Often in the household, during all kinds of repair work, it is necessary to bend a piece of pipe in a special way, and in this case you need to think about how to make rollers for a profile pipe with your own hands. Naturally, the easiest way is to buy professional rollers at a hardware store, but not everyone has the extra money for this device.

You can make the pipe material take the desired shape using a conventional torch. This method is often practiced, but the master faces some difficulties:

- it is almost impossible to get the product even, this is explained by improper distribution of forces and inaccuracy of movements;

- emphasis is required and, as a result, a lot of physical strength;

- it becomes necessary to have a large lever to change the shape.

To get a high-quality result, you need to use rollers. With their help, you can easily transform a profile pipe with your own hands.

Conventional rollers are a structure that has a special lever that drives several steel shafts, passing through which the metal pipe receives the required curved shape. To make rollers with your own hands at home, you need to have the necessary drawings on hand and thoroughly know the principle of the device. Homemade rollers for bending profile pipes will have good performance and decent quality if the assembly technique is strictly followed.

Machine for strengthening profile pipes

Reinforcement means the formation of ribs at the corners of a square or rectangular profile during rolling on specially shaped rollers.

Pipes with a reinforced profile are characterized by high bending strength and are used to create curved structures of any degree of complexity.

The profile is strengthened using specialized equipment.

Application area

To obtain the desired configuration, profile pipes are sequentially processed on profile strengthening machines, a forging block and a pipe bender.

A pipe bender allows you to bend profile pipes along a longitudinal section along a given radius. Such products are used when installing canopies, gazebos, and canopies.

Reinforcement is a necessary stage in preparing a profile pipe for making a curl using the cold forging method. The forging block allows you to create decorative elements from pipes with a square or rectangular cross-section, curved in the most bizarre way. The resulting products are distinguished by their volume, lightness, and low price.

Design

The machine for strengthening the profile is in many respects similar in principle of operation and design to a conventional rolling machine.

In addition to the frame and the motion drive, the main components of the machine for reinforcing a profile pipe are:

- Lower (support) shaft – 1 pc. It is leading, with its help the pipes move.

- The upper shaft is a pressure shaft. Deforms the profile - presses the pipe against the lower shaft.

The supply and receiving shafts are securely mounted on a massive base (housing); it must ensure the stability of the installation during operation. The feed mechanism ensures the rotation of the shafts around its axis.

Process technology

The amplification process on the simplest machine is performed sequentially, with two pipe installations:

- Step 1 – installing the pipe on the rollers.

- Step 2 – rolling the first 2 symmetrical sides.

- 3rd step - reinstallation of the pipe (rotate 90 0).

- Stage 4 - rental of the second 2 symmetrical sides of the profile.

Machine for profile reinforcement

Profile reinforcement is performed on a cold forging machine equipped with rollers for compressing the profile pipe before bending it into a curl.

Profile pipe

The rolling process depends on the wall thickness of the profile pipes and the grade of material from which they are made

Drive mechanism

According to the principle of operation, there are different types of wire mechanisms:

The manually driven machine has a simple design, compactness, and is designed for small volumes of work. Only a physically developed person can work on it. The metal will have to be deformed using muscle force.

An electrically driven machine for strengthening a profile pipe also does not take up much space. It is powered by an electric motor and has high performance.

Hydraulically driven equipment is too bulky. Allows you to roll profile products with maximum dimensions. Designed for large volumes of work.

Functionality

Multifunctional stationary modules, which are equipped with:

- rollers to strengthen the profile pipe;

- rollers for rolling out the ends of blanks in the form of artistic elements;

- forging block for cold forging.

All operations are performed without readjusting equipment or changing tools. The modules make it possible to produce various decorative forged elements of different sizes and required shapes.

An example of a multi-purpose installation is a reinforcement unit with rolling crow's feet (PGL), produced commercially, adapted for several operations:

- “crow’s feet” type reinforcement (squeezing, squeezing);

- rolling out the ends of the workpiece.

After this treatment, the pipe is completely ready for making a decorative curl on a forging block.

Disadvantages of profile pipes and solutions

With all the advantages of profile pipes, they also have a disadvantage. Manufacturers try to use materials of small thickness. Therefore, when designing long products, it is necessary to lay larger workpieces. The lightness of appearance is lost.

But homemade structures are quite often made from a rather thin initial blank. To strengthen the profile pipe from deflection, additional ribs are added to it. The result is increased rigidity.

The issue can be resolved by tapping with a hammer on one of the sides, crushing the edge. You can approach the issue more rationally: make a device that will slightly change the shape of the pipe profile.

- if you roll a square from above and below, you can additionally create reinforcement ribs;

- bending strength increases by 20...30%, which allows the use of smaller format pipes of one or even two standard sizes.

As a result, the master saves material and creates a lighter and more interesting design.

Making a machine yourself

It doesn't always make sense to purchase a professional machine. For one-time work, simple DIY installations are more suitable. The main thing is to have drawings, carefully study the design principle and operation of the machine, select high-quality materials for the workpieces and the necessary tools for assembly.

