Low carbon steel and its properties

Low carbon steel belongs to a large group of structural steels. The carbon content in it is no more than 0.3%; due to such a low percentage, it has the following properties:

- High plasticity and elasticity;

- Well suited to the welding process;

- High impact strength.

This brand is widely used in construction due to the fact that it is very easy to weld, since there is very little carbon in its structure, which has a bad effect on the welding process, since brittle structures and porosities can form in the metal seam, which then lead to failure. Also, due to its high softness, parts are made from it using cold stamping.

High carbon

Steels with a high carbon content are very difficult to weld. Other alternative methods are used to connect parts made of such materials.

Welding of high-carbon steels that are resistant to corrosion is carried out only during repair work.

In this case, pre-heating of the seam area to 250-300 °C and subsequent heat treatment of the seam are used. It is absolutely not allowed to carry out welding work with high-carbon steels at air temperatures below 5 ° C or if there are drafts at the welding site.

Welding carbon steels

Absolutely all grades of steel can be welded. However, each type of metal has its own technology for welding. The welding technology for carbon steels must meet the requirements, which include:

- Uniform distribution of seam strength along the entire length;

- The absence of welding defects, the seams should not have various cracks, pores, grooves, and so on;

- The dimensions and geometric shape of the seam must be made in accordance with the standards prescribed in the relevant GOST 5264-80;

- Vibration stability of the welded structure;

- The use of electrodes with low hydrogen and carbon content, which can have a negative impact on the quality of the seam;

- The structure must be strong and rigid.

Thus, the technology must be as efficient as possible, that is, give the highest process performance while ensuring high strength and reliability.

The mechanical properties of the weld metal and welded joint completely depend on the microstructure, which is the chemical composition, and is also determined by the welding mode and heat treatment, which is carried out both before and after welding.

Equipment selection

The type and operational features of welding equipment for working with carbon steels vary widely and depend on factors such as:

- selected welding method;

- workpiece characteristics;

- required seam quality;

- design welding mode;

- features of the external environment;

- required performance;

- financial and economic criteria.

Most often, carbon steels are joined using one of the electric arc welding methods. If manual welding is expected and the amount of work is relatively small, you can use a conventional welding inverter, the main advantages of which are its compactness and low cost. A good choice would be the Fubag IR 200, Wester MMA-VRD 200, Elitech AIS 200, Resanta SAI-220 and others.

Approximate cost of Resanta SAI-220 devices on Yandex.market

Otherwise, it is better to give preference to industrial transformers with higher performance, for example, Kavik TDM-252U2 (250 A, 12 kW) or Brima TDM1-315-1 (315 A, 24 kW). In areas where connection to the electrical network is impossible or difficult, welding generators equipped with internal combustion engines are used.

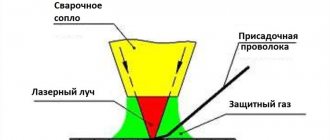

For semi-automatic welding in shielding gases or under a layer of flux, specialized welding machines of a combined design are used, which provide the generation of welding current, as well as the supply of shielding gas and a consumable electrode to the welding zone (in addition, filler wire can be supplied). In the niche of budget models, the leader is Aurora Overman 180, in the top segment – Blueweld Starmig 210 Dual Synergic.

Approximate cost of Aurora overman devices on Yandex.market

For gas welding, you will need oxygen and acetylene cylinders with pressure gauges, flexible hoses and a torch that allows you to adjust the proportional ratio of gases. Equipment for alternative types of welding is specific; it belongs to industrial devices and is extremely rarely used in everyday life.

Low carbon steel: welding technology

As mentioned above, low-carbon steels lend themselves best to the welding process. They can be welded using gas welding in an oxy-acetylene flame without additional fluxes. Metal wires are used as an additive. Hydrogen, which can form pores, can negatively affect the welding process. To prevent this problem, it is recommended to carry out the welding process with a filler metal containing a small amount of carbon.

After the welding process, the structure must be thermally treated to improve the mechanical properties - ductility and strength will be the same. Heat treatment of welded structures is carried out by a normalization operation, which consists of heating the product to a certain temperature, approximately 400 degrees, holding and further cooling in air. As a result, the structure is equalized, carbon in the form of cementite in the metal diffuses into the grains, due to which the structure becomes uniform.

Gas welding is carried out in the presence of argon, which creates a neutral environment. Structures that are welded in an argon environment have a more important purpose.

Welding of low-carbon steels can be done manually; arc welding of such materials requires the correct choice of electrode. When choosing an electrode, it is necessary to take into account the following factors, which will ensure a uniform weld structure without defects. Before carrying out the welding process, it is necessary to calcinate the electrodes in order to prepare them for further work and remove hydrogen. Welding low-carbon iron alloys must be precise and fast, and the metal parts must be prepared before starting the process.

Stainless steel

Most often, stainless steels used in industry obtain their anti-corrosion properties through the introduction of alloying additives - chromium and nickel.

When welding chrome-plated parts, it must be taken into account that at high temperatures (more than 500 °C), oxidation of the joint of parts is possible.

To avoid this, argon arc welding, or TIG welding (TIG), is used. This technology involves the implementation of welding operations without air access directly to the welding zone. Accordingly, the absence of oxygen, the presence of which is mandatory in the air, eliminates the prerequisites for oxidation of the material.

