What water pressure is needed to cut metal?

The water pumped by the pump should have a pressure of about 1,500–6,000 atmospheres. Coming out through a narrow nozzle at near-sonic or supersonic speeds (up to 900–1200 m/s and more), the water jet is directed into the mixing chamber, where it mixes with abrasive particles. The resulting jet comes out of a mixing tube with an internal diameter of 0.5–1.5 mm and cuts metal. To dampen the residual pressure of the jet, a layer of water 75–100 cm thick is used.

Disadvantages of technology

The disadvantages of this technology include:

- design difficulties that arise when creating high fluid pressure;

- insignificant resistance of water and abrasive nozzles - quick erasing (the service life of domestic nozzles is 50 hours, foreign ones - 500-1000 hours);

- complexity of nozzle manufacturing;

- formation of slants up to 1.5 along the height of the workpiece.

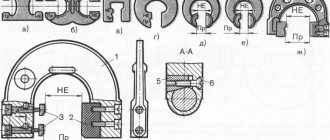

- a – at high cutting speed;

- b – at a very low cutting speed – the upper edges of the cut have a slight rounding

When the abrasive nozzle wears or the cutting speed increases, the width of the gap increases - the profile of the gap has a weakly expressed V-shape. At very low cutting speeds, the slot profile is A-shaped - turbulence causes erosion of the material. The case is considered positive if rounded top edges are required.

- a – with a distance between the nozzle and the workpiece of 2-4 mm;

- b – when the distance between the nozzle and the workpiece is more than 4 mm

Read also: Table of drill sizes for threads

Every year, metallurgical enterprises around the world smelt hundreds of thousands of tons of steel. Increased demands on cut quality have led to the emergence of new processing technologies. Especially considering that many alloys are quite hard. The most advanced technologies are laser and water cutting of metal (water jet). We will consider the essence of the latter in detail in this article.

Technological parameters

The main technological parameters of the waterjet cutting process are:

- cutting speed;

- type, properties and thickness of the cut product;

- internal diameters of the water nozzle and mixing tube;

- type, size, flow rate and concentration of abrasive particles in the cutting mixture;

- pressure.

Cutting speed (the speed at which the cutting head moves along the surface of the workpiece) significantly affects the quality of the cut. At high speeds, the water-abrasive jet deviates (drifts) from straightness, and the jet weakens noticeably as the material is cut. As a result, the taper of the cut and its roughness increase.

Read also: How to connect an electric bell to your home

Drawing. Typical cut shape depending on cutting conditions

Drawing. Jet drift when cutting at a speed higher than optimal

Separation cutting can be performed at 80-100% of maximum speed. High-quality cutting usually corresponds to a speed range of 33–65%, fine cutting – 25–33%, and precision cutting – 10–12.5% of the maximum speed.

Photo. Type of cut surface depending on the speed of water-abrasive cutting

Some cutting head models feature automatic taper compensation technology, such as Flow's Dynamic Waterjet. Taper compensation is achieved as a result of a software-controlled dynamic tilt of the cutting head by a certain degree. This allows you to increase cutting speed while maintaining cut quality and, accordingly, reduce production costs.

As the internal diameter of the mixing tube decreases (other things being equal), cutting productivity and accuracy increase, and the cutting width decreases (it is approximately 10% larger than the internal diameter of the tube). This also reduces the service life of the tube. During operation of the mixing tube, its internal diameter increases by approximately 0.01–0.02 mm for every eight hours of operation.

Table. Approximate abrasive sizes for various cutting modes

| Application | Particle size of garnet sand (Garnet) | Int. water nozzle diameter | Int. mixing tube diameter | |||

| mesh (USA) | micron | inches | mm | inches | mm | |

| Standard industrial configuration | 80 | 178 (300–150) | 0,013–0,014″ | 0,330–0,356 | 0,04″ | 1,02 |

| High speed cutting | 60 | 249 (400–200) | 0,014–0,018″ | 0,356–0,457 | 0,05″ | 1,27 |

| 50 | 297 (600–200) | |||||

| Precise cutting | 120 | 125 (200–100) | 0,012–0,013″ | 0,305–0,330 | 0,036″ | 0,91 |

| 80 | 178 (300–150) | |||||

| High precision cutting | 120 | 125 (200–100) | 0,010–0,011″ | 0,254–0,279 | 0,03″ | 0,76 |

The abrasive consumption depends on the diameters of the mixing tube and water nozzle, cutting conditions, etc. The approximate optimal values are given in the table below.

