Resanta welding machines are simply extremely popular in Russia. The equipment is reliable and, of course, convenient to use. Instruments of this brand have been known on the domestic market for a very long time - since 1993. They can be used both at home and at work.

The model range of the Resanta brand presented on the domestic market is quite wide. If desired, consumers have the opportunity to purchase equipment of this brand with a variety of technical characteristics and functionality. At the same time, one of the most popular models from this manufacturer is the Resanta 160 device. This equipment has received simply excellent consumer reviews.

Who releases

is a Latvian company SIA RESANTA. This company began its activities in 1993. Initially, it was engaged only in the production of voltage stabilizers. These company products are also well known throughout the former USSR.

The quality of the devices is really quite good. And therefore it has always enjoyed enormous popularity among consumers. Thanks to this, by 2008 the company was able to increase its production volumes 10 times compared to 1993.

Today, in addition to voltage stabilizers, the company produces compressors, multimeters, thermal equipment, testers, etc. And of course, this company also supplies high-quality inverters to the market.

Main advantages of the model

The Resanta 160 welding machine has many advantages. These include, for example:

- high level of operating current;

- ability to work at low voltage;

- Possibility of use at unstable network voltage.

This device is also compact. It is believed that it is simply ideal for work in domestic conditions. But, unlike many other Resant models, this equipment can also be used in production. This device belongs to the inverter type devices. That is, its design contains a unit designed to convert alternating current from the network into direct current.

Compact Resanta SAI-160K

Cheap model from the Resanta-160 line. The K in the name means “compact”. This is an advantage of the device for those who often need to travel to the welding site, including by public transport. You can’t easily take previous models with you.

The inverter weighs three kilograms, and SAI-160 weighs 4. It is so small that it can be carried in a backpack without purchasing a special bag. This is relevant for those who are just starting to learn how to cook and often make house calls.

The dimensions of the device are what distinguishes this model from others; in other characteristics it is completely similar to them.

It requires electrodes with a diameter of no more than four millimeters. This is enough to weld pipes. SAI-160 operates from the home network and can withstand voltage drops down to 10 V.

General description of the model

One of the undoubted advantages of the Resanta SAI 160 inverter welding machines is a wide range of current strength. At the same time, the wizard can set the required value manually. Thanks to this feature of the device, it can be used both for delicate welding using thin electrodes and, for example, for cutting thick metal.

The housing of the Resanta 160 welding machine is equipped with fans. These elements perfectly complement the natural air cooling of the device. If desired, models 160 can be used in low power networks. It is also possible to connect them through generators.

Of course, this model has all the functions that distinguish modern inverters from previously produced less advanced and convenient devices:

- preventing sticking;

- hot start.

If the electrode sticks to the surface being welded, the current in the machine automatically decreases. And this, in turn, reduces heating. As a result, the electrode easily comes off the metal.

At the very beginning of operation of the Resanta 160 inverter, the current increases sharply. This leads to rapid heating in the place where the electrode contacts the metal surface. Therefore, a welder using this equipment never has problems with electrode sticking at the beginning of work.

Universal model Resanta SAI-160 (160A)

This is a small, simple device for basic use. Used for RDS welding with one welding rod with a base coating.

The description of the unit says that it is used for domestic needs. It is used by beginners to learn welding and by garage workers for work.

The maximum current strength is 160 A. With this parameter, you can weld garage doors, repair gates, make a greenhouse or a barrel. Connects to a home network with a voltage of 220 V. You can cook with small electrodes up to 4 millimeters.

The Resanta SAI-160 package is small: two cables, a terminal and a holder. A two-meter cable is enough for a home. If you need a longer wire, you can always purchase an extension cord. The power cable is short, 170 centimeters.

The mask is not included in the package, you need to buy it yourself, but in this case it is a plus.

The masks that come with the devices are usually of low quality and deteriorate after the first use. The cables included in the kit do not last long, so you should immediately buy spare ones.

The SAI-160 device has a hot start button and an anti-stick function. They guarantee a reliable arc and prevent the electrode from sticking to the metal. These are common problems that new welders encounter.

