General design of an electric scooter

To understand how to assemble a scooter yourself, you need to understand its design. The structure consists of the following parts:

- Frame;

- Wheels;

- Electric motor;

- Controller;

- Accumulator battery;

- Brakes;

- Controls.

Deciding on the wheel size

Before you make an electric scooter yourself, you need to decide on the features of its design. Of great importance are the size and type of wheels (they can be cast or inflatable), the presence of suspension, the size of the dropouts for mounting the motor wheel and the location of the battery. The optimal wheel diameter depends on the quality of the roads you plan to drive on. The “micro” option is only suitable for rolling on tiles and good asphalt. “Mini” – allows you to overcome small obstacles on the way. "Midi" allows you to confidently ride at speeds of 40 km/h and above, without fear of small potholes. "Maxi" is perfect for those who like to drive on rough terrain and difficult roads. The suspension partially smooths out impacts. But there is a rule - a wheel can overcome an obstacle not exceeding 1/2 of its diameter.

Frame (base)

The easiest option is to take a frame from a factory scooter. The disadvantage of this option may be the additional load on the frame. After all, the weight of additional equipment will be added to the person’s weight. The undoubted advantage of this is its relative simplicity.

The second option is manufacturing, as they say, from scratch. The advantage of this method is that the device will take into account all individual wishes and characteristics.

For making your own frame, a square pipe with a wall thickness of 2-2.5 mm is suitable. True, here you will need additional skills for designing and calculating the base, skills in working with materials and tools.

We introduce an electric battery and automatic

The battery was wrapped with tape to provide better protection from moisture. It also makes sense to attach it to the deck using double-sided tape or Moment glue. Between the deck and the electric battery you need to install a gasket made of some dense material - it will be better! Our professor settled on a plastic folder for papers!

The automatic switch is the switch for the electric scooter, so without it there’s no way! In our case, it was glued to the electronic drive, but you personally can adapt this device anywhere.

Wheels

Wheels are divided by size into micro, mini, midi and maxi. The first have a size of less than 20 cm, the second - 20 cm, the third - from 25 to 30 cm, the fourth - more than 30 cm.

Note!

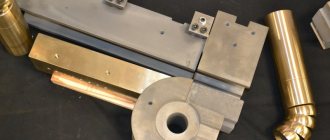

DIY induction heater ♨️ - reviews of the best manufacturing options. Varieties of homemade device designs + step-by-step master class (160 photos)

- Do-it-yourself Gauss cannon: TOP-130 photos of the best ways to create it yourself. Design features + master class for beginners

DIY clamps - a step-by-step master class for beginners. Schemes for manufacturing different designs + 170 photos

The choice of wheels to be installed on the scooter depends on its operating conditions. If you drive on smooth roads, then micro-sized wheels are suitable. An electric scooter with them will be light and compact.

If the roads are of average quality, with small cracks and unevenness or are paved with tiles, then the mini option is better. If you plan to move on poor asphalt or dirt roads, then it is necessary to install midi or even maxi size wheels. Inflatable wheels are also suitable.

Electric scooter made from a screwdriver.

There are a lot of interesting videos on the Internet, and while watching videos on YouTube once again, I came across a review of the RAZOR . I wondered how popular this type of transport is. After surfing the Internet, it turned out that this is a very common thing. Later, while relaxing on the Azov Sea in the city of Yeysk, I saw with my own eyes an industrial Chinese electric scooter with wide wheels with brake discs. Apparently those with large batteries and the charge lasts for 40 km. I was amazed by the powerful frame. A kind of small moped))))). The price of scooters is captivating. From 12,000 for a scooter with an electric motor power of 350W. But I didn’t stop there and found several articles on homemade electric scooters. I really liked the idea of a homemade electric scooter from a screwdriver and decided to create my own scooter from plywood. And I used some kind of Austrian screwdriver. It was a cordless drill/screwdriver with an impact and a 24V battery. I got it for free. Of course, it was scary at first, I had doubts whether the engine power would be enough to carry my 78 kg of live weight))), but it turned out to be so much that I couldn’t hold the scooter even when resting on the asphalt, the wheels began to slip.

