11/18/2021 Author: VT-METALL

From this material you will learn:

- Pros and cons of fusion welding

- 7 types of fusion welding

- 2 types of electrodes for fusion welding

- Fusion welding technology

- Fusion Welding Standards and Requirements

- Evaluation of the finished product

- 6 Common Fusion Welding Mistakes

Fusion welding has become widespread due to its ease of execution and high degree of reliability. This method is used both in the manufacture of household appliances and in the creation of space technology. The technology is so accessible that it is also used at home.

There are several methods of fusion welding, the choice depends on the task at hand. Read more about what stages this technology consists of and how the quality of execution is controlled in our material.

Pros and cons of fusion welding

What is fusion welding of metals? This is the process of connecting the components of a structure, during which melting of mating surfaces that are not compressed occurs. The power characteristics of the energy source used must ensure the process of melting the filler material and the edges of the parts.

You can ignite a high-temperature arc by performing three steps in sequence. First, you need to touch the workpiece with an electrode, which will cause a short circuit, leading to heating of its tip. After this, the electrode should be slightly removed from the part, but the stability of the arc should not decrease. This distance is determined empirically. Warming up the electrode tip is necessary for the stability of electron exo-emission, which also helps maintain a stable electric arc.

At the moment of melting of the electrode, its filler material is transferred to the weld pool, due to which the parts are connected. On some models of welding equipment used for welding parts using fireproof electrodes, the arc is ignited in a non-contact manner. Ignition is achieved using a special device called an oscillator.

At the same time, melting of various contaminants occurs with the metal, which leads to the formation of slag on the surface of the bath. The temperature of the top layer of the welded joint is higher than the molten metal, which leads to changes in the mechanical characteristics and structure of the weld after it cools. The advantages of electric fusion welding technology are the ability to join metals with dissimilar structures and versatility.

Automatic and semi-automatic welding using flux or gas

Automatic and semi-automatic welding using flux or gas is a more advanced method of joining metals. Here, some of the work is mechanized, for example, feeding the electrode into the welding zone. This means that the welder feeds the rod not with his hands, but with the help of a special mechanism.

Automatic welding involves mechanized feeding and further movement of the electrode, while semi-automatic welding implies only mechanized feeding. The welder carries out further movement of the electrode manually.

Here, protecting the weld pool from oxygen is simply mandatory, so gas is used (by analogy with arc welding using gases) or a special flux. Flux can be liquid, paste or crystalline. Using flux, you can significantly improve the quality of the seam.

Fusion welding technology

With any fusion welding technology, the process of joining parts must consist of the following steps:

- Preparatory work. The edges of the workpieces are cleaned from corrosion and grease residues, after which the edges are cut off taking into account the thickness of the part.

- The parts are installed and fixed in the required position.

- The arc is ignited (any method can be used). Sometimes the workpieces are heated using another method.

- A weld is formed, after cooling, the joint must be cleaned of slag inclusions.

Arc welding using shielding gas

The method of arc welding of different metals using shielding gas is performed using consumable and non-consumable electrodes. The welding technology is the same as with classic manual arc welding. But here, for additional protection of the weld pool, a special shielding gas supplied in cylinders is supplied to the welding zone.

The fact is that the weld pool is easily susceptible to the negative influence of oxygen and under its influence the seam can oxidize and turn out to be of poor quality. Gas helps to avoid these problems. When it is supplied to the welding zone, a dense gas cloud is formed, which prevents oxygen from penetrating into the weld pool.

Fusion Welding Standards and Requirements

The following documents have been developed to regulate the processes of fusion welding of metals:

- GOST 30242-97 (description and methods for eliminating defects);

- GOST R 55143-2012 (welding parameters);

- GOST R ISO 5817-2009 (requirements for seam quality);

- GOST 11969-79 (basic terms and designations).

The requirements for welding seams depend on the purpose of the structure. But in any case, the strength and hardness of the joint should be approximately the same as that of solid products.

We will weld tightly, inexpensively, call

Tacking structures before welding.

Basic welding methods are a common but incorrect classification in this context. “The most popular” would be more correct.

Here are three well-deserved winners:

- Manual arc - gold.

