Often the desire to make their home even more attractive and interesting prompts owners to use very rare and intricate materials in their work. Previously, vinyl records and metal alloys, matchboxes and scorched wood, textiles and leatherette, and much more were used for decoration: an experienced craftsman will find a use for everything. Today, polymer plexiglass has gained wide popularity, which can be used both for decorative purposes and as a material for creating intricate devices for household use. Thanks to a creative approach, skillful hands and certain knowledge, you can create truly unique objects from organic glass, which will later become your pride and home decoration.

Main features of working with organic glass

To achieve good results when working with bending organic glass, you should take into account its features. They will allow you to get rid of possible defects and waste of material. Bending plexiglass at home is not a complicated operation.

Plexiglas in decor

First of all, it is necessary to correctly calculate the dimensions of the future part, taking into account the bending radius. If experience is not enough, it may be advisable to make a mock-up of the future part from cardboard or thick paper (if the part is not large in size).

When choosing a material, it is necessary to clean the workpiece, it is better to rinse it with clean water and remove all small particles that are on the surface. This occurs due to the formation of an electrical charge on the surface. It is necessary to avoid the use of any abrasive materials, even the smallest fractions. This will lead to a significant decrease in the transparency of the future part. After washing, professionals let the plexiglass dry for 24 hours, preferably at room temperature. If time is limited, you can use a hair dryer. In this case, it is necessary to observe the thermal regime. The temperature of the directed air flow should not exceed 80 °C. To get a good result, use an empirical approach that allows you to calculate the drying time. According to this approach, you need to spend one hour for every millimeter of glass thickness. Therefore, if the glass is 3 mm thick, it must be dried for at least three hours.

After drying, you can begin work. However, it should be remembered that it is more expedient to heat the required area on the opposite side from the bend surface. If it is necessary to obtain a given internal angle, the outer side of the glass is heated.

Plexiglas parts

The heating temperature must be taken into account. Plexiglas, as a material made from organic compounds, can not only heat up, but melt and even catch fire. Professionals advise maintaining the heating temperature at approximately 150 °C. If, in addition to the task of changing the surface configuration, there is a need to fill a certain shape with organic glass, it must be heated to a temperature of more than 170 ° C.

An important feature is the need to heat an area of organic glass that is three times the thickness of the glass. When bending glass 4 mm thick, a strip 12 mm wide should be heated. For material with a thickness of more than 5 mm, it is necessary to heat it on both sides along the line of the planned bend.

After completing the work, it is necessary to cool the part, without using quick cooling methods (flow of cold water or air). Such haste can lead to the formation of internal cracks, bubbles, and deformation. Therefore, to obtain the required bending angle, it is necessary to carefully follow the technological sequence.

Welding composite rods

Fiberglass rods cannot be electrically welded. In field conditions, this problem can only be solved by gluing products or using other methods of connecting elements - clamps or plastic clips.

But electric welding of fiberglass reinforcement is still possible. This problem is solved by installing special steel tips, which act as the welded element. The tips are factory installed and attached to the rod using special collet clamps. This method allows you to weld or prestress a fiberglass element.

Thus, there is a real solution to the problems that may arise during the operation of composite reinforcement. Despite the inconveniences that arise, fiberglass reinforcement is the optimal solution for low-rise construction, in which none of the structures are subject to significantly high loads. Reinforcing foundations with fiberglass rods significantly reduces labor costs for installation and construction of the structure, and allows saving on the cost of building materials.

(2 ratings, average 5 out of 5)

Preparatory stage

This stage involves preparing the necessary tools and the workpiece itself.

Plexiglas cutting

Depending on which method is chosen, the following tools and equipment will be required:

- a vice or several clamps for securing the workpiece;

- a manual or mechanical cutting tool (this could be a hacksaw, an electric jigsaw);

- form for bending (usually a metal pipe, wooden block, tabletop or other equipment is used that can provide the required bending radius);

- abrasive material for smoothing the edges of the structure;

- water container;

- source of electric current (can be alternating or direct);

- soft liners to prevent mechanical marks from a vice or clamps on the surface of the part.

Heated plexiglass

Any operation of bending organic glass involves heating it. This can be heating the immediate bend or the entire part, if its dimensions are not large. For these purposes, various heat sources are used.

Bend polycarbonate

Polycarbonate sheets are often used to make canopies, canopies, and greenhouses. This material has excellent strength and flexibility. Bending polycarbonate is not difficult. There is no need to heat the material for this. You just need to check with the seller for what minimum bending radius the purchased polycarbonate is designed for. Well, take into account the obvious - that the thicker the material, the more difficult it is to deform.

Bend, but don't bow to difficulties! And then you will succeed!

Stairs in a house can be a significant design element of interior design. We offer you over ten staircase design options: from simple to complex. Some of the ideas are suitable for implementation in small two-level apartments and country houses, others will be more appropriate in spacious cottages. Choose!