I started making this miracle by assessing the size of the scooter by eye, placing my daughter’s children’s toys on the floor. Then I decided on the size of the wheels of the future scooter. As far as I remember, 140mm in diameter. I ran to the “Everything for the Garden” store and bought 2 wheels for 180 rubles each. Then I glued together several A4 sheets to mark the parts in real scale. On it I laid out the wheels, drew the base and depicted the entire scooter in profile, life-size. Then from it I transferred images of individual parts to other sheets and glued them onto plywood. And I cut out the details directly from them.

My design also includes 40x50 timber. It serves to strengthen the platform on which a person stands. Since the scooter is made of 8mm thick plywood, the platform is very long and carries a decent amount of weight. And besides, it lies flat, without reinforcement it will break even under a baby. It still sags a little at the edges to this day. There are plans to eliminate this, but at the time of writing, these are just plans. The timber was tested for strength in a barbaric way. He cut me the length I needed, placed one edge on the threshold of the bathroom, and the other on the floor. It turned out to be 2 support points on the sides. The middle was completely in the air. I took my little daughter and together we jumped as best we could in the middle of the beam. Not only did it survive, but it didn’t even crunch.

The steering wheel is made of a tube presumably of titanium origin, since aluminum and duralumin do not have such strength. At the end of the handle under the right hand there is a variable resistor responsible for the speed of the scooter.

A small board with a k561la7 microcircuit is soldered to the resistor at the back. I have a home-made shim implemented on it and it’s all located right in the steering wheel. But I used a 60A IGBT power transistor, since 3 IRFZ44Z field switches failed immediately)))). You will probably think that I forgot to install a reverse surge diode in parallel with the motor, but you would be mistaken if you think so. I can only guess that the transistors were knocked out due to direct voltage surges, since these field devices are only designed for 40 volts. It's difficult to shock them, I paralleled them. But I had a good IGBT, because it is designed for 600V. But one day, after gasping on the sand, it struck. At first I was perplexed, how did this happen? Could he really not withstand the current? But everything turned out to be more banal. My motor is not protected by anything, and a protective diode is soldered to its terminals. And then I noticed that this bastard had fallen off with one leg of the engine. I decided not only to move it to the board (for greater reliability, so that it would not fall off anymore), but also to change the control to a push-button one. After all, as practice has shown, it is not convenient to twist the gas while driving, this is not a motorcycle. Although maybe I just made an inconvenient gasulka. But the push-button one is more original and functional; I’ll attach dynamic braking to it. And in the future, create an on-board computer. After all, the MK will already be ready. Yes, yes, it is he who will be entrusted with controlling the IGBT transistor based on signals from the buttons. And also close the transistor before turning on the dynamic braking relay. I want to use a car relay; they have a fairly high switching current and are affordable.

In general, I only program PIC microcontrollers, but I have long wanted to try my hand at AVR. So the idea came to my mind to use the AT90S1200 I had lying around. Moreover, this is already an antique item. But at the time of writing, these are only plans. For now I will describe everything that is now.

I bought the batteries one-on-one with an uninterruptible power supply for 7A/H and 12V. Two pieces cost me 1400 rubles. These batteries are gel batteries. At one time, I read a lot about them before purchasing. The main selection criterion was that they can be charged at home without fear of harmful fumes. My homemade charger for a car battery turned out to be useful, because it is also automatic, and gel batteries really don’t like overcharging. I charge them with a current of 500mA. I have never ridden with fully charged batteries. But presumably they will be enough for 40 minutes of intense driving. I won’t say anything specific about the mileage either, but it is clearly less than we would like))). 10 kilometers is the limit. It’s a pity my smartphone died, at least check with GPS how fast it’s going.

Engine

A wheel motor can be used as a motor. It can be purchased separately or taken from a broken hoverboard. A motor from a cordless electric drill can also be used as a propulsion device. Some craftsmen use a screwdriver or a car radiator cooling engine as an engine.

Engine power is selected depending on the conditions in which you intend to drive. For children, it is better to take low-power engines. For driving at speeds up to 30 km/h, a motor with a power of up to 300 Watts is suitable.

For fast driving, you can use motors with a power of 350-400 watts. Such an engine will allow you to reach speeds of up to 40-50 km/h. It is important to consider safety issues here.

