The tool, which is popularly and professionally called a bolt cutter, is rarely used for cutting bolts. Essentially, this is a tool designed for cutting any metal rods of various diameters. Much more often it is used not for bolts at all, but for cutting reinforcement, rods and similar building elements.

However, the word “rebar cutter” found on some websites and catalogs is too artificial from the point of view of the Russian language. There is another name - hydraulic shears. By using a well-known name, you can count on the understanding of your interlocutor.

Manual bolt cutter: capabilities of a special purpose tool

A bolt cutter is a specialized tool that is designed for cutting reinforcement and other metal products. According to the principle of operation, it is similar to wire cutters or scissors, but has a reinforced design. The tool is widely used in construction, industry, everyday life and rescue operations, which determines the choice of product type. The most popular is the manual bolt cutter, which is the subject of this article. Metal shears: manual, electric, tools overview (read more)

A bolt cutter is designed for cutting bolts, fittings, wires and other metal products.

Characteristics and types of bolt cutters

A bolt cutter, reinforcement shears or pin cutter is a special-purpose tool that is designed for cutting metal products in the form of reinforcement, bolts, steel cable, wire, chain, rods and other workpieces.

Manual bolt cutters are equipped with lever mechanisms.

The operating principle of the device is based on the concept of a double lever mechanism. The working part of the tool consists of two blades, one of which has a sharp edge, and the second is dull. A metal blank is clamped between them. As a result of the influence of human muscular force, electric or hydraulic drive, the product is cut into two parts.

The bolt cutter is characterized by a wide range of actions. It is used in industry, construction work, and everyday life. The tool is a necessary device for rescue operations, since it is used to clear passages and unblock rubble.

Depending on the method of influencing the shear blades, a distinction is made between hydraulic and mechanical bolt cutters.

A mechanical or manual bolt cutter is often used in everyday life to perform a small amount of work, since it has limited productivity, which is determined by the physical capabilities of the person who drives the lever mechanism.

The hydraulic bolt cutter is characterized by its large size and extended range of action, since its capabilities are not limited by the operator’s strength. The cutting mechanism is driven by a hydraulic cylinder, in which a special fluid is pumped under pressure.

The effectiveness of a bolt cutter largely depends on the physical strength of the master.

Characteristics of bolt cutters

To select the correct equipment, you need to be guided by its main characteristics. These include:

- maximum diameter of the cut rod;

- working force on jaws;

- ability to quickly change blades;

- the presence of an additional grip for reliable holding of the rod;

- minimal backlash;

- type of drive;

- adjusting the gap between the blades;

- handle shape.

Before choosing a specific model from all the variety on the market, it is wise to outline the range of operations that you plan to perform using the device.

The type of drive is determined by the location where the bolt cutter is used.

Manual drive gives maximum autonomy and allows you to save on purchases.

However, its power is limited. The electric drive does not have these restrictions, but requires connection to the electrical network. Battery units combine the advantages of the first two types of drive, but are very expensive, and their power drops noticeably as the battery discharges.

Often, when there is a need to organize mobile work, a networked bolt cutter and an electric generator are used.

Manual bolt cutter: features of the tool

A manual bolt cutter is similar in appearance to ordinary wire cutters, but it is larger in size. As can be seen in the design drawings, a manual bolt cutter consists of the following elements:

- two handles 20-1150 cm long with cut ends, which are covered with rubber or polyurethane nozzles;

- double-arm cutting mechanism. When compressed, the tool handles act on the auxiliary arms, which transmit force to the cutting edges;

- pairs of cutting elements (jaws) with a sharp edge, which are made of hardened steel and sharpened at a certain angle;

- a return spring, which helps return the tool to its original position;

- an adjusting screw with a lock nut, with which you can change the position of the jaws depending on the diameter of the workpiece being processed.

On a note! The longer the mechanical reinforcement shears, the more powerful they are and, accordingly, require less effort to carry out the work.

Manual bolt cutter Zubr.

The main advantages of manual rebar shears are their light weight, size, mobility of the device, independence from the energy source, the ability to be used under water and affordable cost.

A significant disadvantage of the tool is the use of human muscular strength, which may not be sufficient to achieve the maximum technical capabilities of the bolt cutter.