Scheme

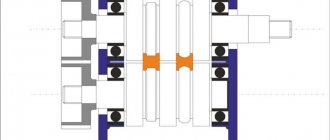

Schematic diagram of a machine for rolling 2 types of profile sections in section. Based on it, you can get an idea of the design and interconnection of the main components and the principle of pipe processing. In this case, the upper shaft is the driving one.

Machine diagram

Accessories

Rolling roller components must not have chips or gouges, have a decent margin of safety, and be made from certain grades of steel.

Shafts and axles are turned on a lathe. Some components can be bought in a store or removed from other mechanisms, for example:

- self-aligning rolling bearings (4 pcs.);

- stars (4 pcs.);

- chain from a bicycle, moped.

To assemble the frame (base), you will need rolled metal (channels, pipes), sheets 5-10 mm thick. The base ensures stability of the installation during operation.

Frame assembly

To strengthen the profile, it is better to make rollers (2 pieces of each type) from alloy steel; for a small amount of work, St3, St10 are also suitable. Roll blanks are subjected to hardening.

Rollers and axles must be many times harder than the pipes being processed. Otherwise, the rollers will have to be replaced frequently with new ones. The hardness of rollers on professional installations is at least 52 HRC.

Tools

When assembling the machine, you will need the following skills (as well as appropriate equipment):

Fastening by welding in some places can be replaced with threaded connections.

- drill, with a set of drills;

- wrenches of different sizes;

- level for setting the horizon line;

- caliper, tape measure.

Design of incoming parts

Special rollers are machined along the edges of the rollers, which reliably fix the position of the pipe during rolling.

Rollers

You can get the dimensions of the rollers for profile drawing from a kit from professional installations. It is not difficult to develop drawings of rollers and axles according to the obtained dimensions yourself. Below is an example drawing.

Roller drawing

Rolling of each profile size is carried out using rollers of appropriate sizes. Making a model with removable elements is not easy; for this reason, it is recommended to make multi-stage rollers for reinforcing the profile pipe when assembling the machine yourself. This will allow processing of pipes of different sizes without reinstalling the rollers.

Both axes have the same dimensions, but different lengths. The movement handle is attached to the longer axis (driving). Below is a drawing of an axle with a seat for the handle.

Drawing of an axle with a seat for the handle

Assembly work

The frame is created gradually as the remaining parts are assembled. The individual elements of the base are connected to each other by welding or large bolts.

The distance between the upper and lower axle depends on the diameters of the rollers. In the absence of precise assembly drawings, the dimensions between the axes are determined experimentally:

- install the rollers on the axle;

- measure the distance between the axes;

- drill holes on the side walls of the frame for installing bearings;

- then the axles are put aside and the bearings are installed.

The connection between the axle and the rollers is carried out in several ways:

- using a key, about 8x8 mm in size;

- welding through pre-drilled countersunk blind holes made with a large-diameter drill.

The second method is available if you have a machine for manual electric arc or semi-automatic welding.

Next, the axle is inserted into the bearing, which is pre-fixed in the axle box, which is pre-welded to the wall of the frame from the inside. Reliability of fastening is maximum. First of all, the axles with rollers are installed in the side wall of the frame where the chain drive is supposed to be located. Then the axles are inserted into bearings mounted on the 2nd side wall of the frame.

After installing the main elements, the frame is strengthened:

- welding seams;

- threaded connections.

Rollers for metal

To give sheet metal a cylindrical shape, it is simply impossible to do without a rolling machine. Pipe rollers are most often used in the manufacture of drainage systems. Rolling machines with forging cylinders carry out cold bending of metal workpieces and belong to the category of rotary models. This equipment can be used to work with thin sheet steel with a thickness from 0.1 to 120 mm. You can also process ductile metals, rubber compounds and plastics.

The rolling machine is selected depending on the thickness of the materials. Twin-roll rollers consist of two parallel shafts. The upper one, with a small cross-sectional diameter, is often made of high-strength steel, and the lower, with a larger cross-sectional diameter, consists of rubber-coated steel. The outlet diameter of the pipe depends on the force with which the pressure is exerted on the pipe. Three-roll rollers can be pyramidal, that is, symmetrical, or asymmetrical. Today they are in great demand in the production of ventilation air ducts, round drains, and radius parts. Three-roll folds are used for processing copper, iron, steel, zinc and other materials.

Four-rollers have an additional roller at the bottom, which simplifies the rolling process.

A sheet of hot metal is placed between the upper and lower cylinders, the front part of which is folded using a bending shaft. During the folding process, the sheet of metal is gradually rounded.

The most used rollers are 3- and 4-roll, they have the following differences:

- Three-roll.

- a sheet thinner than 6 mm slips between the shafts;

- the rolling speed of the metal sheet should not exceed 5 m/min;

- the sheet clamping point does not have exact coordinates, making it more difficult to control the machine;

- low cost.

- Four-roll:

- all rollers provide reliable adhesion to each other and the likelihood of sheet slipping is minimal;

- rolling speed can be more than 6 m/min;

- the work process is automated, the operator only needs to enter the machine operating parameters;

- overcharge.

