Photo source Tima Miroshnichenko/Pexels

Automation in many industries has reached such a level that the role of workers has been reduced to running programs on computers and replacing consumables. But there are industries where manual labor is valued. For example, everything a turner does involves manual labor. He cuts threads, turns parts and manually adjusts equipment.

History of the profession

In ancient times, people processed hard objects (stones, metals, animal bones) mainly using the impact method, breaking off particles of material from the surface. Over time, in Ancient Rome (approximately in the 7th century), a technology appeared that required the participation of two people in the process: one rotated the workpiece mounted on an axis, and the second processed it.

To produce a high-quality part, it was necessary to achieve fast and uniform rotation. In France in the 16th century, a water wheel was adapted for this purpose, but a real breakthrough in turning occurred after the invention of the electric drive. This made it possible to process hard metals and use only one worker.

Personal qualities of representatives of the profession of lathe-borer

A lathe-borer must meet certain requirements, for this they use a number of personal and professional qualities. This occupation is very unique - not everyone can do this type of work. A boring lathe must have good health and excellent coordination, because he works for at least 6 hours under constant stress. His main responsibility is strict compliance. Good prospects for a specialist open up when he is assigned a 5th or 6th category. The salaries of such professionals are very high. He receives his professional education at college. In the process of work, a turner understands drawings and diagrams, develops skills in working on a machine and masters the technology of processing parts. A turner must be hardy, responsible, neat and attentive.

Description of the profession

Turners work on specialized or universal machines. They can be automatic or semi-automatic, vertical or horizontal depending on the direction of the spindle, metal and woodworking, powerful and lightweight. There are nine main types of equipment in total.

The name of his specialization depends on what machine the turner works on and what production operations he performs:

- the carousel operator makes flanges, with their help the pipes are connected;

- a revolver is a craftsman engaged in the production of all kinds of parts, the blank for which is a calibrated rod;

- the boring machine enlarges the internal cavities and gives them the desired shape;

- the sharpener brings the product to the required parameters and calibrates it;

- The all-rounder can do all of the above.

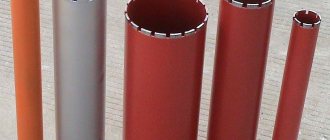

A turner is a profession that combines the art of using a machine and the ability to see the final product in a faceless workpiece. The number of operations performed in this case is very large: cutting threads, reaming holes, countersinking, drilling, turning all kinds of surfaces. Craftsmen who know how to work on numerically controlled machines are valued.

Specialization, career and prospects

The craft of a turner has several directions:

- Carousel driver. The workplace is a rotary machine, with the help of which a technician produces cylindrical and cone-shaped objects by cutting various grooves, holes or threads of various types on their surface.

- Lobovik. This master is in demand in the aircraft industry and specializes in processing housings and semi-finished parts made of stainless steel and titanium.

- Revolverman. Working on turret lathes, he deals with external and internal threads of various shapes.

- Borer. A specialist with the skills of high-precision manufacturing and processing of blanks for parts in various industries.

- Milling operator. In demand in any production. Works on a milling machine, producing parts according to given parameters.

As for professional growth, a turner can move up the career ladder, increasing his qualifications from the second to the sixth category.

And after receiving higher education he can become:

- head of a team of turners;

- workshop manager.

Subsequently, it may have the opportunity for further growth.

Important! A special feature of the lathe profession is the danger posed by machines, since this equipment is connected to high voltage and has rapidly rotating elements that can become hot during operation. Therefore, it is extremely important for the machine operator to comply with the safety precautions provided for in production.

What specialties are best to study in?

To learn turning, you need to graduate from a technical school or college. The specialty is called “turner,” although in some colleges they immediately indicate the direction of future work (revolver operator, carousel operator, etc.).

Admission to a secondary specialized educational institution is not difficult; there is often a shortage in secondary schools. It is enough for the admissions committee to submit a document on education, a medical certificate and write an application. There are no exams required; selection is based on grades on the certificate.

Turner's working day

Now I already have the 6th category, which I received at the enterprise. As with a lower rank, at the beginning of the work shift I receive an assignment (per shift or daily allowance) from the site foreman. At the end of the work shift, it is necessary to put the workplace in order, i.e. remove consumables, tools, incl. measuring, and devices.

