Metal welding has been known since at least the 17th century. But at that time, the types of metal welding were few: blacksmithing and casting. The options we are familiar with appeared only at the moment when the electric arc began to be used and the types of welding became more diverse. Today, the classification of the types of welding used is much more diverse.

There are currently three main options for performing work:

- mechanical;

- thermal;

- thermomechanical.

The introduction of electronics made it possible to increase productivity and accuracy and automate the process.

Physics, chemistry, a little poetry

Welding is the process of permanently joining different structures by heating, deformation, or both.

In short, from a physics point of view, welding uses either heat or pressure, or heat and pressure together. In short, from a chemical point of view, welding uses a huge number of different types of flux-cored tapes, fluxes, electrodes, gases and other components. It depends on the materials and conditions. Thanks to chemistry, we have a huge number of technical options.

Important! We will not burden you with complete lists of welding types or all the classifications that exist. We don't have enough paper to write, you don't have the patience to read. Understand the logic of grouping welding methods so that you can easily find information on each specific type. There are many sites on the Internet dedicated to welding: you can find everything you need.

Criteria for selecting equipment and materials

Before starting any training, it is necessary to equip a home craftsman welding station. First of all, this concerns welding machines and electrodes, and then move on to the basics.

To carry out one-time work, you can rent a welding machine from specialized companies, but if there is a lot of work to be done, the best solution would be to purchase a reliable unit with a sufficient level of power.

You can weld with gas, but this is a more expensive method. For various purposes, the industry produces the following types of equipment:

- welding machine (transformer), designed to convert alternating currents into high-power welding current. Cheap welding machines can overheat greatly even under light loads, and they produce uneven welding current with large differences;

- Rectifiers convert alternating current from the network into direct current. These are the most productive devices with good characteristics, but they cost an order of magnitude more;

- Modern inverters are capable of converting alternating current into direct current; they are distinguished by high performance characteristics with small dimensions and weight. Today this is the most affordable, reliable type of welding equipment; many welders use them. This is the best option for beginners, where you can practice the basics of working with electrodes.

Beginners need to know that electrodes are used for electric arc welding.

Information about electrodes refers to the basics of training. The success of welding depends on the quality of the electrode and a suitable core composition. The product is quite simple in design. This is a steel wire made of various materials and alloys, with a special coating applied to it.

The coating prevents unwanted gases from entering the weld pool. For household use, electrodes with a core thickness of 3 mm are most suitable. Manual welding of very thin sheet metal is carried out using electrodes with a cross section of 2 mm.

Principles of classifications, overview

Classification of arc welding methods.

The classification of welding types is carried out according to a variety of criteria; they neatly fit into a semantic framework. What criteria are the most important? Let's go through some of them; first, it's better to see the big picture.

How many types of welding exist today? You can say the number 150 with the word “about”. Maybe 250. But we don’t recommend naming numbers. While you are reading this article, the number of species may change - technology does not stand still. But what kind of welding there is according to materials, physical processes, popularity, control methods - we need to talk, these are precisely the very principles of classification that we need to understand.

An example of a simple, understandable classification by energy source in welding:

- electricity;

- electric arc;

- friction;

- gas flame;

- laser radiation;

- electron beam;

- ultrasound.

Another example of a list by type of weld. There are many of them, whole bunches of different types:

- butt, corner welds - along the connection of the edges;

- by shape, length - horizontal, vertical, circular, straight, intermittent, continuous, long, short, medium seams;

- by type of material used - seams for steel, non-ferrous metals, bimetals, polyethylene, etc.;

- by volume of deposited metal - reinforced, weakened, normal welds;

- in shape - longitudinal, transverse seams;

- by the number of layers – continuous, intermittent, tack, multi-layer.

The “sewing” list can be continued, but it is important for us to understand the general principles, so let’s finish with the lyrics and move on to the main methods.

Safety precautions + possible defects

The welding process must not only be correct, but also safe. Losing your eyesight or getting a major burn are some of the many dangers that await a person who decides to take the path of a welder in the Russian Federation.

Precautionary measures:

- inspection of instruments for mechanical damage;

- grounding;

- regularly checking the connection between the workpiece and the contact;

- high-quality cable insulation;

- humidity not more than 75%;

- use of masks, gloves and other personal protective equipment;

- presence of a fire extinguisher near the workplace.

Now about the defects. For a novice welder, punctures during training are par for the course. Knowing the reasons for certain distortions, a person will be able to prevent the occurrence of such situations, therefore, the risk of being in a disadvantageous position is reduced significantly.

An ideal seam is neat in appearance, with the same thickness and height along its entire length. If there are jambs, in 80% of cases they will be visible immediately. Let's take a closer look at the most common defects.

| Defect | Cause |

| Lack of penetration | Occurs when the rod moves at high speed along the seam, or due to incorrect voltage calibration in the circuit. |

| Undercut | Groove along the seam. Occurs due to the electric arc being too long. Correction during the welding process requires adjustment of the amperage. |

| Burn-through | Holes in the welded surface at the seam site. |

| Porosity | When a draft in the room blows away a gas cloud that protects the bath from external influences. |

Sometimes transverse/longitudinal cracks may appear, but here the defect indirectly affects the welder, because the material may simply not withstand the temperature conditions. For each type of metal, it is necessary to select specific operating conditions. Even an experienced welder cannot insure himself against failures in this regard.

Basic concept of the welding process

Welding is a technological process of creating reliable connections by heating or plastic deformation with the establishment of interatomic bonds subsequently. The structure of the products is continuous. Energy is supplied to the electrode and welding material through an inverter. First, the metal of the electrode melts, this creates a weld pool, in this pool the electrode is mixed with the base material, and the slag that floats to the surface serves as a protective film. The welding process is nothing more than the hardening of the metal after all of the above influences. Electrodes come in several types - consumable (the electrode rod melts) and non-consumable (with a non-consumable electrode, filler wire is used, which melts separately in the bath).

Sequencing

Step-by-step instructions provide for performing several types of work. First you will need to equip a welding inverter. 2 cables are taken from it. One is for connecting the ground wire.

On another, of sufficient length, an industrial or homemade holder is connected. The process of learning electric welding is quite complex and time consuming.

Start of welding: light the arc

When everything is assembled and connected, wearing a mask, you can begin to ignite the electric arc. Use a rough piece of metal for training. The arc is excited by tapping on the surface or striking it, like a match.

The new electrode has a bare tip and ignites fairly quickly. An electrode that has already been used for cooking, if it has had time to cool down, is more difficult to ignite, since a “visor” of coating has formed at its end. You need to hit 3-4 times to fight it off. But do not overdo it, otherwise, without coating, the rod will begin to stick to the product.

Electrode tilt

When the arc strikes, don't panic. Get used to the specific light. Your task is to first learn to keep the gap between the electrode and the product within 3-5 mm. Don't try to weld the joint right away. Just learn to hold the arc so that it does not go out (if you move too far) and the electrode does not stick (if you move too close).

The task is complicated by the fact that the length of the consumable electrode is constantly shortening, so you have to move your hand closer to the product. A “steady hand” comes with time, so you will have to burn more than one electrode before you get used to it.

When you have already mastered holding the electric arc, you can move on to welding. First of all, hold the electrode correctly. Usually they cook it by tilting it towards itself within 30-60º. Some welders choose the optimal tilt position of 45º. Backward angle welding provides good visibility of the weld pool, the metal is heated deeper. Welding at an angle forward (when the seam is pulled away from you) helps reduce heating. This is suitable for joining thin metals 1-2 mm.