According to the method of bending, rollers are divided into:

- mandrel. They are capable of deforming thin-walled pipes;

- segmental. The pipes are bent under the action of a separate segment, which pulls the pipe;

- spring. The presence of a spring that bends the plastic without deforming it. This is a manual method of processing materials;

- crossbow They are designed for pipes of a certain diameter.

Recommendations

Special requirements are placed on the alignment of the rollers: they must be located in the same vertical plane and be strictly parallel. Any misalignment will lead to uneven compression of the profile, which will significantly reduce the quality of the rolled product.

A machine made at home specifically for strengthening profile pipes should not pose a danger to humans during operation. During assembly you should:

- Fix all moving parts as reliably as possible. Prevent them from bouncing during operation.

- Provide protective flaps.

Properly assembled home-made installations are not inferior to professional models in terms of the quality of their products.

Rollers for profile pipes: making manual profile bending with your own hands

Making rollers for a profile pipe with your own hands, using drawings and knowledge of the operating principle of this useful device, is quite possible. Using such a device, which is highly versatile, you can independently produce bent structures of any degree of complexity from corrugated pipes.

Rolling profile pipes for a canopy on a homemade machine

The main working parts of the rollers, which exert a mechanical effect on the processed profile pipe, are rotating rollers, the number of which can vary from 3 to 5 pieces. It is in the gap between the rolls that plastic deformation of the corrugated pipe occurs.

Main technical parameters

How to make a sheet bending machine with your own hands? To do this, it is necessary not only to develop drawings of such a device, but also to determine its technical characteristics. It is best to take the design of a serial model as a basis and independently adapt it to your own needs.

Assembly drawing of a factory-made three-roller machine (click to enlarge)

Considering the fact that you are going to install your rollers in a certain room, you should immediately decide on their dimensions. This parameter, which directly depends on the length of the installed shafts, will determine what width of sheet blanks you can process on a device made by yourself. When deciding on the size of hand rollers, you should also take into account the fact that processing sheet blanks with a width of more than 1.2 meters using them will be quite difficult physically. The weight of a homemade machine will affect the ability to move it around the room and transport it.

Drive shaft. Drawing (click to enlarge)

Folding shaft. Drawing (click to enlarge)

Pressing shaft. Drawing (click to enlarge)

Drawing of three-roll plate bending rollers with electric drive (click to enlarge)

In addition to the dimensions and weight of future rollers, it is necessary to determine the following characteristics of such equipment:

- the diameter of the rolls - the main working parts of the device (this parameter, which is quite important, will determine the maximum radius with which you can bend the metal sheets being processed);

- the maximum distance at which the upper thrust roll can be located from the lower ones;

- the maximum distance to which the lower rollers can move apart;

- the speed at which the processed sheet material can move between the rolls.

Studying the technical parameters of factory models will help you decide on the size and design of the machine.

An important parameter that you should pay special attention to when developing a drawing of future rollers is the rigidity of their design. When processing metal sheets, significant mechanical loads are experienced not only by the rolls, but also by all other components - bed, drive mechanism, etc. That is why the choice of the roller operation scheme, as well as the selection of materials for its implementation, should be done with particular care.

Most often they are used for the manufacture of 3-roll rollers, since an increase in the number of working parts of such low-power manual devices leads to an increase in the level of load exerted on its drive mechanism.

Types of devices with rotating rollers

Rolling of a profile pipe, which results in a change in its original configuration, can be performed on equipment of various designs. Such devices for rolling profile pipes can differ according to the type of drive used and the main technical characteristics. Thus, rolling rollers can have:

- manual drive (the use of such devices for rolling profile pipes requires significant physical effort);

- electric drive;

- hydraulic drive mechanism.

Manual rolling rollers serve as a prototype for self-manufacturing of the machine

The simplest (and, accordingly, inexpensive) devices used to roll a profile pipe are manual profile benders. Along with their reliability and ease of use, they are distinguished by a number of significant advantages. The design of a manual profile bender consists of the following elements:

- a massive frame that serves as a reliable foundation for the entire structure;

- rollers that perform feeding and receiving functions (these structural elements, with the help of which rolling is performed, are connected to each other via a chain transmission);

- a set of clamping mechanisms (clamps) designed for fixing pipes of various sizes.

Main parts of rollers

This rolling machine, which has a simple design, is also equipped with a special pipe, which acts as a guide for the bent workpiece. It should be borne in mind that using such a machine requires the performer to exert significant physical effort. In addition, this device does not allow rolling with high productivity and is most often used for simple work at home. That is why the design diagram of this machine is used to make a profile bending machine with your own hands. Such a simple design profile bender allows you to perform rolling of profile pipes with high quality and high efficiency.

An electric machine for rolling profile pipes, even one made independently, provides higher productivity of the technological operation. This is explained by the fact that an electric drive, the power of which can be quite large, is responsible for performing the main operation - pulling the professional pipe through the rollers. That is why electric rollers for profile pipes, which you can make yourself using drawings, are used both by small organizations or home craftsmen, and by manufacturing enterprises.

