The GS526U screw-cutting lathe is industrial equipment designed for carrying out turning operations of various profiles (including cutting inch, pitch, metric or modular threads).

Modifications

The GS526U screw-cutting lathe is produced in several basic modifications, each of which has its own functional features and equipment. The modification is indicated by an index in the name of the equipment. The main modifications of the GS526U screw-cutting lathe are as follows:

- C - the machine is equipped with a drilling and milling device, which makes it possible to carry out work on milling, drilling, boring, countersinking and cutting threads at an angle on workpieces mounted on a support;

- B - the maximum diameter of the workpiece that can be processed on the machine has been increased (630 mm above the bed and 420 mm in the support);

- G — screw-cutting lathe GS526U with a recess in the bed;

- D - the maximum diameter of the rod installed in the spindle hole has been increased to 89 mm;

- L - equipment with a division value of the movement dial in the transverse direction of 0.02 mm;

- M - screw-cutting lathe GS526U with a mechanized drive for the movement of the upper part of the support;

- C - a machine with digital indexing of workpiece feed and linear displacement transducers;

- RC - screw-cutting lathe GS526U with digital feed indexing, stepless control of spindle speed and linear displacement converters;

- E - equipment that complies with European Union safety standards and is marked with the “CE” marking.

Modifications can be combined if necessary. This allows you to order a screw-cutting lathe GS526U with the required set of characteristics and equipment.

The GS526U screw-cutting lathe is used in industrial enterprises, machining shops or private workshops.

Purpose

The GS526U screw-cutting lathe is used to remove a layer of metal from the surfaces of bodies of revolution. It is screw-cutting, which allows you to create various types of threads. The technical potential and relatively low cost of the GS526U determined the spread of this model in a wide variety of industries. Despite the fact that a screw-cutting lathe is technically inferior to modern equipment, its maintainability and affordability make it a rather attractive offer for factories in the mechanical engineering industry.

Introduction to the topic

The Belarusian development, the screw-cutting lathe GS526U, offers many possibilities. The functional purpose of the equipment includes not only turning with class P precision on cylindrical workpieces and parts of other shapes, but also cutting threads of various types. An undoubted feature that makes this family of units very popular in repair shops and tool shops of enterprises is the ability to order the desired version of the machine, as well as additional sets of tools and equipment.

Peculiarities

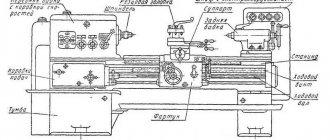

The GS526U machine in question has technical characteristics that allow it to be used for processing parts with accuracy class P. The manufacturing plant produces this model in various versions to order from the buyer, its purpose is turning conical and cylindrical surfaces, thread cutting. Design of a screw-cutting lathe:

- The GS526U 01 lathe has a variety of holes in the spindle. The manufacturer allows you to specify this technical parameter depending on your needs.

- Gears are made of high-strength steel, which makes it possible to significantly increase service life: the gearbox can withstand heavy loads. The screw-cutting lathe GS526U has a design that allows you to replace gears at the time of gearbox repair.

- The replacement gear guitar does not change when cutting threads 11 and 19. This characteristic significantly simplifies the tasks assigned to the master. A universal screw-cutting lathe is used to produce high-quality threads.

- The GS526U screw-cutting turning machine is equipped with an apron that has its own drive.

- The center in the tailstock quill is Morse 5, created according to established standards.

- The feed box makes it possible to adjust the supply of the cutter. The feed box is connected to the main kinematic circuit. The mechanical feeding method is also highly accurate. The transverse stroke is also mechanical.

- The spindle speed varies from 16 to 2000 rpm. The installed gearbox allows you to adjust the processing mode with the greatest precision. The lead screw is also manufactured using high strength steel. The machine motor can operate smoothly all day long thanks to an efficient cooling system.

- The weight of the equipment together with the delivery set of screw-cutting equipment is 3,500 kg. Before installation, it is worth considering this characteristic, since the base must withstand the load and absorb some of the vibration. The heavy weight complicates the process of transporting the screw-cutting lathe GS526U.