- Gas - silver.

- Semi-automatic - bronze.

Each winner belongs to a different welding family; in theory, it is better to describe them in their rightful places together with their close “relatives.” But we will do the wrong thing - we will introduce welding champions at the beginning of the review.

Manual arc welding RD

People's favorite No. 1, the most common type in everyday life and in industry. The three main words in RD are simplicity, cheapness, and transportability. The physics of the process consists of melting a special coated electrode, which leaves behind a mark in the form of a weld seam. Different electrodes are used, depending on the metal. The arc is the distance between the electrode and the surface of the metal, which plays the role of a second electrode.

Essentially, an arc is a powerful discharge in a gas space (air). During RD, three objects melt: the edges of the two surfaces connected to the electrode. The better the triple melting products are mixed (to do this, the electrode is moved left and right), the better the quality of the seam.

RD welding has serious advantages over other types:

- the RD method is easy to learn;

- you can cook in any position in space;

- You can cook a wide variety of metals; there are electrodes for sale for every taste;

- accessible transportable equipment

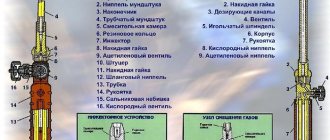

Gas welding

People's champion No. 2, well-deserved silver medal.

This is when welders carry gas cylinders with them: they need a mixture of oxygen with some flammable gas - acetylene, propane or butane. The physics of the process is also melting, but the heat is supplied not by an electrode, but by a gas burner. The metal surfaces are melted by the torch, the process occurs smoothly and rather slowly. The thicker the metal layer, the slower it melts. Why gas welding is better than other methods:

- Non-ferrous metals are excellently welded;

- the equipment is simpler than electrical methods;

- the ability to control the mixture and flame;

- no powerful energy source is needed, the method is autonomous.

You can’t do without disadvantages, the “gas” disadvantages are as follows:

- very slow heating of surfaces;

- low heat concentration due to dissipation;

- high cost of electricity.

In terms of the cost of electricity, arc methods can compete with gas methods: with RD, electricity is also wasted mercilessly. But in the end, the gas method, due to its “low speed,” is much more expensive.

Important! Where there is a pair of words “flammable gas”, there is always a second pair “safety precautions”. Safety rules are well regulated, but compliance with the requirements requires additional money and time.

By the way, gas welding is more than 100 years old - here it is, a stainless classic, applause.

Semi-automatic welding

Classification of the welding arc.

Bronze champion, closes the popular top three, but in terms of his prospects he will easily surpass the first prize-winners. In fact, this is a type of arc type familiar to us, a progressive evolution of the RD. It features a large number of technological nuances, options, and instructions. It is enough for us to know that the “automatic part” of the method is the feeding of the welding wire.

The manual part is the welding process itself with wire feed control. You can cook with gas (carbon dioxide for beginners, argon for professionals), or without gas, with direct current. The option without gas is popular in garages and summer cottages; in this case, a special flux-cored or flux-cored wire is needed. When it burns, a gas with vapor is formed that protects the combustion area.

Semi-automatic is the only method at a service station: body work is carried out only with its help. The semi-automatic machine uses gas and a special wire instead of the usual electrode. Gas from the torch with wire is supplied to the welding sleeve. As a result, the process is protected from environmental influences. The process modes are determined by the welder depending on the thickness of the metal.

The semi-automatic method has serious advantages over other types:

- excellent seam quality;

- high speed;

- ease of use;

- welded as non-ferrous and ferrous metals;

- You can cook rusted or galvanized metals;

- wide selection of materials, modest financial costs.

Evaluation of the finished product

When welding structures that are not included in the critical category, the quality of the weld can be checked only by visual inspection. For critical structures, the following quality control methods are used:

- radiation;

- capillary;

- magnetic;

- ultrasonic flaw detection.

The requirements for welding seams depend on the purpose of the product. But there is a mandatory condition: the hardness and strength of the welded joint should not be lower than that of the metal workpiece itself.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

Before proceeding with visual inspection, it is necessary to clean the seam from scale and slag formed during fusion welding of metal. The width of the welded joint along the entire length should be the same, and the surface should have a fine-scale structure. The presence of narrowings, omissions and sagging is unacceptable. If, after welding, cracks and pores are found on the surface of the metal, then such a weld must be rejected.