The machine can be equipped with an electric drive later, the main thing is to take this into account initially and develop a sufficiently powerful design

However, of course, the hydraulic profile bending machine has the highest power, which is quite difficult to make with your own hands. Devices of this type, intended for rolling profile pipes, are used mainly in industrial enterprises, where it is necessary to carry out such a technological operation with high productivity.

Design Features

Rollers (also called sheet bending machines) allow controlled plastic deformation of sheets made of metal. Operating on the rolling principle, such a device is equipped with several shafts, which, when a metal sheet or pipe passes between them, changes their configuration. Serial models of such sheet bending equipment and homemade rollers work on the same principle and, accordingly, have a similar design. Let's look at the main elements of the machine.

Device of manual three-roll rollers

Bed-base

This is a load-bearing element that ensures the stability of the rollers, as well as the correct relative position of all their components.

Two vertical support posts

In their bearing units, shafts are installed, of which there can be only two (two-roll machine), three (three-roll machine) or even four. In the design of most rollers equipped with three working bodies, the two lower rollers can change their position only in the horizontal plane, and the third, a thrust roller located on top, is also adjustable in height. In addition, the upper roller for removing the finished part is equipped with a quick tipping mechanism.

Upper pressure roller lifting mechanism

Rolls

In the process of processing a sheet blank, the rolls must rotate, for which any rolling machine is equipped with a drive mechanism, which can be chain or gear. The operation scheme of such rollers is such that only the lower rollers are driven into rotation, and the upper one, tightly pressed against the surface of the workpiece, rotates under the influence of friction forces.

Roll operation diagram

Rollers can be equipped with various types of drives. Thus, depending on this parameter, rolling devices of the following categories are distinguished. Manual

These are the simplest rollers, which are most often made by hand. To drive such devices, chain and gear drives can be used, the parameters of which should be selected depending on the characteristics of the material being processed. Hand rollers, taking into account the fact that significant physical effort is required to operate them, are used primarily for processing small workpieces.

Electrically driven

In terms of their performance, such rollers belong to the average category. Electrically driven three-roll rollers, due to the sufficiently high power of the drive mechanism, make it possible to process workpieces of considerable size.

Electromechanical rollers are often a modification of a manual machine to which a motor and control panel have been added.

Hydraulically driven

This is the most powerful of all rolling equipment on the market today. Due to the fact that the hydraulic drive with which such rollers are equipped allows their working bodies to act on the workpiece with great force, such a device can effectively process metal sheets of even very significant thickness.

Among industrial hydraulic rollers there are even such giants

The quality of processing performed on rollers is primarily influenced by the characteristics of the rollers. Since the rolls experience significant mechanical loads during operation, high-strength tool steel is used for their manufacture. In addition to the mechanical impact, when processing sheet blanks of considerable thickness, which are preheated to give them greater plasticity, the rollers also experience thermal impact. It should be noted that such an impact, which can be very significant, has a rather negative impact on the operational characteristics of the rolls.

The quality of processing performed on rollers can be improved by equipping them with CNC systems, the tasks of which include coordinating all operating modes of the machine (the relative position of the rollers, the amount of pressure exerted on the workpiece, etc.).

Homemade devices for rolling pipes

It is practically impossible to do without such a device as a device for rolling corrugated pipes in those situations when you decide to do your own repairs, during which you will have to deal with bent pipes. To do this, you can purchase a serial device for this purpose or use a homemade profile bender, the design of which is not very complex. It also makes sense to ask the question of how to make a profile bender for the reason that serial models are quite expensive, so purchasing them (especially if they are required only for home repairs) is not always advisable.

Approximate dimensions of homemade rollers

In order to make high-quality homemade rollers, you can study theoretical information, watch a video on this topic, but the main thing is to follow the recommendations of those who have already achieved good results in solving this issue. Of course, to make your own roller, you need to have not only the appropriate knowledge, but also certain skills in the manufacture and use of various technical devices.

Kinematic diagram of the machine

Homemade rollers can even be made from scrap materials, which are almost always available in any garage or home workshop. Moreover, the efficiency of such rollers, if they are made taking into account all the recommendations, will not be much lower than that of commercially produced models.

Machine shaft drawings:

Methods for installing load-bearing structures

When installing load-bearing structures, the joining of elements is carried out in two ways:

- By welding . The connection of elements by welding is strong and durable. This is especially important in places where there is a lot of pressure on the connection.

- Using bolts . This connection is more profitable, since not everyone has a welding machine. Bolts can be used to connect elements of greenhouses, sheds and shelving.

Load-bearing parts on which a large load is planned are best made using I-beams or channels. These elements are not so beautiful, but have high strength compared to a profile pipe.

How to make a profile bender yourself

To make a profile bending machine with your own hands, you need to follow the following sequence of actions.

- First of all, the base or frame is made, for which large-diameter pipes or steel channels can be used.

- Serious attention should be paid to the manufacture of a vertical support for the machine, the material for which can be a U-shaped profile. It is in the upper part of such a support, which must be highly reliable, that a pipe-deforming unit - a roller mechanism - is installed. To mount a vertical support, the lower part of which is securely fixed under the frame, you will need a clamp of the appropriate size. With this method of attaching the vertical support, the deformation force exerted on the bent profile pipe will be evenly distributed over the two feed rollers.

