do not form in the seams, they are not subject to further corrosion and have the same heat resistance as the base metal. Suitable for metals with different structures.

- OZS-12 are intended for steel alloys with a low proportion of alloying additives and carbon. It is possible to work in any spatial position and is tolerant of surfaces with rust. The weld is formed with excellent characteristics: strength and durability. Stable arc. There are no releases of toxic substances during operation.

- TsL - 11 are also highly specialized electrodes, which are intended for steel alloys with additions of chromium and nickel, as well as corrosion-resistant steels. Welded seams are resistant to corrosion. The metal hardly spatters, the arc is stable, and the slag in the form of a crust is easily separated.

- ANO - 21, despite the fact that they are also intended for carbon and low-alloy steel alloys, like previous brands of electrodes, these consumables are extremely popular among craftsmen of various levels of professional training. Their features are a fine-scale structure of the weld metal, excellent arc ignition, softness, slight metal spattering, and so on.

- LB – 52U are distinguished by the high productivity of the welding process with their help. The arc is stable, the metal hardly spatters, work is possible in any position in space, and almost no cracks form in the seam.

- MR - 3 typical universal electrodes, which are rightfully present in both lists - for both alternating and direct current. Pores and hot cracks practically do not form in the weld, the arc is powerful and stable, there is little spattering of metal, and easy separation of slag in the form of a crust.

- OZCH – 2 are intended for welding cast iron. Despite their seemingly narrow functional focus, they have solid advantages in the form of versatility, ease of use, an excellent arc with excellent characteristics, ductility of the weld without cracks, and a well-separated crust with slag at the end of the process.