From classic to modern, from pompous style and high-tech to minimalism. Today, giving the bedroom interior an original look is not particularly difficult: the choice of materials is limitless, the technologies are simple and can easily be mastered independently. We invite you to get fresh design ideas from our short review.

Using a hair dryer

If it is necessary to bend a large piece of organic glass or a fairly long part, a powerful hair dryer is used as a heat source. Its power should be such that it allows heating a sufficiently large area of the part.

Bend plexiglass using a hair dryer

The sheet is clamped in a vice, or if this is not possible due to its large size, several clamps are used. With their help, it is fixed to the tabletop. Mark the future fold line and gradually carefully warm up the area adjacent to the future fold line with a stream of hot air. After softening this area of plexiglass, bend it to the required angle. The resulting part is cooled naturally for the required time.

What is plexiglass?

Organic glass is durable. This artificial material is highly transparent. Glass does not break thanks to the polymers in its composition. In terms of its chemical composition and many characteristics, plexiglass is completely different from natural glass.

This material is also called polymethyl methacrylate, acrylic glass and plexiglass. Plexiglas is mainly used for making aquariums, shelves, table tops, photo frames and other items. In addition, it is used as interior doors. Craftsmen who know how to bend plexiglass correctly make figurines, key rings and various decorations from it. To give organic glass the desired shape, you must follow certain rules.

Bending in hot water (boiling method)

This method is considered by professionals to be the simplest and least energy-consuming. To implement it, practically no special tool is required.

Its implementation is as follows:

- the prepared container with water is heated so that the water begins to boil (the size of the container is chosen so that it can be used to freely work with the workpiece);

- immerse a plexiglass part in boiled water and keep it there for five minutes (the time depends on the thickness of the part);

- After the workpiece is well heated, it is necessary to remove it and give it the required shape.

Bending plexiglass by placing it on a heated surface

The peculiarity of this method is that you have to work with a fully heated workpiece. Therefore, it is necessary to provide methods of protection against high temperatures.

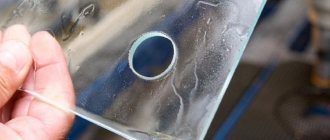

Using special nichrome wire

This method is considered the most technologically advanced. To implement it, a special nichrome wire and a constant voltage source are used. The power of the source must ensure heating of this wire to the required temperature.

Use of special nichrome wire

The process itself is implemented in several stages.

- The workpiece must be thoroughly dried. Without this operation, moisture bubbles may form in the bending areas, which can have a negative impact on the strength in the bending area, reduce transparency, and significantly worsen the appearance. Drying must be done in accordance with the recommendations given earlier.

- The finished part is fixed on the surface of the workbench. Nichrome wire is pulled over the intended bend line. The height from the surface of organic glass should not exceed five millimeters. It is not advisable to apply preliminary markings to the sheet with a pencil, marker, or other dyes. Heating the bend can cause the dye to diffuse into the surface layer of organic glass. It is almost impossible to remove such a strip.

- The wire is connected to a direct current source. It will be more convenient to work if the source is adjustable. In this case, there is the possibility of a gradual increase in the strength of the electric current passing through the filament, and therefore a gradual increase in the filament temperature. It is necessary to achieve a heating temperature of approximately 150 °C. It is from this temperature that deformation of organic glass occurs.

- Having reached this temperature, the bend line will become plastic and part of the sheet will begin to bend downward under its own weight. All that remains is to give the workpiece the required angle. After completing the process, you must allow the finished part to cool.

Reviews about fiberglass reinforcement

Its popularity is due to a number of advantages and a wide range of applications. This composite includes glass fibers, in the form of a rope or threads, and a synthetic resin.

The first component serves as a filler, and the second; binder. It is not yet possible to say that fiberglass reinforcement has completely replaced its steel counterpart, but its popularity is growing every year. All this thanks to a number of excellent characteristics:. In addition, composite fiberglass reinforcement also has the property of being magnetically inert. It can be supplied for sale in the form of:.

There are two options for solving this problem: ordering the production of fiberglass reinforcement from the manufacturer according to the customer’s drawings. At the production stage, composite rods can be given absolutely any shape that will be preserved; use of a hybrid frame with a combination of composite and metal rods. This option of connected frames is quite common in reality and is completely justified. Welding composite rods Fiberglass rods cannot be electrically welded.

How to properly knit fiberglass composite reinforcement - description

Order form . Fill in the “Your order” field with the name and required quantity. If delivery is required, the delivery location, date and time must be indicated. Please enter your name. Anyone, even an untrained person, can cope with the work, since you just need to insert the rod into the groove of the plastic clip and press it until it clicks.

