The use of [metal pipes] in the production and installation of metal structures involves the need for cutting across, along and at an angle. And you don’t always have special equipment at hand. We will describe in this article how to cut a pipe evenly using available tools.

Structure and capabilities of the grinder

An electric angle grinder is used for grinding, polishing and cleaning surfaces, welds and edges. The technique is effective in cutting various materials and making products from metals, stones, bricks and concrete. The development of artificial diamond technology has made it possible to turn the grinder into a universal cutting machine. Now the quality of their execution is regulated by GOST R IEC60745-2-3-2011 and is tested in laboratories.

Grinder grip

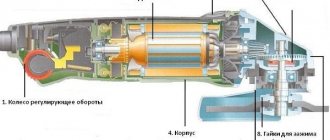

In general, the device in an angle grinder is as follows:

- The rotation of the motor rotor is ensured by an electric motor with a control unit and a current supply cable.

- A gear and a fan are installed on the shaft. The mechanism is engaged with a driven gear mounted on the drive spindle. The latter rotates the working tool - a disk or stone.

According to their design, there are one- and two-handed grinders:

- One-handed tools. There is no main handle, they weigh up to 2.5 kg, the diameter of the circle is 100, 115 and 125 mm.

- Two-handed instruments. There are main and additional handles, the diameter of the circle ranges from 125 to 230 mm, the weight of the machines is 2.5-6 kg.

Preparing to work with an angle grinder

The rules for working with power tools and their accessories always provide for preparatory work. Bulgarian is no exception. First of all, you should prepare the required protective equipment.

Safety precautions when working on a lathe

Note! The minimum program is glasses and a casing. Failure to comply with these requirements may result in sparks entering the eyes and injury.

You should also have protective gloves. During the labor process, the hands are close to the disk. This causes particles, scale and sparks to land on your fingers and palms. Thick gloves are used to protect hands and preserve their skin. This is a minimal set for home use. If we are talking about production, then in the work area you need full protective clothing that covers all parts of the body.

Features of working with an angle grinder

Safety precautions when working on a drilling machine

A modern angle grinder allows you to replace the emery when working on metal. To avoid problems, it is useful to remember a few guidelines when using the tool:

- The angle grinder should be held with both hands during operation. In the event of a kickback, a strong fixation will minimize displacement. Otherwise, the risk of injury increases.

- Work should be carried out on a flat surface, confidently maintaining balance.

- Place the power cord on the opposite side of the disk. The operating instructions for the angle grinder make these requirements in order to avoid short circuits and shock waves from the unit.

- When completing work, the tool should be held firmly in your hands until the disk comes to a complete stop.

- If there is a power outage, you must unplug the tool from the outlet. Otherwise, the angle grinder may start working without operator control.

- The work process is accompanied by heating of the disks. After turning off the tool, they should not be touched until they cool down.

Fixing the material

How to hold an angle grinder correctly

Many people have an angle grinder, but most people do not know how to use it correctly and how to hold it. This leads not only to work failure, but also to serious injuries. An angle grinder is a rather dangerous power tool.

The circle should be installed with the pattern facing up and clamped with a special nut.

The person with the leading right hand holds the grinder by the handle with his right hand. In this case, the circle should be located on the left side of the machine, and the protective cover should cover it on top. The rotation occurs in such a way that during cutting, sparks fly towards the worker. If the grinder's circle jams and the grinder breaks out of your hands, then it will not go towards the carver, but in the opposite direction.

The left hand holds the machine by the handle, which is screwed into a threaded hole on the body. There are several of them for special cases of use, but the correct position of the handle is only the upper one.

This position of the machine requires the use of protective equipment. To protect the eyes and the exposed part of the face, use safety glasses, or even better, a protective mask. To protect exposed parts of the body from sparks and small fragments during the cutting process, it is necessary to wear a suit made of thick material.

Methods for fixing trimmed trim to the door frame

Attaching the trim to the door frame can also be varied. The simplest is to attach telescopic trims. The main thing here is to correctly trim the elements to size, and then simply insert the cash tenon into the groove of the box. Additional fixation is usually not required.

Other types of platbands can be fixed with finishing nails. They have practically no cap, and therefore they will be completely invisible. The next option is self-tapping screws. There is also a nuance here - you need to think about how to hide them. Otherwise, the hats will spoil the appearance.

A separate option worth noting is fixation with liquid nails. But, despite the simplicity of such fixation, it has its drawback - if it is necessary to replace the platbands, you may encounter the problem of dismantling, while the previous options allow you to easily remove the elements.

