Feeding mechanisms (welding wire feeders) are the main device in the semi-automatic welding process. Feeding mechanisms for semi-automatic welding machines - devices for feeding electrode welding wire into the torch.

A cassette with welding wire is installed in the mechanism. The feeding mechanism has a gear drive for feeding welding wire at a certain speed depending on the specified parameters of the welding process. Depending on the thickness of the welding wire, the feed mechanisms can have from 1 to 3 pairs of feed rollers that push the wire into the torch. In addition, for large wire diameters, welding torches with engaging rollers can be used.

Feeding mechanisms for semi-automatic machines produced by ITS are represented by a whole line of devices for working with welding wire with a diameter of 0.8 mm to 5 mm. In addition to the basic configurations, upon special request, the ITS can manufacture a mechanism for working with thicker types of wire, incl. thick flux-cored wire for non-standard welding work.

In accordance with the wire used, the feed mechanisms of semi-automatic ITS can be configured to work with the required parameters of the welding current. Various ITS feed mechanisms are configured to operate with currents from 50A to 700A. The feed mechanisms are connected to welding inverters, the resulting device is called a semi-automatic welding machine. In this case, we mean complete semi-automatic welding machines; in addition to them, there are ITS welding monoblocks, the housing of which combines a feeder and an inverter.

With high voltage, the use of semi-automatic welding is a complex, unsafe and ineffective task; such problems are better solved by automatic welding.

The feeding mechanisms of semi-automatic ITS machines have a one-year warranty, and additional components and spare parts are always in stock.

The main models of feed mechanisms produced by ITS:

Feeding mechanisms

| Name | Number of rollers, pcs. | Rated welding current, A (PV) | Wire feed speed, m/h | Wire diameter, mm | Welding cassette capacity | Dimensions, mm | Weight, kg | ||

| Steel | Powder | Self-protective | |||||||

| PDG-312-5 | 4 | 315 (60%) | 40-960 | 0,8-1,6 | — | — | 15 | 630x280x500 | 20 |

| PDG-322 | 2 | 315 (60%) | 70-930 | 0,8-1,4 | — | — | 15 | 160x430x270 | 7,5 |

| PDG-421 | 4 | 400 (60%) | 60-960 | 0,8-1,4 | 1,2 | — | 5 | 490x185x295 | 12 |

| PDGO-510* | 4 | 500 (60%) | 120-1100 | 1,0-1,6 | 1,2-2,0 | — | 15 | 640x240x420 | 18 |

| PDGO-511 | 4 | 500 (60%) | 60-960 | 0,8-2,0 | 1,2-2,0 | 1,6-2,0 | 15 | 440x290x530 | 17 |

| PDGO-601 | 4 | 630 (100%) | 60-820 | 1,2-2,0 | 1,2-3,2 | — | 15 | 640x240x420 | 18 |

| PDGO-602** | 4 | 630 (100%) | 104-980 | 1,2-2,0 | 1,2-3,2 | — | 15 | 560x350x360 | 26 |

| PDGO-603 | 4 | 630 (100%) | 104-980 | 1,2-2,0 | 1,2-3,2 | — | 30 | 1000x500x400 | 28 |

* - the standard production program also includes a modification of the PDGO-510 feeding mechanism - PDGO-510A

(supplied with an autonomous BUSP-2K-506/24V).

**- PDGO-602 has stepwise regulation of the electrode wire feed speed (28 steps) using replaceable gears

Feeding mechanism PDG-312-5

| Feeding mechanism PDG-312-5 is closed type. Inside there is a 2-roller gear drive CWF 3110, a cassette for welding wire, a braking device, a control board and a solenoid valve. On the mechanism panel there are resistors for adjusting the welding wire feed speed and voltage, and technological time intervals. There is a version PDG-312-5 with digital indication of welding modes and a four-roller feed drive. More details: |

Feeding mechanism PDG-401

| The PDG-401 feed mechanism is designed for semi-automatic DC welding with consumable electrode wire in a shielding gas environment, complete with sources for MIG/MAG welding. Smooth adjustment of the output voltage of the welding source and the feed speed of the electrode wire from the feed mechanism. Provides stabilization of the welding wire feed speed and voltage feedback on the welding wire feed motor, which allows for high-quality welding at a distance of up to 40 meters from the welding source. Stable feed speed of welding wire with a torch train length of 3 - 5 m and bends in the train. More details: |

Feeder

Let's take a closer look at what the feeding mechanism consists of:

- Welding sleeve. It is a flexible frame hose covered with multilayer rubber to protect and insulate the power cable. Inside there is a special steel spiral channel for feeding the welding wire to the welding site. The hose also to protect the weld pool from the environment. Near the welding torch there is a button to turn on the wire and gas feed mechanism.