Table. Optimal consumption of abrasive material at certain ratios of the diameters of the mixing tube and nozzle

| Inner diameter of water nozzle (mm) | Mixing tube inner diameter (mm) | Abrasive consumption (g/min) |

| 0,25 | 0,76 | 270–360 |

| 0,36 | 1,02 | 500–640 |

| 0,46 | 1,27 | 800–1100 |

The maximum operating pressure is usually 3000–3200, 3800, 4150 or 6000 bar. The higher the pressure, the higher the cutting speed and efficiency. At the same time, more frequent replacement of gaskets in the pump is required.

Table. Dependence of straight separation (roughing) cutting speed on material thickness at pump pressure P = 4100 bar (approximately 4046 atm)

| Type of material | Cutting speed (m/h) * at thickness | ||||

| 5 mm | 10 mm | 20 mm | 50 mm | 100 mm | |

| Stainless steel | 52,62 | 28,56 | 13,02 | 3,84 | 1,44 |

| Titanium | 68,46 | 37,20 | 16,98 | 4,98 | 1,86 |

| Aluminum | 142,20 | 77,40 | 35,40 | 10,20 | 3,72 |

| Granite | 251,40 | 137,10 | 62,76 | 18,00 | 6,60 |

| Marble | 295,20 | 160,80 | 73,50 | 21,24 | 7,80 |

| Carbon fiber | 247,20 | 134,70 | 61,74 | 17,70 | 6,60 |

| Glass | 272,76 | 148,62 | 67,92 | 19,62 | 7,26 |

| * : pressure – 4100 bar; abrasive brand – Kerfjet #80; abrasive consumption – 250–450 g/min; internal diameter of the nozzle – 0.25 mm, 0.35 mm; internal diameter of the mixing tube - 0.76 mm, 1.01 mm / data from TechnoAllianceGroup LLC, Moscow, BarsJet GAR installations | |||||

Table. Dependence of the speed of straight dividing (roughing) cutting on the thickness of the material at pump pressure P = 6000 bar (about 5922 atm)

| Type of material | Cutting speed (m/h) * at thickness | ||||

| 5 mm | 10 mm | 20 mm | 50 mm | 100 mm | |

| Stainless steel | 86,64 | 47,16 | 21,48 | 6,12 | 2,40 |

| Titanium | 112,38 | 61,50 | 28,08 | 8,22 | 3,06 |

| Aluminum | 233,76 | 127,44 | 58,44 | 16,92 | 6,24 |

| Granite | 413,46 | 225,42 | 103,08 | 29,70 | 10,92 |

| Marble | 485,28 | 264,60 | 121,02 | 34,80 | 12,84 |

| Carbon fiber | 406,56 | 221,88 | 101,40 | 29,22 | 10,86 |

| Glass | 448,14 | 244,38 | 111,72 | 32,16 | 11,88 |

| * : pressure – 6000 bar; abrasive brand – Kerfjet #80; abrasive consumption – 250–450 g/min; internal diameter of the nozzle – 0.25 mm; internal diameter of the mixing tube - 0.76 mm, 1.01 mm / data from TechnoAllianceGroup LLC, Moscow, BarsJet GAR installations | |||||

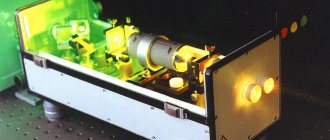

Photo. Parts obtained by waterjet cutting: made of stainless steel 15 mm thick; made of aluminum alloy 6 mm thick; made of aluminum 30 mm thick; made of fibre-reinforced plastic, 20 mm thick; made of tool steel 60 mm thick

Advantages of the waterjet metal cutting method

Equipment used for cutting metal using waterjet is indispensable when working with thick-walled workpieces. Only these machines are capable of providing high quality steel cutting lines during pipe laying.

After grinding the working area of a 200 mm metal sheet, there is no scale or burrs on the surface of the steel cutting line.

Ideal cut quality combined with gentle temperature conditions are not all the advantages that water-abrasive technology has.

The high cost of installations is compensated by savings on fasteners and components, which are not needed even when working with thin-walled workpieces.

The absence of smoke and dust, as well as other unpleasant factors, is another of the many advantages of waterjet cutting.

In addition, there is no need to replace a worn cutting tool and control the sharpness of the cutter, since, in fact, it is absent.

Instead, the function of a cutting tool is performed by a stream of water in combination with abrasive components.

At the same time, the speed of the work process proceeds without slowdown, the cutting speed does not decrease, even if it is necessary to process thick-walled elements, as, for example, when laying pipes.

The universal characteristics of metal cutting machines allow simultaneous processing of different materials on one installation - it can be plastic, glass, rubber or a multi-layer product.

Waterjet installations for cutting metal are safe to use and can therefore be used in factories with a possible risk of explosion.