Technical and operational capabilities of manual bolt cutters

The length of the tool’s handles determines its technical capabilities, namely the diameter of the element being bitten. The standard provides options with lengths of 350, 450, 600, 750 and 900 mm, designed, respectively, for products M12, M16, M24 and M30. The last three versions of the tool are reinforced. Devices with handle lengths of 200-300 mm are considered pocket-sized. Various options can be seen in the photo of bolt cutters.

The operational capabilities of the tool depend on the shape of the cutting part. There are straight and angled mechanical bolt cutters. The first type of tool, in which the handles and cutting jaws are straight, is more in demand.

An angle bolt cutter is used for working in hard-to-reach places because it has inclined blade parts located at an angle of 25-35 degrees to the cutting plane.

Using rebar shears, you can cut steel bars of various diameters.

The position of the jaws is selected using a sliding thrust plate, which is fixed in the seat and secured with a pin. This tool has a special option that allows you to install the cutting elements in an inverted position. Angle bolt cutters are often used in rescue operations when dismantling metal structures.

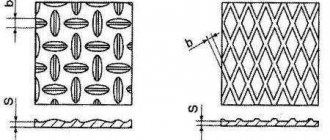

There are bolt cutters with flat attachments, thanks to which the tool can cut strip metal into elements of the same length, carrying out the so-called flash cutting.

On a note! It is best to purchase a mechanical bolt cutter with the ability to change jaws, which will allow you to replace worn elements, or expand the capabilities of the tool using straight, flat or angled attachments.

Operational Capabilities

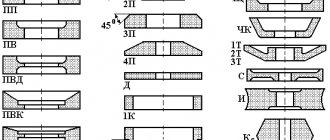

The capabilities of the device are determined by the size of the bolt cutter, or more precisely, the length of the handles, the design of the lever system and the shape of the blades. The operating principle and mechanical design of a bolt cutter has not changed for centuries, since the optimal design has been found. The use of high-quality steel for the handles allows us to somewhat reduce mechanical losses due to their bending and increase the useful force of the bolt cutter. The main increase in capabilities comes from improving the shape of the blades. Replacement attachments, which are supplied with both manual and hydraulic shears, are of the following types:

- Corner. The cutting plane is inclined at 24-35° to the axis of the rod. In the place where the rod is grabbed, a special plate is placed for a stop, which has the ability to slide. It can be secured with a pin after the bar is securely grasped. For ease of cutting in hard-to-reach places, the nozzle can be rotated 180° relative to the longitudinal axis.

- Flat. Specialized for cutting metal sheets. Equipped with a template to facilitate cutting strips of equal width.

- Centrifugal. The movement of the blades is symmetrical and equidistant from the surface of the rod. This is a standard attachment; bolt cutters with non-replaceable blades are made using the same design.

Universal nozzles are most effective when cutting reinforcement.

Working principle of hydraulic bolt cutter

A hydraulic bolt cutter, or hydraulic shear, is equipped with a hydraulic cylinder instead of a cutting drive. It is driven by hydraulic force, cutting rather than biting the workpiece. In this case, one blade remains stationary, and the second quickly moves relative to it. Among the advantages of the tool is its high productivity, which allows you to cut through fairly thick metal workpieces, while it requires minimal effort from the worker.

Hydraulic rebar shears.

Based on the type of drive, a hydraulic bolt cutter can be manual, electric, or equipped with an external pump.

The manual hydraulic bolt cutter is equipped with one rigidly fixed handle. The second handle acts as a lever. The tool is put into operation by pumping the moving element, like a pump, up to 10 times, due to which the blade is compressed. When the lever moves, the piston moves inside the cylinder, creating pressure that causes the cutter piston to move. Such manipulations require minimal effort from a person.

Hydraulic shears have a sharpened moving part, and the fixed part is presented in the form of a sharp-edged plate.

The manual hydraulic bolt cutter has increased power. It is capable of cutting through steel workpieces with a diameter of up to 18 mm.

