A pipe bender is a device using a mechanical or hydraulic operating principle for bending pipes, angles, rods and other metal products. It is possible to make a pipe bender for a profile pipe with your own hands, which allows you to bend most types of profiles.

There are several main types of pipe benders: volute, manual roller and jack. It’s more difficult to make hydraulic and electric models yourself, so let’s look at mechanical models.

Required Tools

To assemble a pipe bender, you need at least the following tools:

- welding inverter;

- angle grinder;

- lathe (or purchase of finished parts);

- vice;

- hammer;

- metal file;

- sandpaper;

- ruler;

- drill.

But the most important thing is the pipe bender drawings. The mechanism must be manufactured strictly according to the drawing. You can take a ready-made drawing from this material or find another one and adapt it to the required dimensions.

But it is impossible to make a pipe bender without a drawing, since precise calculations are needed to ensure the operation of the mechanical parts.

How to make different types of pipe benders

The principle of operation of pipe benders is different - you can influence a section of pipe in different ways. For example, a spring-type device will help deform polymer pipes due to pressure. Segmental devices will stretch them, giving them curvature.

The method of making a template pipe bender is accessible even to a beginner. To do this, you need to accurately draw a part of a circle of the required diameter (or other type of curvature). This hemisphere or other curve is drawn on a wooden blank, as in the photo of a homemade template-type pipe bender.

The resulting part must be fixed on a stable base along the plane (wall, table).

After the template stop is ready, you need to figure out how to use a pipe bender of this type. This is clear from the drawing - the pipe is secured between the template and the thrust beam.

By exposing the opposite end to a heated aluminum or thin steel billet, the desired bend is obtained. If it is necessary to obtain segments of different curvature, several suitable templates are made.

Materials for volute pipe bender

When making such a pipe bender with your own hands, the dimensions of the parts must be selected to suit individual needs, since this model does not have a specific working diameter. This is also an advantage, since it allows the use of available materials.

To assemble the structure you need:

- meter channel;

- Sheet steel;

- 3 shafts;

- 2 stars;

- steel chain;

- 6 bearings;

- a two-meter pipe with a diameter of 12.7 mm for the production of knobs;

- screw for clamping;

- bushing with internal thread.

Alternative options

As already mentioned, the proposed scheme with three rollers is one of the most successful, since it combines sufficient simplicity and efficiency. However, we offer you a few more diagrams and drawings of manual pipe benders.

The simplest template-type pipe bender is suitable for use only a few times. Although, of course, this depends on the materials chosen. The principle of operation is clear from the photo: a template cut out of wood or other material is fixed to the edge of the workbench, along which the pipe is “rolled” using a primitive clamping mechanism. It is advisable to carry out work with heating, since in a cold state it is not so easy to bend even a thin-walled pipe.

A collapsible template made from hooks is also possible.

By using a simple traction device - for example, a winch - you can reduce the level of manual labor and bend larger diameter pipes.

If you plan to use two rollers - the main one and the pressure one - you can use the mechanism drawing presented below. Interestingly, for copper pipes and rolled soft alloys it is more convenient to use wooden rollers.

The guide grooves of the rollers must correspond to the diameter and cross-section of the pipe being bent.

An example of such a mechanism, where a rectangular template with a rounded corner acts as a stationary roller, and the drive is a lever.

Interestingly, when using rollers - stationary and crimping - with a spiral profile, you can get not just a bent pipe, but a spiral from a pipe. This will be especially useful for those who want to make their own coil for a moonshine still?

A variation of the three-roll mechanism with a wheel instead of a handle makes it possible to use less force to pull the pipe through the device.

Manual pipe bender on a roller mechanism

Making a manual pipe bender on rollers with your own hands is somewhat easier, since there are fewer mechanical elements. The device allows you to bend pipes in certain places.

The device must have a long lever, since direct manual force is required to bend the products.

Clamping mechanism

Many craftsmen make a clamp from a regular car jack (mechanical or hydraulic). The forces that it is capable of creating are quite sufficient to give the metal workpiece the desired configuration.

greysv FORUMHOUSE user

I used an old gazelle screw jack as a clamping screw. Easily bends two 20x20 tubes.

If a hydraulic jack is used, it must be rated for 2 tons or more. The main advantage of a hydraulic clamp is that it can be operated without much effort. Advantages of a screw jack: it is easier for them to set the bending radius.