You can weld from right to left or from left to right, tilting the electrode on different sides of the weld pool. It all depends on access to the connection point.

Electrode movements

On thin metals 1-2 mm, where the two sides are pressed tightly against each other, no additional movements are required. The arc is excited, the electrode is placed at the beginning of the joint, and is slowly drawn along the connection line. The seam will be narrow and scaly.

On thick metals, provide a gap of 1-2 mm so that the liquid metal penetrates deeper. If the plate thickness is more than 5 mm, cutting the edges at an angle of 45 degrees is necessary. Then the first seam (called the root) is laid without additional movements. And the subsequent ones are needed to fill the width and require transverse oscillatory manipulations. These movements could be:

- crescent;

- in a round, triangular spiral;

- zigzag.

Ideally, place the part at a slight angle so that liquid slag does not flow into the weld pool. If this is not possible, periodically make a sharp movement with the tip of the electrode to the side, throwing away the slag. Otherwise, lack of penetration will occur.

Technological properties of welding works

There are many technological varieties of types of welding work depending on the material and equipment, the most common of them are: arc, electroslag, gas, light, plasma and electron beam.

Types of welding by type of mechanization and uninterrupted technological properties: air, vacuum, foam, flux and submerged types.

Based on the degree of metal melting, welding is divided into atmospheric and jet welding. Jet welding is characterized by molten material at the weld.

Basic mistakes

Let's look at the main mistakes that beginners make when welding RDS:

- Rush. There is no need to rush to move the electrode, the metal must melt, so get used to slow, calm movements.

- Inability to distinguish slag from metal. Often, beginners think that they have welded the joint, but after knocking off the slag, there is a lot of lack of welding in it. The fact is that when welding, it seems that the joint is filled with liquid metal - in fact it is slag. Liquid metal looks white through a filter, and slag looks red.

- Trembling hand. A hand support will help to achieve a constant gap between the tip of the electrode and the workpiece. Never hold your hand suspended, otherwise the electrode will stick. You can rest your hand on the table or knee.

- Do not immediately beat off the slag. (although I really want to check the quality of the connection). Let it cool a little. This way you will not damage the seam, and flying hot slag that gets on your skin will not cause a burn.

Welding process

Regardless of the number of types of welding, there are 3 main stages of the welding process, inherent in all technological varieties, these are:

- Formation of contact;

- Education Communications;

- Creating a seam.

Forming a contact

The formation of contact occurs as a result of bringing the metal to the melting or boiling point; the main thing is not to confuse the weld pool with the melting of iron.

Formation of chemical and metallic bonds

The second, most important step is the formation of a weld pool; it always looks the same, regardless of the type of welding. The bath appears as a result of the fusion of metal and auxiliary material, for example an electrode, under the influence of temperature, and appears as a white spot. The quality of the seam depends on the width and length of this spot.

Creation and types of strong connection

The main qualitative characteristics of seams are their width and height.

By type of connection there are (the most common):

- butt – parts in one plane (pipes, sheets, etc. are welded).

- overlapped - the parts are arranged in parallel, only one overlaps the other (sheets are welded, the thickness of which is no more than 12 mm).

- end - weld 2 ends of the elements.

- angular - elements are located at an angle to each other.

Gas flame welding

It is carried out using a flame from a burner. To create a flame, acetylene or propane (as a flammable gas) and oxygen (to increase the power of the flame) are used. The temperature of the torch reaches 2800-3100º C, which allows the edges of the metal to melt. To fill the weld pool, filler wire is used, fed with the welder’s free hand.

Gas welding is most often used to connect ferrous metals, pipes, and patch containers. Energy independence allows welding to be used in field conditions, on roofs, in tunnels, and basements. Connection to the cylinders is made through reducers with pressure gauges. The oxygen reducer has two pressure gauges - high and low pressure. Additional components will be required (hoses, mouthpieces, nipples) to connect everything into one system.

Burner working part and nozzle diameter:

We will weld tightly, inexpensively, call

Tacking structures before welding.

Basic welding methods are a common but incorrect classification in this context. “The most popular” would be more correct.

Here are three well-deserved winners:

- Manual arc - gold.

- Gas - silver.

- Semi-automatic - bronze.

Each winner belongs to a different welding family; in theory, it is better to describe them in their rightful places together with their close “relatives.” But we will do the wrong thing - we will introduce welding champions at the beginning of the review.

Manual arc welding RD

People's favorite No. 1, the most common type in everyday life and in industry. The three main words in RD are simplicity, cheapness, and transportability. The physics of the process consists of melting a special coated electrode, which leaves behind a mark in the form of a weld seam. Different electrodes are used, depending on the metal. The arc is the distance between the electrode and the surface of the metal, which plays the role of a second electrode.

Essentially, an arc is a powerful discharge in a gas space (air). During RD, three objects melt: the edges of the two surfaces connected to the electrode. The better the triple melting products are mixed (to do this, the electrode is moved left and right), the better the quality of the seam.

RD welding has serious advantages over other types:

- the RD method is easy to learn;

- you can cook in any position in space;

- You can cook a wide variety of metals; there are electrodes for sale for every taste;

- accessible transportable equipment

Gas welding

People's champion No. 2, well-deserved silver medal.

This is when welders carry gas cylinders with them: they need a mixture of oxygen with some flammable gas - acetylene, propane or butane. The physics of the process is also melting, but the heat is supplied not by an electrode, but by a gas burner. The metal surfaces are melted by the torch, the process occurs smoothly and rather slowly. The thicker the metal layer, the slower it melts. Why gas welding is better than other methods:

- Non-ferrous metals are excellently welded;

- the equipment is simpler than electrical methods;

- the ability to control the mixture and flame;

- no powerful energy source is needed, the method is autonomous.

You can’t do without disadvantages, the “gas” disadvantages are as follows:

- very slow heating of surfaces;

- low heat concentration due to dissipation;

- high cost of electricity.

In terms of the cost of electricity, arc methods can compete with gas methods: with RD, electricity is also wasted mercilessly. But in the end, the gas method, due to its “low speed,” is much more expensive.

Important! Where there is a pair of words “flammable gas”, there is always a second pair “safety precautions”. Safety rules are well regulated, but compliance with the requirements requires additional costs of money and time. By the way, gas welding is more than 100 years old - here it is, a stainless classic, applause.

Semi-automatic welding

Classification of the welding arc.

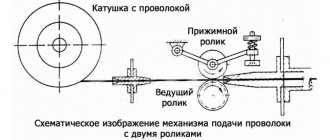

Bronze champion, closes the popular top three, but in terms of his prospects he will easily surpass the first prize-winners. In fact, this is a type of arc type familiar to us, a progressive evolution of the RD. It features a large number of technological nuances, options, and instructions. It is enough for us to know that the “automatic part” of the method is the feeding of the welding wire.

The manual part is the welding process itself with wire feed control. You can cook with gas (carbon dioxide for beginners, argon for professionals), or without gas, with direct current. The option without gas is popular in garages and summer cottages; in this case, a special flux-cored or flux-cored wire is needed. When it burns, a gas with vapor is formed that protects the combustion area.

Semi-automatic is the only method at a service station: body work is carried out only with its help. The semi-automatic machine uses gas and a special wire instead of the usual electrode. Gas from the torch with wire is supplied to the welding sleeve. As a result, the process is protected from environmental influences. The process modes are determined by the welder depending on the thickness of the metal.

