The era of electric tools did not come with the first electric drills, but when the electric motor became an attribute of a narrower tool: scissors, hacksaws, impact wrenches and, of course, jigsaws.

Moreover, the jigsaw became one of the first in this series. Today it is one of the most popular tools in the home (and not only) workshop. And first of all, we are talking about hand tools.

But in this article we are considering jigsaw machines, and these are practically stationary devices that often have their own specific place in the workshop, because for comfortable work they require a base with given parameters: height, so that the hand placed on the work table has a bend at the elbow of 90º and stability to dampen vibrations of the machine itself.

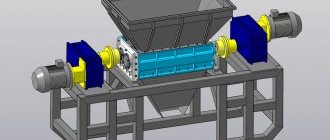

What does a jigsaw consist of?

All variations have the same configuration, and, therefore, a single set of components and what is worth remembering when deciding to make a jigsaw:

- File;

- Tire-connecting rod type assembly;

- Drive unit;

- A special device that allows you to tighten the files;

- Working surface or bed;

- Additional mechanisms (optional).

Main characteristics of a jigsaw

Remember that any option must comply with the established parameters:

- The optimal size of a work surface or table should be between 30 and 40 centimeters. The smaller size is not convenient for processing parts, the larger one represents industrial designs;

- The drive power is equal to 150 Watts. This is the most real value that can belong to a structure made at home;

- The rotational force imparted to the saw is transmitted using a special mechanism. It has a complex name - crank mechanism. Its main task is to change the rotation into a special reciprocating motion;

- The file has a certain vibration limit of one minute. This figure should be between 800 and one thousand movements per minute;

- Jigsaw files have a number of features. The file also has a limit on vertical movement - it should not exceed five centimeters;

- Most models have a speed control function, this allows you to perform work more efficiently and adapt to the different technical qualities of the material with which you interact;

- A jigsaw has a limit on the parameters of the material with which it works. So a manual jigsaw should work with plastic and wood, whose parameters do not exceed ten centimeters in thickness, and the length of the product is not more than thirty-five centimeters;

- Each material (be it plastic or wood) has its own saw. The width of the saw on average can vary from two to ten millimeters;

- Smooth operation is ensured by the tension mechanism.

Note!

- DIY induction heater ♨️ - reviews of the best manufacturing options. Varieties of homemade device designs + step-by-step master class (160 photos)

Do-it-yourself Gauss cannon: TOP-130 photos of the best ways to create it yourself. Design features + master class for beginners

DIY clamps - a step-by-step master class for beginners. Schemes for manufacturing different designs + 170 photos

While studying all the features of jigsaws, remember that there are exceptions to the rules. These are industrial designs and variants intended for small-sized figurative work. Most often, their first difference is their high cost.

Files used

The saw blade is the main working element of the machine, with the help of which the process of sawing workpieces occurs. Their design is radically different from the files mounted on manual electric jigsaws. They have a thinner and more flexible thread-like structure.

Externally, such files are similar to the blades used on manual jigsaws, but they have one difference - special slots are installed on the flat ends for more convenient fixation in the cams of the machine.

In addition, they are classified according to the shape of the teeth. Depending on this they distinguish:

- standard;

- blades with missing teeth;

- files with double teeth;

- blades with reverse teeth;

- spiral;

- saw blades with crown teeth.

Each of them performs its own specific function and allows you to perform different types of cuts. The most commonly used blades are those with standard teeth.

What is the difference?

Each species has its own nuances and advantages over its neighbors. So options with a lower support are the most popular in everyday life. They are the vast majority. The lower frame has several functions at once - a controller, a motor, a main gear, and a button to turn the device on and off.

Models with two (upper and lower) have their own significant advantage. The top has a rail, which is additional to the design. It copes well with cutting small parts and point work. It is important to remember that for this type the thickness of the material during work cannot be more than eight centimeters.

Variations on the suspension do not fix the frame stably. But their advantage is mobility. In this case, the material being processed is fixed and does not move, and the jigsaw itself moves with the help of an attachment behind the master. This variation makes it possible to create very complex and subtle patterns.

The scale and stops are necessary for carpentry masters who work exclusively from drawings. Markings prevent inaccuracies.

Note!

