Transferred from a neighboring community.

Apparently, for more than four years of use, my Olympic Gold was never polished and the paintwork of the body lost its original shine and acquired quite a few small scratches. I was not going to give my Gold to a service center for professional polishing, because they asked for a full body polishing of 10K rubles.

I watched quite a few videos on YouTube and re-read a huge number of entries on Drive and decided that everyone, including me, can polish the body of their car.

In general, whenever possible, I try to do everything in my car with my own hands, be it washing, soundproofing, installing music, etc. In general, wherever there is an opportunity to do something myself and there is a desire (and there is always one), I do it myself, because... I’m sure that no one but myself can do it better... And so I went shopping and bought everything I needed.

The consumables I needed were:

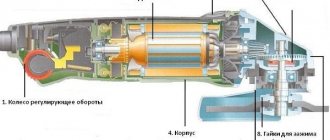

The most convenient tool for polishing is considered to be a professional polishing machine, which differs from a regular grinder only in the presence of a speed controller and a comfortable handle, but its cost is several times higher. True, there are several other tools that can also be used to polish a car body. The only tools I had were an eccentric sander and a regular drill with a speed controller. Of course, you can also polish the entire body by hand, but this will take a lot of time and effort, and the result may not satisfy you.

Let me start by saying that I like to keep my car clean. And it doesn’t matter whether it’s new or old, slow or fast, whether I bought it for a year or many years. After the purchase, it becomes a part of my life, my partner, assistant, and simply my mobile office and even a mobile home. Therefore, I am more than careful about car maintenance, from consumables and replacing outdated interior/exterior elements to regular washing and taking care of its appearance.

I was prompted to buy my own polishing machine by local detailers with their super-effective polishes (some can do it in an hour) in combination with body treatment with magical, well-advertised nano-ceramics. All this, of course, for a lot of money. By the way, a colleague at work paid a thousand euros for such polishing of his 2015 M3 and received a five-year guarantee. This type of body protection and commitment is worthy of respect. Just to maintain this “guarantee” you will need to visit the guys once every six months and pay a symbolic 100-150 euros. Yes, only for maintaining the properties of this very ceramic. What they will do there is already clear - cover the body with a new layer. It’s funny, but people, as they say, are eating up and demand continues to give rise to more and more new offers.

I don’t really believe in fairy tales and am used to controlling the process myself. Control, or even better, participate in it. Therefore, taught by experience, I believe only in abrasive polishing and inexpensive “so short-lived” (lasts only a few months) hard wax or more advanced modifications based on it, such as Fusso Coat. According to the manufacturer, it should also last for 12 months, but this is all relative. If you wash your car ten times a year without harsh chemicals, it will last a year. And if you wash it a couple of times a week, and also with a powerful degreaser, then after several washes this product will be successfully washed off along with the foam. Just a jar of good wax costs no more than $50 and lasts for years. And believe me, real high-quality abrasive polishing of all zones/areas of the body in at least two steps (and often three or more are needed) cannot take one master less than at least 5 hours. And provided that he himself washes the car, wipes off the polish and wax ten times, then this will definitely take at least 7-9 hours.

How to do something yourself, with your own hands. home handyman website

How and which one to choose an eccentric sander. Characteristics, brands and useful features.

Choosing a tool - an eccentric grinder

When using an eccentric sander, you can grind and polish wood, metal, organic glass and various varnished surfaces, and also remove paint from any material.

This commonly heard tool is suitable for most tasks solved in the workshop. After all, a clean, smooth surface is not only a design move, but also a serious requirement for some repairs, for example, preparing the surface for painting.

Rating of the best models

Summing up the review of the types of polishing and grinding equipment, we can confidently say that they are very diverse. But there are still a number of models that deserve close attention. Among the inexpensive versions, it is worth mentioning Sturm AG1014P . This device, although marked with the logo of a German brand, is assembled in China. The designers were able to create an excellent mechanism capable of removing dirt and unnecessary coating, as well as artificially aging wood.

The 1400 W electric motor spins at speeds of up to 3000 turns per minute. The total weight of the tool is only 3.35 kg. There are options for soft start and locking the start key. The speed in loaded mode is maintained at a stable level. A more advanced (professional) option is Bosch GSI 14 CE .

This model of polishing machine is capable of performing rough and decorative processing of a wide range of materials at a high level. The electric motor, as in the previous version, has a power of 1400 W, and the shaft torsion speed is the same. The handles of the machine are rubberized. Total weight - 3.5 kg. Judging by the reviews, this tool is quite convenient and safe to use. But this model cannot be called budget.