The semi-automatic method has serious advantages over other types:

- excellent seam quality;

- high speed;

- ease of use;

- welded as non-ferrous and ferrous metals;

- You can cook rusted or galvanized metals;

- wide selection of materials, modest financial costs.

Which polarity to choose when welding metal with electrodes

The inverter for manual arc welding produces direct current. If you look at the front panel of the device, you will see that there are two connectors for connecting welding cables marked + and -.

Straight polarity : a “clothespin” is connected to the plus of the device, and a holder is connected to the minus.

Reverse polarity : the electrode holder is connected to the plus of the device, and the “clothespin” clamp is connected to the minus.

Which polarity should I choose? Many copies have been broken about this issue. If you open educational materials on welding and ask on the Internet, you can often hear the opinion that with “straight polarity” the metal being welded is better heated and melted .

Practice refutes this.

When welding, more heat is generated at the contact with the plus, therefore, in reverse polarity , the holder is connected to the plus, the penetration is always deeper . As a result, it is better to weld metal with thick walls using reverse polarity. This is a profile pipe, plates, corner with a thickness of 4-5 mm. Conversely, with direct polarity it is necessary to weld thin metal, no more than 1.5-2 mm thick, in order to avoid melting of the walls and the appearance of holes.

You can verify the veracity of this statement in practice. Take a welding inverter, set the welding current to 100 A. Connect the electrode holder and ground to the connectors of the device and cut the metal - a plate 4-5 mm thick, an angle or fitting, first in direct and then in reverse polarity, without changing the current strength and electrode with a diameter of 3 mm. You will see that metal cutting is faster with reverse polarity.

We cook metals

We’ve sorted out the people’s favorites, let’s move on to the “correct” classifications.

Let's start with the real heavyweights - types of metal welding, which are divided into three groups according to:

- Physical signs.

- Technical characteristics (mechanization, process continuity, metal protection).

- Technological characteristics (separate classifications for each method - for example, types of electrodes).

According to physical characteristics, we have three main classes for all types of metal welding:

Thermal class - the welding process involves melting with thermal energy:

- gas;

- arc;

- laser;

- radiation, thermite, etc.

Important! The main types of fusion welding are the most common in everyday life and in industry. This is the most populous class; the vast majority of welding methods belong to it.

Mechanical class using mechanical energy:

- ultrasonic;

- cold;

- friction;

- explosion, etc.

Metal welding table.

Thermo-mechanical class, methods of combined action of thermal energy and pressure:

- blacksmiths;

- diffusion;

- contact, etc.

As an example of metal welding, we present MAWP - mechanized argon arc welding with a consumable electrode. A true hybrid for electro-gas joining of metals. Without it, welding of non-ferrous metals or complex alloys is impossible.

Advantages of MADP:

- connection of any alloys;

- stability of the product’s shape due to low heating;

- electrodes need to be changed rarely;

- widest scope of use;

Flaws:

- difficult for beginners;

- low execution speed.

Electroslag welding

The essence of electroslag welding is to connect two sides of the metal using the heat generated by the slag pool. To do this, the joining area is filled with conductive flux. A welding electrode (wire) is connected to it, which heats the flux, forming liquid slag. The electrode continues to conduct current while immersed in the welding slag pool. Arcless method. The temperature rises and the edges of the metal melt together.

The thickness range of metals welded using this method is 20-3000 mm. Slag welding can be used to connect:

Technology is used in the chemical industry, mechanical engineering, shipbuilding, and the aviation industry.

We cook polyethylene

Applications of plastic welding.

What can you cook besides metals? Ceramics. Glass. But in second place of honor are plastics or polymers, primarily polyethylene pipes. You can work with polyethylene using thermistor, electrofusion methods, or electrical resistance: these terms are listed in the technical literature. Don’t be alarmed, all options can be called briefly – NC welding. NZ – embedded heaters.

The essence of the process is the melting of polyethylene at the joints using metal spirals of an electric heater, which is embedded in the part. The method is extremely popular, it has great prospects in industry: it is used in various pipelines, replacing old metal pipes with new polyethylene ones, installation and repair, and the development of new polymer technologies.

When working with plastics, another method is used: welding or welding with a heated tool. The simplest option for supplying heat to heat polymer surfaces. There are many options for welding tools for working with NI - from a simple electric soldering iron for small parts to special welding machines of various sizes. Self-respecting plumbers keep this kind of equipment in their work suitcases without fail.

By the way, welding methods NZ and NI are included in the list of mandatory methods of a professional welder with confirmed qualifications, for example, certification from NAKS - the National Agency for Welding Control.

Now classification by type of process mechanization:

- Automatic

- Automated

- Mechanized

- Manual, let's start with it.

How to ignite an electrode

There are two ways. Option one: ignite the electrode - end-to-end (by touching). Option two: strike. The methods are clear from the photo below.

The second method is similar to lighting a match on a matchbox. The first method is sometimes replaced by lightly tapping the workpiece. When the electrode is new and the metal of the rod is visible at the tip, ignition of the arc occurs easily.

If the electrode has been in use, a coating may appear around the rod. The protective coating of the electrode does not conduct electric current. Therefore, it needs to be knocked off by tapping the tip of the electrode on the part to be welded several times. Easy ignition of the electrode is a skill that has been brought to automaticity.

Manual welding

Examples of welded joints.

Despite the rapid growth of new automated methods, manual methods are indispensable in many cases, this type of welding has long occupied a legitimately important place in modern technology.

Advantages of manual methods:

- can be cooked in hard-to-reach places;

- in different positions in space;

- you can quickly move from one material that we melt to another;

- selection of electrodes for every taste for all types of steel;

- The equipment is easy to transport and easy to maintain.

In addition to the familiar electric arc method, this group includes a manual version of argon arc welding with the same operating principles as the mechanized version described above.

Manual types include do-it-yourself spot welding, a contact method that is possible at home, unlike other contact methods used only in industry.

Classic gas welding also refers to manual methods.

Arc welding techniques - welding methods

To get a high-quality seam, you need to learn how to maintain and then move the arc. The length of the electric arc especially affects the quality. If it is more than 5 mm, then it is considered long.

In this case, nitriding and oxidation of the molten metal occurs. It splashes out in drops, making the seam porous and not strong enough. If the arc is too short, lack of penetration may occur.

The electrode rod can move along different trajectories. With experience, each welder chooses “his own” option, or more often a combination of several movements

Various techniques are used to perform welding. Let's look at the main ones in detail.

Option #1: Bottom Butt Joints

The most common and simplest way to connect parts. For metal thicknesses up to 0.8 cm, double-sided welding is used. For connections made of metal thinner than 0.4 cm, only one-sided welding is performed.

For work, electrodes are selected whose diameter is equal to the thickness of the metal. If it exceeds 8 mm, welding is carried out with cutting edges. In this case, the cutting angle is about 30°.

Welding is performed in several passes. It is advisable to use removable pads made of steel or copper to avoid burns. The first pass is performed with a small diameter electrode, no more than 4 mm.

When making the first seam, its accuracy and penetration depth are very important. After applying it, there should be no fused metal behind the edges.

For the second and all subsequent passes, larger diameter electrode rods are used. They are chosen for high-quality filling of the recess formed between the edges.

The electrode is slowly moved along the seam, performing oscillatory movements, as if rocking the electrode from side to side, in order to completely fill the voids with molten metal.

Option #2: Bottom Corner Joints

Experienced welders claim that good results can be achieved by welding corners “in a boat”. This means that the parts to be connected are installed at an angle of 45° or other.