Safety precautions

The waterjet cutting process is not particularly dangerous. The distance from the tube from which the jet comes out to the surface being treated is only 2.5 mm. This eliminates the impact of the jet on the hand. When the water pressure exceeds the permissible limit, the relief valve opens, which reduces the pressure to operating pressure. However, when working on machines, certain safety precautions must be observed.

- Do not expose your body to the jet under any circumstances. Such a jet is capable of cutting metal 150 mm wide, let alone a hand. While working, keep your hands at a very reasonable distance from the cutting area. Before turning on the machine, make sure that there are no foreign objects in the cutting path.

- Protect your eyes and hearing. Be sure to use safety glasses and earplugs (or headphones).

- Don't put your hands on the desktop.

Water versus metal: what can a pressure washer do? Ministry of Transport

The favorites in the production of waterjet cutting machines are the South American companies Jet Edge, Flow, OMAX, and the Italian WaterJet Corp Inc. and Caretta Technology, Dutch Resato, Czech PTV, Swedish Waterjet Sweden, Finnish ALICO, Swiss Bystronic.

Auxiliary elements

High pressure pump with water filter. As already mentioned, the inlet pressure is thousands of atmospheres. Such parameters require a continuous supply of liquid in appropriate volumes.

To minimize costs, water and abrasive garnet sand are reused. Passing through the filter system, the liquid is cleaned of dirt and oil formations. Often machines are equipped with a separate water tank.

Garnet sand for hydrojet cutting - video

The abrasive is dried and separated from pieces of material, especially if it is plastic or metal. Magnetic separators are used to separate metal. Just like water, sand is stored in separate containers.

Control

Control can be carried out through the interface of the machine itself, or by loading prepared task files into the system in the form of drawings and technological parameters prepared in the format of any graphic editor compatible with the machine software (CAD. COREL-DRAW or similar).

The operator, using the interface service, can set the coordinates of the beginning and end of the movement, adjust the cutting speed and direction.

The task is transferred to the automated control system to perform operations.

After this, you need to install the cutting head at the starting point and start the machine. The machine software converts the task file data into control commands for the pump, abrasive dispenser and head drive motors.

The ACS feedback reads sensor readings, adjusts the water supply and the speed of the head, monitors the completion of the task, and ensures planned or emergency shutdown of the machine.

In addition, the operator has the ability to stop the device at any time, turn off the pump and relieve pressure in the system.

Advantages, disadvantages and comparative characteristics

Using a waterjet or water jet, you can cut almost any material. In this case, neither mechanical deformation of the workpiece occurs (since the force of the jet is only 1–100 N), nor its thermal deformation, since the temperature in the cutting zone is about 60–90°C. Thus, compared to heat treatment technologies (oxygen, plasma, laser, etc.), waterjet cutting has the following distinctive advantages:

- higher quality of cut due to minimal thermal effect on the workpiece (no melting, melting or burning of edges);

- the ability to cut heat-sensitive materials (a number of fire and explosive materials, laminated, composite, etc.);

- environmentally friendly process, complete absence of harmful gas emissions;

- explosion and fire safety of the process.

The water jet is capable of cutting materials up to 300 mm thick and more. Cutting can be performed along a complex contour with high precision (up to 0.025–0.1 mm), including for processing volumetric products. You can use it to make bevels. It is effective on aluminum alloys, copper and brass, due to their high thermal conductivity, thermal cutting methods require more powerful heating sources. Additionally, these metals are more difficult to cut with lasers due to their low ability to absorb laser light.

The disadvantages of water-abrasive cutting include:

- significantly lower cutting speed of thin steel compared to plasma and laser cutting;

- high cost of equipment and high operating costs (typical for laser cutting) due to the consumption of abrasive, electricity, water, replacement of mixing tubes, water nozzles and seals that can withstand high pressure, as well as waste disposal costs;

- increased noise due to the flow of a jet at supersonic speed (typical for plasma cutting).

Waterjet cutting price

There are at least five components that determine the high price of equipment:

- high pressure pump and piping system;

- high-precision head movement control drives;

- intelligent control system;

- a nozzle made of precious stones (albeit of artificial origin);

- mixing tube made of high hardness composite.

And if we take into account that the last two components are consumables and add the high price of the abrasive, then the cost of waterjet cutting will be the most expensive among all types. But the advantages of this method and the quality of processing of the part are worth it.

Sawing process

Before starting cutting with a new rope, you need to cut for the first hour or two at a lower speed of 4 m/sec from the recommended one. This will ensure that the diamond wire opens properly, removes any plastic residue and ensures work in the best conditions. Before starting sawing with a previously used rope, you must check:

- - average diameter of bushings;

- - eccentricity (maximum deviation - 0.3 mm);

- — taper (maximum deviation — 0.3 mm);

- - condition of the rope connection, integrity and working condition of the bushings; (absence of cavities, opening of diamonds

When passivating a block

Sawing on slabs can be carried out at fairly high speeds. In this case, cutting without lower guide pulleys located at the entrance and exit of the block is allowed, since they are used primarily to guide the supply of the rope when entering the cut, as well as to weaken the vibration of the rope.

