Manufacturers of chemical anchors

A considerable number of both domestic and foreign manufacturers present their products on the Russian market.

In practice, materials produced by well-known European companies have proven themselves to be impeccable. The table below presents the leading manufacturers and a short overview of their product range. In fact, the variety of products they produce is much wider.

| Company `s logo | Anchor type | Scope and Features of Chemical Anchor |

| (Germany) | ||

| R.M. | “Reaktionsanker” is an ampoule with an adhesive mass, inside of which there is a compartment with a hardener. The manufacturer produces ampoules of different sizes - M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170), M30 (30×280). | |

| FHP | “Hammerpatrone” is an ampoule with glue and hardener for installing metal elements into a concrete base. Produced in the following sizes - 10 (13×90), 12 (15×110), 16 (18×125), 20 (24×180). | |

| FIS V 360S | “Injections-Mortel” Double cartridge, requires a special gun to operate. Main cartridge with a volume of 360 ml and two mixers. | |

| FIS VS 150 C | "Injections-Mortel" One standard size cartridge. To work, you will need a regular construction gun for standard cartridges. The kit includes a 150 ml cartridge, two mixers and an adapter. | |

| (Liechtenstein) | ||

| HVU | "Adhisitive Capsule Anchor". Ampoule with meta-acrylic polyurethane resin, quartz sand and hardener. Capsules have the following volume: M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170), M30 (30×280), M33 (37 ×300), M36 (40×330), M39 (42×360). | |

| HIT-HY150 | "Fast Curinq Injection System". These are two dual cartridges with acrylic resin and hardener. A special gun is required for operation. Cartridge volume 330 ml and two hardeners, HIT-HY20 has one hardener. | |

| HIT-HY50 | ||

| HIT-HY20 | ||

| (Switzerland) | ||

| MSP | "Schlagpatrone". Ampoules with resin and hardener. Capsule volume: M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170). | |

| MYA | "Verbunanker". Ampoules with two components. Volume: M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170), M30 (30×280). | |

| MIT-P | One cartridge. A standard construction gun is used for the job. Cartridge volume 150 ml, two mixers. | |

| MIT-P | Double cartridge. Set: 235 ml and two mixers. | |

| MIT-SF | Double cartridge. Volume 380 ml and two mixers. | |

| MIT-EA | Double cartridge. Volume 825 ml and two mixers. | |

| (Finland) | ||

| KEM | “Kemiallinen ankkuri” - ampoules with polyester resin and hardener, volume M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170), M30 ( 30×280). | |

| KEMLA | “Kemiallinen lyontiampulli” - ampoules with polyester resin and hardener, volume M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170). | |

| ITH | "Injektointitekniika". Cartridge with injection mass based on polyester resin, volume 380 and 150 ml | |

| (Germany) | ||

| TVA | "Verbund-Anker". Ampoules with resin and hardener, having a volume of M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170), M30 (30×280). | |

| THP | "Hammerpatrone". Ampoules with resin and hardener, volume M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170). | |

| TVM-K | "Verbundmortel". Cartridge with injection mass, volume 380 and 150 ml. |

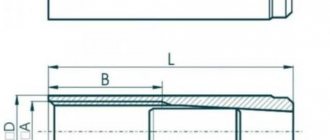

The labeling of capsule products indicates their dimensional parameters. For example, M10 (12×90): the letter “M” is the metric thread of the stud, “12” is the diameter of the stud in cross-section, “12 and 90” is the diameter of the hole and the depth of seating of the metal fastener in the base.

Particularly noteworthy are Hilti chemical capsule anchors - this is a modified material adapted to the temperature range during installation from -18 to +40 degrees. The manufacturer supplies products for holes from 8 to 30 mm in diameter, so they can be used for installation of powerful reinforcing bars into the base.

How does the chimanker work?

How to make a comfortable table for a balcony with your own hands

A chemical anchor fastener consists of a steel rod element and a binding adhesive composition, with the help of which it is held in the hole and forms a single whole with the base material. The “liquid anchor” penetrates deep into the pores, resulting in a strong bond with the base. The structures are then attached to the protruding end of the rod. It is no longer possible to dismantle the steel element, unless it is torn out along with a piece of the building foundation.

