A pipe bender is a machine designed for bending pipes made of various metals, including steel. The machine ensures uniform deformation of the workpieces at the required angle. In this case, the pipe itself bends smoothly, without the formation of folds. This is especially important if it is used to transfer liquid or gas, since the standard throughput is maintained. Pipes with a diameter from 5 to 1220 mm are subject to bending. Industrial-type machines are used to bend thick rolled metal.

Where is a pipe bender used?

The machine is indispensable in construction and repair work. It is used for preparing pipes used for gas and water supply. It is also used to bend parts for the manufacture of frame structures:

- Sports equipment

- Greenhouses, supports for grapes and flowers

- Furniture

- Car and motorcycle frames

- Door canopies, railings.

A pipe bending machine is used not only for deforming pipes, but also for bending squares and other rolled metal products. The use of this equipment is indispensable in cases where it is necessary to provide bending at an angle of up to 180 degrees. With a stronger bend, there is a risk that the workpiece may break, since cold metal has low ductility.

When using a pipe bender, you can make blanks of the same type. This is especially important if they are used for the construction of frame structures such as greenhouses.

Pipe bender Kinds. Device. Job. Application

A pipe bender is a machine designed for bending pipes made of various metals, including steel. The device ensures uniform deformation of the workpieces at the required angle. In this case, the pipe body bends smoothly, without the formation of folds. This is especially important if it is used to transfer liquid or gas, since the standard throughput is maintained. Pipes with a diameter from 5 to 1220 mm are subject to bending. Industrial-type machines are used to bend thick rolled metal.

Where used.

The machine is indispensable in construction and repair work. It is used for preparing pipes used for gas and water supply. It is also used to bend parts for the manufacture of frame structures, sports equipment, supports for grapes and flowers, furniture, car and motorcycle frames, greenhouses, door canopies, gazebos.

A pipe bending machine is used not only for deforming pipes, but also for bending squares and other rolled metal products. The use of this equipment is indispensable in cases where it is necessary to provide bending at an angle of up to 180 degrees. With a stronger bend, there is a risk that the workpiece will be broken, since cold metal has low ductility. In this regard, the vast majority of machines do not have a stroke range of more than 180 degrees.

When using a pipe bender, you can make blanks of the same type. This is especially important if they are used for the construction of a frame structure; such a pipe bender deforms pipes along a given radius. To prevent the formation of internal folds when bending the material, it is required that the length of the bend section be 3-4 times the diameter of the workpiece. Shorter processing results in a violation of the desired geometry and can cause thin-walled metal to tear or become corrugated. When using a pipe bending machine with welded pipes, there is a possibility that the seam will come apart. The maximum quality of bent products is achieved only with soft metals and seamless workpieces. To create a bend, the pipe is clamped in the machine, after which its arms are folded and an impact is exerted on its walls. The contact points are made in the form of rollers, so they easily roll around the perimeter of the workpiece, providing impact in different places. This prevents the formation of dents at pressure points. The number of rollers may vary. To adjust the bend angle of the tube, the design of pipe benders has replaceable nozzles, the so-called punches. The punch presses on the pipe, causing it to deform. The edges of the workpiece are blocked by roller stops, so it cannot move away.

A type of pipe bending machine.

The pipe bender is a popular tool that comes in various types. Some machines are designed for thin tubes, while others are designed for thick ones. According to the principle of operation, all pipe benders are divided into the following categories

- Manual

- Hydraulic

- Electrical

- Hybrid

- With induction heating

Manual pipe benders are used for processing thin workpieces. With their help, pipes made of stainless steel, titanium, copper, aluminum and brass are deformed. Compression with such a tool is carried out by exerting physical force on the operator. Such a machine is mobile and can be transported to the assembly site. To reduce the load on the hands of a person who uses a pipe bender, its mechanism is equipped with long levers.

The main disadvantage of such equipment is that it is unsuitable for performing a large volume of work. One operator gets tired after several deformations of workpieces and therefore cannot operate for long. If the manual type is used by a team of workers, then when changing operators, this drawback is not significant.