You will also need to pay a significant amount of money for the Makita BO6040 . Using such a device, you can remove rust and polish various flat surfaces. BO6040 is considered ideal for car paint treatment. The number of oscillations and the rate of shaft rotation are determined using an electronic system. Thanks to the smooth start, processing is carried out in a gentle manner.

Features of vibrating grinders

Observing the principle of operation, an eccentric sander is not entirely different from an orbital sander or a grinding wheel. This means that, together with the known movements of the vibratory grinder, it makes rotational movements of the grinding wheel. The result of this grinding method is the highest productivity and especially a smooth working surface.

The secret of the good properties of the processed surface lies in the composition of movements consisting of rotations and vibrations: the rotational movement ensures the removal of material, and with the help of vibration a smooth surface is created. In this case, the round sanding plate is movably attached to the drive shaft and rotates around its own axis parallel to the working surface freely, or under pressure. Maintaining pressure increases the chip removal performance, so even rough grinding work can be done.

Straight grinder

This type of grinder differs from a grinder in the location of the spindle. If in an angle grinder the spindle is installed on an angular gearbox, then in a straight grinder it is installed along the axis of the tool. The straight grinder is used for work in hard-to-reach places thanks to its long trunk with accessories.

Also in production, a straight pneumatic grinder is often used to clean welds and remove burrs from the edges of metal workpieces.

The face grinder can be either with a collet clamp or with a three-jaw chuck, which allows you to clamp equipment with different shank diameters.

Technical characteristics of eccentric sanders

A significant parameter that influences performance is the diameter of the vibration circle, which is also called working, ground, in other words, eccentric stroke. The higher the stroke, the higher the performance. The force with which the user presses on the tool during operation also affects the result of grinding.

Please note that the highest chip removal performance is not necessary. For example, when working with painted or varnished surfaces, accuracy is more important. Data on the diameter of the vibration circle indicates the accuracy with which it is possible to work.

When sanding smoothly, strong pressure slows down the rotation of the sanding pad, which ensures a particularly good final result. The basic rule says: the smaller the circle, the cleaner the grind, and vice versa. Thus, a small vibration circle is not only suitable for spotless grinding, but a large one (in combination with a massive motor) is for processing large surfaces with the highest chip removal performance.

Attention! The higher the speed of the grinder , the faster and at the same time rougher the surface treatment. Solid tools are characterized by the highest performance.

Belt type machines

Belt sanders are designed for pre-grinding floors, leveling, stripping and sanding.

In appearance, a belt sander resembles a miniature crawler tractor. Its working surface is an abrasive belt glued into a ring, which moves between two rotating rollers, like on a conveyor. Tape width – 65-110mm. The sole on which the tape rests is made of a thin metal plate and complemented by a soft backing.

The rotation speed of the abrasive belt is in the range of 150-500 m/min. Productivity directly depends on this indicator. However, only if the additional speed is supported by increased power. Otherwise, it will not be possible to “press” the rapidly rotating belt to the floor and the increased speed will not improve the quality of the tool’s work. The optimal speed value - 300 m/min - is achieved with a power of 650-700 W.

To “press” the abrasive belt to the surface, the machine’s design is equipped with a metal platform of different sizes. Powerful professional models are equipped with a wide 100 mm sole, ensuring their high performance and stability on the surface. For a hobby class tool, a width of 75 mm is sufficient. Separately, it is worth mentioning the so-called “electric files” - machines with a very narrow working blade (width from 6 mm), allowing you to reach the most inaccessible places.

The technical characteristics and important features of working with belt sanders are described in the video (using the example of the Interskol LShM-76/900 model):

Brake system for grinders.

Eccentric machines from some manufacturers will first be applied to the surface being treated and then turned on. The sanding pad brake, or simply put, an automatic braking system, prevents the formation of grooves when the pad is placed on the material, if the machine is already turned on.

The diameters of the sanding pads for eccentric sanders , 115, 125 and 150 mm, are the most convenient. Often, the very name of the instrument contains an indication of the size of the plate. Sanding pads with a diameter of 115 and 125 mm are especially good for processing concave and convex surfaces, and also various curves. The 150mm plates, on the other hand, are not just suitable for rough work and are designed for huge flat surfaces. As a result, with a larger diameter of the grinding plate, depending on the grain size of the grinding wheels and the vibration circle, the grinding performance is higher. If you need precise work in narrow places, a machine with a plate of the smallest diameter is preferable.

