Soldering guns are tools designed for soldering and welding. Hair dryers can be manufactured industrially or domestically; depending on this, they are divided into household and industrial. Household ones can have several operating modes: blowing, air supply mode without heating, etc. An industrial hair dryer has a larger range of modes. Household soldering guns can be purchased on Aliexpress.

The simplest soldering devices are housed in a plastic case, but more advanced models have rubberized handles and metal parts. To make it easier for you to decide on the choice of a soldering hair dryer, we have compiled a rating of the TOP 20 best soldering hair dryers from Aliexpress.

Rating of the TOP 20 best soldering hair dryers from Aliexpress: review of the most popular models

The rating includes soldering guns, which are most often ordered on Aliexpress. The rating is based on reviews from real customers. In addition, all soldering guns presented are tested by us personally. We evaluated heating speed, smooth operation and ergonomics.

| Photo | Name | Rating | Price | |||

| Rating of the top 10 best hair dryers with a pump built into the soldering station | ||||||

| #1 | Soldering station 220V 8586 700W 2 in 1 SMD with soldering iron | ⭐ 5 / 5 | Find out the price | |||

| #2 | High frequency soldering station | ⭐ 4.9 / 5 | Find out the price | |||

| #3 | 2 in 1 soldering station with LCD display | ⭐ 4.8 / 5 3 - votes | Find out the price | |||

| #4 | 960I Temperature Controlled Portable Soldering Station | ⭐ 4.7 / 5 1 - voice | Find out the price | |||

| #5 | SMD soldering station | ⭐ 4.6 / 5 | Find out the price | |||

| #6 | 2-in-1 hot air soldering station with built-in pump | ⭐ 4.5 / 5 1 - voice | Find out the price | |||

| #7 | Soldering station NEWACALOX | ⭐ 4.4 / 5 | Find out the price | |||

| #8 | Soldering station 8586, heat gun 220V + soldering iron + heating element | ⭐ 4.3 / 5 | Find out the price | |||

| #9 | Soldering station 8586 2 in 1 with ESD | ⭐ 4.2 / 5 | Find out the price | |||

| #10 | Soldering station Qsunrun 858D | ⭐ 4.1 / 5 | Find out the price | |||

| Rating of the top 10 best soldering guns with a built-in turbine | ||||||

| #1 | Industrial electric hot air dryer Prostormer2000W | ⭐ 5 / 5 | Find out the price | |||

| #2 | Hot air gun | ⭐ 4.9 / 5 1 - voice | Find out the price | |||

| #3 | Hot air gun 100-450 degrees | ⭐ 4.8 / 5 | Find out the price | |||

| #4 | Industrial hair dryer 8858 SMD set B | ⭐ 4.7 / 5 1 - voice | Find out the price | |||

| #5 | Soldering gun 8858 set A | ⭐ 4.6 / 5 1 - voice | Find out the price | |||

| #6 | Heat dryer with built-in turbine | ⭐ 4.5 / 5 | Find out the price | |||

| #7 | Electric gun with LCD display | ⭐ 4.4 / 5 | Find out the price | |||

| #8 | Portable heat gun Yarboly 8858 | ⭐ 4.3 / 5 | Find out the price | |||

| #9 | Manual soldering heat gun 220 V with built-in turbine | ⭐ 4.2 / 5 1 - voice | Find out the price | |||

| #10 | Soldering station Quick 857DW + hot air gun 580 W | ⭐ 4.1 / 5 2 - votes | Find out the price | |||

Which soldering iron would you choose or recommend on Aliexpress?

Take the survey

Soldering the bumper with a soldering iron

Using a soldering iron, you can repair cracks and chips on plastic bumpers. It is best to solder bumpers made of polyamide with a soldering iron; worse, those made of polypropylene; it is better not to repair bumpers made of ABS plastic with a soldering iron.

The soldering iron does not have the ability to adjust the power, so it is very difficult to maintain the desired temperature, which leads to overheating. It is very difficult to heat the plastic to the required depth and temperature with a soldering iron, which makes it impossible to obtain a homogeneous monolithic connection.

To solder bumpers made of polyurethane, polypropylene, polyvinyl chloride (PVC), use an 80-watt soldering iron. To solder bumpers made of polyamide and ABS plastic, use a 100-watt soldering iron.