When sawing slabs for further polishing, high cutting accuracy and surface smoothness are required. To do this, the cutting speed must be reduced to prevent deviations at the beginning and during the cutting (in general, the cutting speed should be 15-20% lower than that used for passivation of blocks into slabs). When cutting short blocks, guide pulleys are used at the entry and exit of the block and a check is made to ensure there is no side play.

When the rope enters the block, it is recommended to avoid working in automatic mode; the feed speed should be reduced by 20-30% of the recommended one. When cutting in automatic mode, the feed speed of the flywheels is controlled through the current in amperes. When the load increases, the feed automatically decreases, and when the load decreases, it increases. In the absence of an automatic adjustment system, it is necessary to visually monitor the load readings (in amperes) and adjust the rope feeding parameters manually.

Applications in various industries

The use of water treatment has virtually no limits. But making such devices with your own hands is extremely difficult, so use at home is unlikely.

In the defense industry

Waterjet equipment provides high cutting accuracy when working with complex composite materials, bulletproof glass, armored sheets, titanium, and alloys. For cutting discarded old shells and working with explosives, this technology is the safest.

In the glass industry

For cutting mirror, plain, laminated, patterned, impact-resistant, armored and reinforced glass, waterjet machines are optimal. They allow the production of glass products of various shapes. Stained glass windows, panels, decorative elements and other items are created from these elements.

In construction

In the construction industry, waterjet technology is used to solve the following problems:

- dismantling of various structures;

- cutting materials (porcelain stoneware, natural stone, tiles, etc.);

- production of decorative inlaid elements;

- creating shaped and complex cuts on pipes.

In mechanical engineering

Waterjet machining machines are used in mechanical engineering to perform the following operations:

- cutting sheet metal, plastic, composite materials and heavy-duty alloys;

- chamfering on workpieces before performing welding work;

- manufacturing with the highest precision elements and parts of complex configurations;

- removal of heat treatment defects (scale, sagging, etc.).

In the automotive industry

Waterjet equipment in the automotive industry is used for the following purposes:

- production of various plastic parts (dashboards, bumpers, etc.);

- cutting out car interior decorative elements (false ceilings, rugs, etc.);

- cutting body elements from thin metal;

- production of three-dimensional parts with complex designs;

- cutting laminated glass for cars (triplex).

In the rubber industry

Waterjet technology is an excellent solution for working with rubber of different densities and thicknesses (up to 300 mm). Cutting occurs at fairly low temperatures (no more than 90°C), so the structure of the material itself does not change and the edges do not melt.

In the electrical industry

In the electrical field, waterjet cutting machines are used for:

- production of parts from mica and composite materials;

- cutting electrical steel, transformer iron, copper and all kinds of alloys;

- cutting of amorphous metals;

- working with rubber, plastic, cellulose.

In the aviation and aerospace industry

Waterjet machines have become indispensable for performing the following tasks:

- production of spatially complex parts from titanium, aluminum, zirconium and various alloys;

- cutting composite materials without breaking the structure or delamination;

- production of elements with complex contours;

- making closed complex cuts in sheet blanks.

In tool production

The use of waterjet technology in tool production makes it possible to process steel, alloys, as well as materials with increased hardness. Using such equipment, mold elements, dies, various monolithic small tools, complex parts and technological equipment are manufactured.

Concrete is smashed with a wedge

Somewhat different from waterjet concrete cutting is a technology that uses a hydraulic wedge to break up concrete. Moreover, the differences between the two technologies are quite significant. About the difference between a butcher's ax and a surgeon's scalpel. And the hydraulic wedge for concrete acts precisely as an axe.

What's the point? If it is necessary to destroy large volumes of monolithic concrete with minimal vibration loads and minimize the possibility of scattering of secondary fragments from the dismantled structure, holes with a diameter of approximately 160-180 mm are drilled into the concrete mass using diamond bits.

The working cylinders of the hydrocline are inserted into the prepared holes, and pressure is applied, as a result of which the massif is split into cakes - individual elements that are either loaded into transport or cut on site using small-sized hand tools.

How does it work

The technology is based on the weak tensile strength of the concrete mass. Concrete tolerates high static loads well, but sharp, local, dynamic, intensely applied loads in a particular area are often critical for it, and lead to deformation and destruction of the mass into fragments of various sizes.

Essentially, a hydraulic wedge is a hydraulic cylinder, the high-speed rod of which moves on a short arm a working mechanism in the form of a wedge of an established shape, made of high-strength alloy steel.

