Pipes are the most common type of rolled metal and plastic. These products are used in various fields. Depending on the purpose, the products are cut to the required length, evenly or with a bevel at a certain degree. Several methods are used for cutting, including using a grinder. You can understand how to cut a pipe smoothly with a grinder by learning all the intricacies of cutting.

Cutting metal with a grinder

How to cut a pipe evenly with a grinder

To ensure an even cut from the grinder, it is recommended to use special devices for fixing the metal workpiece. Prepared templates, miter boxes or vices are suitable for this.

It is necessary to mark the place for cutting very evenly so that the cut does not go to the side. For large volumes of work, for industrial purposes, special equipment in the form of lathes or tape machines is used to cut pipes.

You can make vertical and horizontal cuts on a metal profile, and cut it at any angle.

Cutting a round hole in metal using an angle grinder

In practice, it is often necessary to cut a circle in metal, and the only tool available is an angle grinder. But it is quite enough for this purpose. The algorithm of actions is as follows.

- Draw a circle with a compass on the surface of the metal or on a pre-made paper (cardboard) template with chalk or a marker.

- Holding the grinder at an angle to the surface of the sheet, make a preliminary marking cut of the metal along the marked contour, making short movements with the disk (sawing in small sections).

- Then, moving the nozzle in the same way, deepen the slot until it is completely cut out.

You need to cut along the outer contour of the circle so as not to reduce the size of the circle. If its diameter is small, then they cut by touching the metal with a disk point by point (without longitudinal movement of the nozzle). The round hole will have an oblique cut, as well as some minor flaws (they depend on the skill of the worker). Afterwards it is processed, if necessary.

The entire process of cutting a round hole in sheet metal using a special tool is shown in the video:

Cutting pipes at right angles

The technology for cutting at right angles is quite simple. You just need to fix the metal part, mark the cut line, and directly cut the workpiece. The end of the cut part of the pipe should be above the support.

To mark the cut, use wide or narrow tape, a marker or a simple pencil. You just need to wrap the product, mark the cut location, and make an even cut. When winding, both ends of the tape must fit together accurately

Methods for cutting metal products at an angle

Conventional perpendicular cutting at 90°, using a grinder, is carried out quickly and efficiently, if you do not neglect the advice of specialists.

Many people believe that if a large tool with a large powerful disk is used for sawing, then there is no need to apply markings. Experts do not recommend sawing without marking, because after cutting the parts may not align.

Note! Before you understand how to cut a pipe evenly with a large grinder, it is better to make markings several times to make sure the calculations are accurate. After cutting a profile or gas pipe incorrectly, you will have to start working all over again.

Features of cutting a cylindrical pipe at 45

Most often, making a cut at an angle of 45 degrees is required when installing heating or plumbing systems. The main difficulty in carrying out the work is that after combining the cut parts of the pipe, a right angle of 90 degrees should be obtained. A simple way to prepare a homemade pattern will help you achieve the quality of the cutting process:

- Prepare a plain white sheet of paper.

- Fold it diagonally.

- The protruding part of the sheet must be cut off with scissors so that when unfolded you get a square.

- The resulting triangle must be wrapped around the pipe so that the long side runs parallel to the section.

A paper template is great for cutting metal products in the middle.

Paper template

The resulting triangle, folded in half, must be divided into two parts. Then the templates need to be wrapped around the pipe and secured with tape or tape. The templates should be positioned so that one edge of the base coincides with the second.

Use scissors to round the top corners of both templates. The resulting two blanks of the required diameter should be placed on the pipe, and the cut location should be marked with chalk or a pencil. The prepared marked part can be safely sawed off.

For small diameter tubes that need to be cut close to the edge, the marking method using a container of water is suitable. The desired angle of inclination of the cut is marked on a deep container, then the end of the tube is placed in the water and tilted towards the marking. The line of contact with the liquid will become a cutting mark.

How to mark a 45mm cut on a profile pipe

Not everyone knows how to cut a profile pipe at 45 degrees with a grinder correctly and efficiently. Experts advise using an ordinary triangular ruler to mark a profile pipe with a square cross-section.

First, a straight strip should be drawn on one of the faces, located perpendicular to the side of the pipe. Then the workpiece must be rotated and an oblique mark applied to the adjacent face. It should go from the edge of the first strip at an angle of 45 degrees.

After this, the product is turned again and a perpendicular line is drawn. On the fourth side, all that remains is to connect the previously drawn stripes diagonally. Now you can start cutting.

Additional Information! Many experts believe that the best way to mark professional pipes is a tape measure. However, using this tool it is very difficult to do the job perfectly; the cut may turn out uneven. The school ruler will do the job much better.

Features of working with thick metal, copper, cast iron, aluminum

When it is necessary to cut thick metal into separate fragments, it is recommended to additionally perform the following steps:

- constantly cool the area of contact between the metal and the disk using cold water due to the strong heating of the slot;

- make all cuts only in a straight line;

- different curved contours should be cut out in separate straight sections of short length, removing unnecessary parts;

- You need to completely cut the workpiece in several approaches, deepening the slot with each subsequent one;

- if you need to cut corners, I-beams, channels, rails, then each of their structural parts is sawed separately.

