The IZH-250 machine, well known to most specialists, was produced for a long time in various modifications. The production of this turning unit, which can be used to perform processing in a collet, chuck and centers, was carried out by the Izhevsk Machine-Building Plant. This machine was used to equip both large and small manufacturing enterprises.

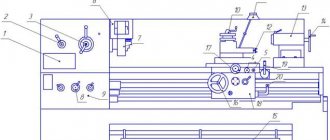

Appearance of the screw-cutting lathe IZH-250ITV

Technical capabilities of the machine model IZH-250

The IZH-250 machine was created by Izhmash specialists for processing small-sized parts. That is why instrument-making and tool factories were actively equipped with it.

The machine of this model is capable of providing high precision processing for a long time if semi-finishing and finishing turning operations are performed on it. To carry out more crude technological operations, during which significant loads are placed on the unit components, it is better to use a modernized version of this machine model - 250ITP.

At one time, the machine model IZH-250 was produced in several design options:

- ITVM03 – unit with increased distance between centers;

- ITVMF1 – a machine additionally equipped with a digital display;

- ITPM is a model used primarily for turning operations that do not require high precision.

IZH-250 controls

It is worth mentioning separately about the modernized model of the IZH-250 machine - ITVMF1. The latter, due to its digital display, allows processing with high productivity. The operator working on such a unit requires much less time to measure the geometric parameters of the part and perform test passes.

Digital display provides this device with a number of other significant advantages: there is no need to remember dial speeds and calculate certain parameters; Linear compensation for inaccuracies in the interaction of machine components, as well as wear of the cutting tool during processing, is carried out automatically, without human intervention.

The technical capabilities of the machine model IZH-250 make it possible to use it to cut various types of threads (metric, inch, modular) with high accuracy and productivity, so they try to perform such a technological operation on this particular unit.

Machine 250.F1 (with DRO)

Purpose and scope

The machine model 250.F1 (Machine 250ITVM) is equipped with a digital display system (hereinafter referred to as DRO), which allows increasing labor productivity by reducing auxiliary time for test passes and measuring parts. The use of a DRO makes the turner’s work easier by eliminating calculations and the need to memorize dial revolutions.

The DRO machine equipment allows:

- display dimensions in mm or inches with discreteness from 0.1 to 100 microns;

- carry out linear compensation for errors in the mechanical elements of the machine, for example, wear of guides;

- introduce compensation for tool wear.

Technical characteristics of the universal screw-cutting lathe 250.01

| Parameter name | 250.01 |

| Main settings | |

| Accuracy class according to GOST 8-82 | IN |

| The largest diameter of the workpiece above the bed, mm | 240 |

| The largest diameter of the workpiece above the support, mm | 168 |

| Maximum workpiece length (RMC), mm | 500 |

| Spidel | |

| Diameter of through hole in spindle, mm | 25 |

| Maximum rod diameter, mm | 24 |

| Number of speed steps for direct spindle rotation | |

| Spindle direct rotation frequency, rpm | 50..2500 |

| Number of spindle reverse rotation frequency steps | |

| Spindle reverse rotation frequency, rpm | |

| Size of the internal cone in the spindle, M | Morse 4 |

| Spindle end according to GOST 12593-72 | 4 |

| Submissions | |

| Maximum stroke length of the carriage, mm | 500 |

| Number of longitudinal feed stages | |

| Limits of longitudinal working feeds, mm/rev | 0,01..1,8 |

| Number of cross feed stages | |

| Limits of working cross feeds, mm/rev | 0,005..0,9 |

| Speed of fast movements of the caliper, longitudinal, m/min | No |

| Speed of fast movements of the caliper, transverse, m/min | No |

| Number of metric threads to be cut | |

| Limits of pitches of cut metric threads, mm | 0,2..24 |

| Number of inch threads to be cut | |

| Limits of pitches of cut inch threads | 24..0,5 |

| Number of modular threads to be cut | |

| Limits of pitches of cut modular threads | 0,2..12 |

| Number of cut pitch threads | No |

| Limits of pitches of cut pitch threads | No |

| Electrical equipment | |

| Number of electric motors on the machine | 3 |

| Main drive electric motor power, kW | 3 |

| Dimensions and weight of the machine | |

| Machine dimensions (length width height), mm | 1790_810_1400 |

| Machine weight, kg | 1180 |

Technical characteristics of modifications of the IZH-250 lathe

All the main parameters of the three modifications of the IZH-250 screw-cutting lathe are presented in the table below.