In general, such a system consists of:

- Hydraulic cylinder with working element.

- High pressure oil stations.

- Working lines made in the form of high-pressure hoses.

- Systems of communicators, made either in the form of quick releases or according to the classic fitting-nut system.

- Control and security systems.

It should be noted that the described technology is characterized by high mobility, transportability and ease of maintenance. In general, if used correctly, hydrocline breakers are reliable and durable.

Important! Another difference from waterjet cutting technology and the use of hydrocline is the fact that the energy carrier is not water mixed with solid particles - abrasive, but special hydraulic oil. Moreover, it is not exclusively a carrier; the working element is a steel wedge, to which the oil only transfers the received energy.

A hydrocline, a thing for breaking concrete, is very convenient, and in some cases where mobility, weight and dimensions are important, it is sometimes irreplaceable. However, what to do when a reinforced concrete mass is stuffed with reinforcement, like a watermelon with seeds. In this case, hydraulic shears will come to the rescue.

Features of operating CNC machines

Waterjet equipment with computer program control is one of the opportunities to expand the scope of use of machines, increase work efficiency and at the same time increase productivity.

More details can be gleaned from the information provided below and the video story.

CNC machines are used to produce blanks from steel, aluminum, copper and other types of metals.

The strict cutting accuracy provided by CNC water-abrasive equipment has virtually no deviations from the assigned tasks.

Video:

Program-controlled waterjet units provide the following advantages:

- CNC-equipped machines operate in accordance with a given program. In this case, each workpiece is processed using individual software. With its help, the jet pressure, the composition of the working cutting suspension and other parameters are automatically selected;

- If on non-CNC machines the selection of the cutting jet can be chosen incorrectly, then in this situation this point is excluded. The equipment independently controls the quality of the cut, then automatically adjusts the mode used;

- Metal processing with the help of software also provides the ability to make holes of the desired diameter;

- As you can judge from the video material, upon completion of the waterjet process, a completely finished part emerges from the workpiece, which does not need to be subjected to grinding or additional processing at the cut points.

Scissors, but not tailor's ones

As a rule, scissors in everyday perception are necessarily associated with cutting fabric, paper, leather and other materials that are not particularly durable. What do you think of the option called hydraulic shears for reinforced concrete? Believe me, there are such people.

Crusher and cruncher: brothers, but not twins

Hydraulic shears are one of the many tools that are equipped with excavators, usually crawler ones. The working mechanism is made in the form of a pair of cheeks made of high-alloy tool steel, which move according to a given algorithm using hydraulic cylinder rods powered by a standard high-pressure hydraulic system.

Hydraulic shears from serious manufacturers are mounted on a rotator head, which allows the working body to rotate around its axis.

Hydraulic shears are a quick-release mechanism, and modern models are designed and made in such a way that they can be installed and removed by one person - the excavator operator, and he directly connects only the hydraulic system connectors with his own hands.

The operator's instructions are designed in such a way that they repeat the working algorithms for the movement of the boom and bucket of an excavator during basic and most common work and therefore can be easily mastered by even low-skilled excavator operators, who make up the bulk of the domestic labor market.

The cost of such systems is high, primarily because effective mechanisms are manufactured exclusively by American, European and Japanese manufacturers. Chinese and domestic developments are extremely ineffective and short-lived, and, in essence, are low-quality copies of well-established brands.

For rough destruction of reinforced concrete structures, a crusher is used - its working body has more massive and larger teeth and larger gripping cavities.

A cruncher is used to crush dismantled concrete fragments. After processing pieces of concrete with its jaws, the resulting mass can be used as crushed concrete when organizing cushions, arranging temporary roads, filling sites and other activities.

You can learn more about the basics of waterjet cutting of concrete and examples of dismantling concrete structures using a hydraulic wedge and hydraulic shears by watching the video in this article.

Operating principle of a waterjet cutting machine

During the cutting process, it is important to adhere to certain parameters and follow the rules for using the machine. It is important here what water pressure is used, what flow rate, jet speed, amount of abrasive material supplied

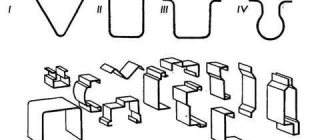

The diagram shows in numbers:

- 1 – water supply;

- 2 – nozzle;

- 3 – abrasive material;

- 4 – mixing device;

- 5 – casing;

- 6 – jet of water and abrasive;

- 7 – processed material.

The process of waterjet cutting of metal includes 4 stages:

- The workpiece is placed in a bath of water and secured. On a non-automated device, this must be done with your own hands; on a CNC machine, using a program.