Instructions and recommendations for cutting with a grinder

Working with materials is characterized by one sentence: the directions of tool movement and disk rotation must coincide.

Safety precautions when working with disinfectants

Note! It is necessary to come into contact with the surface being cut at maximum spindle speed - otherwise jamming may occur.

Wherein:

- The cutting line should pass by the working person, and not rest against him. If the disc jams, the reactive movement of the tool will pass by the operator.

- Start cutting profiles from the place with the smallest cross-section.

- The protective cover provides safety only if it is between the person and the circle.

- When cutting walls, a cable, fittings or pipe may get caught, which will lead to a kickback. Be away from the possible displacement line.

Disadvantages of trimming tiles to form outside corners

When using the technology of sharpening the edge of tiles or porcelain stoneware at an angle of 45 degrees, the edge of the finishing material becomes thinner. As a result, its edge becomes very fragile and susceptible to destruction under external physical influences. Therefore, the use of this technology is not allowed when finishing steps and external walls in areas with high traffic. In such cases, it is recommended to use special decorative plastic or metal corners.

Electric tile cutter

Any professional team will prefer to solve the task using an electric tile cutter. This device operates in two modes: one allows you to make a straight cut, the other allows you to cut at an angle of 45 degrees. Using the second function, it is easy to make any cutting angle from 0 to 45 degrees. The main thing is to set the desired notch on the settings panel.

To complete the job you may need the following tools:

- Masking tape.

- Pencil.

- Ruler.

- The machine itself has a rotating bed.

- A grinder that has a speed control mode.

Painting tape is applied to the tile in place of the cut. Take a pencil and a ruler in your hands. They are used for marking. The tiles are laid out on the tile cutter platform at an angle of 45 degrees. The operating principle of an electric tile cutter is the same as that of a conventional circular saw. The cutting is done with a diamond strip so that the tiles do not melt during the operation; water is supplied to the cutting site

It immediately washes away dust and debris. The cut turns out beautiful if, using a tile cutter, it is possible to obtain a beveled corner without damaging the glaze layer (it is important to cut only the clay). If you touch a layer of glaze with a disk, the corner will end up with torn, chipped edges

After finishing the cladding, the two connecting elements will look sloppy and ugly. Only an experienced tiler can cut the glaze and still make the edge smooth. And all because he knows certain professional secrets.

To do this, first use a tile cutter to make an even cut, and only then try to form the desired angle from the back side. The affected layer of glaze is then simply processed with sandpaper. After this, the tiles will look neat.

What is a kickback?

This is the name of one of the most dangerous cases that can happen during work. The effect occurs when the wheel is strongly jammed into the workpiece, as a result of which the power tool is sharply thrown back. It is necessary to carefully monitor the process and hold the grinder tightly.

The points weren't enough

How to avoid kickback

To do this you need:

- Always hold the tool by the standard handles.

- Take a stable position on the ground.

- Use both hands.

- Be slightly away from where the tool will hit.

- When the angle grinder moves away from itself during a reverse impact, it bounces onto the person.

- Be especially careful when working around corners and edges.

How to cut smoothly

To cut something evenly with a grinder, you need to make the correct markings. For example, before cutting a piece of pipe, you need to mark the size with a marker or thin chalk. Then we take a sheet of paper with a straight edge and wrap the pipe around the mark. We will get a paper pipe on top of a metal one. The border of the paper will be the exact trajectory along which part of the pipe will be cut off.

For these purposes, you can also use construction tape, which makes it easier to wrap the pipe and secure it. Draw a cutting line along the edge of the paper or tape. We remove the paper, heal the pipe in a vice and cut it with a grinder.

You can cut a corner, profile or sheet in a similar way. Just don’t forget that you can’t change the position of the machine while cutting. Misalignment of the circle will lead to jamming or breakage. Do not press too hard on the circle, especially thin ones. The deformation will immediately be reflected by curvature. The machine should eat into the material itself, you just need to hold it.

The evenness of the cut also depends on the correct selection of the wheel. It is difficult to achieve an even trajectory when cutting off part of a thick-walled pipe with a thin circle.

Methods for cutting metal pipes at an angle

There are several ways to saw off a pipe or cut it into pieces. Of the available tools, a grinder is the best for this task. But the biggest problem remains the need to correctly mark the cutting lines. They can be different, most often you have to maintain either a right angle relative to the axis of the pipe, or 45 degrees. The techniques vary somewhat depending on what products need to be cut:

pipes for laying water supply, gas and for heating distribution;

profile products for assembling gates, canopies, and other metal structures;

large-diameter pipes - as a rule, this is rarely needed at home, where the widest clearance is only in the sewer system;

pipes made of steel, cast iron, thin-walled of non-ferrous metals and soft alloys.