Assembly algorithm

The battery is assembled like this:

- the circuit is checked;

- the voltage and internal resistance of the cells are measured - it should be the same;

- the cells are connected in parallel in accordance with the diagram (to assemble the capacity) - they are placed in pairs in fireproof bags, observing polarity;

- power and balancing wires are connected to the batteries;

- to set the required voltage, the packages are connected to each other in series;

- the connectors are brought out using extension cords;

- a serial connection of balancing wires is ensured;

- the cells are tightly pulled together, placed in a large-diameter heat-shrink tube and packaged;

- if necessary, the assembled battery is placed in a case or box with pre-drilled holes for the wires to exit;

- BMS board is connected;

- wires are pulled out;

- a plug is attached at the top for recharging the battery;

- the holes are thoroughly sealed;

- The battery cable is connected to the controller;

- The battery is installed on the frame, trunk, deck or other place of the scooter.

Accumulator battery

The distance the scooter travels depends on the battery. There are several types of batteries: lead-acid, lithium polymer, lithium ion, lithium iron phosphate. The former are known for their use in motorcycles and cars. They are heavy and have a small number of charge-discharge cycles compared to other types.

Note!

DIY rocking chair: TOP-120 photos of the best manufacturing options. Master class on creating a rocking chair at home

Smokehouse from a gas cylinder - the best master class on making a homemade smokehouse with step-by-step photo diagrams for beginners

- Do-it-yourself compressor: TOP-130 photo reviews of finished compressors. Step-by-step instructions + diagrams and drawings

Polymer and ionic are the most suitable in terms of weight, technical characteristics and price. For lithium-polymer batteries, the number of discharges and charges is up to 800, for lithium-ion batteries – up to 1000 cycles. Both types are lightweight and dependent on ambient temperature. In cold weather the discharge occurs faster. In addition, there is a danger of fire or explosion when overcharging.

The lithium iron phosphate battery is not afraid of mechanical damage, is resistant to low temperatures, is not afraid of overcharging and has up to 2000 charge-discharge cycles. But it is heavier and more expensive than polymer and ion batteries.

You can buy a ready-made battery pack, or you can assemble it yourself, for example, based on 18650 batteries. Which one to use depends on personal preferences and available resources.

Battery installation is done in different ways. Can be installed below in a platform called a deck. This option is preferable as it does not raise the center of gravity. But in this case, additional protection against impacts and mechanical damage is required.

Another location for installing the battery is the steering column. There, either a hanging container is made, or installation is carried out in a rack if it is made of several pipes.

Note!

- Do-it-yourself wind generator: TOP-170 photo reviews of finished devices. Detailed DIY instructions for beginners

- Do-it-yourself spot welding - the best master class on making homemade spot welding with step-by-step photo diagrams of do-it-yourself work

- Do-it-yourself tennis table: TOP-150 photos of the best manufacturing ideas. Master class on creating a tennis table at home

No matter how the battery is mounted, it must be protected from moisture. Waterproofing of a self-made electric scooter is carried out using electrical tape, sealants, and the manufacture of moisture-proof covers.

Assembling an electric scooter with your own hands should develop according to the following scenario:

1. The place of the rear fork should be replaced by an expanded part and an MK should also be introduced there.

2. The next step is to assemble the body, and for this we will use an aluminum profile.

3. Next, we organize fastenings for the cover on which we will stand while driving.

4. Making a lid.

5. We adapt the controller and accelerator handle.

6. We install an electric storage device and an automatic machine.

7. We connect all the components.

Next, a detailed description and images will be presented, which will enable the “inventor” to understand the entire process at an accelerated pace. The owner of the described device has been using his creation for three years and during this period, he was tormented by frame play and for this reason, Kulibin decided to make the scooter non-folding, reinforcing the structure with thicker bolts in those places where the play made itself felt.

In addition, several housings and electric batteries were changed on the homemade product in three years, so it was necessary to adjust everything to the holes already made before. My advice to you: first bend the side ribs, figure out what will happen where and only then start drilling the necessary holes - this way you are more likely to get everything straight!

Controller

The controller is, one might say, the brain of the engine. How the scooter will ride and its acceleration at the start depends on it. Selected according to engine parameters. If the motor consumes 36 V, then the controller must be 36 V.

The power is selected taking into account the reserve for the starting load and forced movement. As a rule, a reserve of 2-2.5 times the current is taken. That is, if the motor has a power of 300 Watts, then its rated current is 8.3 A (300W/36V). This means the controller must withstand up to 21A.