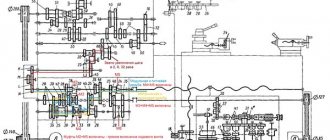

- The delivery set includes a passport, which indicates the design of the GS526U screw-cutting lathe, an electrical diagram, an instruction manual and a kinematic diagram.

Download the passport (operating instructions) of the GS526U lathe

The technical characteristics of a screw cutting machine may differ significantly, so you need to study the description. In this case, the electrical circuit remains unchanged; a new caliper or an upgraded drive can be installed. The manufacturer provides additional indexes to indicate the changes made. The cost of a GS526U 02 lathe can reach up to 2,000,000 rubles. From time to time the manufacturer upgrades this model. Therefore, before purchasing, you should pay attention to the description of the screw-cutting lathe GS526U; the review is also carried out by the manufacturer.

Electrical circuit of the GS526U machine

GS526 – Lathes 1K62, 16K20 and modifications

In general, I visited Gomel, the GZSU plant, walked through the production, looked at the full cycle of their activities. And, yes, this is the only manufacturer of a full cycle of universal lathes. The plant employs about 600 people. Production is operating. However, the production is clear that it is not new, the main park is from Soviet times.

From the purchased ones - only cast blanks. The camps are either Gomel or Sasovo. At that moment when I was in the camp there were Sasovskys. This can be seen by the molded "SASTA" on the open end of the bed. I examined with my own eyes the manufacturing cycle of the frame - milling, grinding, high-frequency hardening, finishing grinding.

Feed boxes, aprons, headstocks are also made there from cast iron castings. Lines for milling housings, manufacturing gears, shafts, spindles. The caliper is the same.

Assembly area - mechanics assemble the machines, scrape down the surfaces for paint. However, doubts crept in here - the caliper came from the factory with fittings on the guide planes made of polymer material. It is the attachments that are scraped onto the frame. Controversial point.

Then there was a meeting with the factory designer, where I asked a question regarding the cut threads on a standard guitar set. Here I fell into a complete stupor. The designer told me that the lead screw has only a direct drive through the guitar, for each thread you need to put your own set of gears in the guitar, and thread cutting in a standard set of guitars occurs not through the screw and the mother screw, but through the caliper drive shaft. At the same time, the designer leafed through the passport for a long time trying to find something there, and eventually showed me the formula... At the same time, I talked about the standard series of metric and inch threads.

But what can I say, at least not China. And they assured me that they haven’t supplied machine components to Russia for a long time - they don’t order them, the last one to take them was Astrakhan, and even that was closed. And Gomel was essentially a branch of the Red Proletary for the production of units, after which it inherited the license for the entire machine.

www.chipmaker.ru

Design Features

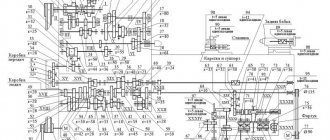

By analyzing the GS526U passport, you can fully learn the specifics of the relationship between the main structural elements. The kinematic diagram fully reflects the rotation of the workpiece fixed in the chuck:

- rotation is transmitted from the main drive using belts to the drive pulley;

- Through the kinematic scheme, rotation passes to the product itself.

The GS526U 01 lathe has a useful modification - a drive for accelerated movement of the support. On such a machine, simultaneously with the support, its carriage also moves, which, according to the passport, is ensured by a separate M2 electric motor.

Technical specifications

Before you start using the equipment, you must fully familiarize yourself with the technical data that the GS526U 02 lathe has.

Model specifications:

- The permissible diameter of parts is 500 mm.

- The permissible hole diameter in the main spindle is 55 mm.

- The length indicator can reach up to 3000 mm.

- The centers are located in relation to the frame at a height of 250-320 mm.

- It is allowed to set the cutter height to 25 mm.

- Direct spindle gears – 22.

- Reverse rotations (gears) – 11.

- The minimum rotation speed of the installation is 16.

- The maximum number of revolutions during rotation is 1600.

- The weight of the structure is 3100 kg.

The GS526U lathe, the technical characteristics of which are presented above, has several additional modifications. Each individual module that is installed additionally completely changes the turning performance, which is reflected in the addition of a certain letter to the serial number.

