For those who constantly weld relatively small parts, a welding table is not a whim, but a prerequisite for comfortable and productive work. At the same time, not everyone can buy a finished product, and the finished model does not always fully meet the requirements of welders. And the main thing that usually does not suit potential buyers is the price, which is especially significant for professional models.

Design, components, features

The rotary round table Slot-Table of the PST series is used for assembly, welding, stripping and other positioning of workpieces. Photos Tehnoveld

The variety of types of welding work determines the design features of the tables . For both simple and professional ones, common components .

- The main distinguishing feature is the stove (countertop). The presence of structural elements such as holes and grooves on it ensures fastening of equipment for precise positioning of the parts to be welded.

- A durable frame serves as a supporting frame on which the slab (table top) is attached.

- Adjustable supports allow you to set the surface in a horizontal position and provide a comfortable height for the welder to work.

- The table can be equipped with both closed and open shelves. Closed shelves contain working and measuring tools, while open shelves contain temporary equipment and other devices used on a one-time basis.

- The tables are equipped with a tray for collecting welding dust and other process waste.

- Along the contour there are brackets used for fastening the welding wire and connecting to the ground loop.

- A suction hose from the ventilation system is supplied directly to the welding zone.

OKOF, depreciation group

The welding table wears out during use. In production conditions, as opposed to personal use, it is important to know the standard useful life of equipment . This will allow you to correctly write off or repair a worn-out object and replace it with a new one.

Welding and assembly table 1200x1200 VTM. Photo VseInstruments.ru

OKOF (all-Russian classifier of fixed assets) serves as the basis for determining depreciation groups. For welder's tables and welder's platform code OKOF 14 2922726 . This code is used to determine depreciation group five (property with a useful life of over 7 years up to 10 years inclusive).

Scope of application: for the manufacture of railings, for welding doors and more

The welding table facilitates the work of the performer both when performing individual individual work and when welding serial parts . In the first case, a large amount of various equipment is required, in the other case, they are limited to standard equipment. Welding is used in almost all metalworking industries.

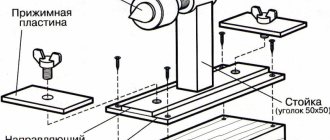

Most large-sized structures , such as fences and frames, are assembled from separately welded assemblies on tables. Such equipment has its own specifics. Each individually welded unit must be mounted into the overall structure with minimal adjustments. Therefore, welding tables contain guides with movable stops and clamps, which are installed in the required position using rulers on their surfaces. If it is necessary to install railing supports at an angle, the design contains rotating substrates with an angular scale. This ensures the necessary manufacturing precision.

Five-sided 3D table TEMPUS SSTW 75-105/35M nitrided. Photo MOSSklad

In addition, the basic structure of the table rotates freely around a horizontal axis for ease of assembly and welding of elements of railings (fences) and frames . The design contains braking devices to fix the product in a certain position. For more reliable fastening, in addition to mechanical braking, compressed air braking is used. The operation of welding tables for the manufacture of railings is shown in more detail in the following video

The operation of tables for welding rectangular frames is also presented:

In mass production, mechanical welding equipment can form a technological chain with other types of technological devices.

Do-it-yourself: assembly kit, drawing, etc.

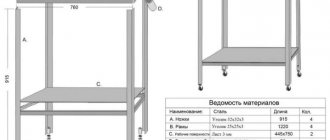

Making a table for a home craftsman who, among other things, also does welding work, will not be particularly difficult . It is better to make a table that will take into account all the wishes of the master according to the drawing . This engineering approach will make it possible to prepare the required set of materials and quickly process the structure in the absence of any standard size material.

It is better to cut workpieces on a saw, instead of using a traditional grinder. They will be exactly the size of the drawing. In addition to the welding machine, you must have a set of plumbing tools, especially marking tools. Thus, to make a welding table with your own hands you will not need a wide range of equipment.

Types of metal tables for welders and assemblers

The range of equipment is diverse : from simple ones used for welding in garages, to serious equipment with elements of mechanization. Information about some species is included in the contents described below.

Welding and cleaning

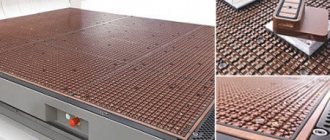

Such tables are equipped with a ventilation system to suck out welding dust and aerosols generated during the welding process. The tabletop grid is made of wear-resistant structural steel , which allows cleaning work to be carried out on the table with removal of cleaning products through the ventilation system.