Manual pipe benders are the cheapest and lightest. They are maneuverable, so they are used by plumbers, gas workers and craftsmen involved in laying heating pipes. Using the machine, you can deform the workpiece locally, without the need to carry a large pipe to the workshop. The screw design of pipe benders is very common. When it is screwed in, the rod is pulled out, which deforms the workpiece. To make work easier, you can heat the pipe body at the bend with a gas cutter.

A hydraulic pipe bender is more efficient. It is designed for thick pipes with a diameter of 3 inches. Such a tool can be mobile or stationary. Its cost is higher than that of manual pipe benders. This is a powerful unit that is equipped with a hydraulic mechanism. Its presence eliminates the strain on the operator’s hands. Although this equipment is very powerful, it is relatively light in weight. Most of the models on the market can easily be taken with you to the pipeline assembly site.

Machines of this type can process large pipe diameters. The standard weight of machines used to deform thin pipes used for laying communications in homes is about 50 kg. Pipe benders, which are used for pipes 4 inches and larger, weigh from 500 kg. They are massive and take up a lot of space in the workshop. They cannot be installed under a wall to provide room for clamping long workpieces. According to the principle of operation, hydraulic pipe benders are similar to car jacks. The advantage of using this type of pipe bender is that it provides smooth deformation.

An electromechanical pipe bending machine is an expensive piece of equipment that has high deformation accuracy. These installations are in most cases stationary. There are portable models that only work with thin tubes and non-ferrous metals. Using a pipe bender of this type requires access to an electrical outlet. Considering the fact that in most cases these are stationary machines that are located in workshops, this is not a problem.

There are electric portable pipe benders on sale that are very compact and capable of working with workpieces with a diameter of up to 42 mm. In this case, the deformation range is 90 degrees. They can usually be found among private craftsmen who assemble greenhouses and other frame buildings that use relatively thin tubes. It is much easier to deliver a compact electric pipe bender and straight pipes to a construction site than to bend workpieces on a stationary machine in a workshop and transport arcs.

Hybrid types of machines combine different types of drives. Typically electric and hydraulic are used. These machines have high processing speed of workpieces, as well as high bending force. They are usually quite massive, so you will need at least two people to carry even the smallest models. To operate such equipment, access to an electrical outlet is required, which distinguishes it from purely manual and hydraulic pipe benders.

With induction heating. There are also pipe benders with induction heating. Their drive can be electrical and/or hydraulic. This equipment heats the workpiece at the point of deformation, after which bending is carried out. This prevents metal rupture. Using such machines, you can even work with pipes made of spring steel, which usually break when stretched or compressed. This equipment is the most expensive. When using it, you must strictly adhere to safety precautions. The workpiece is heated almost red-hot, so if you touch it, a burn is guaranteed. In this regard, it is imperative to have personal protective equipment, in particular gloves. If you are bending an old pipe with rust on the surface, then there is a possibility that hot scale may fly off during deformation, so it is advisable to use a mask or glasses. There is a risk of injury when working with a pipe bender. It is observed not only when using machines with induction heating, but also conventional installations. To reduce the risk of injury during operation, do not approach a bent pipe from the side from which it is being bent. If the guide slips, the workpiece springs back. As a result, the pipe may hit the chest or abdomen, hitting with high force. This is enough to break ribs, so ignoring this rule can have serious consequences. It is also possible that the shaft on which the roller is attached will simply fly off under the influence of pressure. If there is already force on the pipe to deform, then it cannot be held by hand. You can touch the workpiece only after the applied forces have been turned off. If the pipe bender can operate at different speeds, then you should not use the maximum one. Accelerated deformation causes the workpiece to break and its ends to fall to the floor, pinching the legs of the operator or people standing nearby. This is especially important if the pipe is long and heavy.

The principle of operation of the tool.

