Anchors for fastening objects and elements to a brick wall allow you to ensure the reliability and safety of the resulting connection. They are characterized by a sophisticated design and are easy to install. No special effort is required, just strict adherence to technology.

Anchor

What it is?

A brick anchor is a popular type of fixing element that can be used both during construction and during repair and restoration work. This product looks like a regular construction bolt, but has design features that allow you to reliably connect all brick elements, as well as fix parts of different weights on their surface.

The fixing element must be placed in a pre-prepared hole , and during the process of deepening, a special sleeve begins to increase, which creates the maximum level of adhesion between the object and the wall.

Manufacturers artificially increase the level of adhesion on anchors by applying special notches to them.

This is interesting: Square pipe - production and application

Application of masonry mesh

Fastening facing bricks to a load-bearing wall is often done using a masonry mesh. This is a fairly old but reliable method. The mesh is inexpensive and does not require complicated installation, but it must be laid at the time of construction of the aerated concrete wall; it will not be possible to attach the mesh to the finished structure. The mesh is needed so that when the building shrinks, the load is distributed evenly and cracks do not appear on the facade. You can use a metal product or galvanized mesh.

Attaching the mesh to the foam block

An option for attaching the mesh to the wall using pieces of cut mounting tape and wood screws

Attaching facing bricks to the walls using a mesh should occur every three rows. If a masonry of 2 blocks is used, then you can lay a grid every 4 rows. If not very strong blocks are used, more frequent laying of the mesh is acceptable, but in no case less frequent. It is necessary to reinforce the row from scratch: this will help firmly secure the cladding and avoid damage in the future.

Another option for attaching the construction mesh

This type of fastening for facing bricks can be made of different materials, for example, steel, fiberglass. When choosing a mesh, you need to pay attention to its rigidity; for example, fiberglass is not suitable for areas of the wall that are subject to heavy loads. Metal mesh is considered the most reliable; it can be used for any type of building.

Steel springs well, is not afraid of strong physical impacts, is tensile strength, and is lightweight and does not overload the structure. This is one of the simplest and most practical fastenings for facing bricks. The metal mesh is sharp, so there is a high risk of injury. Basalt in this regard is much safer, moreover, it does not rust, and can withstand the same loads.

Fastening a wall made of facing bricks to aerated concrete using a mesh has the following features:

Conclusion: fastening facing bricks to aerated concrete is possible in a variety of ways, the choice of which depends not only on the cost of the products, but also on the stage of construction.

Source

The principle of working with fasteners

One of the features of mounting an anchor is the location where it will be installed. Installation should be carried out clearly in the brick, and not in the gap of the masonry.

Also, when drilling, you cannot use a hammer drill. This can destroy the body of the brick, especially if it is hollow.

When drilling, you need to make sure that the hole is horizontal and does not deviate. The strength of the structure depends on this.

When driving, you should remember to use the anchor carefully so as not to damage the fastener itself or its parts. For example, carving.

Composition and installation process of the material

The chemical composition of the anchors is suitable for all types of fasteners made of steel. It can be used for decoration and buildings, for working in conditions with high humidity, as well as under water. This fastening system does not destroy the brick material, so fasteners can be installed at the very edge of the surface.

The principle of installation is that the anchor is securely fixed with a chemical composition located in the drilled hole in the brick wall. Strengthening is carried out due to the hardening of the composition, which does not create stress deformations at the base of the surface. As the chemical solidifies, it bonds molecularly to the material inside the hole. Thanks to their equal expansion coefficients, a monolithic fastening connection occurs.

Requirements common to all anchors

It is pointless to list the nuances of using all types of anchor fasteners that exist today - each manufacturer provides detailed recommendations for their hardware, in accordance with their design and purpose. But there are a number of requirements common to all products that are intended for installation in brick walls:

Holes for mounting any types of anchors are drilled exclusively in the body of the brick. Drilling masonry joints is prohibited, since they are most often not able to hold fasteners. In addition, the destruction of part of the seam leads to a weakening of the load-bearing capacity of the wall in this place.- Any anchor is installed strictly perpendicular to the brick structure. Even a slight slope is a gross violation of construction technology and leads to weakening of the fastening.

- When calculating the hole depth and drilling, the thickness of the finishing layer - plaster or putty - must be taken into account. It must be taken into account that the anchor is fixed in the thickness of the wall, and not in its cladding. Errors in the depth of fasteners can lead to the most unpleasant consequences.

- Before installing the anchor, the hole in the brick must be cleaned of dust and debris that got into it during drilling. This can be done using a special brush, an industrial vacuum cleaner or improvised means.

These requirements are mandatory, since the quality of installation of anchor fasteners directly depends on their compliance.

Installation Tips

In the modern construction industry, a large number of types of anchors are used for hollow and porous materials. With rational selection, each of them will last for decades. You just need to follow some simple installation rules, namely:

- For structures made of hollow bricks, it is strictly not recommended to use a hammer drill. Such an “aggressive” tool can easily damage the wall.

- Do not install anchors in masonry joints. These places are much “weaker” than the brick, so a fastener installed in such a weak place may lose its holding capabilities over time.

- The hole in a vertical wall must be strictly horizontal. Even a slight vertical deviation up or down will reduce the reliability of the fastening.

- When installing drive-in anchors, do not hit the metal directly with a hammer: this can damage the fastening. It is better to place a wooden block.

- Before screwing in the bolt, you need to clean the sleeve hole to avoid damaging the threads.

Compliance with installation technology will ensure reliability and long service life of the fastening.

