Questions about self-healing

The problem in many cases is complicated by the lack of complete information about repair techniques. According to foreign manufacturers, after the saw has exhausted its service life, it must be taken out of service, so the maintainability of many models at the budget level is a reasonable doubt.

It is more difficult to restore professional grade chainsaws.

- The problem is complicated by the high cost of spare parts.

- It is possible that special equipment will be required to restore the efficiency of individual components and mechanisms, in particular, for adjusting fuel equipment.

Replacing expensive branded spare parts with affordable but short-lived Chinese analogues is not economically justified. Practice shows that these components produce a resource of 50-60% at best.

Summing up

Having sufficient experience, the setup is completed in 5-10 minutes. Provided all carburetor parts are in good working order, the adjustment process should not cause any difficulties. If something is faulty in the carburetor, then you won’t be able to adjust it, no matter how hard you try. To do this, before making adjustments, you need to eliminate all faults.

I will write about what kind of malfunctions there are, how to find and fix them, in the next article about repairs, provided that this is of interest to you. Therefore, if the article helped, rate it and write in the comments below whether the second part of the article is needed. Thanks to all.

Fault detection algorithm

The cause of saw failure or deterioration in its efficiency may be:

- The suction of the fuel tank cap is clogged;

- Air intake of the carburetor due to destruction of the gasket or loosening of threaded fasteners;

- Mechanical jamming of removable dust equipment and other minor defects.

Before disassembling, make sure that major repairs are required.

Most likely, you will not be able to assemble a new chainsaw yourself after repair with original quality. The design of modern chainsaws often uses press fittings for burning parts, which have minimal repairability.

Even a partial analysis of a chainsaw using a convenient tool can lead to undesirable consequences. In most cases, disassembly may be limited to the removal of one unit or system.

This list includes:

- Connecting rod and piston group;

- Carburetor;

- Clutch mechanism;

- Sprocket drive chain

Necessary tool

The fundamental structure of this element is the same on all modern chainsaws. However, the technical execution differs, so different brands and models may require different tools.

To remove the clutch on all chainsaws you need:

- A screwdriver for removing the locking ring of the gear cover from the shaft,

- Depending on the model, you will need a regular wrench to unscrew the centrifugal mechanism itself (drum), or a wrench with two cotter pins, like the one used to tighten the nuts on an angle grinder.

- The stopper is required in order to fix the flywheel shaft (crankshaft) on which the centrifugal mechanism is screwed.

The crankshaft is locked by securing the piston in the cylinder using a soft metal rod or knotted rope.

It is not advisable to use hard metal; it can damage the piston. Weak materials such as plastic should also not be used. They can break, crumble and get into the cylinder windows, carburetor cavity or crankcase. Then you will need to completely disassemble the engine to get them out, and these are unnecessary problems.

Compression recovery

Less complex piston repair. To disassemble the cylinder, simply remove the threaded fasteners and place the saw on its side to prevent damaged compression rings, piston skirts or other foreign objects from entering the crankcase.

The cylinder bore wears unevenly, so installing a new piston does not have a significant effect. Typically, during a major overhaul, after checking the suitability of the crankshaft, a kit consisting of a cylinder, piston, compression ring and piston pin is installed.

What do you need to adjust the Husqvarna carburetor yourself?

To correctly adjust the carburetor of a chainsaw, you need to stock up on the appropriate tools in advance.

You will need the following list:

- The most common screwdriver used to unscrew or tighten the adjusting screws;

- A tachometer designed to count crankshaft revolutions. It is necessary when setting the idle speed, since it is quite problematic to determine the number of revolutions per minute by ear;

- Phillips screwdriver. It is needed to be able to unscrew the screw (T);

- A compressor with a special gun connected to it. A purge device will help get rid of excess debris and dirt, since the carburetor must always be clean.

Startup Recovery

Disassembling the starter to replace the cord is not a problem for an experienced user, but the plastic housing is in most cases beyond repair. The range of Chinese chainsaws is mainly a copy of the most popular European models, so we disassemble Chinese chainsaws according to the standard scheme.

Worn parts of the dust collector cannot be repaired.

- At home, you can shorten the new chain to fit on a shorter bus.

- The resource of proprietary bus components is equal to the resource of three dust circuits.