A pipe bender deforms pipes along a given radius. To prevent the formation of internal folds when bending the material, it is required that the length of the bend section be 3-4 times the diameter of the workpiece. Shorter processing results in a violation of the desired geometry and can cause thin-walled metal to tear or become corrugated. When using a pipe bending machine with welded pipes, there is a possibility that the weld may come apart. The maximum quality of bent products is achieved only when using soft metals and seamless blanks.

To create a bend, the pipe is clamped on a machine, after which its arms are folded and an impact is exerted on its walls. The contact points are made in the form of rollers, so they easily roll around the perimeter of the workpiece, providing impacts in different places. In connection with these actions, the appearance of dents at pressure points is eliminated. The number of rollers in machines may vary. To adjust the bending angle of the material, the design of pipe benders has replaceable nozzles, the so-called punches. The punch presses on the pipe, causing it to deform. The edges of the workpiece are blocked by roller stops, so it cannot move away.

How to prepare pipes

To get a high-quality result with a hydraulic pipe bender, you will need a little mathematics. It is necessary to take into account that such a fairly powerful device can damage pipes. This applies, first of all, to products characterized by the following ratio:

Sst/Din < 0.06,

where: Sst. – wall thickness; Din. - outer diameter.

For example, for a 20 mm pipe with a 2 mm thick wall, this figure is 0.1, which is quite acceptable. But a thin-walled (1 mm) pipe of the same diameter is not suitable for this condition, since the ratio is 0.05. If you use a manual hydraulic pipe bender, you will not be able to avoid fractures and jams in the walls of such a pipe product. You can avoid these troubles by filling it to the brim with dry and clean sand and sealing the pipe on both sides.

To prevent creases on a thin-walled pipe, it is filled with sand.

And one moment. Let’s say you don’t have a segment of the required size for the workpiece to be bent, but there are some for larger diameters. Installing an additional soft copper or aluminum insert between the segment and the pipe will help solve this problem. Its thickness is calculated using the following formula:

Svst = (Dpr.s. - Dt)/2,

where: Sst. – insert thickness; Dpr.s – diameter of the segment groove; Dt. - pipe diameter.

Consider the following example. There is a segment designed for pipes with a cross-section of 26 mm, and the workpiece installed in the manual pipe bending machine has a diameter of 18 mm. Substituting this data into the formula, we find that the thickness of the plate should be (26-18)/2 millimeters.

For manual hydraulic pipe benders, there are also restrictions on the minimum permissible bending radius - 4 pipe diameters. That is, a tubular product with a diameter of 20 millimeters can be bent to a minimum radius of 80 millimeters.

Manual pipe bender.

Used for processing thin workpieces. With their help, pipes made of stainless steel, titanium, copper, aluminum and brass are deformed. Compression with such a tool is carried out by exerting physical force on the operator. Such a machine is mobile and can be transported to the assembly site. To reduce the load on the hands of a person who uses a pipe bender, its mechanism is equipped with long levers.

Manual pipe benders are the cheapest and lightest. They are maneuverable, so they are used by plumbers, gas workers and craftsmen involved in laying heating pipes. Using the machine, you can deform the workpiece locally, without the need to carry a large pipe to the workshop. The screw design of pipe benders is very common. When it is screwed in, the rod is pulled out, which deforms the workpiece. To make work easier, you can heat the pipe body at the bend with a gas cutter.

Manual pipe bender Stalex TR-40

Voting for the best pipe bender

Which pipe bender would you choose or recommend?

Virax Eurostem II

0.00 % ( 0 )

TOR HHW-G76

18.75 % ( 3 )

Bison Expert 23522-H7

0.00 % ( 0 )

VIRAX 240233

0.00 % ( 0 )

Voll V-Bend

6.25 % ( 1 )

Stalex MHPB-1A HHW-1A

6.25 % ( 1 )

BLACKSMITH MB32-25

6.25 % ( 1 )

Smart&Solid BendMax-300

18.75 % ( 3 )

Blacksmith MTB10-40

37.50 % ( 6 )

Hydraulic.