What are the differences between the categories?

The sixth category is the maximum. Qualities appear here, starting from the fifth and ending with the first. You need to be able to literally do everything: polish parts, achieving a high level of accuracy, cut all types of threads, sharpen particularly complex tools. To save processing time, process several sizes with one cutter. And I’m generally silent about tables with processing modes. Even the cutting speed must be increased and decreased, relying on experience.

At one time, it was interesting to observe the colors of tarnish (this is the formation of an oxide film on the surface of the metal due to high temperature); from these colors you can roughly determine what the heating temperature of the steel is. This all comes with experience, at first they usually give 3-4 ranks, work with devices (dividing head, steady rests), alignment with indicators, cutting almost all types of threads begins.

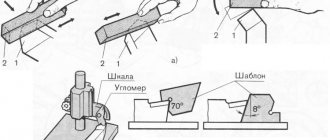

I was always told: proper sharpening of a cutter is the key to its long service life.

Nowadays, cutters are sharpened less often due to the fact that the same cutters with a replaceable plate are used (the plate is simply mechanically fixed to the cutter body, and not by soldering, as before).

Tolerances

Even in a secondary school or university, they always hammer in tolerances and qualifications. The point is that we need to get, for example, a hole with a certain diameter and depth. Tables of tolerances and fits immediately open (it’s like a turner’s bread, one might say so). In the table, the turner looks for the hole diameter (in the “Nominal” column). The drawing always indicates the quality to which this surface (well, in this case, the hole) needs to be processed. Again, look at the table, after finding the diameter of the hole on the side of the table, the quality is searched. That's all, on the intersection lines there is a number that we need (qualities are written as H6, H11, etc.), the value in the table is measured in microns. Moreover, if the letter h is a lowercase letter, then the hole must be made smaller than the size given in the drawing; if it is a capital letter, then it must be larger.

Working at a bus depot, I can say that turning work here is not entirely ordinary; after all, the company primarily repairs parts and produces a minimum of new ones. Usually this is the processing of complex surfaces (for example, crankshafts, but more often bushings) using 6-8 grades with alignment using flying calipers, and cutting of threads, most often metric, multi-start.

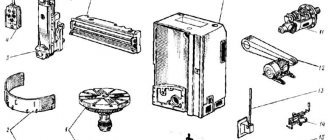

Soviet lathes vs CNC machines

Over all the years of operation, it stood for 16K20 (this machine has been produced since 1973), using the appropriate equipment. These include rests (if the workpiece is too long, I can’t do without a steady rest; it serves as an additional support), faceplates (if the part is not strictly cylindrical in shape, which cannot be installed in a regular chuck, a faceplate is used), center (for securing long workpieces on the machine by pressing them with this center installed in the tailstock quill), and much more. But now preference at the enterprise is gradually given to CNC (computer numerical control) machines; three years ago we bought several HAAS TL-1. This is pure automation, like a computer; the precision of manufacturing a part, of course, increases significantly. Most likely, in six months you will need to retrain at the enterprise (there are special courses) on these new machines, learn to write programs. Training, of course, is free.

The best colleges for studying

Employers have several colleges in good standing that teach turners:

- Polytechnic College No. 47 named after. V. G. Fedorova is one of the leading educational institutions in Moscow for training workers. This educational institution trains highly qualified turners to work on CNC machines. Graduates do not have any problems with employment, since the strategic partners of the college are powerful enterprises, such as OJSC MMP im. V.V. Chernysheva, PJSC Aviation Complex named after. S.V. Ilyushin” and others.

- Yekaterinburg Industrial and Technological College named after. V. M. Kurochkina. It trains universal turners capable of performing all basic processes on the machine. There is a resource center for career guidance and assistance, as well as an assessment and certification center. Employers of graduates: Ural Diesel Engine LLC, MK Uralmetprom CJSC.

- Malookhtinsky College (St. Petersburg). This educational institution provides skills in working both on CNC equipment and on conventional machines. The industry of the Northern capital and the Leningrad region is in need of college graduates; the profession of a turner is among the top 50 most in demand in the region.

- The Irkutsk College of Aircraft Engineering and Materials Processing graduates masters in working with CNC machines with the qualification “revolver operator”. You can study to become a turner at this educational institution full-time after the 9th grade (duration – 2 years and 10 months).