Technical characteristics of modifications of the IZH-250 machine

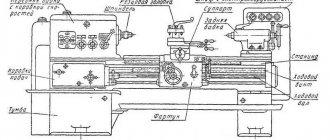

Design features of the device

The screw-cutting lathe of this model, due to some design features, has a number of special characteristics. Let us list these design features.

- The lead screw is automatically lubricated during threading operations.

- The feed and spindle speed parameters can be adjusted over a wide range.

- The IZH-250 apron is equipped with a special stopping mechanism, which allows turning on the machine against a hard stop and protects the box and feed mechanisms from possible overloads.

- The cutting head of the unit is fixed according to a backlash-free scheme, which ensures high accuracy and rigidity of its installation and position during processing.

- To select the spindle rotation speed, a preselective control system is used, which allows, when performing a certain technological operation, to prepare its subsequent switching on with the specified parameters in advance and carry it out when required.

- Due to the special design of the spindle unit, drive belts can be changed very quickly and easily; there is no need to disassemble it for this.

- Cutting various types of threads on the IZH-250 (metric, modular, inch) is carried out not by changing the gears in its guitar, but due to the versatility of the feed box.

- The IZH-250 bed is made of a special grade of cast iron - chromium-nickel, and the carefully polished guides on it are hardened using high-frequency currents.

Feed control on the machine of this model is implemented according to a mnemonic (facilitates memorization) principle and is carried out using a handle. According to this principle, the direction of movement of the handle coincides with the feed movement that the unit support with its cutting head will make.

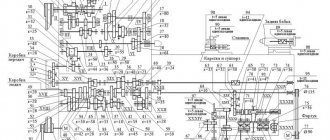

Kinematic diagram of IZH-250 (click to enlarge)

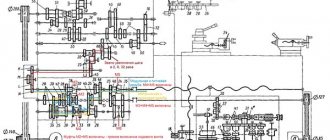

Principle of electrical machine (click to enlarge)

Universal turning machines IZH 250 ITVM.01, 250ITVM.03, 250ITVM.F1, ITVM250.F3

IZH 250 ITVM (1I250V) is a modern machine of the Udmurt, Udmurt-2, 161-AM, IZH-250, 95TS-1, IS1-1, 1I611P, 1IS611V model range, produced in Soviet times.

At the moment there are 2 pieces of IZH 250 ITVM.01 IN STOCK.

We supply spare parts and equipment for IZH machines, and carry out repairs of any complexity of Izhevsk-made machines.

Universal screw-cutting lathe IZH 250 ITVM.01 is the basic model of the range IZH 250 ITVM.03, IZH 250 ITVM.F1 250 ITVM, ITVM 250 F3. Modern model after IZH 1I611P (or 1 I611). The screw-cutting lathe IZH 250ITVM.01 is designed for performing a variety of turning operations on centers, collet or jaw chucks, as well as for cutting metric, modular, and inch threads. The IZH 250 ITVM.F1 machine is additionally equipped with a digital display system. The IZH 250 ITVM.03 machine differs from the base model in its increased center-to-center distance of up to 750 mm. The IZH 250 ITPM machine, unlike the base model, is designed to perform less precise work, just like the IZH 1I611P machines or simply 611 IZH.

Design features of lathes IZH 250 ITVM

A wide range of speeds and feeds ensures productive machining with good surface quality. Preselective control of spindle speeds allows you to prepare the subsequent switching on while the machine is running and quickly implement it at the right time. Mnemonic feed control is provided by one handle, the direction of activation of which coincides with the direction of the selected movement of the support with the cutting head.