To achieve the required fastening strength, the chemical composition must completely fill the cavity between the metal element and the walls of the hole. In accordance with technical regulations, the hole is filled with injection mixture to 2/3 of its volume. With the correct dosage of the composition, after inserting the rod, excess glue should protrude to the surface.

Instructions for use

25 chemical and folk remedies on how to quickly remove mold from walls in an apartment or house

Drill holes before filling in one of two ways:

- using a diamond machine;

- use of a hammer drill.

The first technology is the most preferable, because the holes are perfectly round and even. As for the hammer drill technology, it should involve the use of calibrated drills. Sludge should be removed using a hand pump or compressor.

Installation of the anchor must be carried out using special equipment. If you decide to use liquid anchor, you must study the instructions for its use. At the next stage, the reinforcement should be installed using the immersion method, acting on it with little force. During this process, a small amount of the mixture will come to the surface, which should be removed before it hardens.

The master should use construction gloves and safety glasses. After installing the reinforcement outlet, wedging should be performed until the anchor is completely hardened so that the element is not pulled out under the influence of its own weight.

Types of liquid anchor

How to choose the right comfortable desk for two children

As mentioned in previous sections, chemical anchors are typically two-part formulations consisting of synthetic resins and a hardener. The ingredients are mixed immediately before using the anchor. There are three types of packaging for chemical anchors:

- ampoule.

They are a capsule with two compartments, one of which contains the adhesive mixture, the other contains the hardener; - single cartridge.

Inside the cartridge there is a special partition separating the adhesive and hardener; - two-cartridge.

The kit includes two cartridges, one of which contains an adhesive, the other a hardener.

The compositions produced in cartridges work on the same principle, however, to use them you will need various dispensing guns designed to dose the mixture into a pre-prepared hole (hole).

Ampoule anchors

The main feature of such fasteners is that the diameter of the ampoule strictly corresponds to the specific diameter of the prepared hole (borehole). One ampoule is intended to fix one rod (stud, screw, etc.). It is advisable to use ampoule anchors in cases where high accuracy and cleanliness of the hole can be guaranteed.

Capsule anchors are convenient to use because there is no need to control the degree of filling of the hole. Minor differences in the diameters of the hole and capsule are fully compensated by the expansion of the adhesive composition as it hardens.

As mentioned above, the ampoule has two capsules: with an adhesive mixture and with a hardener. The connection of these components occurs by screwing in a threaded metal rod, such as a stud or screw. It should be noted that mixing of the hardener and filler occurs more evenly than when using compounds packaged in one or two cartridges.

The disadvantages of capsule chemical anchors include the inability to use them in a vertical position. This is due to the fact that the filler will flow out of the hole much faster than setting occurs.

Cartridge anchors

As mentioned above, this type of anchor can be placed in one tube, separated by a partition, and in two separate cartridges.

When using one cartridge, the filler and hardener simultaneously enter the cavity of the mixing spout, where they are mixed using a special spiral insert. To work with such anchors, you can use a regular construction dispenser gun.

The two-cartridge system works a little differently. Mixing of components also occurs in a common spout, but they go there separately. To work with such packaging, you will need a special dispenser gun that ensures simultaneous supply of filler and hardener into the mixing spout.

Types of cartridge anchors

All cartridge anchors can be divided into two types:

- universal;

- for fastening metal rods in concrete foundations.

Universal chemical anchors

The popularity of this type of anchor fastening is due, first of all, to its ease of use. During installation work, there is no need to accurately calculate the volume of material required for one fastening.

Anchors designed for attaching metal rods to concrete foundations

Chemical anchors, the main purpose of which is gluing threaded or reinforcing bars into a concrete base, most often have a thick consistency. In addition to the main components, their composition includes corrosion inhibitors and deoxidizers, which significantly increases the reliability and service life of the fastener.