Making a lid

The element was made from an aluminum profile using metal shears. But to remove the excess internal ribs of the lid, we will need pliers: we kind of clamp the edge of the rib and begin to rotate the tool - the rib being processed should easily be screwed onto the pliers. It will be just great if you glue the inside of the product with film, and in our case, a paper folder was used.

Control

The scooter controls consist of a power switch, gas and brake handles. It is better to make gas in the form of a hook, because it is safer. In case of an unforeseen situation, such a handle is instinctively released.

The brake handle must be equipped with a switch that will turn off the engine when pressed.

Now let's look at a few instructions on how to make an electric scooter using different engines.

Making a connection

When connecting all the equipment, you need to make sure that the wires are not pinched anywhere and do not rub against the metal.

Here he is - our handsome man!

Conclusion

That's all! Our homemade electric scooter made from a regular scooter is ready for use! Of course, the master who built this vehicle, as they say, is on point, but this does not mean that you will not succeed in exactly the same way, and maybe even better!? Before starting the process, carefully weigh the pros and cons, and only then get down to work. Naturally, it will be very good if someone knowledgeable in such events helps you.

So, feel free to try your own execution options - it worked for others, it will work for you too! Do not worry!

With a hoverboard wheel

It's enough to make a scooter using a broken hoverboard. Such a device will look quite aesthetically pleasing. In addition, it will have good technical characteristics.

The manufacturing scheme for an electric scooter from a hoverboard is as follows:

- Take one motor-wheel from a hoverboard;

- If we use a frame from a finished scooter, then make a fork to attach the rear wheel under the wheel from a hoverboard. If we make the frame ourselves, then we immediately take into account the fastening;

- Install the motor controller;

- Install the battery;

- Install the throttle handle and the power button.

After installing all the parts and elements, we check the functionality and use it for your pleasure.

Let's remember our skills

Finally, after much painful thought, you came to the conclusion that purchasing an expensive item is not for you! What is the further course of events in this case? First, check your skills: you must be able to use a soldering iron well and operate a screwdriver, that is, make neat holes in metal using this device.

So, if you love to design and don’t see any obstacles to realizing your ideas, follow the tips below and you will succeed without any doubt.

Using a screwdriver

One of the simple options is to make an electric scooter with your own hands from a screwdriver. In this way, it is unlikely that you will be able to make a powerful and high-speed scooter. But this is undoubtedly the most accessible and cheapest option. For this you will need:

- Screwdriver;

- Regular scooter;

- Bicycle chain;

- Bicycle sprocket;

- Wires.

The sequence of actions is as follows:

- A bicycle sprocket is rigidly attached to the rear drive wheel.

- A small drive sprocket is made of metal, which is clamped into a screwdriver.

- A screwdriver holder is made from square pipes or corners.

- The holder is attached to the frame using bolts or rivets. The holder must be attached in such a way that it is possible to adjust the chain tension.

- The bicycle chain is measured and cut to size.

- A control button is attached to the handle.

This option is good because you don’t need to place the entire device next to an outlet to charge.

The battery is simply removed from the screwdriver and placed in a standard charger. There is also no risk of fire or explosion of the battery from overcharging.

We are installing the controller and accelerator handle

In principle, everything is clear with the gas handle, but the controller needs to be removed from the aluminum case and sealed with tape. For the device under discussion, the owner purchased an Infineon 6 FET controller, but for its successful implementation, it was necessary to file down the textolite so that it could adequately fit in its rightful place.

There is also a budget class controller Bafang 500W. It is made in a small case that has three speeds and the possibility of recovery, and it consumes 14 A from the electronic storage device. However, its main advantage is that the product fits into our deck, albeit without a case - there is no need to finish it.

A hole is made in the side of the deck, and there are holes in the controller’s radiator through which it is possible to fix the device using this very hole.

The niche with the wires and the controller must be covered with a lid. To make the lid, sheet plastic will do; in our example, it was made from a laptop, and specifically from the lid of its matrix.

As for the throttle, in our time there are no problems with this - we purchase the most suitable modification and calmly move the equipment to its rightful place.

Recommendations

Making an electric scooter with your own hands is not a very complicated process, it is creative and interesting. On the Internet you can watch a video on how and what you can use to realize your idea.

As a result, it is possible to make a device of an unusual design with outstanding technical characteristics. There may be mistakes and failures along the way. It is worth noting that a homemade version may not always be cheaper than a factory one.