This ensures the highest quality penetration of the product walls, and the danger of undercutting and lack of penetration is reduced. This welding method allows welding of large cross-section seams to be deposited in one pass.

Craftsmen remind that when welding a T-type corner joint, the electric arc should be ignited only on a horizontal plane (+)

There are two types of boat welding - symmetrical and asymmetrical:

- The inclination of the parts is 45°. The likelihood of sagging or undercutting one of the walls is minimal. Welding of reverse and direct polarity is carried out at maximum current values. When carrying out reverse polarity welding, the length of the electric arc should be minimal.

- The parts are tilted at an angle of 60° or 30° - an asymmetrical “boat”. This option is very convenient if work is carried out in hard-to-reach places, since the amplitude of movement of the electrode is small. The welder directs the arc to the very root of the seam, and care must be taken that it does not go beyond the boundaries of the future seam. It is also not allowed to deposit too much metal in one pass.

Corner joints can be T-type, so you need to learn how to weld metal correctly and without errors using electric welding in several passes.

The use of one pass is only possible when welding simple structures with sides that form an angle of 45° in a fillet weld. The diameter of the electrode in this case cannot exceed the thickness of the metal by more than 0.15-0.3 cm.

Standard multi-pass T welding is performed as follows. For the first pass, an electrode with a larger diameter is taken than those selected for subsequent passes. For example, an electrode is used whose dimensions vary from 0.4 to 0.6 cm.

Some welds are made in multiple passes. In this case, the size of the electrode for the first pass and for all subsequent passes is different.

Welding is carried out smoothly, without transverse oscillatory movements. When performing other passes, they are necessarily carried out. It is important that the vibration amplitude is within the permissible seam width.

Another significant point. When performing T-welding on a fillet joint, the electric arc should always be ignited on a shelf positioned horizontally.

When doing electric welding of corners with your own hands, you can use an overlap type of connection. In this case, the parts to be welded are placed one on top of the other with an overlap. The arc during direct polarity welding should be short, and during reverse polarity welding it should be as short as possible. Direct the arc exactly to the root of the connection.

During the welding process, it is necessary to perform small amplitude reciprocating movements with the electrode. This will allow the entire joint area to be heated evenly. In this case, the weld pool will be evenly filled, and the seam will be convex and full-sized.

Option #3: vertical seams

Seams directed vertically are made only with a short arc. In this case, the working current should be 10% -20% less than when welding parts in the lower position. These requirements are easy to explain.

A lower current strength means that the molten liquid metal will not drain from the weld pool. A smaller arc is more convenient to use.

Welding vertical seams has its own characteristics. They are explained by the fact that in this position, liquid metal can flow down the seam. Therefore, the welding current and electrode angle must be selected correctly

Experienced welders prefer to weld vertical seams from the bottom up. The arc is set on fire at the lowest point of the future seam. After that, a small horizontal platform is prepared, the dimensions of which correspond to the cross-section of the future seam.

Then slowly move the electrode rod up. In this case, movements across the connection must be performed.

They can be in the form of a herringbone, corner or crescent. The last option is the easiest to implement. In addition, it is important to maintain the correct position of the electrode. Theoretically, penetration is best achieved if the rod is positioned perpendicular to the seam, that is, horizontally.

Butt welds are characterized by the following criteria:

Practice shows that in this position of the electrode rod, liquid metal flows down the seam. To avoid this, the angle of inclination of the rod is chosen within the range of 45°-50°. This is the optimal option for vertical welding. To weld parts in the bottom-up direction, select electrodes whose diameter does not exceed 0.4 cm.

Option #4: Pipeline Details

At home, you often have to remember how to electric weld a metal pipe. A vertical seam is usually made on the side of the part, and a horizontal seam along the circumference. Steel pipes are butt welded. All edges must be well boiled.

To ensure that the sagging inside the pipe is minimal, the electrode is brought to the product at an angle of no more than 45°. The seam width should be 0.6-0.8 cm, height – 0.2-0.3 cm.

Pipe welding is carried out using various seams and in different areas. Depending on the wall thickness of the part and its location, the diameter of the electrode and the type of seam are selected

Before starting welding work, the parts to be joined are thoroughly cleaned. The ends of the pipe are inspected. If they are deformed, they are straightened or cut using a pipe cutter. Then the edges of the parts are cleaned from the inside and outside to a metallic shine at a distance of at least 1 cm from the edge. Then start welding.

The joint is welded without interruption until it is completely welded. For non-rotating joints of pipes with walls up to 0.6 mm wide, two welding passes are performed, for products with walls from 0.6 to 1.2 cm wide - three passes, for parts with walls wider than 1.9 cm - four passes.

In this case, each subsequent seam is applied only after the scale has been removed from the previous one.

The quality of the first seam is most important. During the process, all blunts and edges should completely melt. There should be no cracks, even the smallest ones. If they exist, they are smelted or cut down. After which the fragment is welded again. Welding of rotary pipes is performed in the same way.

Automatic methods

Classification of welding methods using automation:

- Electric arc technology.

- A gas-electric arc is protected by gas, most often an inert gas such as argon or helium.

- Electroslag technology.

Tungsten welding - application diagrams.

Electric arc method: A close relative of the manual arc method, automatic submerged arc welding or AF is a type of arc method with excellent performance indicators. Here, too, a consumable electrode is used; all work is carried out under a special protective layer of flux. In the manual arc method, there is a serious risk of the arc itself burning in the air, so the strength of the supplied current is limited.

With AF, the arc is protected by a layer of flux, there is no risk of burning. The strength of the welding current is not limited in any way. This makes it possible to penetrate the metal deeply, resulting in a seam of excellent quality. The flux layer prevents metal splashing and loss during the process. Complete mechanization of the method allows less qualified welders to be admitted to AF. As a result, the productivity of the AF method is 5 to 10 times higher than that of manual arc AF. Let's be honest and present the shortcomings of AF, there are few of them:

- fluxes are not cheap;

- there is a harmful effect on the operator;

- You can only work in a limited space.

Electroslag technology, “heavy artillery” on the modern industrial front. This is a fundamentally new arcless method of melting. The source of thermal energy is not an arc, but an alternating current that passes through the molten slag. The metal surfaces are covered with slag, which is heated. This way you can weld metals of almost any thickness.

Advantages of arcless technology:

- high-quality tight seams;

- seams of complex shape;

- absence of deformations, especially angular ones;

- no need to process edges;

- ease of implementation

- labor automation, minimal human participation

The method is used mainly for large-sized structures.

What types of welding tools are there?

Before you learn how to use welding at home, let's look at the types of electric welding tools. The arc that occurs when melting metal can be formed in two ways - using direct and alternating current. If welding is performed with alternating current, then this indicates the use of transformers. Inverter devices cook with direct current.

Transformers for welding are used less and less, as they are being replaced by more efficient, reliable, inexpensive and lightweight inverters. Transformer types of devices are welded using alternating current, which results in the occurrence of arc jumps. Transformer devices are heavy because they are based on metal cores with copper windings.

If we talk about other disadvantages of transformer welding machines, they have a lot of them:

- Makes noise when working

- The network “sits down” when performing work, so voltage drops are observed that negatively affect the operation of household appliances

- It is very difficult for beginners to master the technique of transformer welding.

If we talk about advantages, then transformer devices also have them. They are easy to use, last almost forever and are not expensive.

Inverter devices operate from a 220V AC network. Their main difference from transformer devices is their size and weight. Instead of a bulky transformer, the design of inverter devices uses a board with semiconductor elements. They are not only small in size and weight, but also easy to use. If you are going to learn how to work with a welding machine, then it is recommended to do this using an inverter device. Using the example of inverter welding devices, we will consider the principle of applying welding seams in order to combine two metal parts.