Which fusion welding method to use depends on the task at hand. If such work is often carried out outdoors, it will be more convenient to use a gas burner with cylinders or a portable arc apparatus. In cases where welding work is carried out at one place, the best option would be a semi-automatic one, and in case of mass production, an automatic welding unit.

Working principle of plasma welding

The nature of the functioning of the devices depends on the method of adjusting the parameters.

Manual method

For simple operations on joining non-ferrous and ferrous metals, equipment that does not have automatic control units is used. After the plasma arc appears, the master brings the torch to the part with one hand, and with the other he feeds consumables into the weld pool.

By moving the tool and filler along the joint, the welder forms a strong weld. The manual welding process can be carried out without wire.

Using automation

Such plasma welding machines are used at production sites. The operator controls all parameters remotely.

There are automatic installations of the following types:

- for connecting sheets of metal or pipes;

- single-pass for welding with wire;

- multi-pass;

- for the formation of reinforcing powder coating.

Automatic penetrating arc devices are often used to weld aluminum and aluminum-based alloys.

Why should you contact us?

We treat all clients with respect and carry out tasks of any size equally scrupulously.

Our production facilities allow us to process various materials:

- non-ferrous metals;

- cast iron;

- stainless steel.

When completing an order, our specialists use all known methods of metal machining. Modern equipment of the latest generation makes it possible to achieve maximum compliance with the original drawings.

In order to bring the workpiece closer to the sketch submitted by the customer, our specialists use universal equipment designed for jewelry sharpening of tools for particularly complex operations. In our production workshops, metal becomes a plastic material from which any workpiece can be made.

Types of electrodes used

A high-quality weld can only be obtained with the correct selection of filler material, so it is worth paying attention to their varieties. The welding electrode is a steel rod coated with a special coating that melts during the welding process and protects the seam from exposure to nitrogen from the air.

In the case of welding with a fireproof electrode or gas, no coating is required; the seam is protected by inert gas or flame from the torch. Therefore, in principle, the electrode, wire and other filler material are practically the same.

https://youtube.com/watch?v=zjLj6lkWBto

The filler material from which the wire is entirely composed plays a primary role in the strength of the weld. During the heating and melting process, alloying elements burn out from the alloys, thereby deteriorating the quality of the connection. In order to avoid this, steel rods are selected whose degree of alloying is equal to or even higher than the grades being joined. If the alloy grades are different, the degree of alloying is estimated based on the maximum alloyed alloy. An excess of alloying elements compensates for their burnout.

If the steel grades are unknown and there is no way to determine them, then a special transition (also called a buffer) electrode or a special filler wire is used. It allows you to weld even dissimilar steels, for example, such as stainless steel and simple black low-alloy steel, playing the role of a transition material.

We cook metals

We’ve sorted out the people’s favorites, let’s move on to the “correct” classifications.

Let's start with the real heavyweights - types of metal welding, which are divided into three groups according to:

- Physical signs.

- Technical characteristics (mechanization, process continuity, metal protection).

- Technological characteristics (separate classifications for each method - for example, types of electrodes).

According to physical characteristics, we have three main classes for all types of metal welding:

Thermal class - the welding process involves melting with thermal energy:

- gas;

- arc;

- laser;

- radiation, thermite, etc.

Important! The main types of fusion welding are the most common in everyday life and in industry. This is the most populous class; the vast majority of welding methods belong to it. Mechanical class using mechanical energy:

Mechanical class using mechanical energy:

- ultrasonic;

- cold;

- friction;

- explosion, etc.

Metal welding table.

Thermo-mechanical class, methods of combined action of thermal energy and pressure:

- blacksmiths;

- diffusion;

- contact, etc.

As an example of metal welding, we present MAWP - mechanized argon arc welding with a consumable electrode. A true hybrid for electro-gas joining of metals. Without it, welding of non-ferrous metals or complex alloys is impossible.