- A tool head is placed in the bath, into which water and abrasive are supplied. In this case, the necessary operating parameters are set (water pressure, flow, etc.).

- The tool head is directed towards the material being processed.

- A jet of water and abrasive cuts the workpiece.

- After cutting, the abrasive material is filtered and dried.

The listed steps are constantly repeated during operation of the device. The metal is cut due to the impact of abrasive particles. Water acts as a carrier of cutting particles (that is, abrasive). The following are used as abrasives:

- quartz sand;

- silicon carbide;

- garnet abrasive;

- electrocorundum;

- olivine

The listed materials have common advantages - low price, high cutting properties and hardness. Due to their hardness and increased stability, these materials can be used repeatedly. In domestic industry, quartz sand is mainly used as an abrasive.

This type of cutting is actively used for processing workpieces made of alloy steel. This is due to the fact that the jet of water and abrasive does not disturb the composition of such steel. In addition to metals, glass, stone (natural and artificial), concrete and reinforced concrete can be processed. But, each material has its own thickness limits:

- Non-ferrous metals, alloys and stainless steel – maximum 150 mm.

- Composite materials, carbon fiber reinforced plastics – maximum 200 mm.

- Natural and artificial stone – maximum 300 mm.

Video: cutting metal with water.

https://youtube.com/watch?v=78FBX3-l8I8

Equipment

The waterjet cutting machine consists of:

- high pressure pump;

- tool head;

- desktop;

- movement systems equipped with a belt drive or CNC control devices;

- working bath (made of stainless steel);

- containers for supplied water;

- tank for abrasive material;

- compressor for supplying abrasive material;

- a sensor designed to control abrasive;

- mixing chamber;

- remote control with a flywheel designed to simplify the control procedure;

- a device designed to remove remains of processed material;

- a device designed to feed workpieces.

pros

- The part being cut does not heat up, so various deformations are eliminated. This in turn ensures high quality of the finished product or product.

- Availability of functional options in the equipment to perform work regardless of its complexity.

- No additional work in refining processed products.

- The ability to make cuts for any materials, as well as make holes in them.

- Efficiency in carrying out work, economic feasibility.

- The safety of the method allows its use in industries with increased fire safety requirements.

- Cutting thick parts and pipes.

- No dust, smoke or other unpleasant manifestations.

Water cutting price

The cost of such equipment, as well as its maintenance, is quite high. It is for this reason that the method is used mainly in large industries - where all costs are compensated by a high-quality final product. The price tag consists of:

- powerful pump;

- expensive CNC system;

- Artificial diamond nozzles.

In the article we told you how to cut metal with water. To finish, we'll show you a few videos:

To clarify the information you are interested in, please contact our managers by phone;; 8 (800) 707-53-38. They will answer all your questions.

Device classification

Waterjet machines are often divided into manual machines and computer numerical control (CNC) machines.

The design of abrasive metal cutting machines significantly affects their technical characteristics and production capacity.

Manual devices

Non-CNC machines are fully controlled by the operator, who sets all the parameters for future processing of parts. In addition, the operator will have to carry out certain stages of working with workpieces independently. But such devices also have a number of advantages:

- Relatively low price.

- Same quality of waterjet cutting of titanium, aluminum and other materials.

- Easy to care for and manage, which does not require the operator to have extensive knowledge and experience in the field of metalworking.

- A sufficient number of functions that allow you to create simple parts with correct geometric shapes.

CNC machines

Numerical software installed on waterjet machines significantly improves their functionality and production efficiency. CNC machines allow you to process all types of metal workpieces with high quality and do it with high precision. Automated devices have the following advantages:

- The software allows you to create holes of the required diameter in workpieces.

- After completing all established operations, the part does not require additional processing.

- The software allows you to select an individual processing mode for each workpiece. The device itself will select the necessary jet parameters and other parameters.

- CNC machines can control the quality of the cut and independently change it in accordance with the established program and sequence of machine actions.

At the same time, such a device also has a number of significant disadvantages. Firstly, the cost of a CNC waterjet machine is significantly higher than the price of its manual counterpart. Secondly, in order to correctly set the parameters of the work being performed, the operator must have certain knowledge in the field of metalworking and experience in creating parts on automated machines.

Cutting tool

The main part of all waterjet machines is the cutting head. The principle of its operation is seemingly very simple, but technologically very complex. Thus, ultra-high water pressure is created by a plunger or piston pump, which delivers it through high-pressure pipelines to the cutting head. Here the water enters the chamber, where strictly dosed mixing with abrasive particles occurs. Next, the mixture of water and abrasive enters a calibrated nozzle (nozzle), which creates a cutting jet. The jet emerging from the nozzle reaches a speed approximately three times higher than the speed of sound.