- Humanitarian and Technical College (Orenburg). The profession of a universal turner in this secondary school can be obtained after the 11th and 9th grades of school, and on the basis of complete secondary education the study period is only 10 months. Good material and technical equipment of the educational institution and teaching staff ensure a high level of student training.

There is also the option of on-the-job training under the supervision of an experienced technician, but this option is becoming a thing of the past as equipment becomes more complex and expensive.

Requirements for a turner

The employer may require the following from applicants for this vacancy:

- Professional education.

- Work experience of 6 months.

- Skills in operating a universal machine.

- Possession of locksmith skills.

- Ability to interact in a team.

- Professionalism and responsible approach to work.

- Desire to work.

- Motivation.

- Honesty and integrity.

So, qualified turners are in demand in many areas of the national economy. These specialists can move up the career ladder and receive high pay for their work. And the variety of professions will allow creative people to fully realize their skills and talents.

Profession turner: video

Responsibilities at work

Now let's talk about what a turner does at his workplace. This specialist performs the following functions:

- preliminary study of the part drawing;

- selection of the required tools, their adjustment and alignment;

- determination of cutting depth and speed;

- processing the part in various ways using a lathe in accordance with technical documentation;

- periodic monitoring of the compliance of the part parameters with those specified in the drawing using measuring instruments.

The worker’s responsibilities also include servicing the machine, its timely cleaning and lubrication, removing chips, slinging and storing finished products.

To successfully cope with these responsibilities, a turner is required to:

- the ability to read drawings and think through the procedure for implementing a plan in practice;

- knowledge of the basic properties of the materials used (different types of metals, wood, plastic, plexiglass);

- understanding of the operating principles of equipment and the ability to operate it correctly;

- knowledge of the main types of lubricating and cooling fluids, as well as cutting tools;

- compliance with safety rules.

If you haven't fallen asleep yet... you need to think with your head here

Interesting and funny incidents sometimes happened in the workplace. Here is one of them that happened to me about 12 years ago.

The task was given: to process 320 bushings in the first shift (they calculated something incorrectly in the design department, it turned out that one batch of bushings for MAZ 103.060 was defective), i.e. the work needs to be done in a fairly short time. I was still “green” then, although I had the 4th category. The cutters were such that it was possible to increase the feed or plunge speed, i.e. It is impossible to somehow increase productivity, the cutter will immediately break (even though it was made of hard alloy, the cutter had a large clearance angle, such work was carried out very rarely). At least cry.

You need to quickly go to the sharpening machine and change the angles of the cutter. The job is done, I start sharpening. Then the shop manager comes running and shouts that there is no defect, leave everything as it is. In general, I only managed to “spoil” 2 details. Since then, there have been no such oddities, but I still wonder how the Quality Control Department missed this?!

And recently there was a case where the company bought two automatic measuring machines (this is a device that has a head with a ruby tip; this tip (probe) goes around all the surfaces of the part, identifying defects). So, when measuring, they did not take into account that after processing the part must be allowed to cool (hot metal expands, which increases the error), as a result, several batches had to be rejected, then at least they thought of measuring the part in a cold state.

Who is it suitable for?

Most often, men with a technical mindset work as turners, although this profession is also open to women (in production they are especially valued for their accuracy).

To work, a turner will need:

- endurance and patience;

- accuracy and attentiveness;

- excellent eye and pedantry;

- responsibility and hard work;

- spatial imagination.

A description of a profession will be incomplete without dwelling on its strengths and weaknesses. Advantages - good pay, demand, opportunity to earn extra money privately. Disadvantages - difficult working conditions (noise, flying hot chips, dangerous machine), monotony and monotony of work.

What professional skills and knowledge are needed to occupy this position?

A turner is a technical profession that requires knowledge of physical laws and the characteristics of the chemical composition of the metal structures and parts being processed. He produces parts according to clearly designed and specified parameters in the drawings, so all turning specialists are distinguished by their unique ability to read drawings. A turner must know the structure of the machine on which he works and the properties of the materials used.

The ability to plan the turning process is also a key requirement.