- This figure can be significantly reduced by incorrect chain pitch selection or excessive wear on the drive sprocket crown.

Finishing work

On some models, the engine controls, start lock and emergency stop system are displayed on the handles up to the point where the operator's hand engages. It is recommended to assemble the chainsaw handle after first cleaning the contacts of all electrical and mechanical communications.

Self-assembly of a chainsaw is a part of repair work that requires special attention. The success of the final result is ensured by the correct sequence of operations, sufficiently high quality of parts, gaskets and other consumables.

Source

Video: How to Disassemble a Chinese Chainsaw

It would seem, why would an elderly resident who grows vegetables and fruits, or the owner of a country house who has a small garden and several flower beds, need a chainsaw? The question disappears when the desire arises to build a bathhouse, repair a greenhouse, demolish an old business, or simply make a bench for relaxation. Unfortunately, any mechanism must be periodically prevented and parts replaced, and for this you need to understand the design of the device; in addition, repairing a chainsaw with your own hands will save time and money.

Starter problems

The starter fails quite often. In this case, repairing the Partner 350 chainsaw with your own hands must begin with the following: unscrew the side cover, which is located next to the gearbox. The starter for the presented saw is located near the engine. In order to inspect this part, the air damper is first removed.

Next you will need to disconnect the carburetor. The starter in this model is connected to the throttle. To separate them, you need to use a screwdriver. If carbon deposits are visible on the starter, this part will have to be completely replaced. In this case, the usual modification is installed, and finding it in the store will not be difficult. However, it is best to purchase spare parts for the Partner 350 chainsaw in specialized workshops. After replacing the starter, all that remains is to screw the throttle back on and install the carburetor with a cover.

Structural elements of chainsaws

All chainsaws are similar in structure, regardless of whether they are made in Europe (ECHO, Stihl, Husqvarna) or at home (Cedar, Urals). The main elements are located inside the body - the fuel tank and the engine, and outside - the starter, handle, part of the saw ( tires) with chain. A sharp tug of the cable starts the motor and it is the saw blade.

To begin with, we suggest you familiarize yourself with video clips that show how a chainsaw works and how it works:

From time to time, saws develop malfunctions that require disassembly. What can happen to such a simple mechanism as a chainsaw? At least the following:

- Stops starting;

- It starts but soon stops;

- It ceases to function in context;

- Loses strength;

Most problems are related to engine failures (fuel system, exhaust system, ignition, piston part of the cylinder) or failures of other systems and components (clutch, chain brake, tire, lubrication system). Let's look at the most common faults and how to fix them.

READ DIY Chain Sharpening Template

The working chainsaw starts with one jerk and does not cut

Replacing the connecting rod mechanism

The connecting rod mechanism of the Partner 350 chainsaw is quite complex. Its malfunctions are often accompanied by loud engine operation. It should also be noted that when the connecting rod mechanism breaks down, the carburetor often fails. In this case, it is more expedient to start repairing the Partner 350 chainsaw with your own hands by inspecting the ignition module. You will also need to fully check the coupling. In particular, the condition of the centrifugal clutch deserves attention.

In order to inspect it, you need to remove the top cover. The clutch itself in this model is located near the carburetor. To get to the centrifugal clutch in the saw, the flywheel is removed. Next, the carburetor head is disconnected

In this case, it is important not to damage the fuel system. The centrifugal clutch is bolted on

This part can be disconnected using a key. If cracks are visible under the cylinder, then the clutch will have to be replaced. However, some experts advise not to rush into this. If the cracks are shallow, you can try to grind the surface a little with a file.

Checking the ignition system

The first thing to do when your chainsaw breaks is to check the spark plug by disconnecting the wire and carefully tightening it with a special wrench.

Components of the chainsaw ignition system: 1 - flywheel with magnets, 2 - ignition module, 3 - spark plug, 4 - high-voltage wire

Unscrew the spark plug to check its condition.

Her appearance speaks volumes:

- Dry. Most likely, the fuel mixture is not getting into the cylinder. This is not an ignition system, so the spark plug screws back in.

- Heavily filled with fuel. The reason for the excess fuel mixture is either a violation of the starting rules or an incorrect carburetor setting. The spark plug is thoroughly wiped, the fuel supply is turned off, and the starter is engaged to remove excess fuel and ventilate the combustion chamber. Then the spark plug is put back in place and the mechanism is restarted.