Arc methods

Above we dealt with the basic concepts and physics of the arc (the famous RDS - manual arc, the absolute champion in popularity).

But the classification of welding methods is a strict matter, so we present the types of arc welding as a separate family:

Structure and properties of the electric arc.

Manual arc:

- RAD – manual argon-arc non-consumable electrode;

- RADN – manual argon arc surfacing.

Automatic arc methods:

- AAD, AADN, ALSN, APPGN, etc. - an extensive family of methods using either electrodes (consumable and non-consumable), or wires, or flux-cored wires. You can cook with or without gas.

Submerged arc:

- the familiar AF, automatic submerged arc;

- various weldings, surfacing with strip or wire electrodes;

- mechanized arc.

Arc with coated electrodes:

- this is where the right place is for the people's champion of the RDS;

- manual arc surfacing;

Mechanized arc:

- MADP, MPGN, MSOD, etc. – a large “mechanical” family.

Let's sum it up

Having learned to work with welding equipment, it will be possible to solve many everyday problems that often arise when working in the country or in the garage. Beginners should pay special attention to the polarity of welding parts of different thicknesses with an inverter.

By understanding how to properly configure the equipment and choose an electrode, you will be able to obtain high-quality seams on any product. Be sure to pay attention to the forward and reverse polarity of connecting the welding inverter.

When welding thick parts, direct polarity is used when welding with an inverter, and for thin parts, reverse polarity is used.

Sources

- https://moiinstrumentu.ru/kak-varit-svarkoj.html

- https://WikiMetall.ru/spravochnik/kak-nauchitsja-varit-jelektrosvarkoj.html

- https://mrmetall.ru/kak-pravilno-varit-jelektrodami-nachinajushhim-jelektrosvarkoj/

- https://sovet-ingenera.com/santeh/svarka/elektrosvarka-dlya-nachinayushhix.html

- https://kak-sdelano.ru/instrumentyi/cvarka-invertorom-dlya-nachinayushhix

- https://instrumentiks.ru/sovety/svarka-invertorom

- https://tokar.guru/hochu-vse-znat/svarka-elektrodami-kak-pravilno-varit-nachinayuschim.html

- https://svaring.com/welding/teorija/azy-svarki-elektrodami

- https://www.svarbi.ru/articles/kak-varit-svarkoy-elektrodami-dlya-nachinayushchikh/

- https://tutsvarka.ru/vidy/svarka-invertorom-dlya-nachinayushhih

Mechanical class

All types mentioned above belong to the first thermal class. The main character in it is thermal energy with melting. The next class is mechanical. The main “mechanical” words in this context are pressure and plastic deformation.

It also has a neat classification of welding:

- Cold welding (forging)

- Friction welding

- Ultrasonic

- Explosion

Sometimes mechanical methods are combined under the name “pressure welding”; there is logic here, but we are talking about the same thing.

One of the promising mechanical technologies is friction welding. Heat is also present in it, but it is formed from the force of friction. The surfaces to be welded rotate and are compressed with force. Friction welding technology is especially effective when working with round parts - drills, cutters, reamers.

Table of welding types.

Types of friction welding:

- Friction stir welding.

- Radial friction welding.

- Friction pin welding.

- Linear.

- Inertial.

Let's take a closer look at these types of welding:

- Friction stir welding is a fairly new method, it requires special equipment for friction welding - a rotating tool with two elements - a base (shoulder) and a tip (pin). The seam is formed by two processes of extrusion and mixing.

- Radial friction welding is used in pipe work: it rotates a ring between the joints, which creates friction.

- Friction pin welding: a hole is drilled and a pin made of the same metal as the parts is inserted. The pin rotates, generates heat, and forms a connection in the form of metal threads. Excellent friction welding technology when “you need to fill a hole.”

- Linear method. There is no rotation here. The parts simply rub against each other until heat is released, plasticity increases, then the pressure is increased until an irreversible connection is achieved. With this method, an ideal, flat surface is formed; no other methods have this.

- Inertia welding. The movement of the surfaces occurs due to a massive rotating flywheel, which is accelerated by a special engine.

The mechanical class involves the use of pressure and mechanical action, energy.

Friction welding (friction)

This method differs from the others - the basis of its method is to obtain elevated temperatures by friction of metal workpieces. One of the parts rotates, then the workpieces are pressed against each other with a gradual increase in pressure.

Friction welding

Cold welding

Cold welding is performed using plastic deformation, which destroys the oxide film on surfaces and brings metal elements together until a bond is formed between them without the use of elevated temperatures. This method is applicable to those metals that have good plastic properties: aluminum, silver, idle, zinc, nickel, etc.

Explosion welding

This method is not very common due to the lack of accuracy of the technological process. The moving part is positioned at an angle to the main part, parallel, and with the help of a controlled part the parts are connected by joint plastic deformation.

Ultrasonic welding

The connection and fastening of parts occurs due to their squeezing together and the influence of ultrasonic vibrations. This method is applicable for spot and contour welding. Ultrasound heats the products and activates diffusion, then molecular bonds are formed and at the end the seam crystallizes, thus creating a strong connection.

What is a welding inverter and how does it work

This device was called an inverter because it converts alternating current of a 220 V network with a frequency of 50 Hz into high-frequency oscillations, and then into direct current. At the same time, the device has a high efficiency: about 85-90%, and even under fairly heavy loads the counter “winds” a little. In any case, you won’t have to pay crazy bills. The consumption will be slightly higher than without welding, but not by much.

This small box is an inverter welding machine

Most inverter welding machines operate from a 220 V household network (there are also devices from 380 V). And this is one of their advantages. Moreover, they have practically no effect on it, i.e. do not reduce tension. Rest assured about your neighbors: they won’t even know that you are welding. The second important advantage is that they can work more or less normally at reduced voltage. Of course, you need to look at the specifications, but at 170 V, most of them still allow you to work with a 3 mm electrode. This is very important especially for rural areas, where low voltage is the norm rather than the exception.

What’s also good for beginners is that it’s easier to get and hold an arc when using inverter welding. And in general, according to many, it cooks “softer” and has a “lighter” arc. So if you want to learn how to cook, try inverter welding first.

Thermomechanical class

Third class from the point of view of physics: both types of influence on the surface are used here: heat and pressure. We present the types and methods of thermomechanical welding:

- Diffusion. The surfaces are compressed, then heated in a high vacuum, achieving mutual diffusion of atoms. It is effective when the metals to be welded do not fit well with each other or the materials are different in nature, for example, metal and ceramics. The method is not cheap, it is used mainly in the aerospace sector and other high-tech industries.

Types of pressure welding.

All the following points are types of resistance welding

- Contact electric. Everything is simple here: before pressing, you need to warm it up thoroughly. The surfaces are heated with current at the joints, then compressed or upset. An excellent, high-performance method that lends itself well to automation. Widely used in construction and mechanical engineering.

- Seam contact welding is a type of resistance welding: the seam is formed by overlapping electrodes.

- Point contact. Surfaces are placed between the two electrodes. The current is turned on after tight compression, resulting in a weld spot with a diameter equal to the diameter of the electrode surface. An extremely interesting variety is relief welding. The contact of the electrodes is carried out along protrusions determined in advance - reliefs, which are eventually deformed, the surface is leveled.

- Spot capacitor welding - “welding with stored energy in capacitors.” It features low power consumption and is used when working with small parts and when using optical instruments - watch mechanisms, aircraft instruments, etc.