Prospects for the profession

Today, turners are highly sought-after specialists in various industries, repair shops, housing and communal services, and design bureaus. Many enterprises are re-equipping, so they need workers who can operate CNC machines. To earn good money, self-realization and become a successful person, it is not at all necessary to go to university. If the profession is chosen correctly, then you can find yourself with a college diploma.

Author: Alexey Kuznetsov

If you still have even the slightest doubt that the turner profession is right for you, then we strongly recommend taking a career guidance test from Profgid . It costs mere pennies, and at the same time allows you to avoid mistakes that can go in the wrong direction and cripple your whole life. Find out more >>

Average salary of a turner

Photo source: Andrea Piacquadio/Pexels

The profession of a turner is in demand in almost any industry and in any workshop. These specialists can be found both in the field of public services and in repair shops, in engineering production and in the construction industry. Each line of work has its own advantages and disadvantages - they differ in salary level and scope of responsibilities. But qualified specialists are valued by all employers.

The labor market requires both universal specialists and highly specialized workers. The level of earnings depends on specialization, work experience and rank.

The average salary of a turner is from 30 to 60 thousand rubles . Specialists without work experience receive about 20 thousand rubles , and the most qualified workers from 45 to 70 thousand rubles .

According to information from employee search services, a specialist can count on the following salary:

- The minimum is 12 thousand rubles.

- The maximum is more than 100 thousand rubles.

When did turners appear?

Boys first become acquainted with this profession during labor lessons at school. History of the emergence of the profession Turner How did the profession develop? Back in the 7th century BC.

Interesting materials:

What were the Phoenicians famous for? What is Kabardino Balkaria famous for? What is Riga famous for? How to break an edge chest? How to grease the buns after baking? How to lubricate a cooler at home? How to remove the sticky layer after topcoat? How to photograph the starry sky? The older the whiskey, the better? How to fertilize onions for turnips?

Goals and advantages of this profession

- The main purpose of introducing this specialty is to save the time spent on obtaining one unit of part, compared to the time spent on a universal lathe.

- With the increased speed of obtaining the finished product, the quality must also correspond to the drawing. It depends both on the abilities of the worker and on the condition of the machine. Only serviceable equipment can produce consistently high quality for an entire batch of parts.

- The number of machines that one specialist can service. If a universal turner can service only one machine at a time, then a specialist can work on several CNC machines at once. Their number depends on the complexity of the parts, the serviceability of the equipment, the proper layout of the production site and the batch of parts.

Note: with the advent of PU lathes, the production of tools with replaceable cutting inserts arose. This provides significant savings in time resources that were previously spent on sharpening the tool and aligning it along the axis of the part. By combining various alloys, it was possible to obtain inserts for cutters and drills that can operate without additional cooling at increased loads and cutting conditions. This allows you to get even more parts in a shorter production time.

How much does a turner get paid?

The salary of a turner depends on experience and place of work. May consist of salary and bonuses. Also, a specialist can increase his rank and thus increase his salary level.

average salary

15500 UAH

Salary distribution 10,000 UAH 24,000 UAH

On average, a “Turner” in Ukraine earns 15,500 UAH. This is the median salary based on data from 643 vacancies posted on with the title “Turner” and for synonymous queries “Turner”, “Roacher”, “Carousel worker”, etc. over the last 3 months. The range that contains the median is highlighted in the graph.

What education is required to become a turner?

The easiest option is to get a job at a factory and start your career as an apprentice. However, in this case it will not be possible to receive a discharge - certain theoretical knowledge is required. Therefore, you will additionally have to attend urgent courses. After passing the exams, the student is assigned a rank and qualification, and is issued a turner certificate.

If you have the desire and opportunity, you can master a profession from scratch by enrolling in a college or technical school. In this case, you will be able to gain both theoretical knowledge and practical skills. Upon graduation, a rank and qualification will be assigned. Employers are more willing to hire applicants who have graduated from educational institutions due to the experience of such specialists.

Conclusion

A turner does hard work , but any representative of the profession is sure that his work is interesting, creative and highly paid. And this is true in reality. After all, you need to create something new from a simple blank, sometimes using unconventional thinking. For many, seeing metal shavings appear is already a pleasure. And if a newcomer at an enterprise is lucky enough to have a mentor, then it will be easy for him to achieve great heights in his work. Therefore, if a young man has a craving for the craft of a turner, then he will not go wrong by deciding to start training.