- It was covered in black soot. This may indicate the use of poor quality oil, an incorrectly adjusted carburetor, or an incorrectly calculated ratio of gasoline to oil. The candle should be washed, cleaned of carbon deposits using a sharp object (an awl or a needle), wipe the electrodes with skin and put them in place.

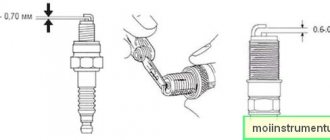

When checking the spark plug, you need to pay attention to the gap between the electrodes: from 0.5 to 0.65 mm is considered normal. Damaged or worn gaskets must be replaced.

A large amount of black soot on the spark plug indicates engine trouble.

The spark must also be checked for complete reliability. To do this, place the ignition cable on the spark plug, connect the nut and spark plug barrel with pliers, start the starter and watch for sparks. If it is not there, the spark plug needs to be replaced. If the new spark plug also does not spark, the problem is a high voltage wire or a missing connection to the spark plug.

Examples of dismantling on the most common tools

All chainsaws have the same clutch design, only two well-known brands have significant differences: Shtil and Husqvarna, and all other saws have a similar design to either the first or the second brand.

How to remove the clutch using the example of a Sht il 180 chainsaw

Dismantling the clutch drum on Shtil 170, 180 chainsaws has its own specifics and is somewhat different from the same operation on other brands. By the way, we also recommend reading how the 170 and 180 models differ; the article reveals the most interesting differences that are not visible at first glance.

Specifically: on these Shtils there is a thin crankshaft connecting rod that carries the piston. If the piston stopper is rigid and there is a strong load on the shaft, the connecting rod can easily break when unscrewing. At the same time, the thread of the drum nut on these models is usually unscrewed easily.

Therefore, it is not necessary to stop the piston with a rope or a rigid rod. Instead of a piston stopper, the spark plug is left twisted, which impedes the piston's movement. The nut is unscrewed with a socket wrench driven by a pneumatic or electric impact wrench at high speeds of the wrench. In this case, strong air compression is formed in the combustion chamber, the piston stroke is difficult, and the high speed of the wrench allows the thread to be unscrewed.

On Shtili and on most models of other brands, the basket thread is unscrewed clockwise (left-hand thread). Such reverse threads are used on parts that rotate counterclockwise during operation. The left-hand thread in these cases avoids unwinding and ensures “self-tightening” of the thread during operation.

When there are no impact wrenches, the basket is unscrewed by blows with a screwed-in candle. A rod is placed in the window of the centrifugal mechanism and hit with a hammer. As a rule, two to four blows are enough to break the threaded fastener out of place.

Specifically, the process of unscrewing “by impact” on Shtil 180 is shown in the video:

The disassembly procedure is very simple and consists of only 4 steps, check out the step-by-step instructions with photos:

- The cover on the chainsaw body covering the tire is removed.

- The retaining ring (item 2 in the photo) is removed from the shaft (item 3 in the photo), which secures the drum cover with the gear (item 1 in the photo).

- Clockwise, the thread is broken using one of the methods described above (with a wrench, blows).

- The basket is unscrewed along the thread all the way by hand and removed.

Assembly is carried out in reverse order. Before assembly, special lubricant is applied to the needle bearings - a few drops of oil or special grease.

What do you need to know to change to Shtil 250?

On all Shtil household chainsaws, the clutch has an identical design and, accordingly, is removed in the same way; for example, on models 180 and 250 there is not even a visual difference. Therefore, if you need to remove the clutch from a Shtil 250 chainsaw, read the algorithm above about the 180 model, it also applies to this model.

The nuances of replacement on Husqvarna gasoline saws

Although the operating principles are the same, the technical design of the clutch on Husqvarna differs from Shtil and some other brands.

- The drum cover with the drive sprocket is located not on top of the mechanism, as in the Shtils, but under the eccentric mechanism (basket). Therefore, to replace this part, the entire basket is removed. (On Shtil this cover is on top; to replace it, just remove the locking ring and do not remove the entire drum).

- Husqvarna does not have a nut-shaped hexagon for unscrewing the eccentric mechanism basket with a hex wrench. Instead, there are holes for the cotter pins of the wrench, like those used to tighten monkey nuts.