The thermomechanical class is characterized by a combination of the use of elevated temperatures and mechanical products.

Forge welding

Forging welding and hand forging are some of the oldest welding methods. The metal is heated to the required temperature and its further connection occurs under the action of a forging hammer or a hydraulic press.

contact welding

Resistance welding uses electric current to join metals. This method involves the formation of an electric arc that melts the metal. Adjusting the current power allows you to process thicker metals.

Spot welding

The most common type is resistance spot welding, since this method can also be used at home. The parts are clamped in electrodes or special pliers, then a current is passed between the electrodes, the metal heats up, the electrodes are compressed more strongly and “forging” occurs, the metal crystallizes under pressure.

Relief welding

Metal workpieces have specially prepared convexities - reliefs, and the welding surfaces contact only in the zones of these reliefs, plastic deformation of these same reliefs occurs; in all other respects, the principle of the method is the same - current is passed through the parts under the compression force of the metals.

Diffusion welding

The basis of the method is the physical process of diffusion. As is known, metals pressed tightly against each other can merge at the molecular level.

Welding occurs in a protective environment - vacuum or special protective gases. The parts are treated to remove roughness, washed with acetone to degrease, then the metals are heated and compressed.

Welding with high frequency currents

When heated by high-frequency currents, the metal is placed in a magnetic field, during this process an electromotive force is induced in the metal, which causes a current in it, a surface effect (the current is distributed unevenly, it is greater at the surface, due to this the metal heats up faster) and the proximity effect (energy is more intensely concentrated near the surface due to the spread of the influence of its own alternating magnetic field and the field of other sources).

Contact type

Point technology performed using electric current. It is used in both domestic and industrial conditions. The combination of intense heat and pressure forms a strong bond with a smooth surface. Particularly convenient for similar products and thin parts.

Spot

Spot welding machines are often used even at home. Popular when working with thin items. Often used in the manufacture of electrical devices, sheet steel having a thickness of no more than 2 mm.

Suture

Contact seam roller welding involves joining parts with a seam consisting of individual points that can withstand increased loads. The joints are often overlapped to further increase strength. When performing work, current is supplied to the rotating disk electrodes. Rollers constantly roll along the seam line, ensuring that the elements are pressed tightly against each other. Recommended for working with thin sheets. Characterized by a high level of performance.

Reflow welding

Typically a high-tech method of joining parts. Refers to electrothermodeformation processes, carried out in accordance with GOST 2601. Fastening is carried out using deep plastic deformation with melting of the ends of the product and is characterized by an increased level of reliability.

Diffusion

Isothermal type at the atomic level, molecules and atoms of the elements being connected are mixed in a protective environment. Acceptable pressure parameters are 0.5 MPa. Different heating sources are used:

- induction;

- electron beam heating;

- radiation;

- glow discharge;

- heating by passing current;

- in molten salts.

The surfaces to be welded are carefully prepared. An evacuated working chamber is required.

Gas press

Rarely used. The first step is heating the surfaces to be welded with an oxygen gas flame. After heating, they are compressed without the use of filler material. Heating is carried out by the flame of multi-nozzle burners. It is characterized by increased strength. Used only in production conditions. Performed by heating with an oxygen gas flame. The heating field is compressed. A single thin and strong connection of parts into a single whole is formed.

Kuznechnaya

The permanent connection provides external pressure on heated parts and elements. It is one of the most ancient ways of doing work, forming a strong combination of parts into a single whole.

Induction-press

Electromagnetic induction of the workpiece is used. It occurs in metal when introduced into an electromagnetic field created by an inductor (winding), which is powered by alternating current. Used since the 40s of the twentieth century to connect thin-walled parts.

Arc press

Used for narrow directional connections. For example, studs to a metal plate. The part itself becomes the electrode. Heat is supplied using an electric welding arc.

Slag press

High performance technology. Heat is generated in molten slag when electric current is immersed in it without the use of an arc. It is most convenient when creating seams running from bottom to top. When performing, the parts are placed vertically while maintaining a small gap. The surfaces are covered with sliders equipped for carrying water tubes. Uniform cooling of the surfaces ensures constant movement of the sliders.

Thermite press

To generate heat, a liquid melting agent is used; it is formed through the use of aluminum powder and metal. Once the heating reaches the level of actual melting, the parts are compressed.

Stove

An option well known to our ancestors. When heating, forges or furnaces are used. When the proper level of incandescence is reached, compression is performed.

Thermal class of welding

Using thermal energy, the surfaces of workpieces and parts are melted locally. Heat is obtained using various methods; they are discussed in detail below.

Arc welding

This type is the most popular. The welding arc uses direct, alternating or pulsating current. The arc is produced by a powerful discharge. The electrode comes into contact with the metal, a short circuit is produced, and the tool is withdrawn no more than 5 mm, due to this continuous action the metal is heated. The stability of the arc charge occurs due to the acceleration of the electrodes in the electromagnetic field, then ionization of the gas connection between the anode and the cathode occurs.

Gas welding

Gas welding is a type of fusion welding with the additional use of gases - oxygen, acetylene. The heat generated during the combustion of gases melts the surfaces along with the filler material, thereby forming a weld pool. The gas supply is regulated using a reducer on the cylinder.

Arc welding

The operating principle of electric arc welding is based on the melting of metals under the influence of an electric arc. An electric arc is formed by increasing the voltage between two electrodes, resulting in an electrical breakdown. The basis of the technological method of electric arc welding is a short circuit, or, more precisely, the saturation of the interatomic space with electrically charged particles. At the moment of contact between the electrode and the product, a current flows, the resulting electric arc, the temperature of which reaches 7000 ° C, melts the metal and forms a weld pool.

Manual arc welding

Devices for manual arc welding are widely used in everyday life due to the relative inexpensiveness of the devices. Also, this method does not require gas or flux, since their functions are performed by the electrode. The principle of arc welding is preserved: melting of surfaces occurs due to the contact of the electrode with the metal product, which forms a short circuit and the arc is ignited.

Non-consumable electrode welding (TIG)

This is a gas welding technology, its essence is as follows: an electric arc is ignited in an inert gas atmosphere between the electrode and the material, thus melting the metal and filler material. The electrode is made of refractory metals - tungsten, zirconium, hafnium. This technology requires highly qualified specialists.

Gas shielded welding

This type of welding can be performed with either a consumable electrode or a non-consumable one. For non-consumable electrodes, an additive is needed, and the consumable electrode itself participates in the process of creating a seam. Inert gases are used to ensure stable arc operation. The choice of gas determines the composition of the product being welded. Gas is supplied either centrally or from the side at higher capacities.

Submerged arc welding

The use of flux is necessary to maintain even burning of the arc and, when forming a weld, affects its chemical composition. Different flux compositions have different stabilizing properties. By varying the content of carbon, sulfur, manganese and others, strength and resistance to cold can be adjusted.

Hyperbaric welding

Hyperbaric welding is welding under conditions of high pressure, for example, in water or a specially created dry environment. Underwater welding uses a waterproof electrode that melts and hits the metal with a gas bubble. Underwater welding is one of the most difficult types of work, which, among other things, has an increased risk of electric shock.

Electric arc welding

This is the most common implementation option. Heating of the metal is carried out through the interaction of the anode and cathode, releasing high-power energy. Melting of the workpiece in such a situation results in the formation of a weld pool. Crystallization of the alloy also occurs during the cooling process. The strength of the resulting joint is similar to that of the metals being welded. In this embodiment, the classification of various types of welding includes the following types.