Hydraulic bolt cutter: proper care and maintenance

A hydraulic bolt cutter is much more powerful than a manual one. It requires special care and periodic maintenance. Before starting use, you must carefully read the instructions. In addition to operating rules specific to a particular model, there are general recommendations:

- Before switching on, you need to carefully inspect the device and make sure there are no mechanical damage, insulation damage or leakage of hydraulic fluid;

- the jaws, lever mechanism and rod must be free of foreign objects and debris;

- handles must be clean and dry;

- It is unacceptable to try to cut a bar with a larger diameter than indicated in the passport data. this will lead to overload and possibly failure;

- Do not use non-standard devices that are not included in the delivery kit of the bolt cutter or the list recommended by the manufacturer;

- The rod to be cut must be inserted between the jaws, carefully fixed there and only after making sure that the grip is secure, apply full working pressure.

When finished, clean all parts of the bolt cutter and unplug it. Particular attention should be paid to the lever mechanism, jaws and hydraulic cylinder rod. If dirt or cutting debris gets on it, it can cause the bolt cutter to fail. Hydraulic shears should be stored in such a way as to prevent access to them by children and unauthorized persons not trained in safe operation techniques.

Technical characteristics of bolt cutter KVT 67657

The main parameter is the force of the hydraulic cylinder. It is 5 tons. The light weight of the bolt cutter is 2.3 kg and the length is only 29 cm, allowing you to work with it for a long time without getting tired.

- Packaging dimensions, cm: 35×16×8.

- The maximum diameter of the cut rod is 12 mm.

Advantages of bolt cutter KVT BRG 12 67657

The main advantages of the device are:

- high hardness of the metal blades (52-54 units);

- fastening of parts without play;

- convenient system for changing cutting elements;

- possibility of quick release of working pressure;

- convenient and ergonomic plastic case for storing the device itself, replacement blades and care accessories;

- reinforced C-shaped working head.

High-quality hydraulics make the device easy to use. They can cut both hardened bolts and reinforcement with a diameter of up to 12 mm

Hydraulic Electric Bolt Cutters

Hydraulic reinforcement shears, equipped with an electric drive or pump, belong to the professional class of tools. They are heavier and bulkier than manual versions. Such powerful scissors are capable of cutting through a workpiece made of carbon steel with a diameter of up to 32 mm, and of alloy steel - up to 20 mm in a matter of seconds. The main disadvantage of such a tool is the need to connect it to the electrical network.

Hydraulic bolt cutter with electric drive.

On a note! There are models of electric bolt cutters that are equipped with a self-contained battery, which allows you to use the tool in areas where there is no access to an electrical outlet.

Electric bolt cutters are equipped with a hydraulic pump that forces fluid into a hydraulic cylinder. The tool, powered by an external stationary hydraulic power station, is characterized by maximum power and performance. This type of hydraulic bolt cutter is used in large-scale production. It is connected to the pumping station using a high pressure hose.

On a note! A hydraulic powered bolt cutter often comes with interchangeable cutters of different types, which provide it with versatility.

Popular models

In the segment of manual hydraulic shears, models mainly made in Russia and China are presented. Foreign samples are quite specific and are not widely used in Russia, including due to the high price.

KVT BRG-22

Leader in the domestic bolt cutter sector. If this rather exotic class of instruments comes across in a store, it will most likely be represented by one of the models from the Kaluga plant. The older model “bites” reinforcement up to 22 mm, there are also younger models with a maximum of 12 and 16 mm. The developed force reaches 12 tons. The model is packed in a plastic case and has replaceable jaws.

Ryabinin Rodion, 39 years old, Vladivostok

I bought hydraulics after I lost my manual one. The handles remained intact, but the incisors were finished. I ordered online for 22 at once, with a reserve, the price difference is not critical for me. It cuts the fittings properly, I cut the bolts on the locks a couple of times. I tried it purely as an experiment - it cuts a 20-piece corrugated one easily, you just have to pump it for a long time, but I didn’t take the risk on hot metal, I was afraid of damaging the jaws.

Budaev Semyon, 44 years old, Ulan-Ude

I took these scissors mainly for rope and occasionally cable for work. I’ll say right away: it’s inconvenient to cut the cable, the wires spread out, because the blades are flat, not round, and crawl towards the cutting edge. You still have to buy a cable cutter. But the rope only pulls this way. The iron on them is quite soft, but still 16 - 18 mm is not a problem, it is clear that there is a reserve not only according to the passport.