//www.youtube.com/watch?v=0DZhJQSHCZ8

Types of fastening systems

A chemical dowel or anchor is most often used for installation in hollow bricks. The peculiarity of this type of fastener is its high resistance to the negative effects of alkalis and water.

Each type of fastener is used in a specific situation.

To attach various objects to walls made of brick and aerated concrete, several types of anchors are used. The difference between fasteners is their size and technical parameters. Each type of anchor corresponds to specific tasks. When choosing an anchor system, it is important to take into account the specifics of the bond and the brick from which the wall is made. For example, clay brick is stronger than silicate brick, and the advantages of porous building materials include all the qualities of faucet brick and gas block. The cladding can be clinker stone masonry, and a certain type of anchor must be selected for it.

Driven type

Anchor systems of this type are considered the most common and easiest to install. They are used to fix a profile pipe or any structure on walls made of solid and slotted bricks. The peculiarity of the driven anchor is that after it is installed in the wall, the spacer part is activated, providing adhesion. Only after this, additional threaded fasteners are inserted into the sleeve using a nut, which is removed at the end of the work. Instead, a corner, hook or ring can be used.

Wedge view

Such fasteners are also suitable for fixing metal channels.

This type of masonry anchor has a special element that is wedged during installation. By expanding inside the wall, this fastener holds heavy objects. With its help, you can even fix a metal channel to the wall. Often these anchor systems have countersunk screws. It is better to use wedge anchors if you need to install through the fixed object.

MSA type fastener

The anchors are made of brass and have a special notch that improves the level of adhesion to the building material. The inner sleeve has a conical shape with a narrowing towards the base. This structure allows the anchor to expand and the device to be fixed in the wall as the bolt is screwed in. Such fasteners are used for hanging light equipment.

Chemical fasteners

This anchor is suitable for hollow and solid bricks, but when working with slotted building materials, chemical anchors are indispensable. After the necessary calculations have been made, an ampoule of polyester resin is installed in the prepared hole. Then drilling is carried out using a pin, which provides a physical and chemical method of fastening. It takes time for the compound used to harden. For slotted bricks, at least 20 minutes.

To reliably connect the components of multilayer structures with air channels and cladding, a flexible ligament anchor with wavy bends is used. Calculating the required quantity is simple: per 1 m² there are 4-5 pieces of flexible anchor connections.

Double spacer system

Such fasteners are usually used for hollow-type bricks.

An anchor or dowel for hollow bricks has a spacer sleeve in 2 places at once. This guarantees a secure fit. This type of fastener is also suitable for solid building materials, but its most popular use is for slotted bricks. If there are 2 spacers, there is a high probability that at least one of them will hit a solid part. Shows itself well in terms of breaking out.

This is interesting: Casing pipes for wells - characteristics, application features

Miscellaneous autonomous equipment

"Fisher" has many significant advantages that are worth paying attention to. Firstly, it is well suited for working with almost any building material

Firstly, it is well suited for working with almost any building material

Secondly, the fastening system itself is quite simple and universal for any construction project.

Thirdly, thanks to non-expansion anchoring, it is possible to reduce the size of edge and axial distances.

Fourthly, such fasteners are quite different and are used for all kinds of devices.

What load can a Fisher anchor withstand? There are some requirements. As for the brickwork, there is no need to worry, since such fasteners provide for any loads that may be placed on a structure made of hollow bricks.

The same applies to aerated concrete structures. If we talk about working with compressed concrete, then it all depends on what kind of threaded rods you use.

Since the Fisher fastener is a chemical device, it is distributed into two separate chambers. The first chamber contains the chemical solution itself.

The other contains the hardener. Before use, they need to be mixed and then squeezed out.

Brick anchor

Each main type of fastener has many small subspecies. However, this should not confuse you. The fact is that in any case, the principle of their application is very similar, and the differences are only small.

You can learn about the features of each subtype of fasteners you are interested in from the consultants of the store where you will purchase them.

When choosing the type of fastener to use in your home, first of all you need to decide exactly what you want to attach to the wall. Analyze what types of fasteners may be suitable for use with your materials, and then choose the most convenient one. an acceptable and economically accessible fastening option for you.

Noticed a mistake? Select it and press Ctrl+Enter. to let us know.

Rules for installing anchor systems

Make a hole for the anchor using a hammer drill in drilling mode

With the advent of household hammer drills, the installation of fastening systems in the walls of buildings has become significantly simplified. The older generation remembers the pain it took to install the anchor.

Using a special metal tube (bolt), under the blows of a hammer, a hole was slowly made in the brickwork. Now such an operation takes minutes.

To correctly and safely install anchors in a brick wall, you must adhere to the following rules:

- Whenever possible, the hammer drill is used in drilling mode. Brick is a rather fragile material and can simply crack and collapse under impact load. The resulting hole will not fulfill its purpose.

- The temptation is to make the work easier for themselves, they drill holes in the cement joints of the masonry. However, this position of the anchors can lead to dire consequences. Under heavy loads, the cement crumbles and hanging objects can simply fall to the floor.

- When drilling, you need to strictly control the horizontal position of the drill. At the slightest downward inclination of the cavity, there is a risk of the anchor falling out under the influence of an increased pull-out load.

- When driving the supports with a hammer, place a spacer (wooden plank) under the anchor. This allows you to protect the stud threads from damage.

- Before installing the anchor system, you need to check the cleanliness of the surfaces of the sleeve and rod. For more information about working with an anchor bolt, watch this video:

By following these fairly simple rules, you will always be confident in the strength and reliability of the fastening of hanging furniture and other items.