Of course, knitting with regular wire will be cheaper, but using clips has a number of undoubted advantages: To make the frame strong and rigid, the clips must match the diameter of the fiberglass reinforcement used. The use of mounting plastic clamps is the second simplest and fastest method of tying composite reinforcement.

In construction and production, the advantages of fiberglass and other composite reinforcement have been appreciated: low weight, high tensile strength, immunity to corrosion and aggressive environments. Thanks to the above characteristics, this material is actively used and allows saving on the construction of a reinforcing frame compared to the use of steel rods. Despite the obvious advantages, there are also a number of known disadvantages, due to which the use of this material is often not possible. Manufactured composite rods cannot be bent directly on the construction site - after removing the load, the reinforcement will return to its original state. The composite that binds the fibers of the rod cannot be re-cured, so the reinforcement will either retain its original shape or collapse under load.

To tie composite reinforcement with plastic clamps, we proceed as follows: simply tighten the clamp with force at the crosshairs of the reinforcing bars. The connection is strong and reliable.

In some places, to provide additional rigidity to the frame, we use two clamps at once, wrapped crosswise around the rods. If this is not done, then a capillary will form around the end of the clamp protruding from the concrete structure, through which moisture will get inside, which will negatively affect the strength and durability.

Using a metal pipe

This method is used if it is necessary to give the workpiece not just a bend, but a certain radius of curvature, and is also applicable at home. In this case, a metal pipe is used as a blank of the required radius. To carry out the operation, either the pipe itself or the bend is heated using a powerful soldering iron with a wide tip or a blowtorch.

Bend using a metal pipe

The sequence of implementation of the technological process is as follows:

- A cold sheet of organic glass is placed on top of a pre-fixed pipe. Mark the starting point of the bend.

- Using a blowtorch or soldering iron, gradually heat the bend area. When the material becomes soft, manually carefully turn the sheet along the pipe, bending it to the desired angle. Using a soldering iron allows you to heat the bending area to the maximum temperature. This moment is easily determined by the crackling sound of the material.

If another option is used, the pipe is first heated and then a sheet of plexiglass is applied. A bend is made around the heated pipe.

Using any of the listed methods involves working with such hazardous factors as:

- instruments and devices connected to high voltage;

- high temperatures;

- possible appearance of fragments when glass breaks (with insufficient heating).

Drawing of a bending machine for plexiglass

Therefore, in order to protect yourself during this work, you must follow safety regulations.

Composite reinforcement

When starting the construction or reconstruction of a house, you will definitely encounter a number of “permanent” building materials that accompany any construction project.

One such material is reinforcement.

The most common and used is its metal variety, but there are also a number of plastic analogues.

In no way inferior and in many ways even superior to the metal “classics”.

In private construction, the use of plastic reinforcements is most justified.

Since there is no shortage of various equipment and devices at large industrial facilities, the use of metal fittings does not entail any additional costs.

But at a “home” construction site, to work with metal reinforcement, you will need to rent special tools, which will naturally increase the final cost of the project.

And the work itself on installing metal fittings requires skills, and a novice master will not always be able to do everything correctly.

But composite reinforcement, although somewhat more expensive, is much less “problematic to handle.”

It is easier to deliver, store and install.

Even a beginner can assemble plastic fittings with high quality.

As a result, comparing the total costs of metal and plastic fittings, we see that using plastic is not at all more expensive, and sometimes even more profitable than metal.

Advantages and disadvantages of organic glass

Organic glass has a number of advantages that have contributed to its great popularity. These include:

- has good anti-shock properties;

- relatively light weight (allows you to create complex and rather bulky structures);

- is an excellent dielectric;

- has high throughput over the entire range of the visible spectrum;

- quite resistant to atmospheric factors (high humidity, various types of precipitation, low temperatures);

- has good environmental performance (when heated, no harmful chemical elements are released);

- sufficiently high resistance to the effects of mildly aggressive agents;

- good mechanical properties (quite easy to process and deformable);

- has a wide range of colors;

- good operational safety (if damaged, no dangerous fragments are formed).

Multi-colored plexiglass

The main disadvantage of this material is its poor resistance to external influences from solid objects (scratches, cuts, and cracks quickly form). In addition, the formation of a surface electric charge due to its electrostatic properties can be considered a negative phenomenon.

How to bend (bend) fiberglass reinforcement?

It is impossible to imagine a bathroom without a sink for comfortable washing. One day there may come a time when such a structural element will need to be updated.

It is at that moment that it appears in the head. Reinforcement is the raw material for reinforcing reinforced concrete structures. Its main function is to impart strength to the building material. According to some criteria, several types of reinforcement are distinguished: Based on the material of manufacture: steel.

Until recently, the only building element used to strengthen the foundation was steel reinforced mesh. Today it has been replaced by composite material, which is lightweight and durable. We are talking about fiberglass reinforcement for the foundation.