A hydraulic pipe bender is more efficient. It is designed for thick pipes with a diameter of 3 inches. Such a tool can be mobile or stationary. Its cost is higher than that of manual pipe benders. This is a powerful unit that is equipped with a hydraulic mechanism. Its presence eliminates the strain on the operator’s hands. Although this equipment is very powerful, it is relatively light in weight. Machines of this type can process large pipe diameters. The standard weight of machines used to deform thin pipes used for laying communications in homes is about 50 kg. Pipe benders, which are used for pipes 4 inches and larger, weigh from 500 kg. They are massive and take up a lot of space in the workshop. They cannot be installed under a wall to provide room for clamping long workpieces.

According to the principle of operation, hydraulic pipe benders are similar to car jacks. The advantage of using this type of pipe bender is that it provides smooth deformation.

Hydraulic pipe bender STALEX MHPB-1A

General information

This instrument differs in its design by a number of features. It is thanks to them that it is possible to bend pipes, including metal ones, without any problems, giving them a given angular radius with minimal physical effort. Such equipment is divided into several types:

- manual pipe benders;

- hydraulic pipe benders. Models of this type can also be classified as hand tools;

- mandrel;

- spring.

But there are devices of other designs:

- electromechanical;

- segmental;

- crossbow

All of the above tools have positive and negative qualities, but each of them allows you to bend a metal pipe product with a round cross-section without significant physical effort and in a short time.

The easiest option is to go to the nearest specialized store, which has devices of this type in its assortment. But a person who has experience in making a wide variety of devices with his own hands will be able to create a manual pipe bender at home.

You can purchase a factory-made tool, but it is quite possible to assemble it yourself from scrap materials

Electrical.

An electromechanical pipe bending machine is an expensive piece of equipment that has high deformation accuracy.

This type of machine is in most cases stationary. There are portable models that only work with thin tubes and non-ferrous metals. On the market for this equipment there are electric portable pipe benders that are very compact and capable of working with workpieces with a diameter of up to 42 mm. In this case, the deformation range is 90 degrees. They can usually be found among private craftsmen who assemble greenhouses and other frame buildings that use relatively thin tubes. It is much easier to deliver a compact electric pipe bender and straight pipes to a construction site than to bend workpieces on a stationary machine in a workshop and transport arcs.

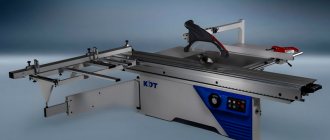

Electromechanical roll forming machine STALEX RBM50

Stationary pipe bender: step-by-step instructions

If you plan to make your own greenhouse from steel pipes, then you will need to acquire not just an ordinary pipe bender, but a reliable product.

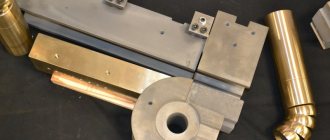

After all, with this approach you will need to bend more than a dozen profile pipes. To make the greenhouse design neat and beautiful, you need to use a stationary pipe bender. Before you start making a greenhouse, you need to make sure that you have the appropriate tool for bending profile products. The following elements will be needed to construct a stationary pipe bender:

- rod at 25;

- 6 bearings;

- channel.

You will also need a welding machine, which will be used to connect all the components. Step-by-step instructions for making a stationary pipe bender are as follows:

- Bearings are welded to the base (channel), which are connected to each other by a shaft in the form of a steel pipe of the appropriate diameter.

- To prevent the shaft from being located too close to the base, the bearings should be welded onto 5 cm pieces of rectangular pipe.

- In order to deliberately produce a unit with which the bending radius could be adjusted, the base must be made of two channels connected to each other by curtains, as can be seen in the photo above.

- Two shafts with bearings are located at the same height, and the third (central) is welded using a rectangular tube 15-20 cm higher.

- An additional tube needs to be welded to the upper shaft, to which the handle will be attached. This shaft will be driven by muscular force.