How to drill a hole in a brick wall

How to attach a sink to a wall

Installation of timber walls

Wall cladding with clapboard on lathing

How and with what to fill a hole in the wall

Installation of beacons for plastering walls

How to anchor a safe to a concrete floor

In the current realities, the question increasingly arises of how and how to securely secure a safe in an apartment, because, firstly, not all merchants offer such a service, and secondly, many prefer to do the installation themselves. Securing a steel vault is usually done to prevent unauthorized removal. This can be done most reliably using anchor bolts on a cement-sand or concrete screed.

Regulatory conditions for the installation of safes are regulated by GOST R 50862-2005. For fastening, an anchor wedge fastening to the floor is used, which can withstand from 500 to 3,000 kg of tensile load. The optimal bolt length is 100-300 mm, and the diameter is from 8 to 20 mm. During installation, the following conditions must be taken into account:

- The thickness of the ceiling or subfloor must be at least 150 mm.

- If it is necessary to drill holes in places not provided for by the design, it should be taken into account that the tightness of a fireproof or backfill safe cannot be broken.

- Independent violation of the integrity of the case may lead to termination of the certificate.

How is the installation carried out?

To install fasteners for hollow bricks, it is recommended to adhere to the following rules:

- The diameter of the prepared hole must be equal to the diameter of the fastening system.

- Before installing the sleeve into the wall, you need to clear the hole in the brick from dust and debris.

- Tightening the inner bolt should ensure that the inside of the anchor is fully expanded. This guarantees the reliability of the fastener.

- The anchor system is inserted only into the body of the brick, and not into the layer of cement mortar.

- The brick wall must be strong and without damage. Cracks weaken connections.

Anchor systems are used as part of external and internal work. For fixation, you need a preliminary calculation of the number of ties, the shear strength of the masonry and the level of resistance, the peculiarities of the fastening principle relative to the type of brick, etc. Sometimes it becomes necessary to use additional devices, for example, a corner for an anchor system.

Recommendations

The hollow brick anchor bolt has successfully replaced the nails, bolts, screws and self-tapping screws that were previously used for fastening. This method, which allows you to hang something or connect elements with hollow brick masonry, is considered the most reliable today. True, to obtain durable fasteners, it is recommended to follow some rules.

When installing a slotted brick anchor, do not use a hammer drill. Its impact will create cracks in the fragile material, and a new hole will have to be made.

It is prohibited to select seam sections of masonry as a point for drilling and mounting an anchor. Cement and sand do not guarantee the required strength, and if there is a significant load on the fasteners, the anchor system will soon fall out.

When hammering in the anchor structure, place a piece of wood under the hammer so as not to damage the threaded area. Before you start screwing, clean the inside of the sleeve to avoid damaging the threads.

Purchase anchor fastening systems that have appropriate quality certificates.

Overview of species

The high level of demand for fixing elements and their wide range of applications have forced manufacturers to develop a wide range of parts that differ in size, design and technical characteristics. These features have a direct impact on the specific operation of the elements, and some parts are designed to solve a narrow range of tasks of increased complexity. Expansion anchors for brick walls and masonry can be used for solid, hollow and hollow building materials , as well as sand-lime and facing bricks. In order to more carefully study all types, it is better to consider each separately.

Double-spacer

A new version of fixing devices is double-spacer anchor elements, which have a spacer sleeve that opens in two directions.

This feature makes it possible to enhance the fixing effect not only in conventional masonry, but also in products made from hollow material.

Drivers

The most common fastener used for working with solid bricks. The principle of operation of a drive-in anchor is the opening of a spacer element in a pre-prepared hole, followed by screwing the threaded part into the drive-in part.

Wedge

Wedge fasteners are special fixing elements that are equipped with a special wedging part.

A distinctive characteristic is reliable fixation after full expansion in the prepared hole, the presence of screws and a recessed head.

M.S.A.

MSA type products are advanced fixing devices that are equipped with special brass sleeves. A design feature is the presence of longitudinal cuts that divide the surface of the product into separate expanding elements.

To maximize expansion of the spacer sleeve, the internal part is cylindrical.

Hex Bolts

Hex head anchor bolts are a fixing element that uses a classic bolt instead of a rod and nut. A distinctive feature is the fastening of the element in the brick cavity at the moment of tightening the nut, which leads to deformation of the sleeve.

Manufacturers also produce models that can be tightened with a screwdriver.

Chemical

Anchor products, the operating principle of which is based on a chemical reaction, are a popular and popular device for working with hollow and porous bricks. The difference is that the drilled hole is filled with adhesive after placing the anchor inside it. Advantages: high fixation level. The disadvantage is that it is impossible to use the structure until the glue has completely hardened. This period of time depends on the components and features of the composition; it must be indicated by the manufacturer in the instructions.

The glue capsule can be located either inside the product or in a separate bottle.

Amplifier options

Great demand and wide scope of application have forced anchor manufacturers to expand their product range into several types. Each of them has certain design features, differs in size, and specific use. A variety of anchors for hollow bricks allows you to solve the most complex problems with their help.

Healthy! Drilling holes in hollow bricks can only be done with a hammerless drill. An exception may be when working with masonry joints.

Double-spaced. Classic anchor element with a threaded rod and a sleeve equipped with opening double-spacer elements. As the rod is screwed in, the petals dig into the structure of the brick, making the contact much stronger.

Hammers. These hardware can be used with hollow bricks only if the hole is made in the masonry joint or the outermost (solid) part of the stone. The anchor design involves the operation of the spacer part when screwing the threaded fragment into the clogged one.

