A technical hair dryer is a universal power tool that is used in the household for construction or repair work. With its help, they prepare surfaces for painting, bend plastic pipes of any diameter when installing water supply and sewerage systems, perform operations with heat-shrinkable materials, solder and perform many other works. If at the right time a construction hairdryer is not at hand, you can make it yourself. This task is especially relevant for those who do not have a constant need for this tool, so it is not economically feasible to buy it for one-time work.

Heating element for hair dryer

The heating element is nothing more than a spiral that is wound on a ceramic base. In many models, the manufacturer integrates a temperature sensor, which, in case of overheating, turns off the power to the hair dryer. Nichrome is usually used as a spiral material. Having a certain resistance, the spiral takes part of the heat when current passes through it and releases it into the environment, thereby providing a continuous hot air flow.

Safety precautions

It would seem that for us there is nothing new or incomprehensible about how to follow basic safety rules when working with electrical appliances. But self-repairing even such a compact device as a hair dryer will require you to be careful. And this is connected precisely with electricity:

- Proceed only if you are familiar with electrical work. If they are absent, it is better to trust the professionals.

- Be sure to unplug the device first. Use an indicator screwdriver or a multimeter to check.

Be sure to disconnect the device from the mains before repair work. - Please note that our recommendations apply only to household hair dryers that are used at home. They are not suitable for professional devices.

Malfunctions of a hair dryer

With intensive use of the tool, it is not uncommon for it to break. They are very different. We will now tell you how to figure out what exactly might break.

The first step is to conduct a visual inspection of the hair dryer. Close attention should be paid to buttons, switches, power cord, plug. A fairly common cause of failure is insulation failure or wire breakage at the junction with the housing. If the wire is damaged, it must be cleaned in this place and insulated with adhesive tape. If the power buttons and switching temperature modes are faulty, they should be replaced with new ones.

If this is not the reason, then you should diagnose the operation of the tool in different modes. The hairdryer can only supply cold air. In this case, it is necessary to inspect the heating element of the device - the spiral. If there is no air supply, your attention should be directed to the fan or motor. Replacing a heating element, fan or wires in itself is a simple and inexpensive procedure, which cannot be said about replacing an electric motor. If it breaks down, repairing the hair dryer becomes pointless.

Safe Operation

In order not to visit the service center frequently and save time and the family budget, you must strictly follow all operating requirements:

- Use only standard, factory-made extension cords.

- Inspect the cord before each use of the product and do not wrap it around the handle when storing.

- You can only use the supplied attachments that come with the kit.

- Do not use the product in a room with high humidity and do not expose it to water.

- Install a special fine-mesh filter in the air intake to prevent hair from being sucked into the device.

- If any malfunction occurs, immediately disconnect the product from the electrical network.

- Do not pull the cord from the outlet or carry the device by the cord. Remember that the wires inside are not steel, but copper, which can be damaged by mechanical stress.

- Do not overheat the hair dryer if you need the device for long-term use - purchase a professional device that is designed to last for a long time.

- Before storing the device, you must give it time to cool for at least half an hour.

- The product must be stored in a dry place, the drawer must be locked.

If you follow all the recommendations exactly, your hair dryer will work without repair, and your hair will look flawless and stylish.

Refinement of a construction hair dryer

During the work process, the user may not be satisfied with some design factory solutions, so he decides to modify the hair dryer.

In general, tool modernization can be aimed at specific purposes. We present some of them below:

- Possibility of using various attachments.

- Adjusting the air flow when installing small parts.

- Make independent disconnection of the coil from the fan and vice versa - for quick cooling of the tool.

Let’s talk separately about options for modifying various elements of the tool’s design.

- A heating element. Here it is possible to remove the standard heating coil and replace it with a thermocouple. To do this, you need to remove the spiral along with two white wires that go to power the motor. The thermal fuse is connected by crimping to the opposite end of the spiral. The thermocouple itself must pass through a free channel. Its end must be connected to the board with screws.

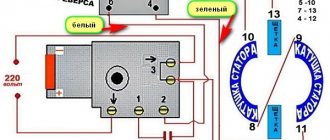

- The engine control unit. In this unit, air flow is controlled by changing the speed of the fan motor. Those, in turn, depend on voltage. The simplest would be control via PWM (pulse width modulation). In this case, the smart transistor must be replaced with a field-effect transistor with a “logical input”.

How to calculate and wind a spiral for a hot air gun

To make a construction hair dryer with your own hands, you need to be able to calculate a nichrome spiral, that is, determine what length of wire of a certain cross-section will be required for the spiral made from it to produce a certain power. The duration of the continuous operating cycle of the tool, and, accordingly, the ability to perform large volumes of work with it depends on this indicator. Depends on the power and heating temperature. But it will also be influenced by other technical parameters of the hair dryer, for example, performance or volume of air supplied per unit of time (usually per minute).

Calculation of the required length of nichrome wire

Having decided on the required power of a technical hair dryer, and for home work it can be from 800 to 1500 W, you need to calculate how long the wire needs to be taken for winding the spiral. To do this, you need to perform a series of sequential calculations:

- Determine the current by dividing the power by the voltage. For example, if you need to get 900 W of power from a 220 V household electrical network, the current should be equal to I = P/U = 900/220 = 4.09 A.

- Calculate how much resistance the spiral should have. Why divide the voltage (U) by the current (I). We get R = 220/4.09 = 54 Ohms.

- The length of a nichrome wire with a resistance of 54 Ohms is determined from the formula R = ρ L / S, where R is the resistance, ρ is the resistivity coefficient of the material (for nichrome it is in the range of 1–1.2), and L and S - length and cross-sectional area of the wire. Let's say wire diameter D = 1.00 mm. Then its cross-sectional area will be equal to S = 3.14 · D2/4 = 0.785 mm2. Therefore, the length of the wire is given by R · S / ρ = 54 · 0.785 / 1.1 = 38.54 m.

