One of the most popular materials used for welding low-alloy and carbon steels is UONI-13/55 electrodes. The brand was developed back in 1940, and since then these electrode products have been widely used at industrial facilities in the USSR, and today they are widely used in Russia. The main purpose is welding of critical and especially critical structures that can be operated under high alternating loads (from summer to very low winter temperatures).

How is the marking of UONI 13 electrodes deciphered?

Electrodes for arc welding UONI-13/55 were created by specialists from the laboratory of the then secret Scientific Research Institute No. 13. Hence the decoding characteristic of UONI-13/55:

- U – universal (electrode);

- O – main type of coating;

- N – research;

- I – institute;

- 13 – institute number.

The institution, founded back in 1922 in Petrograd, still operates successfully today. The current name is FSUE “Central Research Institute of Materials”.

Features of application

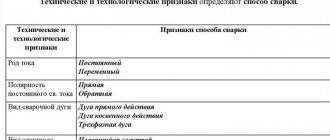

Each of the melting elements has its own niche of application; USI electrodes are used with the following parameters:

- The welding process occurs using reverse polarity current; the process is required by GOST.

- The seam eliminates the presence of gases and excess impurities by using a special coating of fluoride formations and various carbonates.

- The metal of the rod is used from low carbon steel compounds, which contributes to the reliability of the weld.

- Thanks to organic compounds, welding electrodes UONI 13/55 have low susceptibility to moisture.

- The design, made of low-alloy materials, avoids cracks and irregularities during the welding process.

Welding using UONI electrodes

The seam is not subject to aging or loss of fastening properties when exposed to temperature. Welding with UUNI electrodes should exclude the use of poorly cleaned materials, as they may be subject to corrosion in the future. The process occurs with a short arc, which avoids loss of connection quality. The main advantage over competitors is the result with the required hydrogen concentration, a connection resistant to the appearance of microcracks.

The chemical composition of materials and technology of use may vary depending on the manufacturer. Before purchasing, you need to inquire about compliance with the requirements and standards according to GOST, or the availability of a certificate of certification of welding materials.

Application of electrode welding in construction

Calcination procedure for welding electrodes UONI 13/55

To reduce the concentration of moisture and other unnecessary compounds in the coating - calcination by keeping it in an induction furnace. Each manufacturer of UONI 13/55 electrodes includes instructions for use and calcination of materials in the packaging. Neglecting the instructions is strictly prohibited, as this will result in a poor-quality connection.

Electrode welding principle

In situations where the instructions are not included or are damaged, it is necessary to follow the basic sequence of steps for calcination:

- The procedure is carried out immediately before use in the welding process. These actions are necessary for a high-quality result, a reliable seam and a stable burning of the welding arc.

- The maximum effect of calcination is 8 hours; if, after a specified period, the materials have not been used, the procedure is repeated again.

- The calcination time should not exceed four hours, and the permissible number of calcinations of the same UUSNI electrode is 3 times.

- The process uses a furnace heated to 250-280 degrees; for a uniform result, special molds are used, only then the melting elements are effectively calcined.

Storage conditions

Obtaining a high-quality result depends on the duration and storage conditions of the materials. Storage takes place in rooms with relative humidity up to 50%, without interacting with direct sunlight, air temperature of at least 12 degrees. Subject to all rules, standards and storage conditions of GOST 9466-75, the shelf life of materials can be unlimited.

Download GOST 9466-75

Electrode storage

Main features of UONI-13/55 electrodes

In accordance with the requirements of GOST 2246-70, electrodes are made from welding wire grade Sv-08A (carbon steel). The coating is of the basic type. Since it contains calcium fluoride, other fluoride compounds, and carbides, it is also called calcium fluoride.

Electrodes for welding UONI-13/55 also have another name - low hydrogen. They provide extremely low hydrogen content in the weld metal. The possibility of intergranular cracks appearing in such a connection is minimized.

The metal is characterized by high ductility and toughness. The tensile strength indicator is also high - it is 530 MPa. Thanks to these characteristics, welded structures can be used for decades at low temperatures, including in northern latitudes.

Calcination of electrodes

Each package must contain a quality certificate and instructions detailing the calcination procedure. If the instructions are not followed, both the quality of the welded products and the quality characteristics of the resulting seam will deteriorate. The calcination procedure must be carried out before using such devices. If they have not been used for 8 hours, then the calcination is repeated again. The same electrode must be processed no more than 3 times , and the total amount of time should not exceed 4 hours.

For high-quality calcination, such devices must first be placed in special boxes and only then in an oven . The operating temperature range of calcination furnaces is from 200 to 300 degrees. Only compliance with the specified conditions will make it possible to make the welding products work for a long time and prevent the formation of various defects during calcination.