Wedges. The operating principle of such anchor bolts for hollow bricks is similar to the above-mentioned double-spacer fasteners. A maximally weakened anchor is driven into the drilled hole; wedging occurs due to the threaded part, which is evenly screwed in and bends the spacer petals.

Bolt type MSA. A more advanced type of anchor for hollow bricks. It has a brass spacer sleeve, does not rotate during installation due to cross knurling, and is equipped with an internal thread, which allows it to be used with any metric bolts and nuts.

Healthy! The MSA type anchor can be used with both hollow bricks and hollow reinforced concrete floor slabs.

Anchor with hexagon head. A classic anchor bolt for bricks, with a bolt that functions as a rod. The spacer parts are unbent according to a principle similar to the previously listed actions: at the moment of twisting.

Chemical hardware. An anchor that provides maximum quality anchorage with a hollow surface. Not popular among amateurs, but in demand among professionals. The operating principle is based on filling the hole and adjacent chambers inside the hollow brick with a special adhesive. An anchor is inserted into it. Once hardened, it will be impossible to remove the hardware.

Important! The disadvantage of chemical anchors is the time it takes for the adhesive to cure. Until it hardens, you cannot load the hardware. The time interval depends on the components of the composition used.

Chemical anchor, fastening with glue

Fastenings based on filling the inside of a metal rod embedded in the wall are used to provide strong connections in stone, brick, sandstone, shell rock, limestone, and cellular concrete. Such connections involve the use of chemical anchors, for example the popular all-season type moment fastener CF900. A metal insert, which is a reinforcement rod, a threaded stud or a sleeve with a thread on the inner surface, goes deep into a prepared hole, the diameter of which exceeds the anchor parameter by 2 mm. After this, a capsule with glue based on polyester, polyurethane or acrylic resinous substances, a hardener and filler in the form of sand is inserted into the sleeve. Then the glass cylinder is destroyed and a metal rod is inserted into it and the binder is waited for setting.

Subtleties of fasteners. What is the difference between an anchor and a dowel?

When choosing wall fasteners, craftsmen often ask themselves the question: which is better - a dowel with a screw or an anchor? This is not an idle question. Let's try to find out what the difference is and what influences the choice.

Anchors

An anchor (or anchor bolt) is, unlike a dowel, an independent type of fastener. Structurally, it is a bolt with a spacer sleeve and a cone nut. The protruding end of the anchor can be made in the form of a ring or a hook. This type of bolt is convenient for hanging lamps from the ceiling.

The anchor is hammered or inserted into a pre-prepared hole. Then it needs to be tightened with a wrench. When tightened, the bushing's petals will move apart and will securely hold the bolt due to expansion. It was this feature that gave the name to the fastener itself (in German Anker - “anchor”). If you need to dismantle the anchor, it is easy to do: just unscrew the bolt and the fastening will loosen.

The anchor is initially designed for high loads, so it is an ideal option for fastening massive structures. Are you making mezzanines or attaching a sports complex to the wall? Use anchors! But first, be sure to examine the wall.

One of the serious limitations to the use of an anchor is that it can only be installed in a solid foundation. As a rule, this is concrete or solid brick. It is strictly forbidden to drive anchors into a “holey” brick. In this case, there is a high risk of the bolt being pulled out of the wall when a load is applied to it. Anchors are also not suitable for relatively soft materials such as foam silicate slabs or blocks. Apart from these shortcomings, anchors are extremely reliable fasteners. True, their cost is noticeably higher than that of ordinary dowels.

Dowels

The basic principle of the dowel is the same as that of anchor bolts. When tightened, the fastener expands, pushing the walls of the hole apart, and the frictional force holds it in place. However, there are a number of significant differences:

- A dowel is not an independent fastener, but only a spacer part into which a screw or self-tapping screw is already screwed. Hardware suitable for the dowel will have to be selected manually.

- The anchor is made of steel, the dowel is often made of plastic, less often of metal.

- The dowel is used for fastening light and medium-weight structures. For example, when installing a wall-mounted clothes dryer, shelves and wall cabinets, you can get by with a simple dowel.

- The dowel is suitable for different substrates. In addition to brick and concrete walls, dowels can be used for walls made of dry plaster, gypsum concrete, plasterboard and even hollow brick (there are dowels of different lengths and configurations for different applications).

Materials

Due to the fact that anchor rods on monolithic cladding are used in cases where it is impossible to tie with a load-bearing wall, manufacturers use basalt plastic and fiberglass for the manufacture of fixing elements. These materials not only have a high level of strength, but are also able to withstand a wide temperature range , and also have a low thermal conductivity coefficient, which significantly reduces the likelihood of the formation of cold islands. During operation, fiberglass products behave best.

Experts do not recommend purchasing steel anchors, which during operation are capable of accumulating condensate, which will inevitably provoke corrosion processes.

Ways to decorate a house

Aerated concrete requires mandatory finishing, as over time it can begin to absorb moisture. Additional cladding helps retain heat and give the building an attractive appearance.

You can clad a building using facing bricks, which can be attached to the wall in different ways: this material not only has an attractive appearance, but will also reliably protect the aerated concrete from damage, cold and moisture.

Insulation can be placed between the cladding and the wall. Another advantage of brick is its ability to breathe: this will remove moisture from aerated concrete and give the facade the necessary ventilation. However, if the mortgages were not made initially, a problem may arise, since there is no fastening of the facing brick to the load-bearing wall. This can be solved; there are several ways to accomplish the task.