The dimensions of the diameter of the nozzle and mixing chamber are determined based on the performance of the working pumping station and the material of the abrasive particles. Basically, garnet sand, also called almandine, is used for abrasive. It has a crystalline structure with extreme hardness and a heavy density of 4.1 - 4.3 g/cm, which allows it to provide high abrasive ability. It is well distributed in nature; its largest deposits are located in the southeast of India and Australia.

Operating principle and materials to be cut

Cutting metal products occurs with a water jet to which abrasive is added, after which it passes through a nozzle. Pressure of 200-600 atmospheres allows you to cut many materials. Work can be carried out at any angle; to do this, you just need to change the angle of the nozzle. In this case, you can effectively cut:

- metals (ferrous and non-ferrous) and their alloys;

- stone products from marble and granite;

- steel (stainless steel, heat-resistant, alloy);

- armored, ordinary and composite glass;

- ceramic products (concrete, tiles, ceramics, ceramic granite);

- composite;

- rubber;

- plastic;

- cardboard.

Cutting of particularly hard raw materials is carried out with water and special sand made from minerals. Soft materials (rubber, plastic, cardboard) are cut exclusively with water without any impurities.

Features of operating CNC machines

Waterjet equipment with computer program control is one of the opportunities to expand the scope of use of machines, increase work efficiency and at the same time increase productivity.

More details can be gleaned from the information provided below and the video story.

CNC machines are used to produce blanks from steel, aluminum, copper and other types of metals.

The strict cutting accuracy provided by CNC water-abrasive equipment has virtually no deviations from the assigned tasks.

Video:

Program-controlled waterjet units provide the following advantages:

- CNC-equipped machines operate in accordance with a given program. In this case, each workpiece is processed using individual software. With its help, the jet pressure, the composition of the working cutting suspension and other parameters are automatically selected;

- If on non-CNC machines the selection of the cutting jet can be chosen incorrectly, then in this situation this point is excluded. The equipment independently controls the quality of the cut, then automatically adjusts the mode used;

- Metal processing with the help of software also provides the ability to make holes of the desired diameter;

- As you can judge from the video material, upon completion of the waterjet process, a completely finished part emerges from the workpiece, which does not need to be subjected to grinding or additional processing at the cut points.

With your own hands

The use of waterjet cutting equipment in a home workshop is quite possible. For example: in the implementation of original works for artistic or decorative processing of small and medium-sized workpieces. But you can make such a machine with your own hands only for cutting wood, plastic, laminate or other not very durable materials.

It should be taken into account that the cost of equipment, plus the periodic replacement of consumables and the constant need for abrasive, makes the direct cost of one working hour of waterjet cutting at least 1,400 rubles. But this is a separate topic, and if you have your own experience in using a waterjet cutter at home, share it with others in the comments block.

The essence of technology

Waterjet cutting of metal is not an innovative technology; it began to be used back in the 1960s. The American aircraft manufacturing company was the first to use machines to perform such cutting. It was the management of this company that made an official statement about this method, describing its advantages and recommending its use for cutting metal and other materials with high hardness. From that moment on, abrasive cutting of metal using water began to be actively used by enterprises and gained increasing popularity.

The essence of this technology is that water, which contains abrasive substances, is supplied to the cutting zone under high pressure. Any waterjet cutting installation works according to the following scheme.

- Water and abrasive material, which is mainly used as fine sand, are supplied from a special container to the mixer of the apparatus.

- After mixing, the water and abrasive enter the nozzle of the installation.

- A thin jet of waterjet mixture is formed in the nozzle, which is supplied under high pressure to the cutting zone.

Operating principle of hydrojet cutting

Technology implemented according to a similar scheme allows not only to perform cutting quickly and with high quality, but also to significantly save on consumables, the most expensive of which is ordinary sand. It should be noted that in terms of speed, abrasive cutting using water is comparable to plasma technology, and in terms of the quality of the resulting cut, it is comparable to laser technology.

Working principle of waterjet cutting

The use of water-abrasive cutting machines is not limited only to the possibility of cutting rolled metal; nevertheless, the bulk of the equipment continues to be used directly in this area of production. The operation of waterjet cutting is based on the technology of supplying water with a certain content of abrasive substance under pressure to the surface of the material. What happens during cutting?

- Water is supplied from a special reservoir under pressure to the mixer.

- At the same time, an abrasive mixture, usually consisting of small sand particles, is sent into the mixer.

- After mixing with the abrasive, the water is supplied to the nozzle for cutting the metal with an abrasive water jet.

- A thin stream is directed onto the surface of the material being processed and cuts it.

This operating principle allows you to significantly increase the speed of metal processing and the quality of its cutting. The only consumable that will need to be replaced is the abrasive powder itself. You will need to add abrasive powder to special containers from time to time.