Machine GS526U in Kazakhstan - where to buy, payment, delivery, warranty

It’s easy to buy a screw-cutting lathe GS526U in Almaty, Nur-Sultan (Astana), Karaganda, Kostanay, Pavlodar, Ust-Kamenogorsk, Shymkent, Uralsk, Aktobe, Petropavlovsk and other cities of Kazakhstan - just call the numbers below. After agreeing with you on the terms of delivery of the equipment, a specialist from our company will provide you with a contract and invoice for its delivery.

In the contract and invoice for Kazakhstani buyers, the price for the GS526U screw-cutting lathe is indicated in Russian. rubles with VAT=0. You can get acquainted in advance with the approximate price (keeping in mind that a discount will also be provided) for this equipment as standard by going to the Russian website, clicking on the inscription KAZAKHSTAN at the top of the site page and selecting any city in the list that opens.

The sale of a machine model GS526U is usually carried out on the basis of 100% prepayment if the product is in stock. In the event of its absence and the need to put the equipment into production, the buyer initially pays 50% of its cost, and the remaining 50% is transferred after our company confirms that the machine has been manufactured and is ready for shipment.

Also, the buyer and the manager of the sales department of our company may agree on a different payment procedure and a different percentage of initial and final payments under the contract.

Delivery of the ordered equipment is carried out by road and rail vehicles of the transport companies PEC LLC (First Forwarding Company), KIT LLC, RATEK LLC, TK Energia LLC, Zheldorekspeditsiya LLC, other carrier companies, as well as by the Buyer’s transport or our company. More detailed information about the conditions of transportation of the Goods can be found in the DELIVERY section on our website.

The warranty for a new screw-cutting lathe GS526U is 12 months, for machines after a major overhaul – 6-12 months.

The manufacturer reserves the right to change the standard configuration and place of production of the equipment without notice!

We draw your attention to the fact that the information presented on the site is not a public offer, and check the current cost of equipment with our specialists in the sale of machine tools!

From the section Beautiful photos of Kazakhstan

If you need to buy a GS526U machine in Nur-Sultan, Almaty, Karaganda, Kostanay, Pavlodar, Ekibastuz, Ust-Kamenogorsk, Aktobe, Shymkent, Aktau, Uralsk, Petropavlovsk, Kurchatov, Baikonur, Turkestan, Semey, Taraz, Atyrau, Kyzylorda, Kokshetau , Taldykorgan, Zhezkazgan, Rudny, Temirtau

Call the following numbers:

+7 +7 +7.

Transmission

Designed for smooth transmission of kinematic force to the drive shaft of the feed box. This transmission occurs in parallel with the installation of a certain combination of replaceable gears. Such machines redistribute gears based on the configured positions of the feedbox inlet holes.

Based on the technical properties of the gearbox, it is often compared to a guitar on which gears are located to change the position of the feed. Each replacement wheel is equipped with its own splined hole; thanks to this element, bolting occurs.

Lathe GS526U

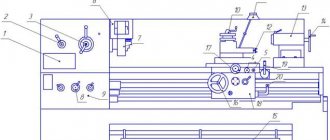

Appearance of the GS526U machine

Basic machine options

The functional capabilities that the GS526u machine has include the following:

- metal workpiece processing;

- processing of metal blanks that have complex shapes;

- creation of various types of threads - pitch, inch or metric;

- other operations for metal processing.

Advantages of the GS526U model

The installation with code marking GS526U can be used for flow mass production of parts, the accuracy of which is not mandatory. Thanks to the increased size, all elements are located at a fairly extended distance, which makes it possible to process large workpieces. The main characteristic of the turning machine is the power of 1600 rpm. This is not a record figure, but it is ideal for full-fledged work with low load impact.

On a lathe of this series it is possible to perform complex technical operations; this provides several angles of inclination of the main cutter, as well as a large range of feed speed adjustment. There is a reverse function, which does not require the master to deliberately stop and additionally secure the part in the required position.

Each module of the machine has increased strength and resistance to loads. During operation, there is no negative impact on the machine elements, this makes working on the turning device completely safe. The machine is intended for use in any workshop with large production capacity. The versatility of the installation is ensured by the wide range of workpieces that can be processed on this machine.