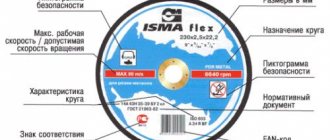

Cutting cast iron, stainless steel, as well as non-ferrous metals, such as aluminum and copper, is carried out using special wheels designed for working with these materials. All necessary information about the discs is contained in the markings of these products, printed on their sides. In this case, the circles differ in the composition of the fillers:

- in some, the additive is a super-strong material that can cut alloy steel;

- others use mild binders.

Cutting stainless steel with conventional metal cutting discs is prohibited, because they contain substances that lead to accelerated corrosion of the cut site . Aluminum and copper are very viscous non-ferrous metals. They are sawed using a grinder, pouring kerosene over the slot formed by the disc. In this case, it is necessary to comply with fire safety rules.

Rules for cutting pipes from different metals

A grinder, even in the hands of a master, is a rather dangerous tool. When working with it, you should take precautions and be as focused as possible. Otherwise, you can not only damage the metal workpieces, but also injure yourself.

Every metalworking specialist should know how to properly cut a pipe at 45 degrees with a grinder. The disc circumference should be installed with the pattern facing up, and clamped with a special nut. Pipes made of different metals are cut in compliance with certain rules.

Working with aluminum blanks

Aluminum is a soft type of metal, so a different type of disc is used for cutting with a grinder. When working with soft metals such as aluminum or copper, it is impossible to make the cut in one go. The cutting disc simply gets stuck in the material.

Cutting with a special disc is performed very carefully. You need to go through the same section several times.

Cutting aluminum pipes

How to cut cast iron pipes

Cast iron is characterized by increased strength, but at the same time it is a rather fragile material. For sawing cast iron pipes, it is recommended to use diamond-coated discs. You can cut fragile material with a grinder only in a straight line.

Important! It is necessary to carry out work with sawing cast iron, steel, and aluminum only with the use of personal protective equipment (wearing a respirator, safety glasses and gloves). During the cutting process with a grinder, a large amount of dust is generated.

Cutting large pipes

The grinder is often used for cutting large diameter pipes. Large metal products have thicker walls and greater weight. To work with large metal workpieces, it is more convenient to choose large disks.

Heavy, non-lifting products must be firmly installed on low supports or on a flat surface so that they do not change their position when cutting the final section.

When working with large pipes, you should choose the correct direction of rotation of the grinder disk circle. Otherwise, it is difficult to hold the tool in a fixed position, and the disc wears down too quickly.

What is a kickback?

This is the name of one of the most dangerous cases that can happen during work. The effect occurs when the wheel is strongly jammed into the workpiece, as a result of which the power tool is sharply thrown back. It is necessary to carefully monitor the process and hold the grinder tightly.

The points weren't enough

How to avoid kickback

To do this you need:

- Always hold the tool by the standard handles.

- Take a stable position on the ground.

- Use both hands.

- Be slightly away from where the tool will hit.

- When the angle grinder moves away from itself during a reverse impact, it bounces onto the person.

- Be especially careful when working around corners and edges.

Features of cutting thin-walled pipes

Sawing thin-walled metal has its own characteristics. When cutting these products, there is a high risk of crushing the edges at the cut points. To prevent this, experts recommend filling the pipes from the inside.

A wooden stick of suitable diameter or sand may be suitable as a filler. For a thin-walled profile, when cutting with a grinder, thin cutting discs are chosen. Working with such material is much faster.

Gas pipe cutting

What are the dangers of an angle grinder?

An angle grinder is a dangerous tool. This is caused by the following reasons:

- high rotation speed of the working nozzle - it exceeds 10,000 rpm;

- openness (unprotected by the casing) of most of the disk;

- the ability to break the abrasive disk into fragments of different sizes, which fly to the sides at considerable speed;

- frequent inability to properly organize the workplace;

- the formation of small particles when cutting metal (or other material) or grinding.

When the disk jams, which occurs even due to its slight misalignment, it is almost impossible to hold the grinder in your hands, especially a powerful tool. This is caused by the high speed of rotation of the nozzle. Therefore, beginners are recommended to work with low-power models equipped with discs with a diameter of 115-125 mm. The latter must be free from the slightest defects that could lead to their sudden destruction and tearing of the angle grinder out of your hands with uncertain consequences.

How to cut a gas pipe correctly

The work of cutting gas pipes is dangerous and quite difficult, so it is best left to the professionals. Before starting work, be sure to turn off the gas supply.

The next step involves freeing the pipe cavity from residual gas. To do this, you need to light the gas burners on the stove and wait for them to go out. Only after carrying out the above manipulations should you begin marking and subsequently cutting the metal.

High-quality cutting of metal pipes is a complex process. However, if you take precautions and listen to the advice of professionals, you can cut metal of any density and thickness using a grinder. A grinder with a cutting round disc is rightfully considered a universal tool in everyday life. The main rule is not to forget about safety precautions when working with dangerous cutting tools.