KVT NGR-40

Also products from Kaluga, but with a slightly different specification. It is intended more for cables; in reality, they do not cut bolts, although it is possible. The developed force is 7 tons, can cut up to 20 mm of low-carbon cylindrical workpieces. But it takes telephone cables up to 40 mm; the crescent-shaped cutting parts are convenient for multi-core cables.

Arzhantsev Nikolay, 48 years old, Moscow

I work in the communications industry and often have to deal with cable installation. When you take out the old Soviet weaving on the highways, they baffle you. You can't do without a good tool. Mostly everyone here uses KVT, and I bought one for myself too, especially for multi-core ones. And the rod also bites, I remembered it when I was knitting reinforcement for the foundation of the bathhouse. It takes a long time, but you don’t need any effort, you sit and pump and that’s it.

TEHRIM 812010-12

This compact tool in a compact box is designed for small diameters - up to 12 mm. It copes with the task well, and most importantly, it is compact in size. Convenient to carry in the car “just in case”, for occasional use.

Alexey Nosov, 27 years old, Rostov-on-Don

I had a funny incident. I usually park my car in the yard. One morning I go downstairs and see: there’s a heavy lock hanging on the handle of the back door, and there’s a paper tag on it that says “I’m selling keys” and a phone number. Well, I think, wait a minute. I ran home, brought my Tehrim, threw out the lock in a minute and left without any problems.

IEK TLK10-50

IEK is widely known for its electrical products. In addition, we decided to produce a corresponding installation tool. Clamp-type hydraulic shears are suitable for cutting cables as well as steel ropes and fittings. The assembly is in China, but the acceptance of a large holding company is quite strict, there are no obvious defects.

Pervushin Alexander, 34 years old, Kursk

Recently I was in a large construction supermarket, stocking up on machines and cables. I saw this bolt cutter nearby, the correct name is hydraulic shears. I decided to take it to work and home. The assembly is good, nothing leaks anywhere, the tool itself is heavy. For the experiment, I cut off a rusty 18 mm pin, it went like clockwork, there were no marks left on the blades. I will test further.

Tor HHG-16

Chinese bolt cutter without any frills, with a force of 10 tons, for rods with a diameter of 4 to 16 mm. Everything is simple and concise: C-shaped, replaceable jaws, pressure relief valve. Although the stated characteristics are a little overstated, the low price justifies the purchase of the device.

Mamin Evgeniy, 57 years old, Syzran

I was sawing the reinforcement with a grinder, and by some miracle, scale flew into my eye, right under the lower edge of my glasses. They pulled me out to the traumatology department, I suffered through so much, I thought I was going to lose my eye. After being discharged, when I returned to normal, I gave up on everything, went to the store and bought this bolt cutter. Now I cut rebar in peace and quiet. And the disc doesn't bite.

How to choose a bolt cutter: basic recommendations

The choice of the type of bolt cutter is primarily determined by the scope of its further use. For domestic needs and work on a personal plot, where it is necessary to cut rods with a cross-section of up to 8 mm, it is enough to purchase a standard mechanical end pocket model. For workshops and garages, it is better to choose a manual hydraulic bolt cutter, the price of which will depend on its technical capabilities.

Household bolt cutters are capable of cutting through rods with a diameter of up to 8 mm.

On a note! It is better to purchase hand tools with some margin in the thickness of the pieces being bitten, which will not only increase its functionality, but will also require less effort when biting a large number of elements with a diameter below the maximum possible for a given product.

The next factor is the value of the maximum cross-section that a bolt cutter can cut through. In manual models, this is determined by the length of the handles.

Before buying high-quality reinforcement shears, you should pay attention to the following points:

- there should be no gap between the cutting jaws when the handles are closed;

- tools with hollow tubular handles have a short service life, since the handles quickly bend;

- handles and hinge mechanism must be made of tool or chrome-molybdenum steel with induction hardening;

- it is better to purchase a tool with removable cutting elements, which will increase its functionality and durability;

- the optimal price-quality ratio must be observed, since models that are too cheap are rarely good.

Before purchasing a bolt cutter, you need to familiarize yourself with its technical characteristics.