Some types of chemical anchors intended for concrete are used only in combination with special chemicals designed to treat the rods and drilled holes. In addition, special devices may be required to press the rods into the holes.

A significant disadvantage of cartridge anchors is the difficulty of controlling the filling of holes with adhesive. If the amount of working mixture is insufficient, it begins to flow out of the hole if the base is porous or hollow type without waiting for setting.

You can significantly reduce the consumption of filler and achieve its uniform distribution on all sides of the hole by using special mesh bushings. These elements can have different sizes and are selected specifically for a specific mount.

HILTI anchor for concrete: types, application, use

Dowel-nail: structure, types and methods of fastening

HILTI anchor is a collective name for a special substance intended for fastening load-bearing anchor bolts and studs in old concrete, brick, foam block, shell rock and other stone materials, including porous and hollow ones.

What is a Hilti anchor for concrete?

The HILTI anchor is a two-component substance consisting of a resin and a hardener. Installing fasteners using a Hilti anchor is one of the most reliable methods of attaching a load-bearing bolt or load-bearing stud, which has the following advantages and disadvantages:

- Highest tensile and tear strength;

- Possibility of use outdoors and indoors;

- The only possible way to reliably install a fastener in porous materials;

- Ease of use;

- Tightness of the connection;

- Average service life from 50 years;

- High resistance to harmful atmospheric and chemical factors;

There are several disadvantages: high cost, long hardening time at low temperatures (5 to 7 hours) and limited shelf life of no more than 12 months.

HILTI anchors for concrete: types and installation features

At this point in time, two types of HILTI chemical anchors are produced, depending on the packaging and technology of use: injection (tubes and cartridges) and capsule (one and two-component).

- The ampoule one-component anchor is a sealed glass cylinder filled with a special polyester resin that hardens upon contact with ambient air. The ampoule is inserted into the hole for a bolt or pin. Then a bolt (stud) is screwed into it. The glass breaks, the resin flows out, fills the space between the fastening element and the walls of the hole, hardens upon contact with air, and after a certain time the fastening element is ready for use. There are also two-component ampoule anchors. The disadvantage of this type of HILTI is that pieces of glass remain in the hole, which somewhat reduce the strength of the connection;

- HILTI injection anchors: cartridges and tubes. A cartridge anchor is a container with a “spout” through which the resin is squeezed into the installation hole. A tube is also a container with resin with a volume of 400-800 milliliters. In this case, a special gun is used to extrude and feed the resin. The cost of installation using chemical anchors of these types is slightly lower than ampoule anchors, due to the fact that a cartridge or tube is enough to install several bolts or studs. A special feature of installation in porous or hollow materials is the pre-installation of a special perforated sleeve into the poured hole. This is necessary so that the resin does not leak into voids or pores.

Chemical anchor HILTI

HILTI frame anchors

The latter method is the only possible technology for fastening loaded elements into: hollow brick, porous foam or cinder block, soft shell rock or limestone.

Where is Hilti anchor used?

Areas of application where it is economically feasible to use chemical anchors:

- Installation of fences in asphalt concrete pavement;

- Construction of staircase fencing and landing fencing;

- Installation of engineering communications;

- Repair of utilities, fences, staircases, etc.;

- Installation of reinforcement overhangs in old concrete or stone materials;

- Installation of all kinds of structures on the facades and walls of buildings and structures;

Any other construction and repair work related to the need for reliable fastening of load-bearing bolts or studs into concrete, brick, limestone, foam block, cinder block, ceramic block and other solid building materials.

salecement.ru

Cost and main features of Hit Re 500 liquid anchor from the manufacturer Hilti

The above-mentioned liquid anchor, the price of which is 2200 rubles. per package, excellent for holes that have an impressive diameter and depth, and were made using a material that is reliable and of high quality. It is capable of withstanding impressive loads and allows the installation of studs with a diameter exceeding M24.

There are no stresses in the concrete, this reduces the interaxial distances and the step to the edge. The anchor is flexible and can be used even in wet holes without reducing adhesion. The packaging has an economical dispenser, so you don’t have to put in much effort when injecting. The volume of construction waste is reduced thanks to unique packaging. The composition does not have a strong odor, so it can be used even indoors. Installed reinforcement and studs can be monitored thanks to the red color of the mixture.