Fastening

To create reliable buildings, experts recommend strengthening structures with special fixing elements - anchors. Anchor fixing parts are simple products, the installation and fastening of which should not cause difficulties even for novice builders. Despite the simplicity of the procedure, before fastening the part, it is necessary to make a pull-out calculation and follow all the recommendations of specialists in order to securely fasten it.

Basic Rules

To obtain maximum results, experienced craftsmen recommend taking into account a number of rules and technological features during the installation of anchors. The size of the drilled hole must strictly correspond to the diameter of the fastener. Do not install small anchors in large holes.

It is strictly forbidden to install anchors at the joints between bricks that are filled with cement mortar. It is also undesirable to choose weak areas with a large number of cracks and chips for work.

To protect the thread from deformation, experts recommend avoiding direct contact of the hammer with the metal and using wooden or rubber spacers.

Before starting work, it is necessary to accurately mark the work area and determine the location of the anchor. It is strictly forbidden to drill recesses close to each other, since the structure of the brick is porous and fragile, which will certainly provoke the destruction of the structure. When carrying out insulation work, clamps can be purchased separately.

If necessary, you can carry out not only horizontal reinforcement, but also vertical reinforcement - the main thing is to avoid the appearance of even a minimal bevel.

When choosing a fixing device, experts recommend adhering to the following standards:

- the length of the sleeve should not be less than 6 cm;

- the optimal level of insertion of the rod into the wall is 9 cm;

- the recommended number of anchors per 1 m2 is 4 pcs.;

- areas near openings and at joints must be reinforced.

Incorrect selection of the size, type and material of the fixing element can provoke weakening of the structure, as well as the appearance of cracks and faults on the walls.

Special brushes, a vacuum cleaner, or any convenient means at hand will help remove debris and dust from the recess.

Technology

In order to obtain a reliable and durable design, experts recommend following the following sequence of actions:

- carrying out marking work and accurately determining the location of clamps;

- drilling a hole of the required diameter in the selected work area;

- complete cleaning of the recess from dust and foreign debris;

- installation of the fixing part;

- Fully tighten the bolt head.

An important point is that the depth of the hole should not take into account the thickness of the finishing layer, which will not allow creating the maximum level of fixation.

You can learn how to use a chemical anchor from the video below.

Using flexible links

Another reliable way to attach facing bricks to aerated concrete walls is to use flexible connections. There are different options and manufacturers. There are several types of these materials: fiberglass, basalt plastic. True, their cost ranges from 10 to 60 rubles. per piece, and it is not always possible to purchase.

The strength of flexible connections is one of the key characteristics that is looked at when choosing such consumables. Craftsmen are aware of the fact that the street part of the wall, under the influence of moisture and temperature changes, can change size and deform, “walking” relative to the stationary load-bearing masonry. Strong balsat fibers allow the outer cladding to change size and move without creating mechanical stress in the wall itself.

Connections from Armplast

The flexible connection is a rod made of basalt plastic with a sand coating. The sand coating serves as anchors when connecting the walls of concrete panels. Sand anchors provide adhesion to mortar and also protect against corrosion in alkaline concrete environments.

The use of balsat rods for masonry significantly increases the service life of the structure.

Company website https://arm-plast.ru

Options from Glen

If you are going to carry out work on cladding the facade with clinker bricks later, then there is no need to lay flexible connections during the construction of the load-bearing wall, but use special flexible connections for working on the finished base.

This basalt flexible connection GALEN 6-AGERATED CONCRETE is intended for installation in a load-bearing base made of a material with increased porosity: aerated concrete blocks or foam concrete blocks

Glen connection

Flexible connection ZV-Welle

The flexible connection ZV-Welle is made of stainless steel and is intended for connecting facing brickwork and a load-bearing wall made of dense building material, such as concrete or solid building brick, and setting a ventilation gap between them.

Flexible connection Bever ZV-Welle

The flexible Bever ZV-Welle connection is used when a load-bearing structure made of dense material has already been erected and it is not possible to use a less expensive flexible connection for installation in the seams of the load-bearing masonry. When using this flexible connection for porous bases (aerated concrete, foam block) only for buildings with low height (up to 4 meters), in other cases for porous bases use the Bever PB 10 Flexible Connection with an enlarged capsule. The Bever ZV Welle flexible tie is supplied with a stainless steel spacer and tie element and a nylon dowel.

Flexible connection Bever ZV-Welle

It is installed as follows: first, a hole with a diameter of 8 mm and a depth of 60 mm is drilled in the load-bearing wall. Then the dowel is driven in. Then, using a special casing element (found in each package) and a hammer, a flexible connection spacer element is installed into the installed dowel. Thus, in double brickwork systems (the inner layer is a load-bearing layer made of dense monolithic concrete or solid building bricks and the outer layer is made of facing bricks), the flexible Bever ZV-Welle connection is used in the sequential construction of double brickwork walls (first the load-bearing base is built, then the facing masonry).

Recommendations for use

Using, for example, connections, the facing brick is attached to the load-bearing wall; for this, it is necessary to select the right products that must meet the following requirements:

Fastening facing bricks with ties is the simplest and most affordable method. The anchors should be positioned in such a way that there are no more than five of them per square meter of wall; they should be placed in a checkerboard pattern: the most convenient is 50 cm horizontally and 40 cm vertically.

If it is necessary to create a frame for openings, the step is 30 cm; in this case, the most durable fastening of facing bricks and aerated concrete occurs, without reducing the load-bearing capacity of the wall. If the distance is measured from the corner of the building, you should not deviate from them by less than 150 mm; ideally, the deviation should be 250.