Device selection

When buying a bolt cutter, you need to be aware that the device must correspond to the tasks that the owner plans to solve. Since in private farming there is most often no need for fast work and large flow volumes, the best option would be a hand-held hydraulic tool with compact dimensions.

Most of these models are structurally simple and have the ability to change cutting jaws in case of wear. The hydraulic mechanism itself is very simple. When purchasing, you should pay attention to the presence of a pressure relief valve, which will allow you to return the tool to its original position.

Expert opinion

Torsunov Pavel Maksimovich

Full autonomy also speaks in favor of a manual unit for cutting reinforcement. You can use the bolt cutter in any conditions, including away from electrical sources. Due to their simplicity, there is practically nothing to break in such units.

Rules for the safe use of bolt cutters

Before you start working with the tool, you should check the integrity of the structure. All elements must be rigidly fixed. The lever mechanism and cutting elements must be free of debris and foreign objects. Handles must be dry and clean.

When working with the tool, you should wear personal protective equipment: overalls, shoes, gloves, goggles or a face shield. The workpiece is inserted between the cutting jaws and carefully fixed. The tool must be held at a certain angle to the reinforcement. After making sure that the grip is secure, you should apply working force to the handles. The biting process must be carried out slowly, without haste, making sure that the cutting jaws do not come off the workpiece. After completing the operation, ensure that the bolt cutter is in its original position, preventing it from moving.

Note! When purchasing replacement cutting elements for bolt cutters, you should choose original spare parts.

When dismantling suspended structures, it is important to take into account the possibility of them falling after cutting and creating a traumatic situation, so it is recommended to additionally secure them.

Note! You should not cut through a metal workpiece with a diameter exceeding the rated value, as this may lead to its breakage.

When working with a bolt cutter, you must wear goggles or a mask and other personal protective equipment.

After completing the operation of the manual bolt cutter, all its elements are cleaned from contamination. After which the mechanism and blades are lubricated with a special product. The tool should be stored in a dry, ventilated area.

Using bolt cutters on the farm

In the household, devices are used:

- for cutting sheet and strip metal as powerful metal shears;

- for dismantling building structures made of metal and reinforced concrete;

- for cutting reinforcement to size from standard 6-meter bars when independently preparing for pouring a concrete foundation or other building structures;

- for cutting chains, cables, locks where the keys have been lost or the cylinder mechanism has failed.

Bolt cutters are also used by intruders to illegally enter locked premises containing valuables. The use of such technical means leads to the reclassification of simple theft into burglary.

There is a wide range of devices on the market - from lightweight household models with handles up to 30 cm long. They can bite the chain or shackle of a small lock, or 6-mm fittings. More serious semi-professional models with handle lengths up to 90 cm and replaceable jaws can be configured to work with various materials - from 18 mm reinforcement to strip metal.

Replaceable jaws have another advantage - if they wear out, they can be replaced instead of buying a whole bolt cutter.

Review of mechanical bolt cutter manufacturers

The market offers a wide range of mechanical bolt cutters from domestic and foreign manufacturers. The following companies have proven themselves to be the best in this segment.

One of the world's best manufacturers of bolt cutters is the German company StailerMaster. The cutting elements are made of a special alloy, which ensures the strength and durability of the tool, which can be purchased at a price of 1000 rubles.

Manual reinforcement shears from the Chinese manufacturer Matrix have the optimal price-quality ratio. The price of bolt cutters varies between 600-1500 rubles, depending on the capabilities of the tool.

The domestic manufacturer Zubr has proven itself well. It offers quality household hand-held bolt cutters made from special alloy steel with forged connectors and dielectric handles. The minimum cost of the tool is 750 rubles.

Rebar shears from the Matrix brand.

Tools from the Russian company Techmax are in great demand. It specializes in the production of various modifications of mechanical and hydraulic bolt cutters. The price of reinforcing shears starts from 800 rubles.

Advantages over competitors

A hydraulic bolt cutter can cut through metal rods!

And there are not so many devices with which you can cut a thick metal rod. The most common is an angle grinder or grinder.

No doubt, it copes with the task, but the rebar shears have a couple of aces up their sleeve:

- Complete energy independence (for manual hydraulic models).

- The cutting edge wears out much more slowly than the cutting disc.

