How to remove the clutch on a Stihl 180 chainsaw

Nuances when installing the clutch system:

- On some chainsaw models, there may be a washer between the drive sprocket and the clutch. Pay attention to which side it faces the engine;

- Some oil pump drives are equipped with a special spring (whisker), which is responsible for transmitting rotational motion from the drive sprocket to the oil pump. It is important to adjust the spring so that its free end (whisker) fits into the corresponding groove on the sprocket body. Otherwise, the saw set will not be lubricated;

Important: after dismantling and assembling the clutch, be sure to check the operation of the automatic oil supply system.

Owner reviews

Vladimir Khlestov, forty-four years old, Armavir

After six months of use, the chain on the chainsaw began to spin constantly. I decided that the problem was with the idle speed. No amount of carburetor adjustments helped. In the workshop it turned out that the spring on the clutch had burst. We changed everything in ten minutes, and for two months I could not find fault. Main. correct diagnosis of the fault.

Yaroslav Nedelko, thirty-one years old, Vinnytsia region

Saw mostly hardwoods. Quite often the chain has to be sharpened and the drive sprocket wears out. The first time I removed the clutch I had to work hard. Metal stuck tightly cannot be unscrewed. Spraying with kerosene did not help. Only after use in Deshki could it be broken. And all because there was an oil leak somewhere, so the coupling was welded to the sprocket. I think so.

Andrey Kosoglazov, twenty-three years old, Primorsky Krai

After three months of using the chainsaw, a longitudinal groove appeared in the sprocket, everything works, but the chain does not rotate. They said the problem was with the clutch. Disassembling it is not at all difficult, the main thing is to find a puller and do not forget that the union nut has a left-hand thread. In short, I unscrewed everything and changed everything without any problems. Works great and there was nothing complicated there, just need to be careful.

Why is it necessary to use AI-92 gasoline?

In this article I will try to explain why it is so important to refuel gasoline engines with AI-92 unleaded gasoline and no other options.

When to remove the clutch

Disassembly of the clutch for the purpose of removal is carried out in the following cases:

- when the spring bursts (the chain turns, the engine runs intermittently);

- the spring flew off;

- a piece of the drum has broken off (in this case, noise will be heard and the chainsaw chain will also spin);

- temporary wear (it’s time to remove and change the clutch due to the end of its life).

Modern chainsaws operate on two-stroke engines, which are connected by a gearbox to the saw chain. The chain moves along the bar, and according to the centrifugal principle, idling should remain motionless, that is, be safe for the person holding the chainsaw.

READ Replacing Oil Seals Stihl 361 Video

If the load on the tool exceeds the recommended load, the clutch

will weaken or completely stop transmitting torque to the tire.

This will cause the engine to stop. When such situations occur, the clutch wears out and therefore needs to be replaced over time. In the operating instructions for chainsaws, some manufacturers have information that the clutch

is a consumable part, that is, it must be periodically replaced.

Video - how to remove the clutch on a chainsaw:

Results

We examined the main causes and malfunctions of the Shtil ms 180 chainsaw, which require replacing the CPG. But, as a rule, in each specific case, the reasons may overlap, and for proper repair, an integrated approach to solving the problem is necessary. Putting a new piston on the saw does not always mean solving the problem. It is imperative to eliminate the causes of the malfunction and the tool will serve for a long time without problems or the need for repair.

Source

Clutch replacement

When replacing the clutch, we do not recommend using metal or plastic objects as a stopper. The former can scratch the cylinder, the latter can litter it.

Disassembling the clutch

:

- We turn on the chain stop brake, remove the protective cover and dismantle the saw set;

- We remove dirt, sawdust, dried grease, if any;

- Remove the air filter and spark plug;

- Using a spark plug wrench, unscrew the spark plug;

- Rotating the crankshaft, bring the piston to the top point, then withdraw it by 6-9 mm;

- Use a rope, 7-8 mm in diameter, to stop the piston in the upper position;

- Use a special wrench to unscrew the nut on the clutch.

Most of the moving parts of a chainsaw have right-hand rotation. Therefore, the clutch nut has a left-hand thread. Remove the cover by turning the key clockwise. It is forbidden to carry out this operation with a hammer and chisel - you will knock off the edges!

- Remove the cover and drive sprocket. We diagnose faults and evaluate wear of parts. We assess the condition of the needle bearing;

- If necessary, we replace parts with new ones (most often the drive sprocket needs this);

Installation of the chainsaw clutch system is carried out in the reverse order, but you should pay attention to some features.