Mains voltage and electrode diameter

The technical characteristics of the welding machine "Resanta 160" are really quite good. The ease of use, and therefore the popularity among consumers of this model, is explained, of course, primarily by the thoughtfulness of its design. In everyday life, the use of 160 devices became possible due to the fact that they operate from a 220 V network. For industrial equipment of this type, as is known, 380 V is required. Previously produced welding machines were designed to operate from precisely such networks.

The maximum current of this model, as can be judged by its name, is 160 A (with a minimum of 10 A). If necessary, welding can be performed with the Resanata 160 machine using fairly thick electrodes. The maximum diameter of the latter for this model is 4 mm. The minimum electrode diameter for the device is 1.6 mm.

Characteristics and reviews from owners of the Resanta SAI 160

Why and who needs a welding machine

In a farmstead, on a summer cottage, in a garage or a small production workshop, you can’t do without a welding machine.

Long gone are the days when they used a classic transformer welder, which weighed well over 50 kilograms, and when working, the light “sagged” throughout the entire street or in a garage cooperative.

With the advent of inverters, the situation has changed dramatically. Compactness, light weight, almost silent operation and ease of use have opened up the world of welding for many. Welding a fence at the dacha, making shelves in the garage or welding hinges that came off the door - with the advent of inverters, this has ceased to be a problem.

Despite the many “classmates”, good reviews and an adequate price of the Resanta SAI 160 welding machine sway the buyer in their direction.

Types of welders

This inverter converts alternating current from the electrical network into direct current. Resanta differs from similar devices in its circuitry that has stood the test of time. Integrated chips control the transformation of electrical current, which provides flexibility in its use.

For garden, dacha and garage use, experts recommend the Resanta SAI 160, Resanta SAI 160 K and Resanta SAI 160 PN models, the price of which is not much higher.

The model with the index “K” denotes the “Compact” series, it is lighter by a kilogram, and the “PN” model, which can work with a voltage of 140-160V, is suitable for gardening and garage realities.

You can find these welding machines in different stores at prices ranging from 5,500 to 7,000 rubles.

Characteristics of the welding machine Resanta SAI 160

- Operating current 10 - 160 A

- The diameter of the electrodes is from 1.5 to 4 mm.

- "Hot start" and "Anti-sticking".

- Weight 4.5 kg.

The Resanta SAI 160 welding machine is a basic model, operating on a voltage of 220 volts +/- small deviations: plus 10%, up to 240 volts, minus 30%, up to 156 volts.

In practice, the inverter cooks normally at 190; if the voltage is lower, you have to change the electrodes to smaller ones. For holiday villages and rural areas, where voltage drops in the network are common, the Resanta SAI 160 PN inverter welding machine is suitable; reviews from owners about it are mostly positive.

The operating mode of these devices is 70/30%. These numbers mean that out of 10 minutes you can cook for 7 minutes, and rest for 3 minutes while waiting for the device to cool down.

Video:

Pros of s/a Resanta SAI 160

The advantage of Resanta SAI 160 welding machines is that they operate on a 220 V network. The protection class of these inverters is IP 21. This means that grounding occurs through the power cord. Resanta SAI 160 works on 10-16A machines, but as practice has shown, 10A machines can no longer cope with the maximum welding current.

The belt will allow you to carry the device with you if you need to frequently move along the workpiece being welded or if it is not possible to put the device on the ground. In this case, the Resanta SAI 160 K will be a good choice, reviews of which on the Internet note the low weight of the inverter.

Video:

Features of operation of inverter welding machines Resanta SAI 160

- There should be no operating electric saws, angle grinders, grinding machines or tools near the operating inverter, which raise dust when working with them. The inverters are equipped with forced cooling - coolers; if there is a large amount of dust, it will get inside the device. For the same reason, there is no need to place the inverter on the ground; it is better to lay a rubber mat or a sheet of plywood.

- Do not cover the welding machine during operation. The reason is the same - the coolers cannot cope with the cooling, the device will overheat and turn off.

- You cannot work in the rain. No comments.

- If the welding machine is brought into a warm room from the street in winter, you should wait at least 2 hours so that the condensation that has formed in the machine has time to dry.