- The handle is welded to the upper shaft, after which the resulting product can be checked for functionality.

When installing a profile tube of any size, you should adjust the radius of the final bend. This can be done using a jack located under the base on which one of the shafts is fixed. Having adjusted the required bending radius, the handle rotates. The result is high-quality curved tubes. The advantage of a pipe bender is the ability to bend materials of any size and diameter.

Among the disadvantages, we can only note the possibility of operation in one place

It is important to understand that such a device can be used for any need. To manufacture such a device, an investment of no more than 500 rubles will be required.

You only need to buy 6 bearings, and all the other elements can be found in every craftsman’s household.

Hybrid.

Hybrid types of machines combine different types of drives. Typically electric and hydraulic are used. These machines have high processing speed of workpieces, as well as high bending force. They are usually quite massive, so you will need at least two people to carry even the smallest models. To operate such equipment, access to an electrical outlet is required, which distinguishes it from purely manual and hydraulic pipe benders.

Hybrid pipe bender

How to make a pipe bender with a pressure roller?

The material for the base of such a pipe bender is selected depending on the expected loads. Therefore, to make it, thick plywood or a sheet of metal is taken.

The holder for the pressure and central roller (template) can be made from a U-shaped metal blank. It should rotate freely around the central roller attached to the base. A lever in the form of a long handle is attached to the holder, and a stop is attached to the base.

For small workpieces, you can make a pressure pipe bender with your own hands for two different bending radii. To do this, the template must be made with rounded corners, each of which must have its own radius. The handle of such a tool should have two holes with which it can be removed and installed in another place.

With induction heating.

There are also pipe benders with induction heating. Their drive can be electrical and/or hydraulic. This equipment heats the workpiece at the point of deformation, after which bending is carried out. This prevents metal rupture. Using such machines, you can even work with pipes made of spring steel, which usually break when stretched or compressed. This equipment is the most expensive. When using it, you must strictly adhere to safety precautions. The workpiece is heated almost red-hot, so if you touch it, a burn is guaranteed. In this regard, it is imperative to have personal protective equipment, in particular gloves. If you are bending an old pipe with rust on the surface, then there is a possibility that hot scale may fly off during deformation, so it is advisable to use a mask or glasses.

Pipe bender with induction heating

Date of creation: 11/17/2020 12:46:16

Features of bending with a homemade tool

When bending pipes, you need to know the principles of the process and the diameter of the products. Then the correct deformation of the material without crumpling or tearing will be ensured. On machines that use hydraulics, bending with heating is possible. This allows you to bend pipes made of polymers, durable alloys, as well as products with a sufficiently large wall thickness. But in practice, at home, the “cold” method is more often used, aimed at working with pipe products made of plastic material - aluminum, copper, metal-plastic. However, it is possible to carry out bending from other metals with the exception of cast iron. In this case, in order to obtain a high-quality bend, before the deformation procedure, water (ice), oil, or salt or sand are poured into the pipe.

The minimum bending radii are indicated in the tables below: the first contains data for copper and brass pipes, and the second for steel.

Table 1

| Lmin | R | d | |

| 60 | 90 | 30 | |

| 55 | 72 | 24 | |

| 50 | 36 | 18 | |

| 45 | 30 | 15 | |

| 35 | 24 | 12 | |

| 30 | 20 | 10 | |

| 25 | 16 | 8 | |

| 18 | 12 | 6 | |

| 12 | 8 | 4 | |

| 10 | 6 | 3 | |

table 2

| D | R, if the wall thickness | |

| Exceeds 2 mm | Up to 2 mm | |

| 60-140 | 5d | — |

| 35-60 | 4d | — |

| 20-35 | 3d | 5d |

| 5-20 | 3d | 4d |

In the tables: L min - length (minimum) of the straight section; R – smallest bending radius; d is the diameter of the workpiece. The unit of measurement for all indicators is millimeters.

You can bend any pipes with a homemade pipe bender, but you need to take into account their diameter and the maximum possible bending radius