Most eccentric sanders have a dust extraction function. It can be done using several methods: through the sole, using a dust extractor, or alternatively using a hose and a dust bag. Of course, models where you can disconnect the dust collector or change its position.

Tips for use

You can use a polishing machine to process car bodies only after applying a special polish to the surface. The chemical composition of this drug is quite complex. In preparation for work, you need to prepare a couple of polishing wheels: one for coarse, and the other for fine impact. A small amount of paste is applied to the discs. Therefore, it is impossible to process large areas in one go.

The speed during rough processing should be minimal, and as the work approaches its logical finale, it increases. Uniform distribution of polish is achieved if you work using the “cross” method - initially horizontally and then vertically. The approach to polishing wood should be different. To get a good result, you should carefully study the features of a particular machine and the manufacturer’s recommendations. You should also take into account the characteristics of a particular type of wood.

Lesson No. 24 Orbital and eccentric sanders, what is the difference. Overview of risks (painting)

Greetings! First, I recommend excellent online stores. products and services inexpensively: Field.

The Russian automotive industry offers a wide selection of grinding accessories. They can be included in the standard equipment of the machine or purchased additionally. Accessories include various types: abrasive, self-adhesive or clamping, on a cardboard or rag base, and additionally of various grain sizes. The smaller the grain size, the rougher the processing.

For polishing, eccentric grinders are equipped with special polishing wheels. Of course, also special wheels for processing wood and coatings, a cotton cloth for removing rust and coarse dirt, a cloth for rubbing in polish, a polishing sponge for rubbing in wax, a special felt cloth for polishing “to a shine,” etc.

Method of fastening consumables.

Replaceable sheets are attached to the sole of eccentric sanders. They are attached to the working plane of the tool using a clamp or Velcro. Models with clamp mounts are cheaper and more versatile, as it is easier to select consumables. But Velcro fastening is faster and more convenient.

Reasons for the need for polishing and restoration of paintwork

The main reasons for the need for polishing remain the natural aging of car enamel and dirt on domestic roads. All road debris raised by passing and oncoming vehicles leaves marks on the body of your car. Micro-scratches are difficult to notice with the naked eye, but their accumulation affects the reflectivity of the varnish. More noticeable on the paint are traces of hard sand, gravel, flying stones, and roadside branches getting into the body.

Scuffs and dull color of car paint are caused by road chemicals, winter sprinkling of highways with salt, sand, and chemical reagents. Various bischofites and modified calcium have a destructive effect on the paintwork of the body. Acid rain, hail, and dirty snow leave marks on car enamel.

Oddly enough, auto mechanics consider trips to an automatic brush wash to be an important cause of scratches and abrasions. From regular washing with rotating brushes, body paint (especially soft enamels) loses its shine and becomes dull. And if the owner of a car wash skimps on timely replacement of worn brushes, the hard ends of the bristles leave deep scratches on the paint. Road dirt gets packed into microscratches and small chips, expanding and deepening the damage.

In addition to the loss of shine and brightness of the factory color, all damage to the paintwork is dangerous with more serious consequences. Scratches, overlapping each other, completely cut through the paint layer and can become sources of rust, which will require expensive body repairs and repainting of the car to eliminate.

Every driver wants to restore the perfect shine of the body and glass, but the services of branded technical centers and road detailing studios are not available to the average car owner every two to three months. With limited financial resources, many Russian car enthusiasts have no choice but to polish the car themselves.

Additional features of eccentric sanders.

Some models allow changing the sole. For example, installation of soles with a diameter of 115 and 125 mm, created for various volumes and types of work.

ergonomics. Some domestic manufacturers equip their tools with special vibration pads on the handles that reduce vibration. For massive models, you will like the additional handle on the body for more comfortable work. Usually there are variations with only a round handle on top and a rounded body that can be grasped with one hand. They do not have an additional handle. and the possibility of joining it is not provided. The handles have the shape of a clamp, arc or bar.

Of course, additional handles can be partially folded out (for example, when sanding along the edge of a surface), moved to different positions, and also rotated around the body.

smooth starting or maintaining a constant number of revolutions significantly simplifies the work)'. You can easily and simply find the number of revolutions and vibrations taking into account the material. Particularly comfortable are the full-wave electronics, which provide smooth speed control. And the function of setting a low number of revolutions allows you to process heat-sensitive materials.

Before turning on the eccentric grinder, you should carefully study the manufacturer's instructions in detail.