Sources used:

- https://edunews.ru/professii/obzor/tehnicheskie/tokar.html

- https://obrazovanie66.ru/prof/tokar/

- https://blog.tutoronline.ru/professija-tokar-vostrebovannaja-i-vysokooplachivaemaja-rabochaja-specialnost

- https://plusiminusi.ru/stoit-li-idti-uchitsya-na-tokarya/

Functions and responsibilities of a turner

Any profession, and turner is no exception, has its own requirements. The functions and responsibilities of a turner include several points, compliance with which is a guarantee of safety at work. The responsibilities of a turner can vary, because they work in industrial and instrument-making factories, in the automotive and shipbuilding industries, in the defense industry, and so on.

A turner's salary also depends on where he works, as well as on the accumulated experience and honed practical skills. The more skill and skill a turner has, the more functions the turner performs, the greater the rank he is endowed with, and the greater the rank, the higher the salary.

Turner functions

Like any worker, a turner has his own requirements. The functions of a lathe are to perform certain actions on a lathe related to the processing of various solid materials called workpieces. These can be metal objects, wooden, plastic and others. The turner cuts these blanks, grinds them on the outside and bores them on the inside, cuts threads and drills holes, and much more.

Responsibilities of a turner

For a turner, the responsibilities and requirements are very high. He must have excellent vision, accurate linear and three-dimensional vision, good motor skills, as well as technological thinking, spatial imagination and sustained attention. In turning, it is absolutely necessary to have accuracy, excellent physical health and responsibility.

A professional turner must have a good command of mathematics and geometry, and a good understanding of physics.

In addition, the responsibilities of a turner include:

- Knowledge of the design features and rules for checking lathes of various modifications.

- To be able to correctly install, fasten and check parts, as well as determine the technological sequence of working with them is a turner’s function and responsibility, without which work at the machine is impossible.

- A turner is required to properly heat treat, sharpen and fine-tune all cutting tools.

- A turner must have the skill of reading drawings and be able to draw these drawings, have an understanding of cutting conditions and the order of turning a part.

- According to his functions, a specialist turner must be able to calculate the work associated with processing very complex parts.

The main responsibility to work as a turner is the need to first undergo training as a turner. During training, he is taught to understand drawings, is given experience in working on lathes, is taught to use various measuring instruments and devices, and so on.

A special requirement for a turner, as in principle for an operating one, is based on the need for knowledge of safety precautions. When training to become a turner or during advanced training, special emphasis is placed on this. Without knowledge of this technique and the ability to use it, a turner, or someone who wants to become a turner, will not be allowed anywhere near a lathe. Such a strict attitude towards this issue is due to the fact that most injuries to turners occur due to a lax attitude towards safety precautions and the rules for using a lathe.

The functions of a turner are contraindicated for people who have serious problems with the musculoskeletal system, disorders of the heart and blood vessels, as well as problems with the nervous system and respiratory organs. Vision problems and a negative reaction to chemical elements also reduce the chances of performing the duties of a turner and obtaining a corresponding specialty.

Each turner is required to undergo confirmation of his specialization. He is either guided or of his own free will sent to advanced training courses for a turner, where he confirms his skills or has the opportunity to increase his level of skill, professionally speaking, “increase his rank.”

The higher the rank, the higher not only the wages, but also the higher requirements for the turner. The turner is now required to process more complex parts; more responsibility for each action now falls on him.

But the most important requirement for a turner is to have a creative approach to his work. Mechanical and automatic performance of certain actions, without the investment of creative potential, will not have any uniqueness or quality of the products produced. Any workpiece from any material installed in a lathe is removed from it after processing by the master as a masterpiece of the art of turning.

A specialist performing the functions of a turner is called a professional not only because he knows how to do it, but also because he understands the reason for this or that action. And understanding can only come from a creative approach to work. Therefore, from the hands of turning masters, real works of art often come out, with high-precision characteristics and verified parameters.

Another variety

A turner working on a milling machine is a milling machine operator. It processes hard materials (metal, wood, etc.) through the operation of a cutter. In the production process of any factory or enterprise, this worker plays a key role.

Tasks performed by a turner:

- operations related to processing parts according to ordered parameters;

- systematic monitoring of the operation of machine tools;

- reconfiguring the machine to produce other products.