Hilti injection anchor systems

This type of chemical anchor (marked with the letters HIT) is a plastic cartridge with two sealed foil containers (one with adhesive filler, the other with a hardener). Today the company presents 7 varieties of this type of chemical anchor. The price of such anchors depends on the capacity of the cartridge (there are two types: 330 and 500 ml), the components of the composition, the area of application and the load that the stud installed with its use can withstand.

For example, the universal hybrid composition “HIT-MM-Plus” is a budget-class chemical anchor (the cost of one 330 ml cartridge is 650÷900 rubles). The two-component adhesive is made on the basis of urethane methacrylate. Recommended for installation of threaded rods in the range M6÷M16 in basic building materials such as brick (solid and hollow), lime-sand blocks, concrete, blocks made of cellular types of concrete, artificial and natural stone. For fastening studs in hollow blocks and bricks, the company offers specially designed perforated plastic sleeves, which increase the fastening strength and reduce the consumption of adhesive.

And the composition “HIT-RE-500-V3”, which closes the line of injection anchors, already costs 2700–3300 rubles for a package with a capacity of 330 ml and is intended for gluing the releases of working load-bearing reinforcement of floors, columns, foundations and flights of stairs. A composition based on epoxy adhesive with additives that allow the installation of studs and reinforcing bars with a diameter of 10÷55 mm even in holes completely filled with water.

We extrude the glue components using a mechanical hand dispenser. For chemical anchors with a capacity of 330 ml, the dispenser “HDM-330” is intended, for 500 ml - “HDM-500”. We insert the capsules into the plastic cassette of the dispenser (it is included in the kit), screw the mixer onto the threaded part of the cartridge (in which the components of the adhesive composition are mixed) and through its conical tube the glue enters the drilled hole. Parallel pistons are connected to the dispenser handle, and when it is pressed once, one portion of the adhesive composition (about 5 ml) is supplied.

Video about using the “HIT-MM-Plus” composition and the “HDM-330” dispenser:

For professional use in large volumes of anchoring work, the pneumatic dispenser “P-8000-D” and the battery dispenser “HDE-500-A22” are used.

DIY making

Paint consumption per square meter, per 1m2

Considering the fairly high cost of chemical type anchors produced by various manufacturers, in some cases it is advisable to make such fasteners with your own hands. As noted above, the composition of the glue is kept a big secret by manufacturers, so it will not be possible to recreate it on your own.

However, no one bothers to use cheaper glue for these purposes, which can be epoxy resin. Along with their affordable cost, epoxy resins are characterized by fairly high strength and good adhesion to building materials (brick, concrete, foam concrete, etc.), which makes it possible to use them for installing anchor bolts.

It is better to take non-shrinkable epoxy resin

Epoxy resins, which can be purchased at an affordable price at any hardware store, include several components:

- the epoxy resin itself;

- a hardener that ensures its polymerization;

- fillers, which can be cement or gypsum;

- solvent;

- additives that improve various properties of the adhesive mass (plasticizers, etc.).

The consumption of plasticizer, which is necessary for preparing an adhesive composition based on epoxy resin, is 5–10%. The mixture formed from resin and plasticizer is thoroughly mixed. Only after that cement or gypsum is added to it as a filler.

The advantages of such an adhesive composition, in addition to its affordable cost, include:

- high strength and wear resistance;

- minimum shrinkage coefficient during hardening;

- Possibility of use in a wide temperature range (from –10° to +35°).

Epoxy adhesives also have a number of disadvantages.

- This composition hardens within 1–2 hours, and reaches maximum strength only after 12 hours.

- Epoxy resin based glue can only be used on dry surfaces.

- The composition may release small amounts of phenolic compounds into the atmosphere.

Design and types

The chemical anchor is a two- or one-component composition with a variety of contents. Usually the composition includes epoxy, polyester or other well-hardening synthetic resin. An adhesive anchor consists of a metal sleeve with a thread on the inside, a pin with an external thread, and an adhesive composition that includes a resin and a hardener.