The thinner the wire, the less it will be needed to make a hot air gun of the same power. The data obtained by calculation must be verified in practice. After all, the wire may have deviations in chemical composition or uneven thickness along its entire length. Before cutting it off from the coil, you need to measure the resistance of the measured piece with an ohmmeter.

Nichrome spiral winding

To wind a spiral from nichrome wire, you must first determine the length of the cylindrical rod or tube on which you will wind it. This is quite easy to do, knowing the diameter of the spiral and the length of wire that is required for this. Be sure to take into account that after winding the spiral rings are slightly springy, so its diameter will be slightly larger than the size of the rod .

Having decided on the length of the rod, you need to make a simple device. There are several types of such devices. For mechanized winding you will need:

- bench vice;

- electric drill with controlled speed;

- two wooden blocks with a cross section of 20 x 50 mm;

- coiling rod (mandrel).

The simplest device for mechanized winding of a nichrome spiral consists of the following parts: 1 - vice, 2 - wooden block, 3 - nichrome thread, 4 - mandrel, 5 - electric drill

Semicircular grooves are cut into the bars, forming a hole of sufficient diameter to accommodate a coiling rod with wound wire. The rod itself is inserted into the drill chuck, and a nichrome wire is attached to its end. The structure is clamped in a vice tightly enough to hold the bars and allow the wire to pass between them when winding.

For manual winding, the same principle is used, but instead of a drill, a wrench is used, and the free end of the mandrel is enclosed in a supporting surface with a bearing. You can slightly modify the design by removing the vice and supporting the rod at both ends for winding onto the bearing assembly.

Video: hand-winding a spiral of nichrome wire

When winding a spiral, you need to follow some rules:

- winding should be carried out without stopping and without loosening the thread tension;

- do not guide the thread with your hand, but only with wooden blocks, to avoid serious cuts;

- avoid bending the wire, which may not break immediately, but will very quickly burn out at the bend;

- you need to choose the length of the rod for winding with a margin and taking into account the possibility of securing it in a vice or on supporting surfaces.

When winding, the turns should be laid close to each other. It is better to then stretch the spiral to the desired length.

In order to make a construction hair dryer with your own hands, you do not need complex devices and tools. You just need to be smart and come up with the most convenient design possible. It is advisable that your homemade product be made taking into account the needs that arise, as well as with a view to using it in the future. After all, a hot air gun will certainly be useful to you in the future for construction, repair or installation work.

Repair of building dryers

When using the tool, certain malfunctions appear. Let's look at the experience of a hair dryer user as an example. What might the future hold for you?

- In the first year of the hairdryer's life, it became impossible to regulate the temperature - the reason lay in the triac overheating and its failure.

- We are already familiar with the fracture of the power cable at the point of contact with the instrument body. This problem is solved by installing the cable in double rubber insulation.

- The high resistance heater winding has broken. The reason could be either a manufacturing defect or rubbing of the nichrome winding on the edges of the ceramic due to heating and cooling processes. In the process of replacing the winding, it was necessary to replace the thermal fuse, which was triggered when the engine suddenly stopped.

- By the end of the second year of operation, the plain bearings in the engine failed.

This is a common list of malfunctions that may occur in the device over the course of three years of operation of the instrument. In addition, there were other minor defects such as a loss of voltage on the heating element coil. This does not mean that all this will appear specifically in your hair dryer model, but these are the things that you should pay attention to when buying and using a hair dryer.

In this article, we tried to highlight as much as possible all the problems that arise during the operation of a hair dryer. Whether to buy this tool or not is, as always, up to you to decide.

Design Features

The set of basic elements of any hair dryer - household or construction, cheap or expensive - is not much different. Critical difference in the quality of parts. Some models use mediocre metals and plastics, while others boast the presence of high-tech materials, such as titanium coating and soft-touch plastic.

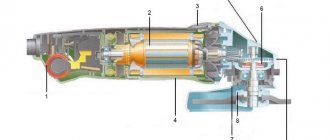

Structural elements of a hair dryer

The main design element is the electric motor. Modern technology is based on a low-voltage collector base (12-18 V) with a voltage rectifier. The spiral of the device can have several windings, which depends on the number of modes: ordinary models have two or three.

Hair dryer heating coil

The heating element requires good airflow, especially for powerful devices, so the fan not only draws in air for subsequent heating, but also acts as a cooling system. If the temperature inside the case approaches critical, the hair dryer turns off automatically. A thermostatic relay with a fuse is responsible for this. Let's take a closer look at their work.

Thermostatic relay

The part includes two contacts located on a bimetallic platform. When the hair dryer is working and the temperature has reached a critical point, the plates heat up and the power circuit opens. Afterwards, when the device has cooled down, the contacts are reconnected and the device can be used again.

Hair dryer thermostat

The thermostatic relay, like other components, can be of different quality. In more expensive models it works like a charm, while in budget devices it can often turn off for no apparent reason.

Fuse

The relay can be called the protection of the first line, while the fuse is the last. If for some reason the thermostat does not work, then after some time the equipment is de-energized by a fuse. It is located, as a rule, next to the thermal relay, less often - in the handle area.

The thermal fuse is a one-time use item and cannot be repaired. Depending on the brand of equipment, the resistance of the element changes, along with the shape. You can buy a fuse at almost any specialized point of sale. Some exotic species are worth looking for in service centers where equipment is serviced.

Fuse for a hair dryer

As for other elements - the power cord and button, here everything also depends on the specific model. More expensive solutions have a flexible and reliable cable, while budget options are constantly twisted and easily broken. In a good half of cases, the button, in addition to turning on the device, serves as a mode switch.