| Place | Name | Characteristics in the rating |

| TOP 10 best lathes |

| 1 | JET BD-920 | High build quality and better handling of small parts |

| 2 | METALMASTER MML 1830V | Better motor overload protection |

| 3 | FDB Maschinen Turner 320X1000S | High processing precision |

| 4 | Zenitech MD 250-550 VARIO | Large safety margin |

| 5 | Stalex SBL-250/550 | Modern design |

| 6 | Stalex SBL-280/700 | Best power |

| 7 | TV-9 produced by Rustan | Multifunctionality |

| 8 | Corvette 400 series | Greater versatility |

| 9 | JET series JWL-1220 | Comfortable work |

| 10 | "Proma" DSO-1000 series | The easiest |

Types of turning equipment

Turret lathes are designed for products that require processing of several surfaces using various tools. In order not to have to install and configure each tool, turret heads are installed on such machines, which can have two or more slots for placing tools. Of course, servicing such a lathe is much more difficult than a conventional model, but this is fully compensated by the functionality of this unit. For example, popular models of such machines are 1E316P, 1G340PTs, 1P371, 1A341.

A rotary lathe is one of the types of lathes

Rotary turning machines are designed for processing workpieces characterized by a short length, significant weight, and large outer diameter. These include dimensional gears, flywheels, etc. The functionality of such lathes (for example, models 1512, 1541, 1550, 1L532 and others) allows them to perform various types of turning work: turning, boring, cutting grooves, end processing, etc. And if you equip such turning units with additional devices, they will become even more versatile: with their help it will be possible to perform some milling operations, cut threads, grind and perform a number of other technological actions.

Working parts of a multi-spindle machine

Multi-spindle machines belonging to the turning group are necessary for performing complex technological operations in mass production conditions. Workpieces that can be processed on such machines can be in the form of pipes, hexagonal, square and round rods, shaped profiles, etc. This technique is distinguished by its high rigidity of design and powerful drive, which allows processing with high productivity.

What is important is that such complex and functional equipment is maintained in exactly the same way as a conventional machine. The list of technological operations that can be performed on such a unit is quite extensive: boring, roughing and shaping, cutting and rolling threads, etc. The most popular models of such turning equipment are 1P365 and 1B140 machines.

Screw-cutting lathe 16K20

Common models of turning machines, which gained wide popularity back in Soviet times, are screw-cutting lathes. Such machines, which can be found not only in almost any industrial enterprise, but also in school workshops, have gained their popularity due to the fact that with their help they can effectively perform a large list of technological operations.

Each such machine, regardless of the model, has a standard design consisting of the same type of components. Along with their functionality, screw-cutting lathe models are characterized by high safety, ease of operation and maintenance, which makes it possible to use them as units for equipping school workshops since the times of the USSR. The most famous and popular models of such turning equipment are machines 16K20, 16K50, 16B16A and 16P16P.

At enterprises that produce their products in large series and use blanks from shaped profiles and calibrated rods in production, automatic lathes are actively used. Such machines, which primarily perform turning operations in the longitudinal direction, cope with equal success in processing workpieces made of various metals: super-hard alloys, soft copper, etc.

On the domestic market, lathes are represented mainly by models from foreign manufacturers (Japan, South Korea, etc.). There are also some domestically produced models, for example 1M10DA.

Longitudinal turning machine 1M10DA

Early drive mechanisms

Several centuries passed from the invention of the lathe to the implementation of a simple drive mechanism on it. You can imagine it in the form of a pole fixed in the middle on the frame on top of the workpiece. One end of the scoop is tied with a rope that is wrapped around the workpiece. The second is secured with a foot pedal.

This mechanism worked successfully, but could not provide the required performance. The operating principle was based on the laws of elastic deformation. When you press the pedal, the rope is tensioned, the pole bends and experiences significant tension. The latter was transferred to the workpiece, setting it in motion.

After turning the product 1 or 2 turns, the pole was released and bent again. Using a pedal, the master regulated the constant operation of the hose, forcing the workpiece to continuously rotate. At the same time, his hands were busy with the tool, processing the wood.

This simplest mechanism was inherited by subsequent versions of machines that already had a crank mechanism. Mechanical sewing machines of the 20th century subsequently had a similar drive design. On lathes, using a crank, they achieved uniform movement in one direction.

Due to the uniform movement, the craftsmen began to produce products of the correct cylindrical shape. The only thing that was missing was the rigidity of the components: centers, tool holders, and drive mechanism. The cutter holders were made from wood, which led to them being pressed out during processing.

But, despite the listed disadvantages, it became possible to produce even spherical parts. Metal processing was still a difficult process. Even soft alloys could not be turned by rotation.

A positive shift in the design of machine tools was the introduction of versatility in processing: workpieces of various diameters and lengths were already processed on one machine. This was achieved by adjustable holders and centers. However, large parts required significant physical effort from the craftsman to implement the rotation.