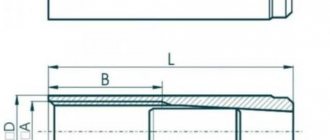

Anchor system design

The device consists of a rod and a spacer sleeve

The principle of operation of the system is the same as that of dowels. The system consists of two parts: a support rod (bolt) and a spacer sleeve. Anchors for brick walls are made in various lengths and diameters, that is, a certain type of fastener is selected for each load value.

To install supports in brickwork, you need the following tool:

- perforator;

- brick drills;

- hammer;

- spanners;

- brush for cleaning holes.

Dowel for hollow bricks - a new fastening option

Among building materials, there is one more element that should not be forgotten. Hollow brick is also one of the problematic materials in which it is difficult to install fasteners. If, for example, you need to install an anchor bolt with a nut, then, for sure, you will be faced with the fact that the fastener will simply turn in the material and dangle; naturally, there can be no talk of any holding force. In order to prevent such a problem, there is a special dowel for hollow bricks.

What is remarkable about it, and why does it so confidently hold the elements installed on it in the hollow material? Of course, the whole point here is in the design of the fastening itself; first of all, it is quite elongated, but no more than the width of the material itself. Due to the size during installation, the mounting surface will necessarily interact with the internal elements of the brick. The second, important design parameter is the significantly enlarged spacer part of the fastener, which further strengthens the fastener and does not allow it to rotate in the hole when tightening a bolt or construction screw. The material for the manufacture of such products is usually elastic nylon, which significantly reduces the cost of the product.

As for the range of sizes of such products, here we have a certain standard, namely length and diameter. The main dimensions are: 6×60, 8×80, 10×90, and 14×90 millimeters, the first number is, respectively, the diameter and the second is the length of the fastening. As you can see, the length of the fastening does not exceed the existing width of the brick, which according to standards is 120 millimeters. This size is quite enough for the fastener to properly hold the structure installed on it.

Advice! The manufacturer recommends using wood screws or universal self-tapping screws for installation, which ensure maximum quality of fastening.

The principle of operation of anchors - how do they cope with loads?

The principle of operation lies in their technology and special prefabricated structure, due to which the load has a completely different character. The fact is that when installed, the anchor bolt already expands in the wall; it cannot be pulled back out with any effort, like a nail, dowel or screw.

In this case, the load is distributed over a small surface area into which the bolt was installed, and not at one point, as with standard fixations. To enhance its ability, a metal sheet is additionally mounted with it, which takes up most of the load and distributes it across the entire plane of the sheet, and the larger the sheet area, the more load the bolt can withstand.

Reviews about anchors for bricks

Purchasing hardware from KREP-COMP allows you to get high-quality products at an affordable price. The product is delivered in original packaging and accompanied by the necessary documents. When accepting the object, the customer does not have any questions regarding fasteners.

Any connections can be formed on the basis of KREP-COMP anchors. The nodes are distinguished by excellent rigidity and functionality. They have compact dimensions and do not require complex maintenance.

I ordered fasteners to renovate a cottage. I am completely satisfied with the received product. The anchors are easy to install and hold the load well. The fasteners have a protective coating and can be used outdoors.

Certain difficulties arose when choosing anchors. KREP-COMP consultants helped in their decision. They talked about the range of products and recommended products that meet our requirements. The store left a positive impression.

Anchors: their effectiveness and types

The effectiveness of anchor bolts speaks for itself, this is the latest modern device that is quickly gaining popularity due to its ease of use and practicality. At the moment, there are no analogues for them that could compare in terms of economy and physical characteristics. Taking the physical laws of load distribution along a plane as a basis, experts came to a very effective solution and created this device.

Anchors come in different types, have approximately the same properties and functions, each has a fundamental difference. They are divided into the following types and subtypes:

- Mechanical: – mortgage; – spacer; – driving; – wedge; – a bolt with a ring or hook; – frame; – hairpin; – façade; – ceiling; – spring.

- Chemical: – monolithic fasteners; – for external and internal work; – for fastening in loose and thin-walled substrates; – resistant to vibrations; – long-serving;

- Plastic.

- Ground.

- For foundation construction.

- Height adjustable.

Visor

The hole for fixing the visor above the entrance is made with a drill. Steel or wooden brackets holding the structure are subsequently secured with anchors.

Important! Construction stores sell special drills for fragile building materials that do not destroy its structure.

Drilling is done carefully and carefully. First, markings are made for the desired height of the visor. There is no need to drill into seam joints. The canopy may collapse.

Anchor products have improved properties compared to other hardware. Provides an increased degree of fixation of heavy objects. This is subject to the purchase of products in specialized construction stores with quality certificates for the existing product. It is important not to skimp on fastening. Such a mistake can be costly.

What are anchor bolts for masonry

A brick anchor is a universal fastener that is equally successfully used both in the field of capital construction and when performing simple repair and improvement work on buildings and premises for various purposes. With the help of such fasteners, which are a bolt of a special design, objects and elements of even significant weight can be securely fixed on the surface of a brick wall. Such anchor bolts, in particular, can be used to secure furniture and interior items, lamps and chandeliers, suspended ceilings, wall-mounted facades and much more.

The design features of this type of bolt and the principle by which it operates are contained in its name: anchor in German means “anchor”. The element that ensures reliable adhesion of such fasteners to the inner walls of a pre-drilled hole in the brick is a special sleeve. Placed in a hole in the wall, when the head of the anchor bolt is twisted, it begins to increase in diameter, pushing out the inner walls of the hole and coming into reliable engagement with them.