Both problems can be solved quite simply even without the use of a special pipe angle pattern.

45 degree cutting

One particular example of such a situation is the need to cut a metal pipe at an angle of 45 degrees. Such cutting of material is often required when laying water pipes or heating systems. In this case, you have to deal with steel pipes. For these purposes, conventional cylindrical pipes are usually used. If we are talking about the installation of some kind of metal structures, then profile pipes of rectangular or square cross-section are more often used. The main problem here is that in order for the elements to be connected to coincide, the cut must be as smooth as possible, which means that especially close attention should be paid to marking the material.

In cases where cutting at an angle is required, a simple square sheet of paper can be used as a marking template. It must be folded strictly diagonally, and then wrapped around the pipe with the template. In this case, it is necessary to carefully ensure that the side of the sheet, which is located closer to the end of the pipe, is perpendicular to its central axis. Next, using marking material, a series of dotted lines is applied and after the marking is completed along the entire circumference, the template can be removed.

Photo of the template for cutting pipes - side view

Larger pipe blank

Marking a 45 cut using a template

If you have to cut a profile pipe, then it is advisable to make a special template from the same pipe, but with a larger cross-section. In this case, you will only have to use the measuring devices once. To apply markings you will need to use a protractor or a construction square. After sawing off the template, the pipes to be cut can simply be inserted into it and marked. This approach will significantly save work time and cutting a profile pipe at 45 degrees will be convenient.

As for what to use when carrying out work, you should choose the most suitable and familiar one. This can be a simple hacksaw for metal, or a grinder with an installed cutting disc.

90 degree cutting

When the need arises to cut at 90 degrees, the situation is even simpler. In the case of cylindrical elements, you can use the same sheet of paper that is used to wrap the pipe as a template. It is important to ensure that the edge of the sheet is smooth and matches the entire circumference. After marking is applied, the element to be cut is fixed and the cut is made.

The video shows the process of cutting a pipe at 90 degrees.

How to cut a profile pipe evenly

You can cut a profile pipe in much the same way, but here it will be easier to use a square. The device is applied to each side in turn, for which the element to be cut will need to be rotated, and markings are applied. Next, the pipe must be secured firmly and work can begin.

Any suitable tool can be used for sawing. If you have to cut a lot of pipes, then it is advisable to make full-fledged templates from scraps. In this case, measuring and marking work will have to be done only once.

Large diameter pipe cutting

When it is necessary to cut a large diameter pipe, a number of special devices and tools can be used. This may be necessary if, for example, a pipeline needs to be repaired.

- Bulgarian. The use of an angle grinder is justified from the point of view of the availability of tools and the comparative cheapness of the work. However, you should not count on greater productivity in this case; in addition, carrying out work in this way is associated with considerable risk.

- Roller machine. Such devices are also often called pipe cutters. In essence, such a device is the same grinder, but more suitable for this type of work. The machine includes a special frame where the element to be cut is fixed, as well as a holder with installed cutting rollers, which do the actual work. It is important to understand that each machine must be purchased for specific tasks, that is, for the size of the pipes.

- Gas cutting. This option is most often used when working with large diameters. Cutting is carried out due to the action of a high-intensity flame, and the waste produced is blown away by gas pressure. The method can be considered the most practical and effective.

Gas cutting is the fastest option in this case.

There are other options for carrying out the task, such as the use of plasma, waterjet or laser cutting, but in private use they are practically not used.

How to cut a cast iron pipe

If the pipe is made of cast iron, then in order to cut it smoothly you will have to apply certain knowledge. The fact is that this material is characterized by high fragility, which means that before cutting such a pipe, you need to determine an algorithm of actions.

- We mark in the same way as steel pipes.

- At the cutting site, you need to place a wooden beam as a support.

- Next you need to make a cut of a few millimeters around the entire circumference.

- After this, a chisel is inserted into the groove and a sharp and strong blow must be applied with a hammer.

As a result, it will split along the line, forming a fairly even cut area, which can be further processed if necessary.

Industrial equipment

In professional construction and when working with large engineering projects, the question of how to evenly cut a large-diameter pipe is solved by using special equipment. Quite often these are stationary units with a certain set of qualities.