Instead of a mechanical jack, homemade screw clamps are often used. They also allow you to bend workpieces exactly according to specified parameters.

moning

Why is a screw worse than a jack? Order a screw with a smaller thread pitch from a turner so that less effort is applied when rotating. This will cost an order of magnitude cheaper than a jack.

Materials for making a roller pipe bender

To assemble the mechanism you need:

- 2 steel rollers 10 cm and 6 cm in diameter. Inner radius – 12.7 mm, thickness – 35 mm;

- 1.5-inch thick-walled (from 3 mm) steel pipe for constructing a lever (length from 1.5 m);

- 4 steel strips 15x6 cm, about 5 mm thick. The mechanism for fastening the device in a vice. Also used for the construction of handles and lever supports;

- steel strip 6 cm wide and 3 mm thick;

- 2 bolts – 60 mm 17.78 mm and 40 mm 12.7 mm. For fixing the rollers;

- steel plate 30x30 cm (thickness from 3 mm);

Manufacturing of rollers

To make rollers, you should look for reliable materials that have already passed the strength test. Some use rotors from electric motors of old washing machines or kingpins from a KamAZ vehicle, others use carbon steel circles. In fact, there are many options, the main thing is not to forget that the chosen material must be strong enough. User Dva11, for example, used wheel hubs from an old sprinkler installation.

Dva11 FORUMHOUSE user

Hub diameter – 75 mm, length – 110 mm, bearings were selected according to the hub (205 fit). I had to buy 5 bearings and 1 pulley, and made the rest of the parts from scrap metal.

Smooth cylindrical shafts are a universal option. They are used to bend pipes of various sections. If the profile of the shafts is brought into line with the profile of the pipes being bent, the quality of bending will noticeably improve.

You can also use blanks designed for different profiles of bent workpieces.

Ideally, removable nozzles or ring clamps (limiters) are installed on the shafts, with the help of which the profile of the rollers is adjusted to the width of the pipe.

rusi45 FORUMHOUSE user

I made some improvements to the design of the rollers: I made attachments for the pipe on the outer shafts, where the stops are located. Tests were carried out on a 1 inch pipe. The attachments are easy to replace. To do this, I made one side of the bearings sliding. The nozzle is made of steel 65G (plus hardening). There is virtually no wear, and the file does not take hardness.

The internal radius of the roller or nozzle for a round pipe should be made with a margin: the radius of the pipe plus 1-2 mm. For example, if the pipe diameter is 24 mm, then the internal radius of the roller will be 13-14 mm. Only in this case the pipe will not jam during rolling.

This is the size we are talking about.

If a pressure roller designed for bending rectangular pipes has a slight convexity in the middle, this will help maintain the geometry of the profile being bent. The roller will press the upper wall of the pipe inward, preventing the workpiece from spreading out to the sides.

Manufacturing a manual pipe bender on a roller mechanism

How to make a pipe bender with your own hands at home - step-by-step instructions:

Make 2 holes with a diameter of 12.7 mm and 17.78 mm at an interval of 80 cm (or other, based on your drawing). The frame has a 19.05 mm hole. Install the appropriate bolt into it and secure it with welding.

Weld a U-shaped part from 15x6 cm plates, a 12.7 mm bolt, a small roller and a 35x60 cm strip of steel. Pre-mount the roller using a bolt in the previously prepared holes. Weld the bolt to the plates. As a result, you will get a product that resembles a spear.

DIY fan: how to make a homemade powerful fan. Basic parameters and properties of fans (130 photos)- Why do you need a security alarm, what functions does it perform?

How to choose winter workwear and not make a mistake - recommendations from the pros

Weld a tube that acts as a handle to the base of the assembled part. Weld the pipe support strip to the base of the entire product. Between the bar and the main bolt there should be a distance equal to the radius of the main roller (which has a larger size according to your drawing) with an addition of 12.7 mm.

At the bottom of the base, weld a 15x6 cm strip, with which the structure is secured in a vice. Mount the main roller into the rod part. Place the latter on the main bolt and secure with a nut. Secure the device in a vice and test it in action.