Depending on the purpose for which the fastener is intended, it is made of steel with an anti-corrosion coating. The anchors also differ in strength, as indicated on the packaging. You can separately buy special resins for chemical anchors. It is produced in different packaging. Capsules are designed to secure one anchor, while cartridges and tubes contain adhesive for a large number of fasteners.

These adhesive bases are used in different ways. The capsules are placed in the hole first, after which they must be pierced with a metal pin to destroy the partition between the hardener and the resin and allow the adhesive composition to come out.

For cartridges and tubes, a special gun is used, into which the required amount of glue components is placed. In this case, you do not need to know the correct proportions of the components: the cartridges already contain the required amount.

Types of anchors for working with brickwork

Today there are many types of these fasteners. They have different purposes, therefore the design of different anchors is different. For example, there are so-called frame anchors, which are used only for attaching windows and door frames to the wall. There are foundation anchors. With their help, metal columns are installed, for example.

Anchors of different sizes are also designed to perform different tasks.

Chemical anchor for hollow bricks and ordinary bricks.

The future strength of the structure we create will depend on the correct choice of the fastening system.

Let's look at anchor systems used for brickwork.

The driven anchor consists of a spacer (sleeve), a bolt and a nut. The spacer part is hammered into the prepared hole. The bolt is screwed into the spacer together with the nut, then the nut is removed. This type of mounting fastener is used for subsequent screwing of hinges or corners using a nut. You can hang shelves, cornices, etc. on them.

There are such types of drive-in anchors as hook bolt, angle bolt, and ring bolt. Their purpose is different from that of conventional bolted anchor fasteners. For example, heavy kitchen cabinets or bathroom water heaters are usually hung on a bolt angle. The ring can be used to hang, for example, wickets or gates in a brick fence.

Scheme for screwing a dowel into a brick wall.

Wedge fasteners are used more often for through fastenings. The wedge firmly holds the attached element on the wall surface.

The so-called MSA. This fastener is made of brass. Like all fastening anchor systems, it has a notch on the outer surface of the sleeve for better adhesion to the inner surface of the hole in the wall material. The maximum internal section of the sleeve is 8 mm. It is intended for fastening not very heavy products and materials to a brick wall.

The double expansion anchor consists of a pin with two expansions and a sleeve with cuts in the middle and at the end. Thanks to two spacers, the fastening is more durable. It is used when installing on a wall made of hollow bricks, when greater resistance to tearing is required.

They also make double-spacer fasteners with a nut and a pressed washer. This type is used for fastening metal. Such systems are made of galvanized steel.

Not so long ago, a new type of anchoring system appeared - adhesive, or chemical. After all, attaching something to a wall made of hollow bricks is very problematic. For this purpose, this type of fastener is used. Instead of a sleeve, it uses an ampoule with a special polyester glue into which a pin is screwed. After a short time, the glue hardens, and a reliable fastening is ready.

Installation technology

The installation process of anchors depends on the type of fastening element.

Installation of chemical anchors

Installation of injection anchors, unlike capsule anchors, is carried out with special equipment - a dispenser.

Chemical anchor installation device

In general, the installation diagram looks like this:

- a hole is drilled in the selected location with parameters that fully correspond to the fastening element;

- If possible, dust and other accumulations of dirt are completely removed from the hole (you can use a syringe or other similar devices);

- a capsule is inserted into the hole (installation of capsule anchors) or the hole is filled with an injection anchor using a dispenser;

- the fastening element is inserted to the desired height;

- wait the time (according to the attached instructions) necessary for the adhesive mixture to dry completely.

How to use

To obtain a reliable and durable connection using a chemical anchor, you should follow simple rules for its installation.

- A hole is drilled in the surface of a structure made of concrete or any other building material, the diameter of which should be 2 mm larger than the cross-sectional size of the bolt being inserted.

- The inside of the hole is thoroughly cleaned of construction dust, for which you can use water and a brush of a suitable diameter.