- Wire feed mechanism. Ensures uninterrupted wire feed through the welding hose. It consists of a direct or alternating current electric motor, a clamping device for pressing the rollers using screw clamps with a certain force.

- Device for installing a cassette with welding wire. It is located near the feed mechanism and is designed to provide the welding arc with filler material for a long time. The cassette can be positioned both vertically and horizontally relative to the feeding mechanism. The cassette is secured using a special nut or clamps.

- Control unit. It is used to adjust the wire feed. The adjustment can be electronic using a rheostat or more coarse thanks to interchangeable gears. Modern ones are equipped with digital displays, on which you can accurately set the welding speed and thereby ensure better seam formation.

The main advantages over welding with electrodes are a faster welding process, there is no need to change the electrode often, and better control over the welding process. The disadvantages are the fear of drafts and strong winds (possible formation of pores), and the connection to the source of protective gas (cylinder, ramp).

Feeding mechanism PDG-421

| Feeding mechanism PDG-421 is a closed type (“Admiralteets”), inside of which a 4-roller gear drive CWF 4110, an electromagnetic valve, a control board and a gas path are installed. The welding mode controls are located on the front panel of the feed mechanism. The connecting unit with the burner is made with a plug-in connection. A version with a Euro connector is possible. The difference from the PDG-322M feeder is that the control board in the PDG-421 feeder is located inside the feeder housing and does not have the same functionality as the PDG-322M. More details: |

Semi-automatic welding

This welding unit is a device with an incomplete automation cycle . The welding process takes place in an inert gas (argon), active gas (carbon dioxide) or a mixture of gases. The principle of welding is that in a semi-automatic machine, an electric arc produced by a direct electric current always burns between the product and the welding wire. During operation, gas passes through the torch to cover the welding zone, creating protection from air exposure. Such semi-automatic machines are good at working with sheet metal.

The semi-automatic machine allows you to significantly reduce operating time and increase the quality of welded joints. The popular model of semi-automatic welding machine MIG MAG works in conjunction with a welding wire pulling mechanism. The device must be located in the welding machine itself in its body or be remote and connected, if necessary, to a power source via a power cable.

The wire wound on a reel must be placed in a semi-automatic spool and then passed through the wire feed mechanism into a special channel. A welding torch is attached to it; gas is supplied from the cylinder to the torch through a specially attached tube. You can also use cored wire and in this case a gas cylinder will not be needed.

Feeding mechanism PDGO-510

| Feeding mechanism for welding wire PDGO-510. Used as part of a complete semi-automatic welding machine. Connects to a welding source for MIG/MAG welding. Serves to supply a welding consumable electrode and shielding gas to the welding point. As a consumable electrode in the PDGO-510 feeding mechanism, it is allowed to use solid types of welding wire, as well as various types of welding flux-cored wire. PDGO-510 allows any type of shielding gas, depending on the type of wire used. The PDGO-510 control board allows you to switch welding modes from 2-stroke to 4-stroke, provides the functions “soft start” and arc stretching,” Inter Lock – arc breaking. Gas purging is carried out automatically before and after welding. More details: |

Design options

The initial requirements for the unit in question are its versatility, relatively fast adaptability, the ability to work with wire of various diameters, compactness and the ability to control the speed of movement of the wire to the welding zone.

The typical design of this unit includes:

- The reel on which the cassette with the source material is mounted.

- Drive asynchronous three-phase AC motor, which is designed to operate with a relatively low operating voltage (not higher than 36 V).

- Multi-stage worm gearbox, with which you can change the speed of wire movement.

- Replaceable gears from which the feed rollers rotate.

- A set of feed rollers that can be axially adjusted to suit different diameters of welding wire.

- Feed sleeve, which, depending on the placement of the unit, ensures the movement of material outside its body.

- The supporting frame on which all the elements of this unit are placed. The frame can be equipped with transport wheels.

- Wire pre-tensioning unit (installed before the rollers).

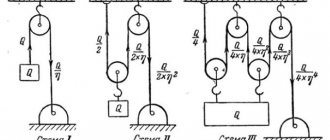

The layout of the individual units that make up the wire feed for a semi-automatic machine depends on the wire feed method. It can be pulling, pushing and mixed.

The pulling option is provided in the case when the power of the drive electric motor is not enough to pull the wire with rollers at the maximum required speed.