In professional services and workshops, to dismantle Husqvarna baskets, they use special probes for the piston stopper and bushing wrenches with two pins for unwinding and tightening the threads.

Such a tool is not cheap. And for one-time work in a home workshop, there is no point in purchasing it. Therefore, the piston is stopped with a rope in the manner described above.

The detailing of the clutch on Husqvarna saws, as you can see, is no different.

To unscrew, use a suitable size monkey wrench with two spikes or the bar of the chainsaw itself. At the end of the tire, which is hidden under the cover, there are two transverse holes located perpendicular to the adjustment groove. Their location matches the size of the holes for unscrewing the basket. Two screws are inserted into the holes of the tire and secured with nuts. The diameter of the screws must fit into the holes of the mechanism. The result is a key with two spikes and a powerful lever.

The use of a Husqvarna tire instead of a special key is clearly shown in the video from 2 minutes 35 seconds. The commentary is in a foreign language, but the process is clear.

Fuel supply system repair

Fuel cannot enter the cylinder for the following reasons:

- Fuel filter is dirty. Remove the fuel hose and check for fuel leaks. If the stream is weak, you may need to clean the filter. It is removed through the filler hole of the fuel tank and cleaned; in case of severe contamination, it is replaced with a new one. As a precaution, it is recommended to replace the fuel filter every three months.

- Clogged breathing tube (holes in the fuel tank cap). Also check by disconnecting the hose to see if the needle is clogged.

- Lack or insufficient amount of fuel. There may be several reasons for the malfunction. The first reason is a clogged air filter. Air stops flowing into the carburetor in the required quantity, and therefore the engine is damaged due to the fuel mixture being too rich. The dirty filter is carefully removed, cleaned and washed with water, then dried and replaced.

Another reason is mismanagement of carbon emissions. Adjustment is carried out with three screws.

Timely replacement of the fuel filter ensures full fuel supply

READ First launch of the STIHL 180 chainsaw

The fuel hose and blower drive must be in tight contact with the valve.

The throttle cable should be in place.

You must use instructions when working, otherwise you may only make it worse.

And the last reason is a violation of the integrity of the membrane or clogging of the carburetor channels.

To repair the carburetor yourself, you need to read all its parts

All parts must be clean, dry and undamaged.

Features of setting up a Makita carburetor

The Makita chainsaw carburetor works on the same principle as carburetors produced by other manufacturers. This important part is responsible for mixing fuel with air. To ensure that there are no problems with the operation of the device, the Makita chainsaw is adjusted. This will help protect the equipment's motor.

By adjusting you can:

- eliminate the risk of the carburetor creating a “lean” mixture;

- minimize the risks of creating a supersaturated mixture, which negatively affects the operation of the engine, causing rapid wear.

If you need a new carburetor for a Makita chainsaw (you will set it up based on the standard instructions), choose one that is identical in structure to the original.

- The basis is a tube for air passage, which is connected to the damper (in the middle). The location of this part affects the amount of air that flows to the engine during operation.

- Diffuser. It is not difficult to identify it by carefully examining the components of the carburetor. This part looks like a narrow tube, the main function of which is to regulate the speed of air flow.

- A channel supplying fuel from the float chamber (connected to the nozzle).

- A separate design that stands out from the others is the float chamber, which looks like a standard reservoir for fuel liquids.

Screws for adjustment

Adjusting the Makita chainsaw carburetor is carried out with a set of adjusting screws, which are located in the body of this design:

- screw marked L – corrects low speed;

- a screw marked H, which is used to adjust high speeds;

- Screw T for adjusting carburetor idle speed.

Preparing for adjustment:

- The engine is left to warm up (run the chainsaw for 10 minutes).

- Checking the air filter and cleaning this part.

- Stop the chain by turning the screw marked T (turn until it stops).

Carry out the following settings:

- place the chainsaw on a flat surface;

- After removing the chain, set it aside.

To diagnose carburetor problems, use a tachometer.

Disassembling and cleaning the muffler

If the engine runs fine at low speeds and starts to stall at high speeds, the cause may be hidden in a spark plug cap clogged with combustion products.