It all depends on what materials and parts to use. However, repairing a do-it-yourself electric scooter will definitely be easier, because you will know all the parts and components.

And you yourself are responsible for their reliability. After all, if you repair a scooter purchased in a store yourself, this may void the factory warranty.

When making an electric scooter, it is important to consider such points as frame strength and engine power. Its rated voltage and current. Select the correct controller and battery based on engine parameters.

It is necessary to protect the battery pack from damage. It is also worth taking care of the moisture protection of all electrical elements and connections to avoid short circuits. You should refrain from using an electric scooter in rainy weather.

What do you want from your vehicle?

First of all, we decide what exactly we need? A bulky device equipped with inflatable wheels, offering its owner a high level of power, with the ability to cover considerable distances, while wrapping asphalt around the wheels? Or a lightweight folding design that can be carried with one hand without much strain and used for commuting to work, and for other places, such as a fitness club, bypassing stuffy and sometimes infrequent public transport?

Here is an example with a folding design. To bring our plans to life, we will need a folding scooter with a rear shock absorber. The product will need to change the rear fork to a wider one and, in addition, adapt the MK there. Naturally, you will need to purchase a controller, as well as a battery, integrate all this wealth into our homemade self-propelled gun and, of course, connect it correctly.

We choose a scooter for our transformations. You won’t have to tinker for a long time, since the choice is extremely scarce. Previously, the ubiquitous Chinese developed a scooter frame equipped with a two-suspension system and on its basis, manufacturers began to assemble various modifications of scooters and it is this “cart” that we will need.

The more expensive the structure, the better its quality, in theory. A folding frame with a suspension mechanism cannot please the user with reliability in principle, but we don’t really have a choice.

An electrified scooter will “delight” its owner with the same misunderstandings as an ordinary unit, so you need to prepare for these troubles in advance. An electric scooter's moving components will also become loose, creak, and make noise.

The more moving parts your device has, the more carefully you need to monitor them. This rule applies equally to both purchased folding scooters and those created by hand. Why then do we give preference to a gadget with a suspension? And then, first of all, the rear fork and wheel need to be replaced.

DIY photo of electric scooters

Balancing a scooter battery

When using any circuit with a series connection of cells, balancing is required - equalizing the voltage of individual battery cells. This is necessary to improve the operating safety of the battery, increase its operating time on a single charge and extend its service life. Cell imbalance slowly but steadily leads to battery degradation. This problem is successfully solved by the use of a balancing cable and balance systems.

Balancers are part of the charge controller boards and equalize the voltage of individual cells. Correct voltage balancing is one of the important conditions for efficient and safe operation of the battery. New balancing technologies provide control of the condition of each cell and help avoid dangerous situations during battery operation. Balancing is not required only in the case of exclusively parallel connection of batteries.

What is needed for the remodel

If you want to make your bike electric, you will need to do your research thoroughly.

Firstly, you will need detailed instructions on how to assemble an electric bicycle with your own hands. You need to understand exactly how difficult it is and how long it takes.

Secondly, you need to determine what is needed to assemble an electric bike. Let's look at a set of parts that will help recreate the desired unit:

Electric motor. It must be suitable for this purpose. If you take the cheapest of them, you will get a low-capacity engine that constantly needs to be charged frequently.

If you take a model with low power, the speed will not please you at all. Therefore, it is not worth saving on such a detail.

Electric battery. Its capacity must also be large enough so as not to be left without transport due to the rapid discharge of the battery.

Controller. This part is also important, because it ensures the interaction between the battery and the engine. Of course, you can buy a wheel motor or all-electric drive, which will save you time on assembly.

Precautionary measures

When assembling a lithium battery for an electric scooter yourself, it is important to be careful and careful:

- Do not heat, deform, puncture batteries, drop or squeeze them;

- Reverse polarity, overcharging, short circuit must be avoided;

- If the battery or charger gets too hot, stop using it;

- It is permissible to use only cells of proven quality, without signs of damage, for battery assembly.

If you do not have enough knowledge and experience, it is better to buy a ready-made battery for an electric scooter or have it assembled by experienced craftsmen. In this case, you will receive a battery of guaranteed high quality, without the risk of accidental flaws during its assembly and problems during operation, in addition, you will save your effort and time.

Read our previous article about the types of bicycle forks, their design and operating principles