Profile bender design

The machine for bending profile pipes is structurally different from the usual one. This is due, firstly, to the greater resistance of the profile to bending loads, and secondly, to the fact that the bending radius usually required is large. Therefore, the design contains three rollers. Two of them are installed permanently, one remains movable. Using a movable roller, the radius of curvature changes. In general, there are two types of pipe benders for profile pipes: with a middle movable roller and with an outer one (right or left, as desired).

You can make a pipe bender for a profile pipe in different sizes with your own hands

Pipe bender with middle movable roller

The two outermost rollers are fixedly mounted on the body. They are raised above the plane of the base. For the middle roller, a special U-shaped frame is welded. A long, large-diameter clamping screw is installed in the middle of its jumper. A third bead is attached to the lower end of this screw (can be welded). By rotating this screw, the roller lowers and rises, changing the bending radius of the profile pipe.

Design of a pipe bender for a profile pipe with a movable middle roller

A cloud is welded to one of the stationary rollers, with the help of which the pipe is rolled through the machine. To make it possible to apply less effort for rolling, two stationary rollers are connected using a chain. To effectively transmit torque, sprockets are welded to the rollers (possibly from a bicycle), and a chain is selected for them. This simple mechanism makes bending a profile pipe much easier.

With extreme movable roller

In this design, the right or left roller is made movable. It moves along with part of the base. This part is connected to the rest of the frame using powerful metal hinges.

Drawing of a bending machine for profile pipes with a lifting platform

You can change the height using a jack, as shown in the drawing. The height of the platform in this case is selected depending on the height of the jack. The bending radius is changed by lifting the movable part of the table.

Pipe bender for profile pipe with lifting platform

Unlike the previous design, this pipe bender for a profile pipe is driven from the central roller - a handle is welded to it. To reduce the required force, you can also weld the sprocket to two fixed rollers and transmit torque using a chain.

Jack pipe bender

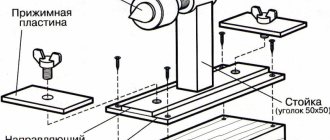

A simple and convenient device for bending profile pipes. For production you need the following materials:

- jack;

- 4 corners 40 cm long with equal shelves of 50 mm each;

- 2 rollers with grooves for belts. There should be through holes in the center. If they are missing, drill, measuring the middle;

- equipment for a jack in the shape of a semicircle with a recess inside;

- 2 channels 60 cm long and 10 cm wide;

- bed;

- 2 mounting bolts.

Methods for bending pipes using a homemade machine

The question of how to bend a profile pipe using a homemade pipe bender is unlikely to confuse you if you read a few more recommendations. Hydraulic machines can be used to successfully bend profile pipes made of different materials, as well as thick-walled products. This operation can be performed using either a cold or hot method, which involves preheating the pipe section.

Thus, a manual hydraulic bending machine can be used to influence the pipe in two ways:

- cold;

- hot.

Another variation with a jack

Cold bending is the simplest bending method, which is used for pipes made of plastic materials. The subtlety of this process is to fill the pipe before the flexible pipe with sand, salt, oil or cold water. This allows you to get a better bend without significant deformation of the pipe.

If you are interested in the question of how to properly bend a profile pipe with thick walls or made from materials of increased rigidity, then the answer to this question is to use the hot bending method.

Construction of a pipe jack bender

Weld the corners vertically onto the station. Make holes in the channels for installing rollers.

Weld channels onto the corners (2 corners - 1 channel). Place the channels with the platforms facing each other. The spacing between parts should correspond to the length of the rollers. Mount the rollers in the prepared holes and secure with bolts.

How to choose an air conditioner for your home or apartmentDo-it-yourself bait - composition, application features and storage methods (115 photos and videos)

DIY sliding gates - how to build simple and automatic gates. Schemes, drawings and review of the best ideas (90 photos)

Mount the equipment in the shape of a semicircle on the jack and place it in the central part of the base between the channel structures.

Next, lay the pipe at the bottom of the rollers and press it using a jack. As you press, the pipe will bend into the required position.

Crossbow pipe bender: step-by-step design instructions

The crossbow bender got its name because it resembles the shape of a hand crossbow. The cost of crossbow devices is about 10 thousand rubles. To save on the purchase of such a unit, it is recommended to make it yourself.