Among the most interesting and functional devices are the following:

- Lathe of various modifications . Using such a machine, you can evenly cut a profile pipe for both ordinary water supply and especially durable products through which liquids with an aggressive environment will pass.

The maximum cross-section of the pipe to be machined will vary depending on the distance between the support heads and the diameter of the holes in the spindle. These units can be called universal, because they can carry out cutting, chamfering, and also carry out a number of other actions, often in automatic mode.

- Belt type cutting machines . Such units are used for cutting pipes of water supply or sewer lines, previously laid in trenches or installed in a building.

The cutting belt machine can process pipes, even those that have undergone quite severe deformation. Additionally, such a cutter can chamfer the required shape.

- Cutting machines with circular knives . Equipment of this type is capable of cutting pipes from any metals, including non-ferrous ones. In addition, they have no restrictions on the shape of the product - they can be either round or profiled, with a fairly large cross-section.

As a rule, such units are installed on conveyor belts and are additionally equipped with a machine, which, after cutting, collects and packages a given number of pipe sections, which will then be sent to customers.

- Manual disc cutters . They are used mainly in cases where cutting a large number of pipes is required directly at the places where they are laid. These machines have a special clamp that tightly grips the pipe during cutting, preventing it from shifting and deforming. Thanks to this quality, such equipment can be successfully applied to metal-plastic, copper or steel pipes.

A number of disc-type cutting machines have a built-in orbital welding and rotation system, which allow cutting and subsequent joining of parts with one mechanism. Such a device can be very useful if it is necessary to perform a very large amount of work on cutting, welding or joining pipes without having stationary equipment.

However, such a multifunctional device is not necessary if you have a small amount of work to do that does not require complex mathematical calculations and compliance with standards.

Often, you can cut pipes evenly using simple improvised tools that every owner has.

Straight cut

An even cut at an angle of 90º can be made only after marking has been applied. Use a piece of paper or masking tape. The latter is preferable, because it is attached directly to the surface and does not move.

The sequence of actions looks like this:

- Using a tape measure, measure a piece of the required length, mark this place with a line with a marker.

- Next, stick tape along the resulting mark around the circumference of the pipe. The smoother you apply the adhesive tape, the better - it is optimal that the wide edges meet as accurately as possible. This will allow you to accurately cut the pipe according to the mark.

- The next step is to secure the pipe in a vice or press it to a flat plane so that it does not move during operation and an even seam is obtained. Note that one end of the pipe must be left in a free position so that during the cutting process the disk is not pinched by the walls. Cutting starts from top to bottom.

- The last thing you need to watch out for is how to cut the pipe smoothly with a grinder. To do this, you need to guide the disc as accurately as possible along the edge of the adhesive tape.

In cases where tubular products with large sections are being cut, the work must be done in small sectors. To do this, the pipe will have to be constantly rotated around its axis upon completion of the next cut.

When working with cast iron pipes, the procedure will be slightly different. First, a continuous cut is made along the entire diameter of the product, then, using a chisel and a hammer, the resulting groove is gradually tapped, as a result of which the pipe should split strictly along the cut line.

Marking a corner with a piece of paper

Marking with a paper sheet is one of the simplest ways to complete the task. A square sheet is required. It folds exactly diagonally. The resulting template for cutting pipes must be wrapped around the product so that the long side runs parallel to its cross-section.

Then an angle of 45 degrees is formed on the smaller side. All that remains is to mark the cut line using a construction pencil or marker on a sheet of paper.

It is recommended to wrap the marking area with narrow tape to prevent it from being accidentally erased. This method is excellent for long, large pipes with the cut location approximately in the middle of the product.

How to properly cut pipes from different metals

Accurate cutting and trimming of pipes depends not only on well-executed markings. The material is also of great importance - metal of different thicknesses and hardness is cut with different forces and side effects. To properly cut a cast iron pipe, it should not be sawed all the way through. Cast iron is a brittle metal, so several cuts are usually made, and then a specialist knocks a piece out of them with one precise blow of a chisel.

To work with thin-walled pipes, you will have to very accurately check the position of the grinder. At the same time, the master must choose the right [discs for cutting metal with a grinder]. In industrial settings, special pipe cutters, gas cutting machines and welding machines can be used to perform the same tasks.

Safety when cutting a gas pipe

When working with gas pipes connected to the mains, it is important to follow safety precautions. First turn off the gas supply valve, then make sure that there is nothing in the pipe. To do this, just open the stove burners and light the gas - when it runs out, the flame goes out.