To do this, the pulling mechanism is located in the handle of the welding torch. Although this makes the torch itself heavier, it contributes to a more uniform speed of movement, which is especially important for ensuring improved quality of the weld and stability of its overall dimensions. To ensure that the welder’s hand does not get tired, a special stand is provided. As a result, this design is less common, since it is designed mainly for professional welders. With the pushing version, all moving parts are located in the body of the unit itself, and precise direction is ensured by appropriate adjustment of the guide sleeve, which is located after the drive rollers. This arrangement requires that the feed unit be located near the welder's station. If any problems arise with this mechanism, welding will be interrupted, which will inevitably affect its quality. Therefore, push feed is more demanding on the reliability of the drive motor.

Combined feed, when the unit has both pushing and pulling drives, is the safest: if problems arise inside the housing, the movement will continue with an autonomous device, which is mounted in the welding torch. Nevertheless, this scheme is characterized by the greatest complexity, and therefore is used forcedly: for example, when there are significant distances between the semi-automatic device and the feed mechanism. The most powerful standard sizes of semi-automatic welding machines are equipped with a push-pull feed.

Thus, the choice of the most suitable welding wire feeding mechanism for a semi-automatic machine depends on the welding conditions and the qualifications of the worker.

Feeding mechanism PDGO-510A

| Feeding mechanisms PDGO-510A-1, PDGO-510A-2, unlike PDGO-510-6, operate in conjunction with a unit with PWM control type BUSP-2K - 24 V, its modifications or similar control units. The semi-automatic machine PDGO-510A-1 has an increased force of pushing the welding wire at low speeds, due to the use of a high-power engine, which is important when welding with large diameter wires, more than 1.6 mm. Feeding mechanisms PDGO-510A-1, PDGO-510A-2, unlike PDGO-510-6, operate in conjunction with a unit with PWM control type BUSP-2K - 24 V, its modifications or similar control units. More details: |

Feeding mechanism PDGO-510T

| Feeding mechanism PDGO-510T is semi-closed type. PDGO-510T is designed to work with rectifiers of the VD-506DK type. Inside the feed mechanism there is a 4-roller gear drive CWF 5110, an electromagnetic valve, a welding cycle control board, a voltage feedback board on the welding wire feed motor and a gas path. Adjustment resistors are installed inside the housing of the feed mechanism to adjust the time of gas purging before and after welding, and the sticking out of the welding wire. Welding mode controls are located on the front panel (resistors for adjusting the welding wire feed speed and arc voltage). More details: |

Popular models

Lincoln Electric produces a whole line of two- and four-roller mechanisms that feed welding wire. Don't forget about other brands.

LF-37, 38

Models LF-37, LF-38 are designed for use in conditions of high humidity and dust.

They work on 300mm (15kg) spools and can also use 200mm (5kg) spools. The wire can be solid or flux cored. There is a gas flow sensor which is useful when working with long cables. All settings are intuitive, after pressing the “select” button, 2/4 stroke modes are visible, you can adjust the pre-pull before starting work, hot and soft start (Hot/Soft) and crater filling are provided.

You can select the language to display information on the screen. The LF38 mechanism has a set of programs and a memory unit that provides recording of 10 modes of specified parameters.

The device has small dimensions and large indicators that display parameters during the welding process. Connection cables for liquid cooling are available. Can work with wire diameters from 0.6 mm to 1.6 mm. The manufacturer provides a 3-year warranty.

MSF 57

One of the best wire feeders for welding work is the MSF 57 from Kemppi.

The MSF 57 has four rollers. A wire cassette with a diameter of 300 mm is used. The quality of this feed mechanism is at a high level. This is perhaps the most reliable and convenient mechanism on the market based on user feedback.

Model MSF 57 with a power of 100 W is powered by 50 V. The welding wire can be fed into it at a speed of 0 to 25 m per minute.

The mechanism can work with stainless wire with a diameter from 0.6 mm to 1.6 mm, with flux-cored wire from 0.8 mm to 2.0 mm, with aluminum from 1.0 mm to 2.4 mm.

Fast and Furious MPTs02

The Forsage MPTs02 wire feeder from a Russian manufacturer has proven itself well. It has digital control of parameters, adjusts the wire feed speed in the range of 2-20 m/min.

The device has replaceable rollers, which allows you to quickly change to different diameters, and works with coils up to 300 mm. The mechanism provides for adjusting the gas purging time before welding from 0 to 0.5 s, after welding from 0 to 10 s. The gearbox power is 120 W.

Some craftsmen make semi-automatic welding inverters by adding a separate wire feed unit. But for the most part, they are unregulated feed mechanisms whose characteristics are significantly inferior to industrial designs.