We examined UONI 13/55 electrodes. An important feature of their use is calcination . It will allow the welding electrode to work for quite a long time and avoid problems with various defects. When purchasing such devices, it is necessary to have certificates indicating compliance with standards and technical specifications. Take good care of the electrodes and they will last a long time. Good luck with your purchase of welding devices!

Electrodes for welding UONI-13/55 – technical characteristics

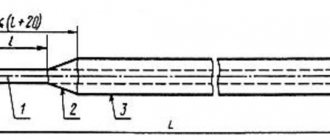

Consumable material of this brand provides a fairly high deposition rate - it reaches 9.5 g/Ah. Other indicators include:

- surfacing productivity for a rod with a diameter of 4 mm is 1.4 kg/h;

- per 1 kg of deposited metal, an average of 1.7 kg of electrodes is consumed;

- weld metal yield strength – 420 MPa;

- relative elongation rate – 22%.

The impact strength of the metal is: at t +20 °C – 130 J/cm²; at t -40 °C – 80 J/cm²; at -60 °C – 50 J/cm².

Explanation of the designation

The letter “E” indicates that E50A electrodes are designed for use in manual arc welding.

The number “50” is the tensile strength in kgf/mm2. Knowing this value, it is not difficult to calculate the loads that the connection can withstand, which is important for critical structures.

The letter “A” means that the metal of the resulting weld will have increased properties in terms of ductility and impact strength. The designation of electrodes always includes a specific diameter size.

Features of welding with UONI-13/55 electrodes

The porous base coating has the property of absorbing moisture from the air well, so before welding, the rods must be calcined in an electric furnace at 250 °C for an hour. Other features include:

- the surface of the edges of the parts to be joined must be clean and dry, traces of scale or rust are unacceptable;

- for welding with UONI-13/55 electrodes, only direct current is used, the polarity is reversed;

- Any position of the weld is permissible, except vertical downhill;

The electric arc can be short or medium; thick products, as a rule, are cooked on a short arc.

Features of use

There are some nuances associated with the use of such devices in welding. Let's look at some of them:

- For welding it is necessary to use reverse polarity current;

- The coating is special, consisting of carbonates and fluoride formations, due to which the seams do not have gases and other harmful impurities;

- Low carbon steel contributes to significant weld durability;

- The absence of organic compounds prevents the formation of moisture on devices;

- In the manufacture of electrodes, the formation of various irregularities, cracks and other defects is completely eliminated.

The result is a strong seam that is not subject to aging and loss of properties when temperature conditions change. It is necessary to control the cleanliness of the connections, because the appearance of rust or oils leads to the formation of pores, and the connection will ultimately turn out bad.

Advantages of welding electrodes UONI-13/55

- Fluorides and carbonates of the coating ensure easy ignition of the arc and its stable combustion.

- Thanks to these elements, the weld pool is reliably protected from nitrogen and oxygen. The electrodes are excellent for working in open space and field conditions.

- Metal losses due to spattering or burning out are partially compensated by iron powder, which is also present in the coating. Hence – lower (up to 15%) consumption of rods in comparison with many analogues.

- The metal of the resulting weld, as already mentioned, has excellent impact strength and ductility, and contains a minimum of hydrogen.

Characteristics

Electrodes of this type have increased strength characteristics. The coating of the internal rods helps to counteract oxidation and the presence of foreign impurities in the weld metal that have a harmful effect.

The benefits of use include:

- Stable arc combustion and ease of initiation.

- Slight spattering of metal during welding.

- Resistance of weld metal to cracking.

- Ability to work under different loads.

- Reduced content of foreign impurities in the weld metal.

However, there is a limitation on application. Stainless steel products cannot be welded with such electrodes. Welding must be done with a short arc. Its lengthening will lead to a significant deterioration in the result and difficulties during the welding process.

The set current strength depends on the spatial position and diameter of the electrode. Different models have slight differences that should be taken into account. For example, electrodes of the OZS-28 brand from this series can be used in all positions, while other types eliminate the downward movement of the electrode from the upper position. It is also necessary to keep track of what type of current is recommended when using a particular brand.

Application of UONI-13/55

The material is widely used in the creation of bridge structures, which is confirmed by its certification by NAKS for such a group of objects as KSM. Also used for installation of oil and gas pipelines, sealing of pipe connections.

Another area of use is construction: connecting assembly elements, reinforcing bars used for the production of reinforced concrete products. Another purpose of electrodes is repair surfacing. They allow you to eliminate cracks when pipes or tanks break.