Limiting the access of air is carried out by introducing argon, an inert gas into the welding zone, which, being heavier than air, displaces it. Sometimes this method is called steel welding with argon. In fact, steel is either simply welded together with an arc, or using filler material.

Tig welding requires special equipment. The work is carried out with non-consumable tungsten electrodes, the requirements for which are determined by GOST 10052-75.

The second problem is this. Stainless steels have a high coefficient of thermal expansion, and when welding sheet steel, when the joint is long in comparison with the linear dimensions of the part, the weld may bend during the cooling process.

The problem is solved by setting gaps between the sheets and using tacks to fix the parts in the desired position.

Requirements

When welding carbon steels, to achieve maximum parameters, the following requirements must be met:

- Welding electrodes and wires must have a low percentage of carbon to avoid unnecessary defects;

- It is necessary to ensure that carbon from the metal does not transfer into the weld under the influence of high temperature; for this, wire is used for welding steels with an average carbon content and higher, for example Forte E71T-1, Bars-71. These types are ideal for welding steels with a carbon content above 0.3%;

- When carrying out the welding process, fluxes should be added, which contribute to the formation of refractory formations;

- Reduce chemical heterogeneity of the seam by subsequent heat treatment;

- Reduce the hydrogen content by calcining the electrodes, using electrodes with low hydrogen content, etc.

Medium carbon

Due to the large amount of carbon, joining such parts is complicated. In the results of the work, this is expressed in the fact that the metal of the part and the welded joint can be of different strengths. In addition, near the edges of the seam, cracks and pockets with pronounced fragility of the material can form.

To avoid these disadvantages, electrodes are used whose material contains a low amount of carbon.

With an increase in current required to heat the parts being connected, penetration of the base metal is possible. To eliminate such cases, the edges of the parts to be joined are cut.

Another measure to improve the quality of the connection is preheating and constant heating of the parts during the process. When welding steels with a semi-automatic machine, to improve the quality of the seam, it is better to move the electrode not across, but along the joint of the parts and use a short arc. Electrodes of the brands UONI-13/55, UONI-13/65, OZS-2, K-5a are used for work.

When using acetylene for welding medium-carbon steels, a burner flame is achieved such that the gas flow rate is 75-100 dm³/h. For products with a thickness of 3 millimeters or more, general heating up to 250-300 °C or local heating up to 600-650 °C is used.

After welding, the seam is forged and subjected to heat treatment. To weld metal products with an amount of carbon close in content to high-carbon steels, a special flux is used.

Peculiarities

The following features of welding carbon steels should also be noted:

- Before carrying out this operation, it is necessary to thoroughly clean the material being welded from rust, mechanical irregularities, dirt, and scale. These contaminants contribute to the formation of cracks in the weld;

- Welding structures made of carbon steels need to be cooled slowly, in air, so that the structure normalizes;

- When carrying out the welding process, critical parts require preheating, up to approximately 400 degrees; with the help of heating, the required strength of the seam will be ensured; also in this case, welding can be carried out in several approaches.

Thus, the welding process of carbon steels depends mainly on their carbon content. Therefore, it is necessary to consider what content and choose the right technological scheme in order to obtain a high-quality, durable product that can last a long time.

How to weld pipes using electric welding

Electric arc welding is the most accessible in everyday life today, since its use does not require special equipment costs. This allows you to move it between objects without difficulty. Electric welding allows you to weld in any position in space and even where access is limited.

Necessary tools and equipment

To weld pipes, you will need a welding inverter as a current source with a voltage of two hundred and twenty volts and DC electrodes. When preparing the product, use a grinder or any other abrasive tool. To avoid injury during work, you need to protect yourself with gloves and a mask, as well as a welding suit that can protect your skin from burns. As a hand tool, a hammer is used to beat off the slag.

Joint surface treatment

Before welding, the ends of the pipes must be cleaned of rust and metal burrs with a grinder. You should also clean out any debris or stray dirt from the pipes. Such procedures directly affect the quality of the resulting seam during the welding process. Any speck, burr or rust will prevent the metals from properly adhering to each other at the weld site.

The principle of welding pipe ends

The vertical type of seams is best suited for welding pipes. Its convenience lies in the fact that the metal from the electrode is applied at the top, and the slag flows down. Thus, when moving from bottom to top, you can constantly monitor the creation of the seam.

Depending on the size of the pipe, the intermittency of penetration varies. A large-diameter pipe is welded intermittently. With a small diameter, you can get by with one continuous seam. Before continuing to weld from the site of the completed seam, it is necessary to clean the part on which the new seam will lie. This must be done in such a way as not to boil the slag.

When welding a profile (square) pipe, all ends are securely secured with clamps so that the connecting ends do not move in different directions.

Checking the weld seam

Upon completion of the penetration, when the metal has cooled, the slag is removed with a hammer. Then the entire boiled area is inspected. It clearly shows cracks, burns and places that could not be completely boiled. After checking, the places of cracks and undercooked spaces are boiled again, covering a larger area. This procedure is repeated over and over again, along with repeated removal of slag, until the final result appears.

Source