Assembly and welding, universal

Before welding, the parts are assembled and fixed on the table using special devices into a solid structure. The base surfaces can be dismantled and moved to the desired position. The use of additional supports makes the design of the assembly table universal.

Assembly and welding table with nitriding from the Professional Extreme 8.7 series. Photo VECTOR GROUP

Transformers

Depending on the size and configuration of the parts being welded, the design of the transforming table may vary . This applies to the shape and size of the countertop, height and other parameters.

Mobile and stationary

Stationary equipment is firmly fixed to the base of the welding station. Mobile ones are made with swivel wheels on legs . They are usually made of polyurethane and equipped with reliable brakes.

Mobile table SibarWelding. Photo by BelSvaMo

Amateur/simple and professional

Simple tables are designed to perform simple welding operations , where the assembly of parts is not particularly difficult. Professional tables have maximum versatility in securing the most complex shapes of welded parts. They work in conjunction with installed ventilation, and it is possible to install additional equipment on them, for example, drilling equipment.

With ventilation

Welding technologies tend to release toxic substances during operation. If work is carried out in a production area, then general ventilation must function . For greater efficiency in the removal of hazardous waste, local ventilation is installed . Suction can be produced by an individual fan or connected to a general ventilation system.

Welding table with exhaust duct. Photo Products for welders

Rotary

Equipment equipped with a tabletop rotation mechanism makes welding as convenient as possible for the welder. By automatically rotating the workpiece fixed on the welding table, the seam is continuous, which improves its quality.

3D

3D tables allow for precise installation of workpieces in both planes: horizontal and vertical . Any parts with a three-dimensional configuration can be welded on these tables.

3D welding tables Tempus SST fix series. Photo Welding Center

Folding/folding/folding

In order to save space in cramped conditions, tables are used in a folding design. Under normal conditions, it does not take up much space and unfolds as needed to perform work.

Nitrided

The nitrided surface of the tabletop has excellent hardness and, as a result, has high wear resistance. Welding splashes will not stick to such a tabletop.

With holes

Holes are made in the tabletops of welding and assembly tables. They are intended for fastening equipment involved in the positioning of welded parts. Depending on the dimensions of the workpieces, larger hole diameters are used for larger sizes.

Assembly and welding table with 28 mm holes. Photo TECHNOVELD

Round

For some types of work it is convenient to use equipment with a rotating plate. This slab is made in a round shape in accordance with the specifics of the work.

Large

In some cases, it is necessary to weld heavy massive parts on tables. The slabs of such tables are made thick and dimensional , capable of withstanding large mechanical loads and not being deformed by the weight of the workpiece. In addition, the large dead weight of the table determines its stability .

Cast iron

Cast iron is a great option for countertop material. When welding, the formation of splashes that fall on the work surface is inevitable. They do not stick to gray cast iron and the table remains clean.

Assembly and welding table made of gray cast iron. Photos Tehnoveld

Frame welding jig

Frame structures can have large dimensions and weight. To weld them, a special jig , which is a device that rotates in a vertical plane around a horizontal axis. The frame is fixed on it and, using an electric drive, is rotated to a certain angle, convenient for the welder.

Optimal sizes

The size of the working area is one of the key points that is very important for welders and affects the ability to perform certain jobs. It is this indicator that determines the size of the workpieces that the welder can subsequently work with. The dimensions of the table surface vary over a wide range of values: from small (approximately 70x70cm) to large (298x148cm). in height it should not exceed 1.4 meters.

Tables with a small workspace are used for working with small workpieces or assemblies. Tabletops of impressive dimensions provide more opportunities. You can place a corresponding structure or several nodes on them. Here you can leave the most frequently used equipment, which is easier to keep at hand.

Manufacturers, brands

A welding table is a fundamental piece of equipment used to produce high-quality welding technology products. Therefore, there are many manufacturers producing such equipment. The competition is won by a company whose product allows welding completely different types of structures at one workplace.

Sovplym

The Russian-Swedish joint was founded in 1989 in St. Petersburg. The main goal is to create ventilation equipment on a domestic basis. One of the areas is the development and production of filter-ventilation equipment for welding tables.

Siegmund

Siegmund equipment fully corresponds to the concepts included in the thesis “German quality”. In combination with the original quick-clamping equipment, the most complex configurations of workpieces are assembled on the tables and quickly reconfigured to other types. Thus, Siegmund welding tables significantly increase work productivity .