- To drive the feed rollers, a chain drive is used, which can be assembled using a chain and sprockets from an old bicycle. Sprockets, which in their geometric parameters must strictly correspond to the characteristics of the chain used, are fixed on the feed and driven shafts. When installing a chain feed mechanism for your homemade machine, you should ensure good chain tension and only then proceed to fix the feed mechanism handle. Naturally, the drive mechanism of your machine for rolling corrugated pipes should ensure easy rotation of the feed and driven shafts.

- The homemade rollers themselves, which will exert pressure on the bent profile pipe and thereby absorb the main load during operation of the machine, are best made from steel that has undergone a hardening procedure.

In order for a do-it-yourself rolling machine for profile pipes to be highly versatile and can be used for processing products of various sizes, its design must provide for the possibility of radial adjustment. This important option allows you to change the size of the gap between the work rolls. To make your homemade rollers even more functional, you can provide in their design the possibility of making angular or, as it is also called, axial adjustment.

Drawings and instructions for making your own rollers for a profile pipe

The advent of cellular polycarbonate for the manufacture of greenhouses determined a new type of structure for protected ground structures - arched structures. To create a metal frame for such buildings, you need to have a machine capable of bending structural profiles along a certain curve. Homemade rollers for profile pipes are designed to help in the manufacture of arches along a given radius.

The technological process of profiling long workpieces is based on pulling the part through rollers located at a certain distance from each other. To give a bend in one direction or another, the length of the length is not passed in a straight direction, one or two rollers are offset.

Types of rollers

To produce a profile pipe and bend it at home and in a factory, completely different tools are required.

Factory production

Rolling is the main technological operation in the process of manufacturing profiled pipe products.

The whole cycle looks like this:

- Flat blanks are rolled into a cylinder, and the joint is welded.

- The resulting product is rolled through rollers, where the desired profile is formed under high pressure.

- The quality of the seams is checked.

- Products are calcined to remove residual stresses from deformation.

Pipe rolling machine

When rolling long pipes on a machine, the center of movement is shifted. Due to this displacement, a curve is formed between the rollers. One roller presses from the inside of the radial contour, and the other two form the external contour of the future product.

Drawing of a pipe bender for pulling profile pipes. All dimensions of parts required for manufacturing are indicated:

Structurally, such a device is made on a strong support made of channel. The lower rollers are located in bearings. Usually the distance between them does not change (there are versions of the machine where, by changing the location of the lower rollers, a different rolling radius is created).

The top roller is located on top. It can be moved in height. By moving the supporting part downward along the thread, significant forces can be developed. They will act on the pipe during the rolling process.

For self-production, you can go a different route. The walls of the device are cut out of a sheet 2...4 mm thick, where the rollers are installed.

Simplified pipe bender design:

The most difficult thing is to make the sidewalls, inside of which are located:

- Support shafts – 2 pcs.

- A pressure roller located on a suitable device.

- A handle that allows you to roll a profile pipe.

Industrial machines are made with manual or electric drive. When manufacturing an electrified machine, the possibility of reverse must be provided. Then you can roll, forcing the length to move in both directions.

Design of a homemade rolling machine

To roll a profile pipe, you need to make a simple device that will implement the following ideas:

- the pipe moves between guide bearings installed with a small gap (0.2...0.4 mm);

- Profiling rollers will press on it from above and below. When pushing the workpiece between them, the upper and lower edges will collapse. The side edges will not change.

Rolling machine for profiling pipes 20·20 mm: 1 – stand; 2 – body-cover; 3 – rolling roller; 4 – bearing

Between the upper and lower housing-covers 2, bearings 4 are located on special axes. The distance is chosen so that with a small gap the profile pipe can pass between them.

Rolling is carried out by two rollers 3 mounted on special stands 1. They are welded to the housings so that the rollers crush the pipe by 2.0...2.5 mm on each side.

Making a pipe bender with your own hands

The simplest pipe bender is relatively easy to make. Need to purchase:

- bearings No. 206;

- bearing housings;

- shafts Ø 35 mm made of hardened steel HRC 40...45 (suitable for the internal size of the bearings);

- bicycle sprockets of the same diameter;

- bicycle pedal;

- lead screw with nut;

- channel No. 8;

- channel No. 6;

- M8 bolts with nuts;

- strip 40 mm, thickness 4 mm.

To make it you need to use:

- Electric drill.

- File.

- Angle grinder with cutting and cleaning discs.

- Welding machine.

- Set of wrenches.

Step-by-step manufacturing of the machine

Having prepared a set of components, we begin manufacturing.

General view of the machine. It is installed on timber 100·50 mm.

All details are displayed in a visible place. The performance of the bearings and lead screw is preliminarily checked.

Blanks are cut from channels. A vertical stand is welded from them, installed perpendicular to the supporting channel.

A hole is drilled for the lead screw. A nut is welded to it. Then screw in the screw. A cross member is welded on top; it will be needed to move the screw along the thread.