For polishing surfaces, it is better to use a model equipped with control electronics, which allows you to adjust the oscillation frequency. What exists is that during such work the oscillation frequency must become less than during grinding. If the user polishes the surface at “high speed”, the engine, as it is also called, will overheat and the material being processed will be damaged.

It is recommended to sand varnished surfaces at low speed. They are very sensitive to high temperatures; to achieve a rational result, you need to ensure that the temperature does not increase. Experts recommend using clean abrasives in such cases and not even pressing too hard on the grinder, so as not to create additional friction.

For grinding plastics, abrasive wheels with a grit level of 240 and higher are used. When processing metal surfaces, the grain size of the abrasive wheel is preferably two or more than 600.

How to grind metal? Here is an example of work

Let's give an example of how an orbital sander works on metal. Let's imagine that we need to paint a car. First you need to get rid of the old paint, clean off the rust and smooth out other defects. To do this, set a low speed of up to 8000 rpm and install coarse-grained equipment - a grinding wheel marked P40 or values close to this will do. Then we sand the surface so that it becomes smooth - change the abrasive to a finer-grained one - P150 - P240 and increase the speed to 12,000 - 16,000 rpm. This is followed by painting work - puttying, matting, priming. After the primer has dried, you should also go over it with a sander at a speed of 12,000 rpm or higher with a wheel of P240 - P480 grit for acrylic and P240 - P800 for metallic. Then paint and varnish are applied. When everything is dry, the car is assembled. The final stage is polishing and eliminating defects. Using a wet method using a special paste, successively using sanding wheels P800, P1000, P1200, P1500 at the maximum speed of an orbital sander, the car is brought to perfection.

An eccentric sander is a multifaceted tool. It can also be useful for a home handyman who makes repairs on his own or often works in the country. Indispensable for professionals - carpenters, painters, car mechanics and other specialists.

Choose an orbital sander and accessories for it on our website - we have a large assortment! And if you have any questions, you can ask our manager before purchasing. We wish you success in your work!

Source of the article: https://www.vseinstrumenti.ru/instrument/shlifmashiny/ekstsentrikovye-orbitalnye/articles/vse-o-rabote/

Choice

Professional models are designed for long-term continuous work. The quality of materials used for their production, the reliability of components and electronics is much higher,

than that of household grinders. Professional-grade tools are designed for multi-shift work in busy conditions, which is why this list is subject to the highest operational requirements. You, they are more than just in size, but their engine is stronger.

the average consumer is designed to work from case to case. They are designed for deployment over a period of 20 hours per month, typically have the least power and weight, lower performance and fewer additional features. The advantages of household systems are the yen applicable to the home handyman and ease of use.

You should look at the manufacturer’s warranty and the availability of service centers where there is an option to repair the instrument, or it is also called technical preventive maintenance. Be sure to decide on the volume and specificity of the work to be done. If the equipment means working every day, it is better to purchase a professional class model.

Household tools will not cope with overwhelming tasks and will fail ahead of time. However, the warranty will not apply to such a machine (if the service turns out that the tool was used in excess of the manufacturer’s recommended regime). The volume of work performed affects the multifunctional features of the tool.

Angle of the polishing wheel to the surface

When polishing paintwork, professionals often recommend placing the circle on the surface over its entire area. The flat arrangement of the circle gives a uniform impact on the surface. The flat placement of the circle on the surface leaves fewer circular scratches.

At the same time, many experienced polishers, perhaps intuitively, tilt it a little. When positioned flat, the movement of the machine is more difficult to control. A very slight tilt of the circle avoids its “dragging”, which causes holograms to be created.

A stronger tilt is sometimes needed when correcting a particular defect. You concentrate on a single scratch and apply pressure to that area with the edge of the circle. See what happens and you can add or release pressure. You need to be very careful not to overheat the paint.

After this method, small circular scratches appear. These can be removed by laying the circle flat again and polishing the surface. The same result can be achieved by laying the circle flat, but it will take more time. In addition, you will have to polish longer in one place, which is not very good.

Popular brands and manufacturers of vibratory sanders

- DeWALT

- Black Decker

- Bosch

- Hitachi

- Makita

- Skil

- Metabo

- AEG

Conclusions:

- Using certain models, of course, grind concrete

- Most systems can handle metal surfaces

- The most necessary work is stripping and polishing wood

- The brand of consumables is the key to durability and performance

- If the diameter of the outlet pipe allows, of course connect it using a vacuum cleaner

- Dust can be discharged into a receptacle that is easy to disassemble and clean

Source

Kinds

ESMs are classified according to several criteria:

- machines with which you can work on wood or metal;

- ESMs that operate from an electrical network or from batteries;

- professional models and devices for household needs;

- miniature units with speed control and large pneumatic ESM.