Manual Arc MMA

When carrying out, piece electrodes are used, which are a metal rod coated with coating. Performed under constant influence of alternating or direct current. The advantage is the formation during melting of consumables of a cloud consisting of a mixture of gases (mostly CO2), which forms protection against oxidation of the metal being welded.

When coating, a variety of chemical compounds are used. In the weld pool, they contribute to the formation of additional protection for the weld seam and support stable combustion of the electric arc. The devices are able to work in any position, including in hard-to-reach places, welding any metals. The technology is equally accessible to beginners and professionals. Areas of use: creation of metal structures, in private enterprise, at vehicle service stations.

TIG (argon welding)

Tungsten, graphite, non-consumable, carbon electrodes are used. Nitrogen, argon, helium or a mixture of them are used as inert gas. The weld includes only the workpiece metal and additives. An additive, which is a metal strip or rod, identical in composition to the metals being welded. The use of inert gases is required for protection from atmospheric air. This ensures stable combustion of the electric arc and eliminates metal oxidation.

Semi-automatic MAG (MIG)

Wire is used as a filler material and enters the working area through the torch. In parallel, active or inert gas is supplied, the composition of which is determined depending on the selected work material. Execution is possible only with continuous contact with electric current, which produces a lot of splashes. Due to this, the seam loses accuracy, which is compensated by high productivity. Consumables are supplied automatically. Welding of a wide range of materials from manganese or cast iron to copper and aluminum. Different types of materials are combined.

What is submerged arc welding?

It is carried out using special flux powders, which provide the working area with protective gas released during the melting process. The flux maintains the melting arc and provides protection for the melt. The process is fully automated from flux supply to movement along the joint. Among the areas of use are the creation of:

- satellite modules;

- tower cranes;

- hulls of sea vessels;

- other equipment where long seams and seams of large thickness are used.

A high-strength seam is formed, which is necessary to create equipment that can withstand difficult operating conditions. Such as enormous pressure and extreme temperatures.

Gas plasma

Today, types of welding and, of course, their brief descriptions include this increasingly less used option. It consists of the formation of new pools along the welding seam under the influence of the torch. Its combustion is maintained by supplying one or more combustible gases mixed with oxygen. The technology is more complex than arc technology. It is most often used by experienced specialists due to its versatility and mobility.

Welding is ensured by the high temperature of an open flame, formed by the combustion of oxygen with flammable gases such as acetylene, hydrogen, butane, propane and others. The most effective is the use of methyl acetylene fraction. Depending on the type of flammable gas, the temperature is:

- 2927 with oxygen;

- 4500 when combining oxygen and MAF;

- acetylenedinitrile 5000.

An open flame is used, independent of the power supply. Due to this, it is widely used in “field” conditions. Cooling occurs gradually, which is convenient when working with sheet materials.

The use of the method is unsuitable in industrial conditions due to the lack of automation and low level of productivity. High complexity of the work requires the invitation of a professional. When considering what types of welding there are and what level of qualification, this is considered one of the most difficult.

Electroslag type

The edges of the parts are connected when heated under the influence of electric flux. It is pre-filled between the elements to be connected. Additionally, molten rod or wire is used. Recommended for joining parts made of cast iron or, less commonly, non-ferrous metals. Used to connect large parts in industry. Effective on all types of metals.

Termite

The name comes from the use of thermite when heating metal. Required in “field” conditions, in the absence of a constant source of electricity and gas cylinders. It is an easy activity option to perform. Most often used for surfacing structures, as well as joining brittle and cast iron alloys in accordance with the requirements of GOST R 57181-2016. When connecting, powder mixtures are used, during the combustion of which a large amount of energy is generated under the influence of which the metals pass into a semi-liquid state.

Foundry method

Another type of work that is used less and less these days. It consists of filling a previously prepared work site with liquid superheated metal. Heating can be carried out, for example, in a crucible. The process is similar to making castings. The welding site must be molded, dried and calcined. When the product is heated, superheated molten metal is poured into the molded joint.

In modern production, the technique is most applicable when working with precious noble materials. We work with bronze products, dishes, and jewelry. This is exactly how lead pipes were made in ancient times.

Using a laser

One of the modern types of technology. The laser becomes the energy source, providing special strength to the finished products. Recommended when working with structures of complex configuration. When joining, a smooth and aesthetically pleasing even seam is created, devoid of the slightest curvature. Used to connect elements made of aluminum, silver, stainless steel. Melting and heating uses a laser beam with a monochrome stream of laser-generated light. Flow control is ensured by focusing the lenses and deflecting the prisms. When working, automatic, semi-automatic and robotic devices are used. Melting occurs smoothly and accurately. There is no need to use a vacuum.

Electron beam (EB)

One of the newest and most modern methods of joining refractory materials. The method was developed in the middle of the twentieth century. Convenient for the purpose of reliable connection of thick-walled and thin-walled products, eliminating or minimizing the possibility of deformation when heated. Can also be used when processing ceramics.

The main method of use is the readiness of electrons to transfer energy. Streams of infected particles are formed under vacuum conditions.

Glow discharge

Glow discharge welding is carried out by diffusion interaction through the use of induction heating. Due to this, the connection occurs at the atomic level.

Light

A powerful light beam is used to make the connection. The source of its supply is a carbon arc and gas-charging arc lamps. The most promising today are considered to be arc xeon lamps, the cylinders of which are filled with xeon under a pressure of 4-10 atm (0.4-1 MN/m2). The pressure during lamp operation further increases to 10-30 at (1-3 MN/m2). In this case, the arc discharge is strongly compressed and forms a highly concentrated source of radiant energy, reaching a discharge temperature of 12,000 °C. An increase in the radiant flux density is formed through the use of combined polyellipsoidal systems. Xeon arc lamps provide focusing of the flow.

Induction

Welding provides heating under the influence of induction current generated in the welding machine under the influence of induction current. Such innovative types are characterized by increased accuracy. The induction coil is excited by using high frequency current.

And for dessert

Special types of welding are a vague concept, given the huge number of technical options, groups, types, subtypes. Everyone sees this list differently.

In our list, the classification of welding is determined by manufacturability. These are unique methods that rightfully belong to aerobatics technologies.

Electron beam and plasma welding:

- Electron beam welding. Here an electron gun and a beam of accelerated electrons from this gun are used. The work is carried out in large vacuum chambers. The energy concentration and heat output are fantastic. The seams are narrow and deep. It is used for the production of high-precision parts from special alloys - not a cheap pleasure.

- Plasma welding. One of the most high-tech types - the name speaks for itself. Plasma is a stream of ionized gas (argon, helium, hydrogen) of the highest temperature. This jet cooks everything - from the most refractory metals to non-metallic surfaces. Outstanding performance with fantastic seam and surface quality.

Plasma welding

Plasma is used to melt the edges and filler metal. The equipment consists of a direct current source, an argon gas cylinder, and a plasma torch. To remove excess heat from the plasma torch nozzle (torch), water cooling is often provided.

The gas is supplied to the plasmatron and heated by an electric arc. Thanks to this, it increases in volume up to 100 times. Due to thermal expansion, it begins to flow out of the nozzle at high speed. This is plasma. Its temperature is 30,000º C, which exceeds the characteristics of other welding methods.

There are two options for implementing the technology:

Using plasma welding, metals up to 9 mm thick are connected in all spatial positions. The method is suitable for welding:

Let's generalize and loop

Welding is the process of forming inseparable joints between surfaces of different structures.