When repairing a bumper made of thin plastic, if the damage site has uneven edges or is located at the edge of the bumper or has a difficult shape, then a metal reinforcing mesh is used for soldering. When repairing minor damage, instead of metal reinforcing mesh, you can use metal staples for a construction stapler, which are soldered in 2 cm along the entire length of the crack. Minor damage can be sealed without reinforcement at all.

Soldering a plastic bumper using a soldering iron is carried out in the following order:

- A patch is cut out of a metal reinforcing mesh, slightly larger in size than the damage on the bumper.

- The reinforcing mesh is soldered with a soldering iron into the inner surface of the bumper, connecting the torn edges of the crack. You should try to bury the mesh as deeply as possible into the plastic, but without damaging the front side of the bumper.

- Use a soldering iron to solder the seam on the outside of the bumper, covering the reinforcing mesh with molten plastic.

When repairing minor damage, when reinforcing mesh is not used, use a sharp soldering iron tip to make transverse notches every 1–2 cm on the inside of the bumper to preliminarily fix the edges of the damage, then use the flat side of the soldering iron tip to fill the remaining gaps and level the surface. Then do the same on the front side of the bumper.

Tips and recommendations when choosing soldering guns from Aliexpress

When choosing soldering guns, be sure to pay attention to the following parameters:

- Power. The higher the data, the better. If you have just started mastering soldering skills, then choose a soldering station with a power of up to 150 W.

- Air flow force. Keep in mind that the higher the air flow, the faster the tool will warm up and the thinner the wire will be. Choose a soldering station with an air flow power of at least 125 Pa.

- Temperature level. The lower it is, the more comfortable it will be to work with a soldering iron. In addition, the temperature melts the solder with less outgassing. When choosing soldering guns from Aliexpress, pay attention not only to the power and strength of the air flow. An equally important characteristic is temperature. It should start at 350 C and reach a maximum of 450 C. This is the temperature used by a professional soldering station. Pay special attention if you are choosing a soldering iron for your home. For this option, a station with a temperature range of 350-450 C is suitable.

- Overheating protection available. This helps protect the electronics from failure. The more reliable the protection, the longer the equipment will last.

- Continuous operation time. With its help, you can adjust the operating time of the soldering gun without additional recharging. When choosing a hair dryer from Aliexpress, also pay attention to its type. It can be either traditional air or vortex. In the vortex version, a jet of hot air is generated by rotating the air flow. This hair dryer is more powerful, but also noisier. In addition, it heats up faster. And if you need a hair dryer for your home, then you should definitely choose a classic air soldering device.

Video - Top 8 soldering stations with hair dryer from Aliexpress

Types of damage to plastic bumpers

Scratches

Scratches are non-through damage to the bumper surface in the form of grooves. Bumper scratches are divided into two types:

- superficial scratches

- only the paintwork of the bumper up to the primer layer is damaged. - Deep scratches

- damage grooves have a significant depth, and not only the paint layer and primer layer are damaged, but also the plastic of the bumper itself.

Don't take too long to remove scratches on the bumper; over time, they can turn into cracks.

Scratches on the bumper can be removed by sanding with sandpaper or a sanding machine. The surface of the bumper is sanded until smooth, then the surface of the bumper is puttied, primed and painted.

Dents

Dents are deformations of the surface of a plastic bumper due to local stretching of the plastic. Dents are formed due to strong mechanical impact on the bumper. Dents are often accompanied by scratches and cracks.

To remove the dent, the deformed part of the bumper is heated using a hair dryer or a gas burner. When the deformed section of the bumper softens, the dent is straightened, returning the bumper to its correct shape.

Cracks

Cracks are called through damage to the bumper, having different lengths and shapes. Cracks are the most common type of bumper damage. Cracks that are not repaired in time increase in length over time due to vibration. There are different ways to repair bumper cracks: welding with a hot air gun, gluing with fiberglass and liquid polymer, soldering in a metal mesh or metal brackets with a soldering iron. The choice of repair method depends on the material from which the bumper is made and the size and appearance of the damage.

Chips

Chips are end-to-end damage to the bumper with separation of individual fragments from the bumper. Chips most often appear along the edges of the bumper after a car collides with obstacles. The methods for repairing bumper chips are similar to the methods for repairing cracks.

What to look for when choosing a soldering gun with a built-in turbine?