Bearings move along the support channel. They are pre-installed in the housings. Shafts are inserted inside. Chain sprockets are welded to one of the ends.

A bicycle pedal is welded to one support shaft. By rotating it in one direction or another, you can force the pipe to move in the desired direction.

Having manufactured the clamping mechanism, the location of all elements is checked. They try to install them according to the drawing presented earlier.

Having installed the parts in place, they are welded. Now it’s time to check the functionality of the device.

Place the pipe and roll it in both directions. There is no pressure from above yet; we are checking how easily the pipe moves.

By turning the screw, press the pressure roller down and push the pipe. By moving the pressure roller, roll the pipe. After each pass, move the roller down. Periodically remove the part and compare it with the template.

Having manufactured the machine, you can begin to manufacture greenhouses and greenhouses, which are based on profile pipes. Below are examples and information on how to make such structures.

Video: homemade pipe bender for a profile pipe.

Recommendations for making a rolling machine

Once the drawings of your future rollers have been developed and the materials have been prepared, you can begin manufacturing the machine. Before assembling it, you need to make the following elements.

Support frame

The lower rollers of the equipment will be installed on it. Such a frame can be made from two sheets of thick metal, which are connected to each other by stiffening ribs (you can use several pipes for this). Steel corners must be welded to the side surface of the sheets from which the frame will be made, to give them additional rigidity. The support shafts on the elements of such a frame are installed in special grooves, which should be pre-marked and cut out.

Homemade frame assembled with rollers

Support posts

The top roll will be located on them. To make such racks, it is better to use not pipes, but a massive U-shaped profile made of steel. To ensure vertical movement of the upper roll, a worm gear is suitable.

Drive mechanism

It will consist of three sprockets, a chain and a mechanism for tensioning it.

End view of the machine before fastening the drive mechanism parts

A homemade machine drive can also be assembled based on a gear drive

It is better to purchase the rolls themselves, which will do the main work of deforming sheet metal, in a factory version, rather than using pipes for this or trying to turn them on a lathe yourself.

You will also need a grinder, a welding machine, a drill and a set of plumbing tools. The procedure for making rollers with your own hands is as follows.

- Pre-prepared machine components, the dimensions of which must exactly correspond to the drawing, are connected to each other by welding.

- The upper and lower rolls are installed in places previously prepared for them on the frame and support posts.

- The roller drive mechanism is assembled.

- After the equipment is assembled, the functionality of its components and the correctness of their interaction with each other are tested.

Using the scheme described above (with minor design differences), you can also make your own machine for bending metal pipes.

> Youtube Working with rollers

Arches for greenhouses and greenhouses

Different types of greenhouses are used in the practice of gardeners

Greenhouse metal frame 3·4 m:

Most often, three-meter arcs are chosen. An entrance is created at the ends. Additionally, a window is installed that can be opened while leaving the door closed. Profile pipes of 20·20 and 25·25 mm are used.

Reinforced arc of an arched greenhouse:

In winter, the load can reach over 200 kg/m². Therefore, a curved arc inside is welded to the outer contour. Additionally, radial connections are welded. Now a more rigid circuit is working that will withstand high loads.

Stationary greenhouse “Butterfly”:

Small greenhouse structures can be made stationary or portable. They are convenient because you don’t need to go inside to work with the plants being grown. It is enough to open the doors slightly to gain access. The greenhouses are called “Butterfly” because they open in both directions. From the end, the raised doors look like butterfly wings.

Portable “Breadbox” greenhouses are installed on the beds for the spring and autumn periods. In this design, the door opens in a similar way to how this issue is resolved in bread bins. It rises up and moves along the back wall. Such devices are in enviable demand among vegetable growers.

The desire to reduce the snow load and create a durable metal frame is pushing designers to create teardrop-like greenhouses. The generatrices of the walls are built along complex curves. The top is pointed, the snow rolls down without stopping on the surface.

Joining semi-arches in the “Droplet” greenhouse:

Inside, the semi-arches are connected in the center of the frame. This solution facilitates the production and delivery of products to the gardener’s plot. All that remains is to make the halves and assemble them on site.

Drawing of a radial arch for a greenhouse made of 20·20 mm profile pipe. Doorway:

The most common design is made along a radius of 1500 mm (outer profile). In it, a height of 2115 mm is reached in the center of the structure. Vertical sections are created on the sides of the generative arc; their length is 615 mm. Users will enter through a 780mm wide doorway. The opening height of 1830 mm is sufficient for the passage of people of average height.

Practice shows that such a greenhouse is in demand in most areas. There is enough space inside to accommodate beds and walkways.

Arch for a heifer 2800 mm wide:

Some people like to use a greenhouse that has a slightly smaller width (2800 mm). In it, the height in the central part is slightly higher, amounting to 2195 mm. Here the vertical sections along the edges have a height of 795 mm. The radius of the generatrix of the curve is 1400 mm (outer dimension).

The large height (2085 mm) and width (800 mm) of the doorway attracts attention. Even tall users will be able to walk inside freely without bending over when entering.

