You can grind metal products not only using electric tools. Many home craftsmen have various types of files in their arsenal. Their main advantage compared to electric tools for processing rough edges is higher safety. Therefore, the only task that the master needs to solve is to choose the appropriate type of file from the assortment offered in stores. Solving this problem is not difficult. It is enough to familiarize yourself with the nuances of performing this work, the types of tools offered and their purpose.

general information

A file is usually called a product that contains two elements:

- Steel bar . Its surface is intended for notches applied in production using special templates. There are several types of notches, among which the most common are rectangular, triangular and round.

- Handle . It is secured to the tool with a clamping ring and is necessary to prevent cracks. It is fastened to a cone-shaped shank. With the help of a handle, which can be made of plastic or wood, more convenient conditions for working with a file are provided. In case of breakdown, replacing it will not be difficult. This element is most often made from beech, birch and pressed paper. The handle should be one and a half times longer than the shank.

Files may differ from each other in their sizes. So, on sale you can find instruments with a length of 9, 10, 11, 12, 13 and 14 cm. They can also differ in diameter, which can be 12, 16, 20, 23, 25 and 28 mm.

All files belong to the category of cutting tools. Their main purpose is to give the processed products certain sizes and shapes. The operation of the tool is based on the principle of layer-by-layer grinding of the surface .

Materials

These devices for grinding metal products are most often made of very hard, high-quality tool steel:

- Brands ШХ15 or 13Х. This is the designation for alloy chromium steel.

- U10A or U13A. Marking indicates the use of improved unalloyed steel.

During the manufacturing process, files must undergo a hardening procedure, which allows them to be provided with a hardness level of 54-58 HRC. Tools intended for processing metal products are made from steel of the indicated grades. If you need to grind wood and other materials, then use tools made of softer steel.

What is a file and why is it needed?

Structurally, a file is a very simple tool. It is a steel plate on which a notch is applied. The notch can have different depths and profiles, which determines the scope of application of the tool. During operation, it is held by a handle made of wood or various composite materials. A tool intended for rough (grinding) work may have two handles and externally resemble a familiar plane.

The purpose of the file is to remove a thin layer of wood, thereby leveling the surface of the workpiece and giving it the required shape. In principle, a grinding machine does all this, but it is extremely problematic to do delicate work with it.

Cross Section Products

The presence of a double notch on the tool indicates that this is a general purpose metal file. If you carefully examine the surface, you can find on it not only the main, but also an additional section. The main section allows you to remove particles of the material from which the workpiece is made, and the auxiliary section allows you to grind them into chips.

The main purpose of a tool with a double notch is the processing of products made of hard alloys and metals.

What is a needle file

A needle file is a special tool for metalwork; it has the shape of a metal bar with a different number of notches.

Mini files come in different lengths: 80 mm, 120 mm and 160 mm, respectively, and the width of the working part varies according to the given size of the product.

The shape and alloy of needle files have certain requirements for quality standards.

Each individual type of tool has a different purpose, for example, GOST 1513–7 needle files are used for working with metal parts.

The quality of peeling directly depends on the choice of the appropriate tool.

Structurally, the mini-file consists of two elements: a working part with notches and a handle.

Typically, the length of the handle is equal to the length of the working part of the file.

To make needle files, round steel of a certain grade is used.

The product is produced under license plates from 1 to 6; the higher the number, the greater the number of notches.

Usually the notch number is indicated on the handle of the tool using a special stamp.

Types of metal tools

Companies specializing in the production of metalwork files rely in their production activities on GOST 1465–59. Taking into account the size of the notches, as well as their number per 10 mm of surface, files can be classified into several types:

- Drachevye . The main feature of this tool is the presence of a large notch. There are from 5 to 12 pieces per 10 mm surface. The fewer there are, the larger the teeth are. This allows the tool to remove more particles from the workpiece in one pass.

- Personal . A type of tool with a medium notch. The number of teeth can reach up to 25 pieces.

- Velvet . They use the finest notch. No more than 80 teeth can be located on a 10 mm surface.