In order to make the adhesion of the anchor bolt sleeve to the walls of the hole in the brick even more reliable, a special notch is applied to the side parts of its outer surface.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

Types of dowels for brick walls

Dowels are used to attach furniture, paintings or other objects to brick walls, as they can withstand heavy loads. In order for the fastener to be securely held in the base, it is necessary to select the correct type and size depending on the grade of brick or concrete. If the dowel is not used for its intended purpose, it may not withstand the load and fall out of the hole.

Types of dowels and their features

1. Externally, the dowel looks like a cork and has a cylindrical shape with a cavity. When the screw is screwed in, its body expands and rests against the walls of the hole. The most common are nylon and polyethylene expansion dowels. To prevent a screw or nail from falling inside, the fastener is equipped with a special collar equal to the diameter of the screw head.

2. For walls made of porous or hollow bricks, anchor fasteners are used. As soon as such a dowel begins to be screwed into the brickwork, its end expands or twists into a knot. The resulting “nut” inside the voids securely holds any object.

3. Nail dowels are used for fastening slats under cladding with finishing material; they are small in size. They come with a nail. Install them together through a hole in the rail and wall. Then they hammer it in with a hammer.

4. Special umbrella dowels are used to attach thermal insulation. An umbrella is inserted into the hole in the wall and through the insulation, and then a nail (plastic or metal) is driven in. For large loads, for example, up to several tons, metal dowels for concrete and brick are used.

5. Metal fasteners are best suited for suspended ceilings. In the event of a fire, the plastic ones will melt and the ceiling will collapse.

- reliable fastening that can withstand heavy loads;

- easy to use;

- Can be used both indoors and outdoors.

Due to the presence of spikes and whiskers on them, they do not turn while screwing in the screw.

How to Attach an Anchor Bolt: A Reliable Anchor for Any Application

Despite its resistance to loads, installation is very simple, in three stages:

– drill a hole in the wall with a drill or hammer drill; – install a bolt in the hole; – spread out the anchor base.

This installation guarantees reliable use for any purpose and load. The anchor base will cope perfectly with any type of application.

How is cladding done with aerated concrete?

Attaching facing bricks to load-bearing walls is one of the most important points, but before you get started, you need to understand the technology as a whole. An important point is the width of the foundation; if brick finishing is planned, it must be wide enough for this work. Usually there are no problems.

Attaching the facing brick to the wall can occur at different distances, it all depends on whether the installation of thermal insulation is planned or not. If there is insulation, then a gap of at least 3 and no more than 5 cm should be left between the aerated concrete blocks and the brick. The insulation should be moisture-resistant, for example, polystyrene foam or similar materials are suitable. Ventilation holes will need to be left in the walls. For finishing, either M-150 ceramic brick or finishing brick is used, the layer is laid in one brick, the installation method is similar to laying walls.

The facing brick can be attached to the insulation closely. If insulation is not planned, then the brick should not be pressed against aerated concrete, otherwise both materials will quickly collapse, since they have different indicators, and there should be an air gap between them.

Varieties

Anchors differ not only in size. There are design features of technical parameters. Anchor products for brick walls are divided according to their intended use. A specific type of hardware is used for certain installation work.

Important! To ensure reliable fixation of an object in a brick wall, it is recommended to take a responsible approach to the choice of anchor products.

Driven type

Allows you to secure critically heavy weights. Made from high-strength material or carbon steel. It is treated with a specialized anti-corrosion coating, which ensures an increase in service life. The product is manufactured in one piece, which increases the reliability of the fasteners. A popular type of hardware is the collet anchor.

Drivers

The anchor is driven into the brick with a hammer. Its working part becomes wedged. This way the element is securely fixed in the wall. Then the bolt or stud is screwed in.

Wedge type

The scope of application is identical to the hammer type analogue. The method of installation in a stressed and unstressed concrete plane is allowed. Refers to reliable fastening elements. Capable of withstanding high loads. Used in dry rooms.

Made from various types of steel. Differs in specific execution. On one side there is a stud with a metric thread, onto which a nut is screwed. On the other hand, there is a spacer system in the form of a coupling with an internal shank.

Wedge

MSA type

Brass products, the outer side of which is characterized by the presence of a special sleeve with a large notch. The design allows you to increase the density of fixation of fasteners in the wall cavity. The permissible intra-sleeve cross-section is in the range of 8-10 mm.

Chemical principle

The external design is a cylindrical tube. Inside there are two ingredients - organic and inorganic. Reacting with each other, they harden and provide the required degree of strength.

Chemical

Important! Chemical-type fastening structures are in high demand because their use is allowed in places with high humidity, in porous substrates. Even in such extreme conditions, they are able to hold the elements together.

The name of the hardware was given in view of the chemical principle of operation - a chemical reaction. Has no smell. It is an environmentally friendly product. Does not harm the environment and the human body.

The negative aspects of using the product include the high price and different setting times of the composition. The latter depends on the variety of adhesive mixtures.

With ring

The peculiarity of the product – the presence of a ring – ensures its scope of application. It is convenient to install suspended structures on wall and ceiling surfaces. In construction it is used for securing scaffolding. Allowed to be used for bricks with a dense internal structure - only solid ones. In porous and hollow materials, fasteners lose their effectiveness.

With ring

Double-spacer

Additionally, a spacer sleeve is provided that opens simultaneously in two places. The first spacer element does not come into contact with the solid masonry surface. The reliability of fixing the product in the wall increases. The sample shows good results in the tensile test, therefore it is used in difficult operating conditions.