- Do-it-yourself electric scooter - a master class with step-by-step instructions for doing it yourself. Tips and simple patterns for beginners + the best photo reviews

- DIY rocking chair: TOP-120 photos of the best manufacturing options. Master class on creating a rocking chair at home

Smokehouse from a gas cylinder - the best master class on making a homemade smokehouse with step-by-step photo diagrams for beginners

Working with a tabletop jigsaw

A jigsaw, like a hand tool, allows you to work with wood, plywood, thin plastic or plexiglass. Homemade products made using this device are distinguished by high accuracy and complex shapes. Using a jigsaw, holes for sockets are cut out in wooden panels, and materials are cut into shapes.

When working with a jigsaw, you need to protect your eyes.

There are a number of rules used when working with this tool:

- Do not apply excessive force to the material. The saw must cut at optimal speed, otherwise it will not be possible to avoid breakage of the blade or the entire tool.

- For different jobs you should use blades of different widths. For example, for long, even cuts, a wide file is used.

- For cutting thin materials, a plywood backing is used. This way the future product will be protected from damage.

- It is necessary to use eye protection, as during operation the jigsaw throws a large amount of small sawdust into the air.

- When working with sheet plastic, the saw speed should be set to minimum. At high speeds, the material overheats, causing it to begin to melt.

- When cutting round holes, first make a small hole in the plywood with a drill, after which a saw blade is threaded through it and secured in clamps. Rectangular holes are made according to the same principle, but right angles are not cut out immediately. To begin with, they are made rounded, and after passing the saw along the entire perimeter, the remaining triangular fragments are cut out.

- To prevent the plywood from vibrating when working with it, the material must be held securely with both hands, pressing it against the table. It is important to ensure that no sharp turns of the material occur during cutting, otherwise the saw may simply jam and break off. In places where there are turns, the plywood should be held in place for a few seconds, giving the tool time to expand the space for action, and then move on.

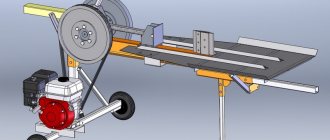

How to make a jigsaw with your own hands?

The easiest option is to make a machine. A homemade jigsaw is probably a better solution. There are a great many variations and drawings, they are easy to find on the Internet. This is all a consequence of the desire to create a unique and inimitable instrument. However, the operating principle will always be absolutely the same.

Step-by-step instruction

To create a jigsaw with your own hands, you don’t need to have superpowers:

- We make a work table that will serve as a support. For this you need a sheet of wood or metal. Lay the size of the base, which will be approximately four times the size of the saw;

- At the bottom of the support we attach the factory device. Cap screws can be used for fastening;

- The structure is mounted on a table.

The trick is that a manual jigsaw is cheaper, but it’s more convenient to work with it on a stand. This will avoid unevenness and shifts when working with the material.

A do-it-yourself jigsaw is a real help for single people who have no one to hold part of the element being cut.

Review of the most popular models

There is a huge selection of stationary jigsaw machines on the domestic tool market, each of which differs in power, depth of cut, set of additional functions and, of course, cost.

It is sometimes difficult for an unprepared person to choose a model that fully meets his requirements. To make this task easier, we have prepared a review of the 3 most popular models presented today.

JET JSS-16

Stationary jigsaw machine of household class. Used for cutting wood products, fiberboard, chipboard and plastic. The body is made from high quality structural steel, powder coated to protect against corrosion. Small dimensions and weight allow it to be used in confined spaces.

Design features allow the use of saw blades with and without pins. The convenient location of the web tension regulator on the frame allows you to quickly tension it. In addition, the designers provided the possibility of fixing the saw blade in several planes, which greatly facilitates the process of cutting workpieces.

For greater convenience, the machine is equipped with a smooth adjustment of the number of saw blade strokes and a system for cleaning the surface from sawing waste.

Specifications:

- manufacturer – Jet;

- model – JSS-16;

- The homeland of the brand is the USA;

- country of origin – China;

- class - household;

- maximum cutting depth, mm – 50;

- power consumption, kW – 0.09;

- saw blade length, mm – 127;

- saw stroke frequency, stroke/min – 1600;

- maximum workpiece width, mm – 406;

- dimensions, mm – 680x340x385;

- warranty, months – 12;

- weight, kg – 13;

- price, in rubles – 16,500.

| Advantages | Flaws |

| universal saw blade mount | not detected during operation |

| desk tilt adjustment | |

| good performance |

Dremel Moto-Saw (MS20-1/5)

Universal electric jigsaw. Designed for figure cutting of wood blanks and its components. The metal body, coated with powder paint, ensures durability of use. The uniqueness of the tool lies in its small size and the possibility of its use as a stationary machine and as a hand tool.