When producing a complete analogue of a model, the cost of components will be significantly higher than the finished device.

Feeding mechanism PDGO-511

| The closed-type feed mechanism PDGO-511 is designed for semi-automatic welding with solid and flux-cored wire at direct current in a shielding gas environment, complete with sources for MIG/MAG welding. The feeding mechanism consists of two frame blocks and a standard 15 kg cassette covered with a casing. The PDGO-511 feeding mechanism is designed to work in difficult working conditions with rectifiers such as VD-306DK, VD-506DK, VDU-506S-4 and others with a rigid or combined characteristic. Inside the lower block of the feeding mechanism there is a 2-roller gear drive with a pressure adjustment device, an electromagnetic valve and a gas path. The upper block houses the welding process control board and process controls. More details: |

Operating principle

An ordinary feed mechanism consists of a DC electric motor, a reduction gear, a pressure and drive roller, a guide and an input channel. In addition, there is a lever with a spring and a screw that acts as a pressure regulator.

When voltage is applied to the electric motor, its shaft begins to rotate at a certain speed. On the same shaft with the electric motor there is a gearbox that reduces the number of revolutions to the required number.

The output shaft of the gearbox rotates the push/pull roller, which in turn pulls the welding wire pressed against it by the second roller. To eliminate slippage, there is an adjusting screw that acts on the pressure spring. It is necessary for a softer and more constant effect on the roller.

The feed mechanism in a semiautomatic welding machine may have a separate adjustment unit, activated from a button on the torch handle. Some models have replaceable bushings on the guide channels.

This allows you to reconfigure the equipment for different wire diameters. In addition, the mechanisms are designed with a valve and fitting for connecting water-cooled burners.

Some four-roller devices have an additional pair of rollers in front of the feed block. Their task is to level the additive. They are usually used when using flux-cored wire with a thickness of 0.8 mm to 4 mm.

Feeding mechanism A-547U

| The A-547U feed mechanism is designed for welding steel products with steel wire in a shielding gas environment using direct current. The semi-automatic device consists of a feed mechanism A-547, a semi-automatic control cabinet and a rectifier VS-300B. Feeding mechanism A-547U is a closed type without a control board. The control circuit is mounted in a separate cabinet. The A-547U feeding mechanism is equipped with a 2-roller gear drive, a cassette for welding wire, a brake device and an electromagnetic valve, and a resistor for adjusting the welding wire feed speed. More details: |

Types of devices

Depending on the method of feeding the welding wire, the mechanism can be:

- pushing;

- pulling;

- combined.

The pushing mechanisms together with the coil are located in the body of the welding machine or as a separate unit. This is the most common execution option.

Through a guide channel, it pushes the filler wire through the torch directly into the welding zone. Thanks to its location, it makes the welder's work easier.

The pulling mechanisms are located in the burner body. This allows you to work with longer guide channels. The disadvantage of this operating principle is the reduction in productivity and efficiency of the welder due to the heavier torch.

Combined devices combine both operating principles, but are extremely rare.

Depending on the thickness of the additive used, the feed mechanisms are two- or four-roller . For wire with a thickness of 1-1.2 mm, a two-roller mechanism with one drive and one clamp is usually used. For additives with a larger cross-section, two rollers of each type are used.

External feed mechanisms can be completely self-contained, portable or stationary. Modern devices are equipped with information panels. They allow you to monitor and adjust equipment parameters.

The device has an electronic control unit, which, if necessary, regulates the feed speed of the welding wire, which varies depending on the technology, working conditions and skills of the welder.

Some models have the ability to memorize welding modes. A cold drawing mode is provided, when the wire is fed into the welding zone without igniting the torch.

It is possible to purge the hose with shielding gas before starting welding work and when it is finished to remove dust and moisture.

Universal trolley for feeder

| Universal trolley for feeding mechanisms PDG-401, PDGO-508S, PDGO-510, PDGO-510T, PDGO-601S. The trolley is designed for transporting the feeding mechanism in a workshop environment. The trolley is equipped with a universal unwinder for placing a coil of welding wire weighing up to 50 kg. More details: |

- Feeding mechanism PDG-312-5

- Feeding mechanism PDG-322

- Feeding mechanism PDG-401

- Feeding mechanism PDG-421

- Feeding mechanism PDGO-510

- Feeding mechanism PDGO-510A

- Feeding mechanism PDGO-510T

- Feeding mechanism PDGO-511

- Feeding mechanism A-547U

- Feeding mechanism PDGO-601

- Feeding mechanism PDGO-602

- Feeding mechanism PDGO-603

- Universal trolley for feeder

- Feeding mechanism PDGO-518