A soldering gun with a built-in turbine can be used for burning plastic, burning out various inscriptions and logos, as well as for soldering various products. Typically, such soldering guns have two main modifications with a power of 300 or 900 watts.

Both options are quite powerful and during their operation a large amount of heat is generated, so it is necessary to use specialized protection during operation. For safety, be sure to wear safety glasses, a special respirator and gloves.

The hair dryer body is made of durable black plastic. There are several keys on it for selecting the desired temperature. The power regulator is located on the body and is designed to set the desired mode. There is also an on and off button located on the handle of the soldering iron. The hair dryer body itself is equipped with a hole for connecting nozzles.

But most often such soldering irons are connected to a 220 volt network. However, there are more powerful modifications that are suitable for working with various materials. Included with this hair dryer you can find a nozzle for dismantling microcircuits, nozzles for burning out small parts, various nozzles for soldering plastic, metal or wood, a nozzle holder, as well as other equally useful little things.

This soldering gun can operate in two modes. When choosing the first mode, the air is heated, during which it is distributed evenly over the entire working surface of the hot air unit. In this mode, the air heats the working surface of the part and melts it, and the molten workpiece is supplied to the soldering site. The second mode is designed for faster soldering and is characterized by more intense heating of the air. Here its power is distributed unevenly.

The air temperature varies from minimum to maximum, depending on the heating temperature. That is why such a hair dryer is called a hot-air hair dryer. This hair dryer runs on mains power. The power of the device can range from 450 to 1300 watts. However, even with such a powerful hair dryer, the temperature that can be set is 500 C. This is the temperature that needs to be set on the soldering table during soldering.

Video - Learn to solder, choose a soldering gun and learn how to use it

Types of bumper materials

The bumpers of modern cars can be made of different types of plastic. Before starting repairs, to choose the correct repair method, you should determine the type of plastic. The easiest way to do this is by looking at the inside of the bumper, where the type of plastic used to make the bumper should be indicated with a letter code. In the absence of markings on the back of the bumper, the type of plastic can be determined by indirect evidence by testing a broken piece of the bumper. Experienced craftsmen determine the type of plastic by appearance alone.

The main types of plastics used to make plastic bumpers are:

- PP - polypropylene

, flexible and tear-resistant, softens when heated, burns with a clear flame, blue at the base and yellow at the top, does not form soot when burning, forms drops during combustion, when burning it emits an odor reminiscent of oil or wax, does not extinguish itself, does not dissolve in acetone. It can be welded well with a hairdryer, soldered with a soldering iron, the use of reinforcing material is not necessary. When welding and soldering, it is important to observe the temperature regime. Melting temperature 300℃, welding temperature 300-340℃, destruction temperature 350-370℃. - ABS - acrylonitrile butadiene styrene

, fragile, when bent the bend turns white, burns with flashes, an orange flame, smokes heavily, quickly passes from solid to liquid, very fluid, bubbles when overheated, smells like rubber when burning, does not extinguish itself, easily dissolves in acetone. It is welded with a hairdryer, soldered with a powerful soldering iron, gas torch, and glued together. Melting temperature 350℃, welding temperature 350-370℃, destruction temperature 380-400℃. - PA - polyamide,

when bent the bend turns white, burns poorly, with a yellow flame with a blue base, melts when burning, foams, emits a pungent odor of formic acid, extinguishes itself, does not dissolve in acetone. It is welded with a hairdryer, soldered with a powerful soldering iron, gas torch, and glued together. Melting temperature 400℃, welding temperature 400-440℃, destruction temperature 450-470℃. - PUR - polyurethane,

difficult to weld and solder, requires good reinforcement. It is welded with a hairdryer and soldered with a soldering iron with precise temperature control. It is important not to overheat the part. The melting point of polyurethane is 200℃. - PC - polycarbonate

, burns with a yellow flame, with flashes and flaming ash, emits a caramel smell when burning, and partially extinguishes itself. Melting temperature 350℃, welding temperature 350-370℃, destruction temperature 380-400℃. - PE - polyethylene

, burns with a clear flame, with a yellow top and blue base, forms drops during combustion and emits a smell reminiscent of stearin, does not extinguish itself. Melting point 270-300℃. - PVC - polyvinyl chloride

. It is welded with a hairdryer and soldered with a soldering iron. The seam must be reinforced due to the low strength of PVC. Melting point 300-400℃. - Fiberglass

- does not have any special markings; it is repaired by laying several layers of fiberglass cloth and impregnating it with polyester or epoxy resin.