Double-spacer

Dowel for aerated concrete - design features

The soft and friable materials from which walls are built have always been problematic when it comes to attaching various household products to them. As a result, not a single manufacturer of fastening structures gave a guarantee that their anchor or self-tapping screw would adhere well to such a surface. In practice, this was very often confirmed; the soft base simply crumbled, and the fasteners lost their holding properties.

But a solution was found, it was the dowel for aerated concrete that solved the problems of installation in soft materials. The immediate solution to this issue was the specific design of such fasteners. Externally, this is a sleeve on which there are ribs made in the form of a spiral; when installing a self-tapping screw, it expands the sleeve, which, with spiral-shaped ribs, seems to cut into the soft surface of aerated concrete. As a result, we get a strong mount that holds a certain load.

Fasteners of this category are available in two versions, plastic and metal. As for the metal version, its design can also be of two types. The first design sample has the same wide spirals on its base as the plastic one, and the method of its fastening is completely identical to its plastic counterpart.

The second type of such dowel has a completely different design. It is made in the form of a bushing, which has teeth along its entire length, and the main feature is its cone-shaped shape, increasing from the bottom edge to the base. On the working surface with teeth, the metal has technical slots, which expand when the bolt or screw is tightened, and the teeth also bite tightly into the soft material.

Rules for fastening anchors

Before proceeding with installation, it is worth clarifying a few important points. Firstly, it is worth understanding what kind of brick the masonry is made of. Depending on this, you choose the type of anchor. Secondly, after this it is also worth taking into account the functional significance of the fastener (what exactly it will hold and what weight and size). After this, you can proceed to the next stages of installation.

The rules for installing anchors depend on the above types of fasteners.

In the case of flood anchors, you need:

- a hole needs to be drilled. It corresponds to the size (length and diameter) of the fastener. The hole must be thoroughly cleaned of dust and brick shavings;

- install the anchor in the hole. The wedge located inside the anchor is driven in. It is driven to the very end of the hole;

- The attached part is attracted.

Hollow brick

What kind of material is this? In modern construction, two types of bricks are used - hollow and solid. The main function of the first materials is the construction of buildings, which should be as strong and durable as possible.

This brick is good in all respects. The material is light, strong, and easy to install. However, it has a significant drawback. It does not retain heat well in rooms. Although hollow brick is practically no different in strength from solid brick, it is more often used in finishing work. The internal void in such a building material can range from 30% to 50%, depending on the type and manufacturer. Low-melting grades of clay are used as raw materials for such blocks. It is from this that red brick is made. There is another option. This is a silicate hollow white type. Let's look at the features and properties of mounting blocks.

Installation features

In the practice of modern construction, anchors are in demand. They provide a reliable way to install equipment and fix massive objects and structures on the walls and ceilings of a building. It is important to choose the right hardware for the job.

Fastenings for solid bricks will not provide the necessary adhesion to hollow material. Therefore, it is important to first determine the base raw materials from which the enclosing structure was erected.

Sequence of work:

- The plane is marked. The work is done with the utmost care. Hollow ceramic bricks are fragile. If you make two holes with a small interval between them, the material will most likely be deformed.

- The hole in the brick is made with a specialized drill. The cross-section of the anchor element and the depth of its placement are taken into account. The perpendicularity of the hole produced is a guarantee of high-quality work.

- After creating the hole, it is cleaned of dust and debris. Depth accuracy is checked.

- When inserting the anchor, make sure that the gap between it and the wall is minimal. If it turns out that the product is loose, it is better to take larger hardware. It should be selected according to the diameter of the resulting hole.

Important! Installing a hammer-type product is the same painstaking process as installing a spacer analogue. If you apply excessive force when hammering, not only the fastener itself will be damaged, but also the wall.

The procedure for installing an anchor in a brick wall

The most important stage in working with brick anchors is the selection of the product, taking into account the characteristics of the material, the type of load on the anchor and its magnitude. Hardware designed to work with solid material will not effectively perform its functions when used with hollow brick, so it is important to find out what building elements the wall is built from.

- The first stage of installation of any part or object is marking. It should be taken into account that in case of an error, it will most likely not be possible to move the hole a couple of centimeters to the side, as is the case with concrete. Brick, especially ceramic hollow brick, is a fairly fragile material and will most likely collapse in the place where they try to drill holes at a short distance from each other.

- Drilling of bricks is carried out with a special drill, taking into account the diameter of the anchor and its depth. As we have already written, the perpendicularity of the hole is the most important requirement for the quality of work. After the hole is drilled, it is thoroughly cleaned of dust and a control depth measurement is made.

- When installing the fastener, you need to ensure that it fits into the prepared hole with a minimum gap. If the anchor moves too freely in the wall, it is better to use hardware of a larger diameter, adjusting the hole to the appropriate size.

- Installing drive-in anchors requires no less care than installing expansion anchors. It is worth remembering that by applying excessive force when hammering in hardware, you can damage not only the product itself, but the wall around it.

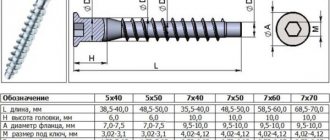

Sizes and prices

The marking of an anchor certified in Russia according to GOST has 3 digits:

- External diameter.

- Inner diameter.

- Total length.

Standard sizes vary within:

- 0.8 – 2.0 cm in diameter;;

- 4.5-12 cm in length;

Bolts are sold packaged in 10, 15, 25, 50 and 100 pcs. packaged.

Prices depend on the size, manufacturer, material of manufacture, purpose of the bolts and other factors.