Replacing the oil pump using the example of a Chinese saw Partner

The oil pump is a fairly reliable element of the chainsaw. However, during operation, malfunctions may occur, the elimination of which requires its replacement. For example, to dismantle the oil pump on a “Partner” chainsaw, you must perform the following steps:

- Unscrew the bolts securing the crankcase cover;

- Remove the cover;

- Move the saw chain to the side and remove the bar;

- Remove the saw chain;

- Remove the air filter housing and the filter itself;

- Remove the spark plug;

- Unscrew the starter cover and remove it. This is necessary so that during the process of cranking the engine crankshaft, the ratchet teeth do not deform and the starter does not break;

- While turning the flywheel, set the piston at top dead center (directly below the spark plug hole) and insert a pre-prepared fabric harness into it. This will help fix the piston in one position and protect the walls of the combustion chamber from mechanical damage;

- Using a puller, unscrew the clutch retaining clip. Unscrewing must be done clockwise. To do this, some models have a stamping with an index arrow and the inscription “Off”;

- Remove the friction element, drum and clutch bearing;

- Remove any remaining dirt formed during work;

- Using a screwdriver, move the cover lock to the side and remove it;

- Unscrew the screws securing the pump;

- Carefully, using a screwdriver, pry the pump housing up and lift it to the side and remove it from the mounting socket. After this, it is necessary to turn off the supply and suction lines.

Installation of a new pump is carried out in the reverse order.

We also recommend watching the video instructions, the author of which explains in detail and shows how to replace the oil pump on a Partner chainsaw.

Removing the clutch and oil pump drive

Before disassembling the clutch

, it is necessary to remove the drive sprocket. To do this, carefully remove the lock washer from the grooves on the shaft and remove the sprocket and needle bearing.

READ For the combustible mixture of a gas-powered saw, use

High head 19, you need to unscrew the clutch

.

The thread on it is left-handed, so it unscrews towards the bar, and not towards the rear of the Stihl

180 saw.

Unscrewing and removing the clutch

, you need to immediately remove the reflective plate and the oil pump drive; this is easy to do, since they are put on the shaft without any fastening.

About washing

In this article we will talk about washing, their structure and operation.

Home_3

Removing and disassembling the engine

The engine is held in place by four screws installed on the bottom of the Stihl 180 chainsaw. To remove

, unscrew them, then carefully remove the engine from the seat and the rubber carburetor tube.

To disassemble the engine, the four crankcase screws are unscrewed and it is removed, after which you can remove the crankshaft assembly with oil seals, bearings and piston rings.

Removing bearings and seals usually does not require additional tools, but if the bearings have been forcefully pressed onto the shaft, a special puller will be needed for removal.

In order to remove the piston from the connecting rod, you will need to remove the retaining ring from the seat using a narrow screwdriver, then the piston pin is squeezed out from the back side, after which the piston is moved to the side.

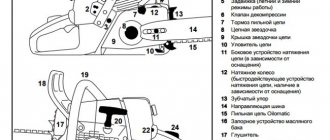

Description of the device and technical parameters

Stihl 180 has a standard configuration. However, like all modern chainsaws. Its components:

- Front and rear handle with anti-vibration system.

- Saw bar with chain.

- Two-stroke single-cylinder engine.

- Fuel and ignition systems.

- Housing made of high quality plastic.

Chainsaw Stihl

180, technical characteristics:

- A gasoline engine that runs on a mixture of fuel and oil in a ratio of 1:50. It has a power of 2 liters. With.

- The weight of the saw is approximately 4 kg.

- The saw is equipped with an easy start system.

- The capacity of the fuel and oil tanks is 250 and 140 ml, respectively.

- The saw bar is 14 inches (35 cm) long.

- Automatic chain lubrication.

About lawn mowers

The one on the right is the ORIGINAL.

A good tool is the key to quality and easy work. And a good spare part is the salvation of a good tool. By purchasing a bad analogue of a Chinese piston, you will ensure: Overheating of the cylinder at idle; rapid failure of the Chinese cylinder due to poor fuel; The short service life of a piston chainsaw is calm. So, how do we choose the highest quality spare part from a huge variety of piston parts? The piston group cylinder includes a piston pin, piston rings, and two stoppers. It is not recommended to assemble a piston from different kits. For example, if you replace the piston with an analogue one for the original piston stil 180, then it will not resemble the original one for a long time and scuffing will quickly appear. It is important that the crankshaft bearing fits tightly into the seat of the piston and pan. If the bearing fits freely into the seat without effort, then you need to choose another piston. The original is very easy to distinguish from the analogue. The original piston has various abrasions and has paint markings: brown, green, white. The original must also have the STIHL logo and name stamped on it. It is worth carefully inspecting the piston for the presence of chrome coating. On the third piston you can see that the chromium coating has unevenness and, therefore, we do not need such a piston for the saw. And finally, try, if you are allowed, of course, to scratch the cylinder with something and make sure there is welding. If everything scratches without any effort, then there is no chrome, just aluminum. Be sure to visually inspect the piston for casting defects. Everything should be smooth and without chipping the radiator fins. How long do the Chinese analogues of the piston for Shtil 180 last? There are many factors that need to be taken into account that affect the operation of a chainsaw. Simply replacing filters and refueling with high-quality fuel and oil will provide longer service life. Usually, according to personal observation and experience, analogues work fine, if you do not forget that the STILE 180 is a household saw and is not intended for professional work. An analog CHINESE piston machine, for large volumes of sawing wood, lasts on average for a year.