“Anti-stick” and “Hot start” make life easier for beginners in welding. Those who welded with old transformer-type welding machines remember well how difficult it is to ignite an arc. Resanta SAI 160 inverters relieve their owners from this problem.

- “Hot start” easily ignites the arc, sharply increasing the current when the electrode touches the surface and creating a high temperature at the point of contact of the electrode.

- “Anti-sticking,” on the contrary, independently reduces the current strength in the event of the electrode sticking to the surfaces being welded. As a result, the heating decreases and the electrode comes off easily.

Video:

https://www.youtube.com/watch?v=j0Hgai4FNsE&spfreload=10

Malfunctions and shortcomings of welding machines Resanta SAI 160

Even the most advanced equipment can fail, and Resanta SAI 160 inverters are no exception. Malfunctions that arise can be divided into two categories - manufacturing defects and violation of operating conditions and requirements.

Common faults:

- Microchip malfunction. This breakdown can be caused by a manufacturer’s defect or dust getting into the device, for example, when working in a dirty, poorly ventilated area or if “dusty” work is carried out near the inverter.

- Frequent and premature shutdowns of the device due to its overheating. In this case, a protective relay is activated, designed to protect the expensive inverter from damage. The reason is most often simple - either poor contact of any circuit inside the device, which always leads to overheating, or again a violation of the rules for operating the device, for example, when the welder is covered with something during operation.

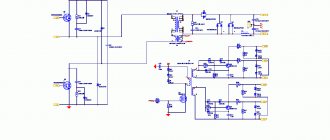

Scheme of Resanta SAI 160:

Click on the diagram to enlarge the size

PS Many users of Resanta SAI 160 welding inverters are dissatisfied with the short welding wires. They are one and a half meters long, which is not always convenient when working with an inverter.

Owners independently change welding wires to longer ones, which is not a violation of operating rules. The main thing in this case is that the new wires have a cross-section of at least 25 mm/sq.

By the way, increasing the length of the welding wires will lead to a loss of welding current power, but for most owners who use an inverter in the country and in the garage this is not critical.

Open circuit voltage

This figure for the model is 85 V. This figure, in comparison with many other modern devices, is quite large. This no-load voltage makes it very easy to ignite the arc in Resanta 160 devices. However, at the same time, the high value of 85 V, unfortunately, somewhat reduces the safety of use (discharge from accidental contact can cause harm to health) of this equipment. However, model 160, like most other modern ones, is equipped with a special function of protection against electric shock to the master.

Inverter welding machine Resanta SAI-160

The welding machine Resanta SAI-160 is designed for manual electric arc welding with direct current with a coated electrode. This device can be used in both the household and industrial segments.

Specifications

| Welding current adjustment range: | 10…160 A |

| Maximum power consumption: | 4.8 kW |

| Maximum current consumption: | 22 A |

| Input voltage range: | 140…260 V |

| Maximum electrode diameter: | 4 mm |

| Length of cable with electrode holder: | 2 m |

| Ground cable length: | 1.5 m |

| Duration of loading: | 70% at welding current 160 A |

| Open circuit voltage: | 85 V |

| Arc voltage: | 26.4 V |

| Anti-stick protection: | ANTI STICK function |

| Overheat protection: | automatic |

| Hot start function: | There is |

| Cooling: | forced |

| Protection class: | IP21 |

| Ambient temperature: | -10…+40 °С |

| Overall dimensions, L×W×H: | 350x140x250 mm |

| Weight, no more: | 4.5 kg |

| Warranty period: | 24 months |

Principle of operation

It consists of converting alternating mains voltage with a frequency of 50 Hz into a direct voltage of 400 V, which is converted into high-frequency modulated voltage and rectified. Pulse width modulation is used to regulate the welding current.

SAI-160 device

The product is made in a metal case, on the front panel of which there is:

- Regulator of welding current value. Using the welding current regulator, you can set the desired current depending on the thickness of the welding electrode.

- Power connectors for connecting welding cables.

- The “network” indicator lights up when the device is turned on.

- The “overheating” indicator lights up for a few seconds when the AIS is turned on and when the device overheats and turns off after it has cooled to operating temperature.

- Automatic switch, the Resanta welding machine is equipped with an automatic switch instead of a conventional switch. It allows you to work in networks with weak wiring and networks that are not equipped with protection (installed on the rear panel).