- A capsule with glue and hardener is inserted into the prepared hole, or these components are squeezed out of the tube or cartridge. When using a cartridge, you need to monitor the glue consumption (it should be such that it slightly exceeds the internal volume of the hole).

- After this, a metal fastener is inserted into the hole. After the adhesive composition hardens, a reliable connection is formed between the chemical anchor and the building structure, which can only be destroyed mechanically, actually breaking it out of concrete, brick or other material.

General installation parameters of chemical anchors

Chemical anchors for concrete and hollow bricks differ in design and, accordingly, installation method

Advantages of chemical anchors

Among the main advantages of such mounts it should be noted:

- wide area of use;

- ease of installation;

- the ability to create a monolithic connection with attached material;

- hermetic filling of the hole;

- Can be used on wet surfaces or even under water;

- long service life;

- high level of strength;

- the ability to adjust the anchorage while the solution is setting;

- absence of toxic materials;

- resistance to aggressive environments;

- absence of internal stresses, etc.

But it should also be noted that this type of fastening has several disadvantages. Firstly, the relatively high cost of such products. Another disadvantage is the long curing time of the adhesive composition. At a temperature of 20°C the glue hardens within 20-40 minutes. At -5°C, polymerization time can reach 6 hours. At even lower temperatures, the hardening process does not occur.

Types of anchors

Chemical anchors for concrete consist of a chemical resin and hardener

The anchor for aerated concrete is offered by manufacturers in various packaging, representing:

- individual capsules or ampoules intended for single use;

- cartridges of increased volume, which can be equipped with a special gun, and are used repeatedly.

A chemical anchor for cellular concrete has different properties depending on the compositions used to fill the drilled hole. Applicable:

- Epoxy based resins.

- Vinylester compounds.

- Polyester binders.

- Epoxy acrylate fillers.

Let us dwell in detail on the characteristics of resins.

Epoxy-based resins are used to secure elements of process equipment and fasten beams. They are characterized by:

- possibility of use in environments with high humidity;

- hardening duration ranging from 8 hours to 2 days;

- absence of internal stresses of aerated concrete during hardening of the composition.

Many companies produce adhesive mixtures without such a toxic component as styrene. This makes it chemically safe

Vinylester compounds are used to provide facade fastening. Distinctive features:

- Resistance to negative temperatures.

- Effective fastening of threaded elements and smooth fittings.

- The absence of harmful substances allows you to perform work safely.

- Hardening occurs throughout the day.

Polyester-based fasteners provide reliable fastening of fencing structures, facade elements and utilities. Basic properties:

- ensuring the fastening of only threaded fittings installed in conical holes;

- ensuring effective anchor fastening in rough holes;

- accelerated hardening, allowing the fastener to be used for 3 hours.

Chemical fillers based on epoxy acrylate are used for various purposes and differ:

- An increased level of fire resistance, ensuring the absence of deformation of fasteners for 2 hours when exposed to open fire.

- Can be used at temperatures not lower than -5 degrees Celsius.

- Achieving performance characteristics throughout the day.

The material from which it is made is resistant to chemical, atmospheric and corrosive influences

Let's dwell on the features of use.

Hilti chemical capsule anchors

This type of chemical anchor is clearly dosed for the installation of only one fastening element. It is a cylindrical polyethylene container filled with an adhesive composition. The two components of the adhesive mixture are separated by an impenetrable partition. Mixing of the mixture components occurs at the time of installation. Products of this type are marked with the letters HVU, indicating the thread of the anchor pin and the depth of the mounting hole for it. For example, the marking “HVU M16X125” means that this capsule is intended for fastening an anchor rod with an M16 thread, a hole depth in concrete of 125 mm. The line of capsules is presented quite widely: from M8 to M39.

The technology for installing a stud using an adhesive capsule is quite simple:

- We drill a hole of the required diameter and depth in the base. The manufacturer recommends choosing a drill or drill diameter 2 mm larger for studs M8÷M16, and 3÷4 mm larger for M20÷M39. For example, for the “HVU M12X110” capsule you will need a drill with a diameter of 14 mm and a hole depth of 110 mm.