For a greenhouse 6 m long you need:

- 7 arcs, they are placed at a distance of 1 m from each other;

- for the manufacture of end elements, 33.3 m is required;

- the longitudinal elements between the arcs will total 42 m;

- To manufacture a metal frame, 20 profile pipes (6 m) will be required. The calculation was performed for a 20·20 mm profile pipe with a wall thickness of 1.5 mm. The total weight is 99 kg.

How to make homemade rollers for a profile pipe?

Curved profile pipe is widely used in the construction of various structures. The curved profile gives the roof a streamlined shape, is aesthetically attractive when constructing arched structures and openings, and can withstand severe dynamic loads. Buying a profile of the required diameter is not a problem. It is impossible to give a straight metal profile pipe the desired bend without the use of special equipment.

You can bend the profile manually using a gas burner and applying physical force. But even for such a simple operation it is necessary to secure the pipe firmly, select a safe place for heating, and adjust the levers to apply force. It is even more difficult to make several symmetrically curved profiles.

This problem is solved using a special technique - rolling a profile pipe.

Creating curved surfaces

In load-bearing structures, the profile pipe plays the role of a horizontal, vertical or inclined support for balconies, ceilings or roofs. But for canopies, canopies or greenhouses it is necessary to create a curved surface.

This is explained by several reasons:

- Aesthetic perception . Round shapes have a calming effect on vision and the human psyche.

- Wind and precipitation . The streamlined shape does not serve as an obstacle to the wind, so during strong gusts the rounded surface poses virtually no threat. In addition, round shapes do not retain precipitation in the form of rain and snow.

To create a curved surface, you need to bend the material. This action can be performed by heating individual areas with a gas burner.

This is the simplest bending method, but it has some disadvantages:

- Firstly , its implementation requires a large lever, a strong stop of the tubular product and enormous physical effort.

- Secondly , it is impossible to achieve uniform bending in this way.

You can create an even sector of a circle using rollers.

What is pipe rolling

For the construction of metal structures, special pipes with a square or rectangular cross-section are used, which have increased strength to static load. Giving these pipes the required shape using a special machine is called rolling. The machine itself is called rollers (roller, pipe bender).

When people talk about pipe rolling on an industrial scale, this term refers to the operation of producing a profile pipe. The blank for obtaining the profile is a round welded pipe, which, by rolling on rollers, is converted into a pipe with a square or rectangular cross-section.

Rolling in production consists of the following operations:

- Preparation of a pipe with a round cross-section from flat rolled metal - the sheet is rolled up and the connecting seam is welded.

- A round pipe is pulled through a roller, deforming it and giving it a cross-section of specified dimensions.

- Carry out quality control of the connecting seam of the resulting profile.

- Additional rolling removes the residual stress of the metal after deformation.

Note! The term “rolling” on an industrial scale has a broader meaning than just a radial change in the shape of the pipe.

A production roller or pipe bender is a machine consisting of 3 or five metal rollers, which are connected into a single mechanism by a drive chain. Such a machine is used in the pipe rolling industry, primarily for the manufacture of the profile itself.

In pipe rolling production or in professional construction, an electric roller is used. This is a device that consists of several specially fixed rollers and a guide system. Between them, with external force, a metal profile is pulled.

When making pipes, the rolling machine looks like a stationary multi-ton machine. In industrial construction, a roller is an industrially manufactured machine for radius deformation of a pipe.

Industrial rollers

The industry produces machines for self-rolling profile pipes for the needs of private construction. The cost of such devices starts from 25 thousand rubles.

These are portable, compact machines:

- with manual drive;

- electrical devices.

Note! Hydraulic driven machines are used in industrial production. These are heavy stationary machines that have great power.

Standard rollers for home use consist of:

- Three hardened metal rollers. The bottom two are servers. The upper pressure roller presses on the pipe, deforming it.

- Threaded clamping device.

- Stable bed.

- Sturdy metal case.

- Handles for driving the chain drive.

It is easy to equip a manual machine with an electric drive. For some industrial rollers, this modification is provided by the manufacturer. At the consumer's request, the electric drive is installed upon purchase.

However, purchasing an industrial machine for home use is a luxury for most consumers. It is possible to make such a device yourself, provided you have some skills and the availability of component parts.

Roller types

There are several types of machines:

- Manual rollers are the most convenient and practical device for deforming materials. There are no difficulties in working with the device; in addition, such machines do not need to be connected to a network. Clamps and feed rollers operating with a chain drive are attached to the main frame.

Profile rollers, manually driven, are most often used for single production, rather than for continuous production. Such devices offer a number of advantages:

- durability, reliability of the design and ease of operation;

- small size of the rolling machine, due to this it takes up little space;

- simple adjustment of the lower and rear rotating shafts;

- the upper shaft is removed;

- low price of the machine.

Manual jewelry rollers are widely used by jewelers to roll and roll flat metal blanks and wires to give them the desired shape. The working cylinders of jewelry rollers are made of wear-resistant carbon alloy steel. These rollers are powder coated to protect them from corrosion.

When working with the rollers of a hand-held device, additional effort must be applied, since hand-held machines do not operate on electricity and the main guiding mechanism in them is a special pipe. Small metal products are suitable for processing on such machines.