Hot start (HOT START)

To ensure better ignition of the arc at the beginning of welding, the inverter automatically increases the welding current. This will greatly facilitate the start of the welding process. Thanks to this function, the device can be used not only by experienced welders, but also by beginners. This function is installed on all Resanta welding machines.

Anti-stick (ANTI STICK)

When starting welding, the arc must be ignited. This often leads to the electrode sticking to the product. In this case, the inverter itself automatically reduces the welding current, and the electrode easily comes off. Subsequently, after the stuck electrode comes off, the inverter resumes the set welding parameters. All AIS are equipped with this function.

IGBT

Without exception, all Resanta inverters are made using IGBT transistors. The effect is that due to them the service life of the device increases by 7 times. In addition, weight and dimensions are reduced. With IGBT, the board is located vertically, dust does not settle on it.

| Electrode diameter (mm) | Current (A) |

| 1,6 | 25-50 |

| 2 | 50-70 |

| 2,5 | 60-90 |

| 3,2 | 90-140 |

| 4 | 130-190 |

| 5 | 160-220 |

| 6 | 200-315 |

PV (on duration)

The meaning of the “PV” parameter is as follows: this is the time during a 10-minute interval that the device is capable of operating at the specified current. This means that for 70% of a 10-minute interval (that is, 7 minutes), the device can continuously cook without breaking the arc at the specified current, and for the remaining 3 minutes it must “rest” at idle, and the device cannot be turned off from the network, so that forced cooling (fan) works.

Open circuit voltage

The higher the open circuit voltage, the easier it is to strike the arc. With this inverter it is 85 V, the arc ignites easily, and it is possible to cook non-ferrous metals.

The holder and ground cable are 2 meters long, the power cord length is 1.7 m, the length of the welding machine is 30 cm. A total of 4 meters of working space. For more convenient work, a regular extension cord of the required cross-section is sufficient.

Equipment

| Welding machine: | 1 PC |

| Cable with electrode holder: | 1 PC |

| Cable with ground terminal: | 1 PC |

| Manual: | 1 PC |

| Package: | 1 PC |

Documentation

Passport for welding machine Resanta SAI-160

Certificate of conformity for Resanta welding machines

Dear buyer!

The manufacturer sets the official service life for inverter welding machines to 5 years, subject to compliance with operating rules. The Resanta Trading House expresses its deep gratitude to you for your choice. Our company has done everything possible to ensure that this product satisfies your needs, and the quality corresponds to the best world standards.

Cooling system and protection class

The Resanta 160 model can serve in the household for a very long time. A good welding machine nowadays should also have an effective cooling system. Of course, when developing the Resanta 160, the designers took this into account. As soon as the equipment warms up to a certain temperature during operation, its fans automatically turn on. “Resanata 160” has two of the latter, which is a good indicator for a modern budget device.

When purchasing an inverter, you should also pay attention to its protection class. Of course, carrying out welding work, for example, in the rain using such equipment is strictly prohibited. However, the higher the protection class of the model, the better, of course. After all, anything can happen in life and the device can, for example, be forgotten on the street. Or it may suddenly rain while working. Resanta 160 models belong to IP21 protection class. This means that they can remain safe in direct rain. When oblique, it is better not to use them under any circumstances.

Reviews about the model

The opinion of consumers on the Resanta 160 welding machines, as already mentioned, is simply excellent. The undoubted advantages of this model include, of course, the ability to work at unstable or low voltage, as well as compactness and low weight. Another advantage of this inverter is its relatively low cost. The price for Resanta 160 devices is approximately 7,000 rubles. That is, this equipment costs much less than much other similar modern equipment.

The 160 inverter rarely requires repairs. The equipment is quite reliable and durable. However, if it breaks, it will not be particularly difficult to repair it. Service points specializing in this brand are available in many cities of the country.

Thus, this model has many advantages. This is a really good welding machine. But this inverter, of course, according to consumers, also has some disadvantages. Masters include, first of all, as already mentioned, short cables. Also, some consumers note the fact that defects are sometimes found in batches of Resanta 160. In this case, the device must be repaired or replaced with a new one.