- Carefully clean the hole from dust using air or a brush.

- Insert the capsule into the hole.

- We twist the pin into the hole clockwise: the lower end of the pin breaks the capsule and when screwed in, the components of the adhesive composition are mixed.

The final hardening time of the adhesive composition, after which maximum loads can be applied to the stud, depends on the ambient temperature: from 20 minutes at a temperature of +20˚С to 5 hours at a temperature of -5˚С.

For studs experiencing increased dynamic loads, the company has developed special “HVU-TZ” capsules. The line of these types of capsules is designed to install studs from M10 to M20.

Installing the mount

Installation

Installation using a chemical anchor is very similar to installation using conventional fasteners, if you exclude the stage of using an adhesive composition. And, since a special tool is used, the use of CA does not delay the work.

- Mark the attachment points. In this case, the distance from the edge does not matter much.

- Holes are drilled according to the marks - 2 mm larger than the diameter of the anchor. Tools with a diamond drill are used, as they give the most even walls.

- Clean the holes from dust - use special brushes and blow out the holes.

- If the fastening is made into hollow brick or foam concrete, then a mesh sleeve is inserted into the holes: it prevents the adhesive from spreading. If we are talking about dense material - heavy concrete, then a sleeve is not needed.

- A mixer is placed on the cartridge and some of the contents are squeezed out. At this point, the components are mixed in the mixing spout to form a homogeneous mixture.

- The mixer nozzle is inserted into the hole until it stops. The composition is squeezed into the hole, filling it to about 2/3 of the volume.

- The fastener is inserted into the hole using rotational movements. Until the mixture has set, its position can be adjusted.

- Until the composition is completely cured, the fasteners are no longer touched.

- For the next anchor on the cartridge, change the mixer and clean the hole.

Instead of a cartridge for multiple mounting, use a larger volume tube of 400–800 ml.

Consumption

The consumption of a chemical anchor depends on the hole diameter, depth, and, of course, the size of the metal pin, if one is used. The consumption can be determined using the formula:

V= π*h(D²- d²)/4, where

- π – pi number:

- D – hole diameter;

- d – pin diameter;

- h – hole depth.

The resulting volume must be multiplied by the number of holes to obtain the total volume of the mixture that will be required for installation.

You will learn more about the price of a chemical anchor below.

Advantages and disadvantages

To make it clearer why a chemical anchor is more reliable than a regular one, and how it may be inferior, it is necessary to consider the strengths and weaknesses of fasteners with glue. Advantages:

- The adhesive composition used does not contain any substances harmful to the human body.

- Average durability, subject to installation rules, is 50 years.

- To perform various installation work, specialized fasteners are produced. For example, you can find chemical anchors on sale that can be used underwater or under conditions of prolonged exposure to high temperatures.

- Resistance of the finished compound to destructive environmental factors.

- The chemical anchor can withstand high tensile loads.

- Reliability, high strength of the finished connection.

- These fasteners are used in various fields of human activity.

- For installation you do not need to have specialized equipment or have any serious practical skills.

In addition to everything described, the connection is sealed. The disadvantages include the high cost of such fasteners, long hardening time (about 6 hours), shelf life - 12 months (in a closed package).

It is advisable to use chemical anchors in places where it is necessary to obtain a high-strength connection that will be characterized by increased tightness and resistance to external factors. In other cases, it is recommended to use standard metal fasteners without special glue to save money.

How to install an anchor bolt in concrete

The whole process is quite simple, the main thing is to take the measurements correctly and implement everything as accurately as possible. But there are several nuances that need to be taken into account.

Practical tips for installing anchors in concrete:

- The strength of the fastener is influenced not only by the anchor, but also by the quality of the base material (concrete in this case), proper preparation for installation, taking into account the material of the attached structure and the design of the bolt itself.

- If a layer of finish is applied to the wall, the hole must be deeper because the finish is usually less durable than concrete.

- It is advisable to take a drill 0.5 millimeters thinner than the diameter of the future hole.