Backlash-free fixation of the cutting head ensures high rigidity and precision of installation. The lead screw is automatically lubricated when cutting threads. The design of the spindle unit allows you to quickly change drive belts without disassembling the unit. The bed of the machines IZH 250ITVM.01, IZH 250ITVM.F1, IZH 250ITVM.03 is made of chromium-nickel cast iron, the guides are hardened by high-frequency currents and ground. The stopping mechanism located in the apron protects the feed mechanisms from overload and also allows you to work against a hard stop when turning. These are excellent successors to the IZH 1I611P machines.

The main movement is driven by an electric motor through a twelve-speed gearbox, V-belts and poly-V-belts. When the flywheel is turned, a certain combination of holes is created in two selector disks for the fixing fingers of the levers that switch the gear blocks. After this, by pulling the handle toward you, the rotating gears are first slowed down, and then they are switched. The headstock contains a take-up pulley, a spindle, a 1:8 ratio, and a link for increasing the thread pitch. The IZH 250ITVM F1 machine is equipped with a digital display system (DDS).

Equipment of lathe IZH 250 ITVM UTsI

- display dimensions in mm or inches with discreteness from 0.1 to 100 microns;

- carry out linear compensation for errors in the mechanical elements of the machine, for example, wear of guides;

- introduce compensation for tool wear.

To accurately measure transverse movements, a vernier mechanism is provided, allowing movements of 0.005 mm/rev. The feed box provides a wide range of cut thread sizes, longitudinal and transverse feeds. To cut precise threads, a direct connection of the lead screw to the guitar is provided, bypassing the feed box mechanism.

The closed-type apron provides longitudinal and transverse feeds of the caliper manually and mechanically from the lead roller, as well as thread cutting using a lead screw. Feed control is carried out with one handle. The direction of activation of the handle coincides with the direction of movement of the support. The presence of a locking device eliminates the possibility of simultaneous activation of the lead screw and the lead roller, as well as longitudinal and transverse feed. The machine is equipped with electric motors and equipment designed for a voltage of 380 V three-phase alternating current with a frequency of 50 Hz, local lighting voltage 36 V. The machine is connected to the electrical network using a packet switch.

Technical characteristics of IZH machines

IZH 250ITVM .01 | IZH 250ITVM .03 | IZH 250ITVM F1 | IZH 250ITPM | |

| Maximum length of the processed product, mm | 500 | 750 | 500 | 500 |

| Maximum diameter of the workpiece, mm: above the bed above the support | 240 168 | 240 168 | 240 168 | 240 168 |

| Maximum diameter of the rod processed in the chuck, mm | 24 | 24 | 24 | 24 |

| Maximum cutter section, mm | 16x16 | 16x16 | 16x16 | 16x16 |

| Spindle end according to GOST 12593-93 | 4 | 4 | 4 | 4 |

| Spindle inner taper size | Morse 4 | Morse 4 | Morse 4 | Morse 4 |

| Tailstock quill inner cone size | Morse 3 | Morse 3 | Morse 3 | Morse 3 |

| Quill movement, mm | 85 | 85 | 85 | 85 |

| Spindle speed, min-1 | 25-2500 | 25-2500 | 25-2500 | 25-2500 |

| Longitudinal feed, mm/rev | 0,001-1,8 | 0,001-1,8 | 0,001-1,8 | 0,001-1,8 |

| Cross feed, mm/rev | 0,005-0,9 | 0,005-0,9 | 0,005-0,9 | 0,005-0,9 |

| Pitch of cut metric thread, mm modular, inch modules, threads per 1" | 0,2-48 0,2-12 24-0,5 | 0,2-48 0,3-12 24-0,5 | 0,2-48 0,2-12 24-0,5 | 0,2-48 0,3-12 24-0,5 |

| Main drive drive power, kW | 3 | 3 | 3 | 3 |

| Accuracy class according to GOST 8-82 | In high | In high | In high | P increased |

| Roughness of product sample, microns | 0,63 | 0,63 | 0,63 | |

| Overall dimensions, mm, no more than length width height | 1790 810 1400 | 2005 810 1400 | 1790 955 1580 | 1790 810 1400 |

| Weight, kg, no more | 1180 | 1040 | 1290 | 1180 |

Repair of lathes:

In addition to the serial production of new machines, we offer services for routine and major repairs of your lathes.

Examples of work we have completed on major repairs of machine tools ( from RUB 550,000 including VAT ):