- Remove the muffler;

- Disassemble (there are inseparable models);

- Clean deposits with detergents;

- Dry;

- Reinstall.

Dry cleaning is not allowed, as tanning contains carcinogenic substances that are hazardous to health if inhaled. After removing the muffler, cover the branch with a clean cloth.

Malfunctions in the chainsaw indicate a possible blockage of the muffler

The composition of the fuel mixture must be controlled to prevent clogging of the muffler. The amount of oil should not exceed the standards recommended by the manufacturer. Poor oil quality also negatively affects engine performance.

Patriot RT 3816 chain saw device

The Patriot RT 3816 chainsaw is powered by a 38 cm3 two-stroke gasoline engine. The fuel system of the device is equipped with a 300 ml capacity. Optimal operation of the saw is ensured by an automatic chain lubrication system combined with an anti-vibration system. The device components are located taking into account ergonomics, however, the oil and fuel tank caps are located on the inside, which increases the risk of being contaminated with gasoline or chain oil residues. For faster cooling, ventilation holes are provided in the case. For operator safety, the device is equipped with a chain brake and a catcher, which prevents injury if it breaks or slips. Also helping to organize safety precautions is the locking of the gas lever, which prevents its accidental operation. The silencer is located at the front of the device, which reduces the negative impact of noise and gases on the operator.

The Patriot RT 3816 chainsaw has a sawing apparatus which includes a 40 cm long guide bar on which a 57-link saw chain is mounted. The chain pitch is 3/8″ with a drive link thickness of 1.3 mm. The main disadvantage of the saw set is the long time it takes to tighten the chain using additional tools. The Patriot RT 3816 chainsaw, among the additional advantages of the kit, has a special container for mixing the fuel mixture.

Assessment of the condition of the cylinder-piston group

Often the engine will not start or will not run at full power due to low cylinder pressure. This may be caused by wear of the piston or cylinder, falling piston rings, or worn bearings. It can be partly assumed that the condition of the cylinder-piston group (CPG) is possible by removing the muffler and looking into the hole.

A compressor placed in the spark plug hole will help measure the compression in the engine - the results of the measurements can also tell you about the condition of the CPG. Accurate data is obtained only after complete disassembly of the mechanism. If the piston is chipped or scratched, it must be replaced. The piston ring should be clean, free of carbon deposits and in place.

Wear of the piston and crank mechanism is a serious problem.

The condition of the CPG parts can be judged by compression measurements.

Assembly Partner 350

In order to correctly assemble Partner 350, it is necessary to install all elements in the reverse order of removal.

An important feature of the Partner 350 chainsaw engine assembly is that the crankcase cover is installed without a gasket. Instead, a red sealant is used, which is applied in a thin layer to the crankcase installation site.

Before applying the sealant, it is necessary to degrease the crankcase cover and its installation location for better adhesion of the sealant.

Setting the flywheel and coil clearance (ignition adjustment)

During the assembly process of the Partner 350 chainsaw, if not only the flywheel, but also the ignition coil was removed, a gap must be set between them. To do this, first install the flywheel, then place a piece of a one and a half liter plastic bottle on it, and then place the coil and fix it with two fastening screws, while the flywheel must be turned toward the coil with magnetic contacts.

After adjusting the clearance, rotate the flywheel. If it does not touch the coil contacts, then the gap is set correctly.

Brake Chain Adjustment

The chain brake often fails due to clogged grease or sawdust in the brake band and the space under the cover. All parts must be clear of debris. The tape may have just worn out and then needs to be replaced.

The chain brake is restored by mechanical cleaning.

Some chainsaw parts wear out faster than others. These include a sprocket, a tire, a chain, and vibration-isolating elements. It is better to always have spare parts on hand for quick replacement. Don't neglect sharpening your chain.

Source

Second place in the ranking - chainsaw CARVER PROMO PSG-45-15

To make the right choice, you need to consider several models. If we talk about the popularity rating, then the second place in it is occupied by the model from. This is also due to the affordable price of RUB 3,800. The equipment is a tool that handles sawing wood and cutting branches. The device is designed for use in yards and gardens.

The quick start system ensures easy engine starting. The operator does not need to use additional tools to access the air filter. The design has an anti-vibration system that makes work comfortable. The chainsaw has a chain brake, which ensures a high level of safety.