What should you pay attention to when choosing a soldering gun with a pump built into the soldering station?

- Hairdryer power (according to the passport).

- Maximum temperature range (indicated on the soldering iron or heating element from 220 to 400 degrees Celsius).

- Maximum air flow (the pump must produce at least 8 cubic meters of air per minute).

- Availability of additional nozzles for soldering small parts, for example, hot-air soldering irons.

- Noise and vibration levels.

- The presence of a smooth mode for warming up the instrument and adjusting the amount of air flow.

- Ease of use:

- temperature adjustment;

- on/off;

- a display showing the heating temperature of the hair dryer;

- smooth or step mode;

- ease of use, adjustment and operation;

- Possibility of connecting an external power supply.

Note! When choosing a soldering gun with a pump built into the soldering station, it is very important to take into account the antistatic heating function. In this case, the hair dryer must be equipped with a handle or be equipped with a special temperature sensor that will give a signal at the beginning of each heating and cooling cycle.

Purpose and device

A soldering hair dryer is designed to heat the leads of elements sealed in an electronic board and soldered into it using a non-contact method. Most often, such devices are used to work with parts that have a large number of leads, small radioelements, or in places where access with a classic soldering iron is impossible for technical or design reasons. The most common area of application is SMD elements, microcircuits and other low-current equipment that are either too difficult to desolder due to the risk of damaging sensitive components, or impossible due to their size.

A hot air gun is one of the components of a soldering station, used to heat solder and circuit boards. In addition, they are used to remove varnish from the legs of parts and wire cores with hot air. The non-contact method of operation of a hot air gun is based on supplying a heated stream to the desired point, which is ensured by the design features of the device.

Due to the narrow focus of the scope of application, soldering guns are used for soldering low-melting solders. In addition, they are used to remove varnish from the legs of parts and wire cores with hot air. The non-contact method of operation of a hot air gun is based on supplying a heated stream to the desired point, which is ensured by the design features of the device.

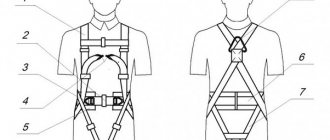

Rice. 1. Soldering gun device

Structurally, the soldering gun consists of the same main parts as the classic models used to solve household and construction problems. The device of a hot air gun is shown in the figure below:

- Housing - made of heat-resistant materials, some models allow heat-conducting ones. The main task of the housing is to protect the operator from interaction with heating elements and the air supply system.

- Handle – used to hold a soldering gun, made of heat-resistant substances with a low thermal conductivity coefficient (hard rubber, porcelain, ceramics, polymer and others). The handle is separated from the heating and air supply system by thermal insulation so that heat is not transferred to the operator’s hand.

- Heating element – designed to convert electrical energy into heat. The simplest and most affordable option is a nichrome spiral.

- Air supply system - performed by tubes supplying heated air to the nozzle, a fan or compressor to force the flow. The simplest option for installing the impeller is at the end of the soldering gun.

- Nozzle - is a conical tube that goes from a larger diameter to a smaller one, with a round or flat cross-section. Most often, it is made of steel, as an affordable and refractory metal.

- Control unit - represented by an electronic board and buttons for turning on/off or launching other functions.

Some models are additionally equipped with temperature indicators, heating controls and other auxiliary functions. For ease of use, smoke traps, tweezers and removal guns, etc. can also be installed.

Voting for the best soldering iron with Aliexpress

Which soldering iron would you choose or recommend on Aliexpress?

Soldering station 220V 8586 700W 2 in 1 SMD with soldering iron

0.00% ( 0 )

High frequency soldering station

0.00% ( 0 )

2 in 1 soldering station with LCD display

27.27% ( 3 )

960I Temperature Controlled Portable Soldering Station

9.09% ( 1 )

SMD soldering station

0.00% ( 0 )

2-in-1 hot air soldering station with built-in pump

9.09% ( 1 )

Soldering station NEWACALOX

0.00% ( 0 )

Soldering station 8586, heat gun 220V + soldering iron + heating element

0.00% ( 0 )

Soldering station 8586 2 in 1 with ESD

0.00% ( 0 )

Soldering station Qsunrun 858D

0.00% ( 0 )

Industrial electric hot air dryer Prostormer2000W

0.00% ( 0 )