- No sparks or scale, the workpiece does not heat up.

- The risk of injury is minimized compared to an angle grinder.

- Relative noiselessness (models with a pump also make noise, but less, and at the factory no one will cut workpieces manually with an angle grinder).

Expert opinion

Torsunov Pavel Maksimovich

All this provides the bolt cutter with its niche in everyday life and in production.

The best models of manual rebar shears

One of the best manual bolt cutters is the Jonnesway P4314 model. The cutting edges are made of hardened steel, which provides them with increased strength and resistance to stress. They have locking ridges that absorb shock when biting stubborn products, ensuring a smooth cut. The bottom of the heads contains an additional cutter, which is used for cutting cables.

Ergonomic handles are made of impact-resistant polymer. They have special recesses that facilitate comfortable and secure holding of the tool in your hands. The length of the bolt cutter is 350 mm. The tool is designed for cutting rods, cables, and wires with a diameter of up to 7 mm. The cost of a bolt cutter reaches 2.5 thousand rubles.

A good helper in everyday life will be the KVT BR-600 bolt cutter, which is designed for cutting metal elements with a diameter of up to 10 mm. The cutting part is equipped with chrome-molybdenum blades, which are characterized by increased hardness, elasticity and resistance to corrosion. They are sharpened at an angle of 30 degrees. Thanks to thin steel handles with non-slip pads and a built-in return spring, comfortable work with the tool is ensured even over long periods. You can buy a manual bolt cutter BR-600 for 2.2 thousand rubles.

Manual bolt cutter KVT BR-600.

The manual bolt cutter Topex 01A118 is popular among consumers. The working part is made of chrome vanadium steel, which provides it with increased strength and resistance to high mechanical loads. The cutting jaws are additionally induction hardened, which eliminates the possibility of corrosion. Thanks to the ergonomic shape of the handles, they are comfortable to grip and hold during operation. To prevent the tool from slipping out during operation, their ends are equipped with rubber pads.

The price of a manual Topex bolt cutter is 950 rubles. The length of the tool is 450 mm. It easily copes with biting reinforcement and rods with a diameter of up to 8 mm.

Rating of professional bolt cutters

The rating of the best professional manual bolt cutters opens with the Norgau N177-42 model. The tool features forged chrome-molybdenum steel cutting heads and tubular arms with ergonomic handles for comfortable grip while working.

The length of the bolt cutter reaches 1050 mm. It can handle workpieces with a diameter of up to 19 mm. Using cam screws, the parallelism of the edges can be adjusted, which contributes to better tool performance. The cost of such a bolt cutter starts from 11 thousand rubles.

Professional bolt cutter Ridgid S36.

A good professional model that has received many flattering reviews is the Ridgid S36 bolt cutter. The tool length of 950 mm allows you to cut through wire, bolts, fittings and other metal products of varying degrees of hardness with a diameter of up to 14.3 mm.

The special design of the thin working head allows you to bite the bolt at the very base. The cutting elements are made of hardened alloy steel, making them durable, load-resistant and durable. Non-slip grips on the handles ensure ease of use, which guarantees precise cutting. The tool is equipped with a cam mechanism that facilitates quick alignment of the knives. The price of a bolt cutter is 12.3 thousand rubles.

The Kraftool Red JAWS 1-23290-105 model, 1050 mm long, is noteworthy, capable of cutting through metal products of varying degrees of hardness with a diameter of up to 14 mm. The cutting jaws are made of alloy steel, which provides them with increased wear resistance and corrosion resistance. Depending on the diameter of the workpiece being processed, the position of the cutting edges can be adjusted using a special pin.

Note! Thanks to the double lever mechanism, easy and accurate cutting of large cross-section elements is ensured.

Professional reinforcement shears Kraftool Red JAWS.

For reliable and comfortable holding of the tool during operation, the ergonomic handles are equipped with rubberized pads. You can buy the tool for 8.8 thousand rubles.

A good craftsman should have many different useful tools in his arsenal. One of them is a bolt cutter, which comes in different types of products. In order for the tool to meet the stated requirements, it is important to choose the right model, depending on the conditions of its further operation. The durability of the device will be ensured by proper handling and proper storage conditions.