Replacing the starter cord

Remove the side cover. Inspect the inside of the protective casing. If there is no damage, check the launch unit. Unscrew the starter bolt and remove the spring. A pulley with a cord is diagnosed. If the rope is intact, then check each part of the launch mechanism:

The starter cord is made of synthetic material and gradually wears out. If it is damaged, cracked or torn, it needs to be replaced.

How to unscrew the clutch

nabenzopilesquiet 180

When storing engines for a long time, it is important to prevent corrosion processes inside the cylinder-piston group. To prevent such undesirable processes, in addition to other operations, it is desirable to achieve a closed state on the intake and exhaust valves. IN.

Description of the piston group of the Shtil 180 chainsaw

The chainsaw has a calmness of 180, the piston group has a diameter of 38 mm. The dimension of the chainsaw CPG is determined by the diameter of the piston; the cylinder is a bit difficult. The standard MS 180 CPG comes complete with a piston pin, 2 piston rings and 2 retaining rings.

The inner surface of the cylinder must be completely polished and have a glossy shine, which is where you need to pay attention when purchasing a spare CPG for a stihl ms chainsaw. If there is damage to the inside of the cylinder, there is no need to install such a cylinder.

Replacing the piston group on a Stihl MS180 chainsaw

In this video we will show you how to replace the piston

groups on a Stihl

MS180, crankshaft oil seals.

Fuel problems

Problems associated with the flow and combustion of fuel in the cylinder are most often associated with improper operation of the carburetor. Typically, such a malfunction manifests itself in the form of:

- The engine starts poorly or does not start at all.

- Interruptions in operation; when you press the gas, the engine “swells” and stalls.

- The idle speed is too high, the saw “roars”.

- Increased gasoline consumption.

- The saw does not develop speed well.

READ Adjusting the Carburetor of the Ural 2 Chainsaw

Adjust the carburetor of a Stihl

180 with your own hands will not be difficult. It has 3 adjustment screws. One is responsible for idling, and the other two are for fuel. Usually a simple adjustment is enough to get the saw working again as it should. If this does not happen, then the carburetor should be cleaned and completely disassembled.

Before completely cleaning the carburetor, you should also wash the fuel filters, breather and tank. Otherwise, the entire system will become clogged again. For some reason, most people only flush the carburetor and ignore the rest of the fuel system. It is best to disassemble and configure this element using the standard manual “ Stihl Chainsaw

180 operating instructions."

Description of the piston group of the Shtil 180 chainsaw

The chainsaw has a calmness of 180, the piston group has a diameter of 30 eight mm. The dimension of the chainsaw CPG is determined by the diameter of the piston, the cylinder is a little difficult. Repair of Shtil chainsaw 180 chains with Pobeditovaya, for the most part, reviews of Shtil saws. The standard MS 100 eighty CPG comes complete with a piston pin, 2 piston rings and 2 retaining rings.

The inner surface of the cylinder should be completely polished and not have a glossy shine, which is where you should pay attention when purchasing a spare CPG for a stihl ms chainsaw. If the inside of the cylinder is damaged, the cylinder should not be installed.

Carburetor repair and adjustment

Carburetor adjustment is carried out on a warm engine. If the engine cannot be tuned, then the cause of excess gasoline in the mixture may be a stuck carburetor. To remove the part, you need to unscrew the fastening nuts, disconnect the ignition and linkage from the engine control lever. Then remove the lever. You can then remove the filter and carburetor.

The muffler is secured with two nuts. You need to unscrew them and pull the muffler towards you. Then unscrew the screws of the coil and dismantle it. The carburetor on the Stihl saw has 1 idle speed adjustment screw. If the idle speed is abnormal, the carburetor needs to be repaired. This is a complex process and difficult to do on your own. You should contact a repair shop.

Sources:

https://crast.ru/instrumenty/sceplenie-shtil-180-ustrojstvo

Owner reviews

Vladimir Khlestov, forty-four years old, Armavir

READ How to Cut a Tree with a Chainsaw

After six months of use, the chain on the chainsaw began to spin constantly. I decided that the problem was with the idle speed. No amount of carburetor adjustments helped. In the workshop it turned out that the spring on the clutch had burst. We changed everything in ten minutes, and for two months I could not find fault. Main. correct diagnosis of the fault.

Yaroslav Nedelko, thirty-one years old, Vinnytsia region

Saw mostly hardwoods. Quite often the chain has to be sharpened and the drive sprocket wears out. The first time I removed the clutch I had to work hard. Metal stuck tightly cannot be unscrewed. Spraying with kerosene did not help. Only after use in Deshki could it be broken. And all because there was an oil leak somewhere, so the coupling was welded to the sprocket. I think so.

Andrey Kosoglazov, twenty-three years old, Primorsky Krai

After three months of using the chainsaw, a longitudinal groove appeared in the sprocket, everything works, but the chain does not rotate. They said the problem was with the clutch. Disassembling it is not at all difficult, the main thing is to find a puller and do not forget that the union nut has a left-hand thread. In short, I unscrewed everything and changed everything without any problems. Works great and there was nothing complicated there, just need to be careful.