The photo shows two options for crossbow devices for bending pipes. The first option is a factory design, and the second is a homemade machine. The difference between these two machines is significant, since the factory version is made of steel measuring no more than 2 mm, while for the homemade one, metal 3-4 mm thick was used. This means that the homemade unit was made not just to have it, but for everyday use.

Feeling the difference, every master will want to acquire a crossbow pipe bender, making it himself. The disadvantage of this version of the pipe bender is the fact that it allows you to bend the corrugated pipe at only one point. This is due to the fact that the device is equipped with a fixed shoe. This option is used for round pipes when you need to obtain a certain bending radius in one place.

To construct such a device, you need a channel and a hydraulic jack. A special shelf is made for the jack in which it is installed. In the upper working part, two rollers made of steel pipe are mounted between two channels. The distance between the rollers and the heel of the jack must be the same in order to be able to obtain even and neat bends.

DIY pipe bender photo

Types of pipe benders and their design

The construction industry produces roll forming machines in a wide range. They are designed for processing rolled metal with various technical characteristics and solving specific problems.

Manual

Compact mobile devices are used for the manufacture of arc elements from small profile pipes. Hand tools work due to human muscular efforts.

Types of manual pipe benders:

- with a leading central shaft;

- with a movable outer roller;

- turning.

The design of a manual pipe bender with a leading central shaft consists of a base, two support rollers and one movable one. The impact is regulated by a pressure screw collar inserted into the upper part of the mechanism.

Roller pipe bender with clamping screw on the central shaft

The pipe is pulled through the shafts manually using a handle and a chain attached to the axles of the rollers. The pressure is increased by lowering the pressure bolt. The profile gradually bends and takes on the shape of an arc.

A manual profile bender can be equipped with a movable end roller. It is secured to a part of the frame connected to the frame with powerful hinges.

The lifting height is changed with a jack, raising the edge of the table. The handle for pulling the metal product is attached to the central fixed roller.

Pipe bender with a moving part of the frame

To produce steeply curved sections from pipes 20x20, 30x20 and 40x20 mm with a wall thickness of up to 1.5 mm, rotary manual pipe benders are used. They allow you to bend the profile up to 360°.

Rotary pipe bender

*

The device is mounted horizontally on a frame or table, and a metal structure is inserted into the groove of the required size. By turning the long handle, the profile is pressed around the template and a bend is formed.

Hydraulic

In such pipe benders, the force is pumped by a hydraulic motor. Hydraulic cylinders transfer pressure of up to 12 tons to the pipe section, which makes it possible to bend even large workpieces.

Hydraulic pipe benders are produced by industry in two versions:

- Manual. The pipe is inserted into a replaceable template of a suitable size - a support shoe, which securely fixes the product during bending. The hydraulic cylinder is activated by a handle and returns to its original position using a check valve. The tool is portable, used for processing profiles up to 50 mm in size.

Hand hydraulic tool

- Electrically driven. More powerful devices allow you to bend pipes with a cross-section of up to 150 mm and a wall thickness of up to 3 mm. The electric motors are equipped with two-stage telescopic hydraulic cylinders. Due to this, a large force is developed at the end of the working stroke.

Hydraulic pipe bender with electric drive

Hydraulic pipe benders have high productivity and process structures with high precision. To give the workpiece a given bending angle, there is a graduated scale on the device body.

Electromechanical

*

Electric roller professional profile bending machine is high-tech equipment for the manufacture of curved thin- and thick-walled metal structures. Allows you to automate large volumes of work.

Electromechanical pipe benders can be manual or stationary. The former are used for bending pipes with a diameter of up to 50 mm in conditions where power supply is available. The second are large machines with powerful engines installed in industrial workshops. They are controlled by operators via CNC.

Electromechanical CNC machine

The profile bend is formed by one or more shafts. Pipe benders are classified according to bending method:

- winding - the element bends when rotating around a stationary pulley;

- rolling - the curvature of the part is imparted by a movable roller, which presses it against the template as it passes;

- rolling - the profile is pulled through three rolls, two of which are stationary, and the third moves relative to the others;

- extruding - works like a crossbow, bends the workpiece with a retractable punch with an attachment made for a pipe of a certain size.

Steel profiles are most often bent using rolling machines, where the force is distributed more evenly.

In roller pipe benders, rolled products with a square or rectangular cross-section experience less deformation, at which the stability of the walls is maintained.