Many craftsmen have adapted a flywheel from cast iron and other heavy materials. The use of inertia and gravity made the work of the processor easier. However, it was still difficult to achieve industrial scale.

Control

Recently, CNC lathes for metal - with numerical control - have become widespread. The controller controls the cutting process, monitors the position of the axes, and calculates the movement according to the specified parameters. Several cutting stages are stored in memory, right up to the finished part.

CNC lathes for metal can have process visualization, which helps to check the written program before the tool begins to move. The entire cut can be seen virtually and code errors can be corrected in time. Modern electronics control the axle load. The latest versions of the software allow you to identify a broken tool.

The technique for monitoring broken plates on a holder is based on comparing the graph of axle loads during normal operation and when the emergency threshold is exceeded. Tracking occurs in the program. Information for analysis is supplied to the controller by a drive system or a power sensor with the ability to digitize values.

Metal parts

The main task of the machine tool inventors was to increase the rigidity of the units. The beginning of technical re-equipment was the use of metal centers that clamp the workpiece. Later, gear transmissions made of steel parts were introduced.

Metal parts made it possible to create screw cutting machines. The rigidity was already sufficient for processing soft metals. Individual components were gradually improved:

- workpiece holder, later called the main unit - spindle;

- the conical stops were equipped with adjustable mechanisms to change the position along the length;

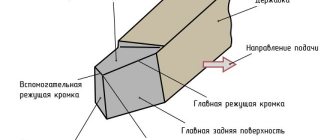

- working on a lathe became easier with the invention of the metal tool holder, but constant chip removal was required to increase productivity;

- The cast iron bed increased the rigidity of the structure, which made it possible to process parts of considerable length.

With the introduction of metal components, it becomes more difficult to unwind the workpiece. The inventors thought about creating a full-fledged drive, wanting to eliminate manual labor. The transmission system helped to carry out the plan. For the first time, a steam engine was adapted to rotate workpieces. It was preceded by a water engine.

The uniform movement of the cutting tool was carried out by a worm gear using a handle. This resulted in a cleaner surface of the part. Replaceable blocks made it possible to implement universal work on the lathe. Mechanized designs have been refined over centuries. But to this day, the operating principle of the units is based on the first inventions.

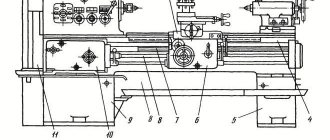

Main nodes

Lathes are ideal for machining 3D parts using rotary cutting. An overview of a modern machine contains the parameters and characteristics of the main components:

- The bed is the main loaded element, the frame of the machine. They are made from durable and hard alloys; perlite is mainly used.

- A support is an island for mounting rotating tool heads or static tools.

- Spindle - acts as a workpiece holder. The main powerful rotation unit.

- Additional components: ball screws, sliding axes, lubrication mechanisms, coolant supply, air intakes from the working area, coolers.

A modern lathe contains drive systems consisting of complex control electronics and a motor, usually a synchronous one. Additional options allow you to remove chips from the working area, measure the tool, and supply coolant under pressure directly to the cutting area. The mechanics of the machine are selected individually for production tasks, and the cost of the equipment depends on this.

The support contains units for placing bearings, which are mounted on a ball screw (ball screw). Elements for contact with the sliding guides are also mounted on it. Lubricant in modern machines is supplied automatically, and its level in the tank is controlled.

In the first lathes, a person moved the tool and chose the direction of its movement. In modern models, all manipulations are carried out by the controller. It took several centuries to invent such a knot. Electronics have greatly expanded processing capabilities.

First mentions

In the 700s AD. a unit was created that partially resembles a modern lathe. The story of its first successful launch begins with wood processing by rotating the workpiece. Not a single part of the installation was made of metal. Therefore, the reliability of such devices is quite low.

At that time, the lathe had low efficiency. The history of production has been reconstructed from surviving drawings and drawings. It took 2 strong apprentices to unwind the workpiece. The accuracy of the resulting products is low.

History dates information about installations vaguely reminiscent of a lathe to 650 BC. e. However, the only thing these machines had in common was the processing principle - the rotation method. The remaining nodes were primitive. The workpiece was literally set in motion by hand. Slave labor was used.

The models created in the 12th century already had some kind of drive and could be used to produce a full-fledged product. However, there were no tool holders yet. Therefore, it was too early to talk about the high accuracy of the product.

The device of the first models

An antique lathe clamped the workpiece between centers. The rotation was carried out by hand for only a few turns. The cutting was carried out using a stationary tool. A similar processing principle is present in modern models.

As a drive for rotating the workpiece, the craftsmen used: animals, a bow with arrows tied with a rope to the product. Some craftsmen built something like a water mill for these purposes. But it was not possible to significantly increase productivity.

The first lathe had wooden parts, and as the number of components increased, the reliability of the device was lost. Water devices quickly lost their relevance due to the complexity of repairs. Only by the 14th century did a simple drive appear, which greatly simplified the processing process.