To make it easier for specialists and ordinary craftsmen to distinguish between these types of files, special numbers are assigned to them: quarrel files - No. 1, personal files - No. 2, velvet files - No. 3-6.

Types of tools by shape

Since the processed products may differ from each other in shape, for the most effective processing, manufacturers produce appropriate types of grinding devices. The special shape of the profile allows this tool to perform the most high-quality grinding of parts. Depending on this characteristic, several types of files can be distinguished:

- oval;

- diamond-shaped;

- hacksaw;

- special;

- semicircular;

- round;

- trihedral;

- square;

- flat.

Thus, there are many tools for processing products, and each of them differs not only in design, but also in purpose.

Purpose of files

- Flat files allow you to process internal and external surfaces of flat and convex shapes with the highest quality.

- Square ones are designed for grinding grooves and holes of rectangular and square shapes. This tool also has another name - whittling. Its standard length is 50 cm. It is most advisable to use it when it is necessary to remove a metal layer of more than 1 mm.

- The triangular file is designed for grinding grooves and holes, grooves and internal corners.

- Using a round one, you can process concave-shaped surfaces. It is most often used for grinding oval and round holes.

- The main purpose of special files is grinding toothed and inclined surfaces, as well as corners. They allow you to select grooves and narrow grooves.

- The largest teeth have brute files, and they are used for preliminary surface treatment, since they can quickly remove a fairly thick layer - from 0.05 to 0.1 mm. But these files have a big drawback that needs to be mentioned - low accuracy. Therefore, after processing, the working surface takes on a rough appearance.

- Personal files are used for finishing sanding. They allow you to remove a layer with a thickness of 0.02 to 0.06 mm.

- Using velvet tools, the final polishing of the products is performed. They allow you to remove a layer with a thickness of 0.01 to 0.03 mm in one pass. The advantage of this tool is its high processing accuracy - 0.01 - 0.005 mm.

The main differences between a rasp and a file

The file and rasp are usually classified into the same class of cutting tools called files. The main difference lies in the structural features of the working surface. The difference is that the rasp is equipped with notches in the form of convex triangular teeth, arranged in a checkerboard pattern, and special grooves. And the file shaft is represented by single or cross flat teeth. A product processed with a rasp file may visually differ in the roughness of its surface, so it requires subsequent grinding with devices with a fine fraction of notches. However, for removing the thick top layer of wood, called bast, this tool is ideal.

A rasp file is a universal device for primary or rough processing of wood. The variety of rod shapes and the characteristic structure of the working surface make it an indispensable assistant when working with wooden products.

Special types

Sometimes the master faces tasks that are difficult to perform with a conventional tool. In this case, he has to think about buying special types of files that will help him perform operations with metal more efficiently and quickly.

Rasp

Along with metalworking tools, you can grind metal products and other materials using rasps, which have their own notch. Their surface contains fairly large teeth , made in the form of a pyramid, and behind them there are special grooves. The notches are located on the rasp in the form of rows at right angles to the axis. Using rasps, you can grind soft materials - duralumin and aluminum.

For the manufacture of this tool, steel grades U7A and U10A are used. They have a hardness level corresponding to 35−40 HRC. Rasps reach a length of 25−35 cm. Manufacturers offer four types of rasps: round and semicircular, as well as pointed flat and blunt flat. They are used mainly in the manufacture of tin products, as well as in medicine.

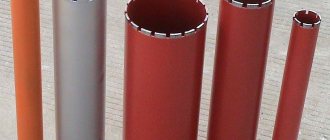

Files

Among all manufactured types of tools for processing products, they are the smallest. They are used to perform work where it is important to ensure high processing accuracy . This type of tool is made from steel grades U12 and U12A with a hardness of 54-60 HRC. If we consider needle files according to their cross-sectional shape, they can be divided into the following groups:

- groove and hacksaw;

- diamond shaped;

- oval;

- round and semicircular;

- triangular;

- square;

- flat.

There is no need for a home craftsman to purchase all of the above types of files. He can easily cope with all the tasks that arise in everyday life, having in his arsenal a flat, triangular and round file. It wouldn't hurt to additionally purchase a set of needle files and a few rasps . This entire set of tools will help you quickly solve any problem related to metal grinding.