Advantages of MADP:

- connection of any alloys;

- stability of the product’s shape due to low heating;

- electrodes need to be changed rarely;

- widest scope of use;

Flaws:

- difficult for beginners;

- low execution speed.

Automatic welding: what is it?

The process of forming a seam automatically comes down to the following operations:

- constant renewal of the consumable electrode;

- maintaining the conditions necessary to obtain a high-quality weld (supplying shielding gas or flux to the weld pool);

- uniform movement of the arc across the working area at a given speed;

- formation of a welded joint.

Difference from semi-automatic

The difference between the technologies is minimal. Processes differ in the degree of mechanization of operations. Semi-automatic devices have a simpler structure. They are equipped with devices for supplying consumables to the holder. The welder is responsible for moving the arc and directing it in the desired direction.

With automatic welding, all processes are controlled by equipment.

Inverter and automatic

An automatic machine differs from an inverter in that when using it there is no need to carry out manual operations. The welder plays the role of an adjuster, setting the desired mode. The inverter uses the same consumables, but the welding technology using it differs from automatic welding. The unit requires manual adjustment of current, voltage, and wire feed speed.

When using the machine, there is no need to perform manual operations.

Principle of operation

The automatic device regulates:

- distance between the workpieces to be welded and the electrode;

- current strength;

- rod movement speed;

- the depth of heating of the parts being welded.

The main parameter is the arc voltage, which depends on the length. When using a consumable electrode, the machine ensures uniform wire feeding. This helps maintain a stable arc length. Violation of the equality of parameters is observed during voltage surges, improper processing of welded parts, and the influence of a magnetic field. The automatic welding machine eliminates these disturbances, restoring the required arc length. When programming equipment, 2 adjustment principles are used:

- independent, triggered at a constant speed of wire withdrawal;

- forced, in which the nature of the wire feed depends on the arc voltage.

The principle of self-regulation underlies a number of simple welding machines that feed wire at a constant speed. When using units with forced regulation, as the length of the arc increases, its voltage increases.

How to cook with automatic welding

The process consists of several stages, the first of which is the preparation of equipment and parts to be welded.

Tools and necessary equipment

In addition to the welding unit, you will have to purchase:

- contact jaws;

- tractor nozzles;

- flux cones;

- rollers for straightening wire;

- current leads.

You will have to purchase rollers to straighten the wire.

Automatic welding modes

To ensure a strong and uniform seam, you need to set up the machine correctly. When choosing a mode, the following factors are taken into account:

- thickness of welded parts;

- geometric shape of the connection;

- seam length;

- the depth of melting of the edges of parts.

To select the mode, use the tables attached to the instructions.

Step-by-step instruction

Automated electric arc welding is carried out as follows:

- Inspect the equipment. If malfunctions are detected, metal welding is started only after they have been eliminated. If necessary, the equipment is cleaned of contamination. Welding should not be performed in rooms that are too small, poorly lit or dusty.

- Check that the diameter of the burner nozzle matches the thickness of the wire. The choice of tip also depends on the cross-section of the additive. If there is splashes in the nozzle, clean it thoroughly.

- Check that the cables are connected correctly and inspect the roller mechanisms. These parts must be free of dirt or rust.

- Check for the presence of flux in the hopper.

- Prepare the parts by carefully cleaning the edges with a grinding wheel. Refill the device with consumables and set the desired mode.

- The welding process is started. Perform final processing of the seam.

Advantages and disadvantages of automatic welding

The advantages of process automation include:

- There is no need for lengthy setup and adjustment of the device. The use of special programs facilitates the process of preparing equipment.

- High performance. The unit does not take breaks, the quality of its work does not depend on the professionalism of the technician.

- Reduce waste volume. The number of rejected workpieces depends not on the human factor, but on the correct settings of the unit.

- Evenness and strength of the seam. The machine forms a homogeneous welded joint of the same height. Sagging or burns appear extremely rarely.

- Economical consumption of wire, gas, electrical energy.

- Possibility of welding in hard-to-reach places, closed containers, hazardous conditions (at high temperatures or gas contamination).

The disadvantages of automatic equipment include low maneuverability, the need for additional adjustment when changing operations, and high cost.