Standards

There is a whole range of bends with different angles - 45, 60, 90 and 180 O. All of them are manufactured in accordance with GOST 17375-2001 from various grades of steel and meet all the requirements of reliability and strength. However, buying them can be quite difficult, especially when you live in a rural area and are far from large stores.

GOST 17375-2001 implies the use of higher quality steel than in the manufacture of pipes, but for such diameters and for everyday tasks the material from which the pipes are made is quite sufficient. Such a 90-degree steel pipe bend carries all loads and serves no less than the main pipeline itself.

How to deal with such a difficult situation and whether it is possible to make a bend with your own hands at home from scrap materials will be discussed in this article.

Safety precautions when operating an angle grinder

Note! It is no secret that when interacting with a dangerous tool, there is always an instruction consisting of rules that allow you to avoid unpleasant consequences when working with an angle grinder.

The following points should be emphasized:

- Compliance with requirements and instructions.

- Do not work with a damaged disk.

- Use the wheel according to its intended purpose: cutting wheel for cutting, grinding wheel for processing.

- A good master is careful, attentive and calm.

- Monitor the situation both before and after the operation.

- When using an angle grinder, do not stretch

Another similar option

You can do it differently. First, the same work is done as in the previous version - a strip is drawn, a corner is laid and pressed. But here the groove is made somewhat deeper - 4-5 mm. After the corner is removed, the remaining metal can simply be broken off, and the edge can be processed using an angle grinder with a grinding disc. However, there may be small pits on the edge, which makes the second option more acceptable.

The groove along the guide angle is made a little deeper than in the previous version

How to cut a pipe with a grinder

To cut pipes with a grinder, it is recommended to use cutting wheels with a thickness of no more than 1 mm, otherwise the cut will be more difficult, and there will also be too many sparks and flying hot particles.

The technology for carrying out the work is as follows:

- The pipe is secured in a vice or secured in another way. In this case, the cut part should hang down. It is not allowed to place the workpiece between two supports and make a cut in the middle, as the cutting blade will jam (due to sagging pipe).

- Markings are applied using a strip of paper and masking tape. The ends of the tape should meet as accurately as possible. Home craftsmen recommend lowering the pipe into the liquid at the required angle, and then marking the cut line along the dry and wet boundary.

- The cut should be made from the top of the pipe, gradually lowering the angle grinder lower. The cutting disc should go along the very edge of the glued strip.

A large diameter pipe is cut a little differently, since the working part of the circle does not allow this to be done in one go. The wall is cut sector by sector, and the pipe is turned to the desired side.

Method 3: Trim by eye in one pass

The fastest way is to trim by eye in one pass. At the same time, with experience you can gain sufficient skills so that the quality of the end is quite suitable for further welding work.

The cutting disc of the grinder is applied to the pipe from above as perpendicularly as possible. With a developed eye, this will work out the first time. After cutting the upper side of the profile, you need to move the disk to the near side. The tool must also run perpendicular to the pipe. Having two intersecting cuts, all that remains is to deepen the disk, and it will cut the profile to the end without distortion on the remaining walls.

Final part

You should not think that a grinder with a cutting disc is a tool used exclusively for dismantling metal structures and does not require careful operation. Quite the contrary. An angle grinder requires extreme concentration and accuracy in work. This is a rather traumatic tool, and therefore, when working with it, you should not forget not only about the correct markings, but also about safety requirements.

Only accurate calculation and cutting will allow the pipes to be perfectly aligned at an angle Sources

- https://instanko.ru/osnastka/kak-pravilno-rezat-bolgarkoj.html

- https://instrument-blog.ru/elektroinstrumenty/kak-rezat-bolgarkoj.html

- https://trubaspec.com/montazh-i-remont/kak-rovno-otrezat-trubu-instrumenty-i-sposoby-otrezaniya.html

- https://rezhemmetall.ru/sposoby-razmetki-i-rezki-metallicheskix-trub.html

- https://WikiMetall.ru/metalloobrabotka/kak-rovno-otrezat-trubu.html

- https://alsver.ru/rezka/metalla-bolgarkoy

- https://HouseChief.ru/kak-rovno-otrezat-trubu-bolgarkoj.html

[collapse]

Similar posts:

- How to work with an angle grinder correctly: step-by-step instructions

- Why is an angle grinder called an angle grinder, and what else is it called?

- FBS GOST blocks: foundation blocks 13579 78

- How to cut a plastic window sill evenly

- The thickness of the brick wall (with and without insulation),…

- How to cut a round pipe lengthwise into exactly 2 parts using a grinder