Hot air gun

9.09% ( 1 )

Hot air gun 100-450 degrees

0.00% ( 0 )

Industrial hair dryer 8858 SMD set B

9.09% ( 1 )

Soldering gun 8858 set A

9.09% ( 1 )

Heat dryer with built-in turbine

0.00% ( 0 )

Electric gun with LCD display

0.00% ( 0 )

Portable heat gun Yarboly 8858

0.00% ( 0 )

Manual soldering heat gun 220 V with built-in turbine

9.09% ( 1 )

Gluing

Bonding with fiberglass and epoxy or polyester resin is used to repair fiberglass bumpers, and in some cases, to repair bumpers made of hard, refractory plastics. The disadvantage of repairing a bumper in this way is the low strength and fragility of the repair site.

The bumper is glued using fiberglass and epoxy or polyester resin in the following order:

- Clean the front and back sides of the bumper at the point of damage using fine-grained sandpaper 5 cm from the edge of the crack, chip or hole.

- Cover the damaged area with tape on the front side of the bumper.

- Degrease the edges of the damage on the back of the bumper.

- Cut several patches from fiberglass measuring 5 cm larger than the damaged area.

- In a plastic container, mix the resin and hardener in the proportions specified by the manufacturer, mix thoroughly.

- Apply resin to the damaged area on the inside of the bumper with a brush.

- Place a fiberglass patch over the damaged area and smooth it out.

- Apply resin and apply the next fiberglass patch, repeat until the thickness of the layer reaches the approximate thickness of the bumper.

- After the resin has dried on the inside of the bumper, remove the tape from the front side, smooth the edges around the damage and form a depression.

- Degrease the surface of the repair area on the front side of the bumper.

- Apply the resin with a brush, apply a fiberglass patch, and smooth it out.

- Repeat brushing the resin and applying fiberglass patches until you are level with the bumper surface.

- Dry the bumper completely.

- Thoroughly sand the surface of the bumper with fine-grit sandpaper.

Specifications

A homemade hairdryer will have the design and principle of operation described above. The invention will, of course, require a certain amount of materials, which will not be difficult to find in home bins.

A homemade hair dryer has a slightly lower temperature of 600 0C. This temperature regime is sufficient to heat the base and solder the radio components. The device can be used for microscopic work at a power of 75 W. When soldering larger parts, higher power is needed (about 110 W). The current value is 4 A, while the voltage indicator is from 24-35 V.

You can assemble it yourself

Additional Information! All parameters must be precisely adjusted to avoid dangerous situations during operation. The material for assembly has been carefully selected. There is no need to rush, each subsequent step is pre-thought out.

Painting

Painting a plastic bumper is done in 2-3 layers, with drying between layers for 5-10 minutes. After the paint has completely dried, varnish is applied to the bumper in two layers. Intermediate drying is also done between two layers of varnish. After painting is completed, the surface is inspected; if paint smudges are detected, light sanding and polishing is performed.

How to properly assemble a homemade one?

Let's look at a diagram for assembling a reliable hairdryer for home use:

- Assembling the temperature unit. It is recommended to use a nichrome spiral with a cross section of 0.5 mm as a material for the heating element. For reliable fixation, it is wound on a cylindrical base. It is important that during the winding process the turns do not touch each other. The leads of the spirals should be secured using temperature glue.

- The temperature unit is placed in a hollow cylinder made of thermal insulating material. The outputs of the spirals are connected to the power wires. Current-carrying parts are passed through a starter and a rheostat in order to regulate the incoming voltage.

- A hair dryer is installed on one side of the tube to create air flow.

- A nozzle is installed on the reverse side, the cross-sectional size of which depends on the tasks assigned.

Making such a welding gun is not at all difficult. To expand its capabilities, we recommend developing a mechanism for replacing nozzles.

putty

Puttying a plastic bumper is done to restore the geometry of the bumper and level its surface. The putty is applied to the area of the bumper where the damage is located, smoothed out, allowed to dry, then sanded using sandpaper. In most cases, putty is applied in several layers.

Primer

Before covering the bumper with primer, it is thoroughly washed with water and allowed to dry. Then apply the primer, let it dry, sand the primer with 800 grit sandpaper. Wash the bumper again with water and then apply a second coat of primer. When the primer is completely dry, the bumper is inspected using a lamp; the bumper should have a perfectly flat surface.