Features of choice and rules of care

When purchasing files, in addition to technical characteristics and dimensions, you should pay attention to the quality of the tool. He must have:

- uniform color of the working surface;

- clearly defined notch;

- a comfortable, ergonomically shaped handle that is securely fixed and does not slip.

To extend the service life of files, you must follow the rules of operation and storage. Firstly, it is undesirable to use a new tool to work with parts and workpieces covered with a thick layer of rust. Before starting treatment, it should be removed using a grinder or metal brushes. In addition, you must:

- Choose the right type and density of notches, taking into account the hardness of the materials and the characteristics of the parts being processed.

- Protect the tool from impacts and moisture, sanding dust, oils and aggressive substances.

- Clean up chips in a timely manner.

- The new tool should be used first for processing soft metals, which will ensure the removal of burrs without compromising cutting properties.

Subtleties of choice

You can understand what type of sanding device you need by knowing the nature of the tasks you need to perform. Depending on this, you should choose a file of a certain size, shape and length. For example, if you have to work with aluminum, brass, copper or bronze, then the most suitable tool for you will be a single cut file. But you shouldn’t buy velvet or personal files. Very soon their teeth will become clogged with chips, and they will no longer properly perform their main function. An important characteristic is the notch number. When choosing, we advise you to pay attention to the thickness of the layer being removed and the accuracy of processing.

Files with cut number 0 or 1 should be chosen by craftsmen who need to file 5-10 mm thick and ensure processing accuracy ranging from 0.01 to 0.2 mm. Keep in mind that the tool removes no more than 0.1 mm in one pass. This will give you a fairly rough finish, so these files are best used for roughing. It is much easier to choose a tool by length . Focus on the size of the surface you need to file: the larger it is, the larger the file itself should be.

For a more accurate calculation, we offer a special formula: add 15 cm to the length of the surface of the product. The resulting value will be the length of the working surface of the file that you need. However, do not forget that during processing it is advisable to pass the tool over the entire area of the working surface.

File for home

Whatever type of tool you are looking for for processing metal products, we advise you to choose it based on the tasks facing you. If you need a tool for future repairs, we recommend purchasing a good set of files rather than buying them individually from different places.

Are you dreaming of creating an environmentally friendly construction set for your child with your own hands, and have you already looked for a suitable tree for this? Then you should pay attention to wood rasps and flat files . First, go through the wood with a rasp, you can easily handle this, it gets clogged less than others. Afterwards you can use a file. At the end of the processing, carefully sand the parts with sandpaper so that your baby does not get hurt while playing.

If you want your homemade construction set to include a variety of arches, cylinders and windows, then we recommend purchasing a round wood file and a rasp of the same configuration.

It is impossible to properly process metal and products made from other materials without having a special tool at hand. Therefore, every home craftsman should have a file in his arsenal. Choosing the most suitable type of tool is not difficult if you know what operations you are going to perform.

But under no circumstances should you save money by purchasing only one or two types of tools from a set. If you have to perform a large amount of work or solve the same type of tasks quite regularly, then the best solution for you would be to purchase a set of files. They will become indispensable assistants for you and will help you process parts much faster and with better quality.

How to use a rasp correctly?

To properly use a file on wood, experience and skills are important. At the same time, attentiveness and caution occupy priority positions. Thinking about the problems of the current day can ruin a craft, get hurt, and make other inaccuracies.

For work safety, experts recommend clamping the surface to be treated in a vice. Working with the tools step by step is as follows:

- The craft or other working part is clamped in a vice;

- The instrument is grasped by the handle with the right hand, and placed on the problematic surface with the left;

- The left hand should exert slight pressure on the working tool;

- Work on surface treatment begins with alternating movements toward and away from you;

- In order to control the quality of work, waste chips should be regularly swept away by hand or in another way;

- By the end of the work, the left hand should ease the load on the tools.

It is impossible to achieve an ideal result when working with a file on wood. The resulting roughness is removed with sandpaper.

To master working with a file on wood, desire and practice are important. Once you learn how to work with tools, you will never forget about it.