First, all types and methods of welding are divided into three powerful classes from the point of view of physics:

- Thermal (heat and melt)

- Mechanical (three, push, push, etc.)

- Thermomechanical (heat and press at the same time)

Tig welding of aluminum.

Within these classes, methods can be grouped as desired:

- with or without arc;

- with or without gas, possible with arc and gas together;

- manual or automatic. Or semi-automatic;

- what types of welding electrodes do you use;

- all types of resistance welding;

- types of welding of metal or, conversely, polymers;

- and so on, the list of options is long.

The main thing is to find out, try, learn and move forward to professional heights. Don't forget to read the reviews, you need to stay informed. We cannot stand still. We wish you pure metal, good orders and a working mood.

https://www.youtube.com/watch?v=ocJFw1HwOpw

How to weld metal correctly?

To carry out the process correctly, it is necessary to study and perform step by step all the operations described below.

It is also necessary to remember that a beginner needs to primarily monitor the quality of work, the thoroughness of operations and the development of skills, and not the speed of work.

So, the first stage is preparation:

- We collect all the necessary tools and equipment, put on special clothing;

- We clean the edges of the part and degrease them;

- connect the electrode;

- We carry out preliminary assembly using tacks; The size of the tacks can be different, usually the tacks are made 10-50 mm, or in the form of points (for small parts).

When it comes to working with pipes, the length of the tack should be at least 2-5 times the thickness of the pipe wall.

The second stage is welding of elements. The process begins with ignition of the arc. There are two main ways:

1st – by touch: the welding arc is ignited by briefly touching the metal surface; it is important to immediately remove the arc to prevent sticking.

2nd – by striking: the welding arc is ignited when held (like a match) across the surface of the metal. This method is preferable because it makes it difficult for the metal to stick, but it is not always applicable due to cramped conditions.

An important point when welding is the inclination of the electrode. If you learn how to hold the electrode correctly, you can avoid many unpleasant consequences. There are three main provisions:

1. Angle forward - the welding arc is deflected from the normal by 30-60 degrees, forming an acute angle between the arc and the seam. In this position, horizontal as well as vertical seams, ceiling seams are made, and pipes are joined in the absence of the possibility of turning the pipe during welding.

2. Backward angle - the welding arc is deflected from the normal by 30-60 degrees, forming an obtuse angle between the arc and the seam. This position is suitable for corner and butt joints.

3. At a right angle - an angle of 90 degrees is formed between the arc and the seam. This position is most often applicable in hard-to-reach places.

A Brief History of Welding

To understand the main stages of development and formation, it is worth considering the history of welding, which briefly talks about discoveries in this area. It dates back to 1802, during which time the Russian scientist and professor of physics V.V. Petrov was actively studying it.

And if you search on the Internet for the answer to the question in what year welding using an electric arc was invented, you will come up with 1802-18004. It is this scientist who owns this invention. And already in 1881, the Russian inventor N.N. Bernados began to use it when joining metals using filler wire.

The main discoveries and scientists will be discussed in more detail in the next section. But still, we should first highlight the main founders of welding - V.P. Nikitin, D.A. Dulchevsky, K.M. Novozhilov, G.Z. Voloshkevich, K.V. Lyubavsky, E.O. Patonov. All of them were actively involved in research into welding technology and discovered many unique technologies that are still actively used in production.

Important discoveries

The history of the development of welding and welding production has many discoveries and stages of development. Over several centuries of its existence, technology has undergone significant changes that have made it popular and advanced. Currently, not a single production or industrial enterprise can do without the use of welding work.

A breakthrough in welding technology occurred during the industrial revolution. At this time, important discoveries were made in the field of electricity, and as a result, scientists of that time also touched upon welding. They studied it carefully and were able to closely connect it with electricity.

In search of an answer to the question of who invented welding, it is worth touching on 1802. During this period, the Russian physicist Vasily Vladimirovich Petrov was able to discover the possibility of using an electric arc for practical purposes. The discovery became a significant event in the activities of the scientist and experimental physicist. In the subsequent period, it began to be used as a prototype for all welding devices.

The inventor of welding outlined all the conclusions of the discovery in the book “News of Galvanic-Volta Experiments,” which was published in 1803. But the scientist was little-known at that time, so his discoveries were not paid much attention at that time.

It is impossible to answer exactly when welding appeared, because the process of its appearance arose gradually. In 1821, Sir Humphry Davy carried out numerous studies using the electric arc. And his student, Michael Faraday, was engaged in intensive research into electricity and magnetism, namely the connection between them. And in 1830 he was able to discover electromagnetic induction.

When considering who invented welding, it is worth paying attention to the events that occurred in 1881. During this period, Russian engineer Nikolai Nikolaevich Benardos was able to discover the electric arc welding process, which was called “Electrohephaestus”. Research was carried out over several years, and in 1887 the invention was patented. Gradually it began to spread throughout the world.

Who invented carbon electrode welding? This discovery also applies to the Russian engineer and inventor Nikolai Nikolaevich Benardos. He was able to develop electric arc welding technology, which involved the use of carbon and metal electrodes. The scientist became the founder of the idea of electric arc welding with a metal rod using alternating current, welding with an inclined electrode, as well as technicalization of the welding process.

In what year did the welding machine appear? The appearance of the first device dates back to 1881-1882. It was at this time that numerous studies and discoveries were carried out, on the basis of which the first welding equipment was developed.

But still, many are interested in who exactly invented the welding machine? At first, the Russian engineer Benardos worked on this, but then Nikolai Gavrilovich Slavyanov took up this issue. In 1882, he was able to create the first welding equipment and electrodes. He patented welding, only after that this technology began to be used in other countries.

The engineer carried out the following work:

- eliminated signs of defects arising during casting of parts;

- restored parts of steam turbines;

- welded worn parts.

Features of technology development in modern times

In what year did welding using metal cutting appear? Cutters appeared in 1904. And in 1908-1909, the technology of underwater cutting of metals began to be used. This technology was widely used in France and Germany.

After the advent of gas welding, they immediately began to occupy a leading position; its demand was observed until the 30s. The technology was used especially intensively during the First World War.

Subsequent development is associated with the scientist and engineer Evgeniy Paton. He organized the first welding institute in 1929. During this period, the development of welding processes took place under his leadership. During World War II, new methods were used in the defense industry. Intensified development of new types of fluxes and electrodes for products with thick walls was carried out. They were used in the manufacture of military equipment - tanks, weapons, bombers and their equipment.

In search of an answer to the question of who invented metal welding, it is worth stopping at the scientist Paton. It was he who was able to develop these methods for welding powder, slag, contact type in a liquid and rarefied environment. At this time, inert gases began to be used to protect the connection. In 1940, tungsten-coated electrodes were first used, and the electric arc was maintained using helium.

Due to the fact that cleaner inert gases were needed for welding reactive metals and aluminum, argon began to be used in 1946. It is the cleanest and safest inert gas for welding.

In 1960, a new welding technology using multiple rods appeared. Its principle was as follows: two or more welding wires are fed into the weld pool area. During this process, they can be applied as an additive, but at the same time they come under electrical voltage. Thanks to this technological process, it is possible to significantly increase the metal melting rate, as well as improve the properties of the operating fluid.

Thermite welding

A welding method that uses thermite, a powdered mixture of aluminum or magnesium metal and iron scale, to heat metal.

When using aluminum-based thermite, the parts to be joined are molded with a refractory material, heated, and the welding site is filled with molten thermite, which is first ignited (with an electric arc or fuse).