ESMs are capable of making surfaces perfectly smooth. The quality of the “orbital” is achieved through the translational-rotational movement of the canvas itself. At high speeds (more than 10,000 thousand per minute), a large amount of energy is generated, which is transmitted into vibration. It is transformed into a force impulse, thanks to which the polishing process occurs. The eccentric needs a counterweight, which is necessary to smooth out excess vibration.

Let's look at the most popular ESM manufacturers.

- produces inexpensive and compact units.

- Bosch produces high-power (more than 650 watt) and medium-power models. The company's products are of good quality and have many different additional options (rotation adjustment, speed, etc.). This type of equipment is most often purchased by professionals. It is quite expensive, but is very reliable and also has a long service life.

- The quality of EShMs is not inferior to German units from Bosch. The devices are ideal for use in service stations and garages. The dust removal system is especially effective on the models. Each model has its own design features. Some ESMs are equipped with a speed controller (up to 6 positions).

Now let's look at some of the distinctive details and functions of the devices.

- “Orbitals” for professionals are equipped with special relays that control a constant rotation speed during operation. In this case, the torque automatically switches to afterburner mode, and the engine's reserve power is used.

- The starting current limiting block is used for several reasons: when it is necessary to reduce the load, and also to avoid noise when the engine starts. This device is found exclusively on professional models.

- Adjusting the sole brake is necessary for quick stopping.

- 90% of ESHs have a socket that allows you to connect a vacuum cleaner (sometimes the vacuum cleaner is replaced by a special container made of a PVC bag or paper bag).

- Professional tools are often equipped with a casing around the eccentric assembly.

- The D-lever allows you to work more comfortably.

- A switch with a lock is most often found in expensive professional models.

Also, the EShM cannot be installed permanently. This is usually necessary when you need to work with small-format products. If there are voluminous depressions or depressions on the workpiece, then the ESM will not penetrate there; there is also the possibility of damage to the edges by the rotating element of the machine.

No. 3 - Bosch GEX 150 Turbo

Price: 26,820 rubles. The second creation of the Germans from Bosch and the third place in the rating is the GEX 150 Turbo grinder. Its main advantage is the power of 600 W, which, together with a rotation speed of up to 6650 rpm, ensures efficient and high-quality grinding of various materials. There is a dust collector to which you can connect a vacuum cleaner and get rid of dust as you work. Bosch GEX 150 Turbo is one of the most powerful and productive grinders. Yes, not the lightest, but the weight plays into its favor, so together with the anti-vibration system, shaking is reduced to nothing. Yes, not the quietest, but quite ergonomic, pleasant to use, and most importantly - durable.

Bosch GEX 150 Turbo

How to properly sand walls after puttying

Sanding walls after puttying is a mandatory operation when preparing them for painting, wallpapering or decorative plaster.

After all, even after the highest quality finishing putty, traces of the spatula will remain. And on a surface that at first glance seems perfectly smooth, after final finishing all the flaws will be visible. You should start sanding only when the putty is completely dry. This usually takes about 24 hours. And this is perhaps the most important rule for high-quality sanding of surfaces.

Safety precautions

- Sanding walls treated with putty is a dusty finishing operation, so the work is carried out in a respirator and safety glasses. Furniture is removed from the room in advance, the floor is covered with plastic film to prevent dust in the space.

- The room is cleared of unnecessary objects that impede safe movement around the space with the instrument.

- The lighting in the room must be of high quality for grinding with a machine in a safe mode.

- The work is carried out using ladders or special stepladders.

- The safest machines are those equipped with a long handle to reduce the risk of falling from the stairs when finishing.

- Construction sanders are electric and can therefore generate sparks. Work is not carried out near flammable liquids or objects.

- Grinding with the machine is not interrupted, so the room is cleared of children and animals for safe work.

- If a strong smell or loud sounds appear from the machine, the equipment is turned off and sent to the service center specialists for inspection.

- Safe operation is ensured for electrical appliances. The plug from the machine must go into the outlet. It is not recommended to replace machine plugs to prevent fire. Only original elements ensure safe work. If the machine has a ground connection, the use of adapters is not allowed.

Experts recommend using equipment from trusted manufacturers. The list of rated and reliable in operation includes grinding machines of the brands Interskol, Makita, Sturm.

Source