Assembly and assembly welding table with wheels Siegmund 16 System. Photo House Welding

Foerster

The German company specializes in the production of modular options . The cast iron or non-ferrite strips that form their surface are easily removed; each new assembly can modify the shape of the table to suit a specific workpiece. For ease of welding, Foerster products are made rotating, rotating or lifting .

Demmeler

The German company is a leader in the production of 3D welding tables and accessories for them. Welding and assembly systems are versatile and are capable of creating designs to suit any customer needs.

TEMPUS

The German company Tempus presents its equipment to customers as an effective means of solving production issues. 3D tables are ideal for the production of prefabricated welded structures (fences, frames, etc.).

Five-sided welding table Tempus from the SSTW fix series. Photo Welding Center

WTO

Ulyanovsk produces a wide range of non-standardized equipment , which includes welding tables and components for them. Tables can be supplied complete with a fan and an exhaust hood.

VTM

The Russian company specializes in the production of welding and installation versions of the “D16” and “D28” systems , as well as standard and custom-made equipment.

IRS

One of the activities is the production of welding tables. They have a full range of elements for precise positioning of workpieces. They are distinguished by a collapsible design , which allows them to be easily transported.

EVIDENCE

Russian is the founder of a product line under the Evidence brand. This brand produces welding and assembly equipment with different tabletop sizes. The tables have a five-sided work surface and are classified as 3D systems.

Welding and assembly table Evidence SS8-2d-as (800x1200). Photo Welder Altai

SLOT TABLE

The Russian company produces welding worktops with a working surface from stacked plates. Plate material: cast iron and aluminum profile - not subject to adhesion of splashes of molten metal. Easily removable plates allow you to transform the working surface to suit any configuration of parts. To facilitate assembly and welding, welding equipment is equipped with electromechanical and hydraulic mechanisms .

SIBAR

A young Russian company is working to expand the range of welding tables and accessories for them. Focuses on the opinion of product consumers.

ESAB

ESAB is one of the most recognizable welding brands. The Swedish company, in addition to excellent welding equipment and consumables, produces professional welding tables. In addition to welding work, it is possible to carry out grinding work, since the removal of gases, welding dust and other particles formed during grinding is well organized.

ESAB welding and grinding table. Photo WeldingPRO

Type overview

Today there are a large number of different models of welding tables. They can be divided into three groups:

- traditional workbench;

- Rotary table;

- universal tables with a set of additional features.

To understand in more detail the functionality of each group of tables, you need to take a closer look at their structure and features.

Crafting table

The simplest option for a mounting surface made of metal. Both the frame and the tabletop are made of metal, which ensures high structural strength. Additionally, the table is equipped with accessories - clamps, angles, clamps, bench vices and other accessories.

Rotary

The next class of equipment in terms of complexity. It has an electric drive, which provides the ability to position the surface according to the angle of inclination or move it along any axis. Such tables are in demand in the production of complex shaped structures. A slot table is a type of rotary structure designed for assembling, stripping and welding workpieces.

Universal

In addition to the functionality of rotary tables, such tables have additional equipment designed to optimize welding, grinding and other operations. The workplace is designed for intensive use, therefore it is equipped with hoods to remove dust and gases from the room.

How to choose, tips and tricks

The determining role in choosing a welding table is played by the factor of time in which this equipment is used. If you use it occasionally, i.e. For any small work, it is recommended to purchase a cheap, simple option. If you regularly perform qualified welding work, it is recommended to purchase a semi-professional product.

First of all, you should pay attention to the presence of welding equipment in the kit . Without it, it will be impossible to secure the workpiece and make a high-quality seam.

On semi-professional tables it is better to provide ventilation . The presence of a copper strip edging will make it convenient to clean the electrodes during operation.

Safety when performing welding work

- Any metal welding work should be carried out only in rooms that are well ventilated or have equipment with an exhaust ventilation system.

- During work, you must use all personal protective equipment necessary for the welder. These include special non-flammable clothing, shoes, leather or canvas gloves, a welding mask or shield, and in some cases a respirator (when welding galvanized metal).

- All welding cable joints must be insulated and their insulation must not be damaged. If damage is detected during visual inspection, it must be insulated immediately.

- There should not be any flammable materials or substances in the workplace.