- When working with a hammer drill, it is best to use a tip made of a special carbide material.

- Read the instructions carefully - the packaging with anchors should indicate the permissible force and the maximum number of revolutions.

- When screwing the anchor into, under no circumstances should you twist it all the way, as the material may collapse.

Eternal fastener: concrete dowel

A dowel is a spacer element made of polypropylene or nylon, which is similar in function and performance to an anchor. It cannot be used independently; it is fixed in concrete with special nails or self-tapping screws. To strengthen the fixation, it is often performed with spikes or antennae.

This type of fastening is used where there are not too large loads on the concrete - fastening shelves, TV hooks, lighting fixtures. The dowels are driven into the dowels with a hammer, and the screws are screwed in with a screwdriver or screwdriver. You will also need a regular hammer to drive in nails.

You can also find dowel nails designed for use with a mechanical gun. The fasteners in concrete are made of metal; in appearance, they somewhat resemble a bullet. Relevant where you need to hang a large number of small items.

Concrete dowel: fast but durable

Pins are those that are most often used for arranging fasteners near the edges of a concrete wall. The fastener does not require additional fixation; it is screwed into the hole, where a little epoxy glue is first poured. There is no need to drill holes - the dowel can be screwed directly into the concrete wall. If you still need to make a hole in concrete, then it is better to choose a drill (a hammer drill can damage the wall).

They screw it in with a screwdriver - and after that it is no longer possible to unscrew the dowel back. Therefore, preliminary marking must be done especially carefully.

HUD-1 Universal plastic dowel HILTI

Loads

Technology for attaching a ceiling cornice to a tensile structure and wall

Characteristic resistance

a) only with a screw with a diameter of 6mmb) only with a screw with a diameter of 8mmc) only with a screw with a diameter of 10mmd) Screw type : W: Screw on wood base C: Screw on chipboard The load data is valid only for the types of screws mentioned, if other types of screws are used, the load may decrease.

Design resistance

a) only with 6mmb diameter screw) only with 8mm diameter screwc) only with 10mm diameter screwd) Bolt type : W: Wooden screw C: Chipboard screw Load data is only valid for the screw types mentioned, if other types of screws are used, the load may decrease.

Recommended loads

a) only with a screw with a diameter of 6mmb) only with a screw with a diameter of 8mmc) only with a screw with a diameter of 10mmd) Screw type : W: Screw on wood base C: Screw on chipboard The load data is valid only for the types of screws mentioned, if other types of screws are used, the load may decrease.e) With a global safety factor g = 5, the characteristic load and safety factor of the element g = 1.4 are design values.

1001krep.ru

How does a chemical anchor work?

A chemical anchor is a universal fastener that has a complex design. It consists of a reinforcing rod or stud with an external thread, a metal sleeve with a thread inside, and a special adhesive composition.

The operating principle of a chemical anchor can be described in several stages:

- First, a hole is drilled in the floor, wall, or ceiling with a hammer drill, which is 2 mm larger than the fasteners.

- The hole is cleared of dust.

- Next, it is filled with a special adhesive composition.

- A metal rod is placed inside the hole.

The glue binds firmly to the metal, concrete base, and fills uneven areas. This results in a monolithic connection.

About the composition

Chemical anchors used in the installation of any structures have a composition that we will discuss below.

So, the composition:

- Special glue.

- Metal fastening insert. It is a bushing that has a thread, a stud and a reinforcing rod inside. The insert is made of galvanized or stainless steel.

The adhesive composition itself must be very strong. After all, chemical anchors are used when working with concrete elements, for example. Naturally, the fixing force of the anchors must be significant.

As a rule, the adhesive composition is prepared using the following components:

- Artificial resins based on polyurethane, polyester or acrylic.

- Quartz sand and cement-type binders. They are used as fillers and additionally provide the strength characteristics of the adhesive.

- Hardener. It is necessary for the glue to dry quickly and retain its properties for a long time.

Now that everything is clear about the composition of chemical anchors, it’s worth understanding what types of anchors there are.