The light weight and dimensions allow the machine to be conveniently placed on any workbench. The surface of the work table is equipped with graduations for more precise cutting of workpieces. Additional convenience is created thanks to the function of quick replacement and tension of the saw blade.

Main technical characteristics:

- manufacturer – Dremel Moto-Saw;

- model – MS20-1/5;

- The homeland of the brand is the USA;

- country of origin – Taiwan;

- class - household;

- maximum cutting depth, mm – 18;

- power consumption, kW – 0.07;

- saw blade length, mm – 100;

- saw stroke frequency, stroke/min – 2250;

- dimensions, mm – 470x370x130;

- warranty, months – 12;

- weight, kg – 4.6;

- price, in rubles – 9,999.

| Advantages | Flaws |

| small dimensions and weight | small cutting width |

| possibility to use the machine as a hand tool | |

| special cutting precision |

How to improve the design?

Of course, a manual jigsaw is not perfect, but it can be modified and brought to perfection.

- A rocker is being made. This type of structure will be tensioned using springs on one side and secured to the file on the other.

- We fasten the file between two rollers. Their function is to be guides.

- We use a factory jigsaw as a drive. A file is pulled between it and the rocker.

Note!

Do-it-yourself compressor: TOP-130 photo reviews of finished compressors. Step-by-step instructions + diagrams and drawings

Do-it-yourself wind generator: TOP-170 photo reviews of finished devices. Detailed DIY instructions for beginners

Do-it-yourself spot welding - the best master class on making homemade spot welding with step-by-step photo diagrams of do-it-yourself work

How to use a sewing machine?

It's hard to believe, but it can also be converted into a jigsaw. How can this idea be brought to life?

- We remove the part that ensures weaving of threads (the lower part of the machine).

- We remove the cotter pin and drive shaft.

- We remove the upper part, which protects the mechanism from mechanical damage.

- We expand the part for the needle for the file.

- Let's modernize the file. The file should not be longer than the needle.

Such a device perfectly replaces a jigsaw for shaped work on plywood and will become a homemade jigsaw that can surprise all your friends and acquaintances.

It allows you to create even the most complex patterns and turns. However, this design has its drawbacks:

- The leg may get tired from working with the pedal;

- Vibrations may occur that complicate work.

If it is not possible to purchase an expensive design, you can get by with small losses. A jigsaw - a machine made independently can be an excellent solution. The main thing is to follow the instructions exactly when working and conscientiously fasten all the elements together.

Consider a table base so that it becomes a reliable support for the mechanism. It is important that the table does not rock or vibrate when the mechanism is running.

The more static all elements are in the end, the easier it will be to work, avoiding unnecessary movements and mistakes. And mistakes in such a matter are most often not acceptable.

A slight change in the angle or position at which you work, and the part may not fit into place or lose its shape. In any carpentry, the most important thing is the accuracy and measuredness of all actions.

A homemade jigsaw machine with your own hands is not such a complicated story as it might seem at first. After studying the article, understanding the basic elements and how to create your own tool, you can get to work.

It is worth noting that very often such a homemade machine is much more convenient than a purchased one. This saves money, but most importantly, this table is personalized. It will perfectly suit your workplace, your height and weight.

Such a design will fully meet the objectives, because the most convenient mechanism can be created only by the person who will use it in the future. In addition, in case of minor breakdowns, it will be clear how to repair and what can be fixed.

For a purchased sample, you will have to look at the instructions and study forums in search of a specific model and its characteristics. Have fun creating, and let the new jigsaw give you confidence and the desire to start a new renovation!

Video description

The process of replacing equipment in a jigsaw with a jig saw is shown in the video:

If in quick-clamp fasteners the file is automatically fixed in the desired position, then in jigsaws it needs to be controlled, which for many is a noticeable disadvantage, as it takes time. In addition, it is important to correctly determine the degree of tightening of the bolts. If you clamp too hard, the blade will be very tense and may break. And if it is weak, it will fall out or dangle in the socket, and working with a jigsaw will become impossible.

The second problem with such fasteners is the abrasion of the slots on the bolts during intensive work and frequent replacement of saw blades. Often the threads of the fastener or block break and cracks appear on its body. This mainly happens with tools made in China from low-quality materials. A damaged pad cannot be repaired, it can only be replaced.