The speed of waterjet cutting of metal can be compared with that of automatic plasma machines. But the quality of work can only be compared with cutting with a laser.

Control

For the effective operation of the machine, the work of several engineers and operators is required. The designer must make the project in a special computer environment. Then the file is placed in the device memory. The machine itself distributes functions to other nodes. The employee is responsible for a sufficient amount of consumables, for launching the program, monitoring its implementation and timely notification of a breakdown. An equipment specialist must conduct a technical inspection (preventive) and also eliminate problems.

Installation of waterjet cutting of metal with water under pressure CNC

Cutting metal with water under pressure is one of the most convenient and effective options for processing products. When using a waterjet machine, additional grinding of materials after cutting is not necessary, but its cost is very high.

Why do you need a waterjet cutting machine?

Water cutting is used in cases where it is not possible to stamp or cast parts, and also when these methods are unprofitable. Using the machine, materials are cut through water without direct mechanical impact. Typically used for industrial purposes when high speed and accuracy of materials processing is required.

How to make a waterjet cutting machine with your own hands

A homemade machine for waterjet cutting of metal is usually made without the use of computer numerical control (CNC). Responsibility for directing the parts falls on the shoulders of the craftsman managing the cutting process.

To make the device, you will need components that cannot be assembled yourself. The most expensive will be the purchase of devices for high pressure in the device for directing the cutting jet.

The simplest option would be to create a manually operated machine. However, it is possible to install CNC waterjet metal cutting, which will expand the capabilities of material processing.

To make the machine we will need:

- High pressure pump;

- high pressure pipelines;

- cutting head;

- coordinate table with bath;

- drives responsible for moving the cutting head, as well as for the operation of the control system;

- abrasive feeding mechanism;

- settling tank;

- low pressure pump;

- filtration system.

The device will be used at high humidity, so parts of the unit must be made of stainless steel, plastic and aluminum. This will protect the water jet machine from corrosion.

Step-by-step instructions for assembly and configuration

To make a waterjet cutting machine with your own hands, you will need a diagram and drawing.

For equipment production, it is recommended to use a direct-acting pump. Its cost is less, and repairs are much easier.

- It is necessary to connect the cutting head to the pump using high pressure pipes. You can buy them at auto parts stores. The cutting head should be supplied with fittings (bushings) for replacement. The bushings make it easy to change cutting attachments.

- A receiver must be installed between the pump and the cutting head. This will help eliminate impulses and increase the stability of the water jet.

- You can make a coordinate table yourself. Stainless steel is used for its assembly. The depth of the bath should be at least 1 meter. If the depth is insufficient, the water jet can destroy the frame. A meter layer of water helps relieve pressure up to 600 atm. The work table is designed in the form of a honeycomb or ribs, and then installed in the bathtub. The work table must be made removable, since even if the depth of the pool is sufficient, the table will eventually be cut by water. The ribs are made of metal or plastic. If the machine is removable, the bed does not move during operation, only the cutting head moves, changing its position relative to the workpiece.

- To ensure movement, you should create a platform that can move (longitudinal and transverse). It is possible to additionally install a rotating mechanism that helps change the angle of the cutting head, and a device that is responsible for the height of the cutting head (this allows cutting parts of various thicknesses). It is recommended to purchase an abrasive supply device, as it is made of special materials and is also equipped with a sand supply regulator.

- Any plastic container with a volume of approximately 2 cubic meters can be used as a water tank. The exiting liquid is supplied to the high pressure pump using a low pressure pump.

- A separator is installed next to the tank, which is responsible for separating sand from water, and a filtration system.

For proper operation of the device, abrasive materials and worn parts (seals and high-pressure pump elements) must be replaced in a timely manner. The abrasive consumption depends on what material is being cut. For example, when processing metal of maximum thickness, the consumption will be approximately 500-600 g per minute.

Diamond wire consumption

Rope consumption depends on many factors:

- Car condition. There is no point in saving on linings and other rubber bands; if they are already worn out, then during operation the rope undergoes additional testing. Load, which is why it may not produce its resource.

- Compliance with sawing technology. As was said earlier, if the rotation speed is too low, the rope wears out faster, and if it is too high, it quickly becomes washed out. Therefore, if you have forgotten what speed you need to set, you shouldn’t experiment, it’s better to call, we will always tell you at what speed and other parameters you need to cut in those. or other conditions, this or that material.

- Material. The service life of the rope also depends on the material that we need to cut - for granite, usually the higher its hardness group, the shorter the service life of the rope.

- Twist. As was said earlier, the service life of the rope depends on its proper wear - it is necessary that the rope bead wears evenly over the entire diameter, in this case we can refine it to the end and achieve maximum service life.