- Hydraulic rollers - hydraulically driven machines are highly powerful. The rolling machine is rated by professionals as the highest quality and most productive unit. However, it is quite weighty, and having installed it once, it is unlikely that you will be able to move the machine from place to place on your own without outside help.

- Electric rolling machines have the highest productivity due to the operation of an electric motor, which allows you to quickly deform the pipe between the rollers. The operating principle of this model resembles a manual one, but there is a motor. Such equipment is often used in industrial production and has many positive reviews from consumers. The only negative is the overpriced electromechanical equipment.

Rolling machines in a home workshop or garage should be:

- mobile. Such a machine should be light in weight for ease of movement;

- taking up little space;

- low-power and energy-saving. A 20 kW machine does its job very quickly, but consumes a huge amount of energy. The wiring in the house simply cannot withstand its work. As an option at home, you can use rollers with a power of up to 1500 Watts, as well as manual ones.

If, for one reason or another, none of the above options for rolling machines suits you, then you can also make the rollers yourself, because few serious repairs can be done without this machine.

Homemade devices for rolling

The pipe bender in the home craftsman's arsenal is not a device that is often used. However, for those craftsmen who are engaged in arranging their own site on their own, rollers are periodically necessary.

Carrying out repair and construction work using bent profiles allows you to create lightweight, durable structures from modern materials. For example, polycarbonate, which is widely used in the construction of greenhouses, gazebos, canopies, and roofs, fits well on a bent metal profile.

A homemade pipe bender is a compact device with dimensions: length - 500 mm, width - 220 mm, height 340 mm.

For production you will need:

- stable base;

- strong body;

- metal rollers;

- chain for transmitting torque to the rollers;

- clamp for adjusting pressure;

- guide pipe.

Note! It is unacceptable to skimp on components. The rolling machine must have sufficient strength and be safe to use.

To make a high-quality pipe bender yourself, you must have skills in working with metal and be able to draw up and read a drawing. With a little effort, you can assemble rollers at home that will not differ in performance from their industrial counterparts.

How to make rollers with your own hands?

Homemade rollers for a profile pipe should be:

Depending on the frequency of use, a homemade machine can be equipped with an electric drive after its manufacture. The motor power should be no more than 1.5 kW (for operation from a stationary network).

Note! Electric profile rollers cannot be called an economical device. If such a machine is used infrequently, then you can get by with a manual drive.

The manufacture of a machine for home rolling should begin with the assembly of its body. For this, it is recommended to use a channel or profile pipe. The base must be wide enough and stable. The body is rigid, the working part is U-shaped. A nut is welded at the top of the body to install a clamp to adjust the pressure of the deforming roller. The second option is to install a hydraulic jack.

The jack is installed under the feed roller from below. In this embodiment, pressure is applied to the pipe from below, for which half of the installation platform (with one feed roller) is made movable.

The rolling mechanism has its own characteristics. The rollers must be stronger than the pipes that are expected to be deformed. They are made of hardened steel and secured with rolling bearings. Two rollers are installed on the lower platform, on the same plane. They will stretch the pipe.

The deforming roller is installed on top in the U-shaped part of the body. Its position is adjusted with a clamp. The rolling mechanism is connected and driven using a chain drive. The chain can be used from a large bicycle. The sprockets are installed on a rolling and deforming roller and connected to a handle, from which torque is supplied.

A guide pipe is installed to hold the pipe in the center.

Description of rollers

The main working mechanisms of rollers are rotating cylinders. Hot sheets of metal are passed through cylinders and thus the metal is bent. Rolling machines, depending on their purpose, have from 2 to 5 cylinders, and the most common are 3- and 4-roll models.

The third rear shaft is responsible for the bending of the parts, and the radius of curvature, in turn, is determined by the distance between the rear and upper shaft.

Due to sometimes very heavy loads, metal rollers can break, which leads to frequent replacement of machines. When working with iron, it must be heated repeatedly; after the rolling machine, the iron layers are sent to the furnace, heated and rolled again. The reheated iron bars are then sent to the sectioning machine.

Passing through the rollers, the cross-section of the metal decreases and it lengthens. This effect is exerted by the high heating temperature of metal products and the degree of pressure on them.

In order to make a cylindrical product, it is necessary to adjust the rear shaft parallel to the front one. When making a metal cone, the rear shaft must be installed at an angle relative to the front one.

There are models of rolling machines that are much simpler; metal processing can be performed on them by installing them on a table. Such models are less functional, since the device must always be held in place during operation. However, you can use fasteners - this will greatly simplify the rolling process.

The smaller the dimensions of the device, the lower its cost. When choosing a rolling machine, you should consider the size of the largest part to be processed and its thickness.

Modern rolling machines are capable of performing the following functions:

- pipe bending up to 180°;

- working with metal pipes;

- deformation of pipes of different diameters.

Recommendations from experts

Key points to consider when making rollers for profile pipes:

- When assembling the machine, it is recommended to install radial adjustment, which will allow you to adjust the gap during operation;

- adjustment of the angular gap should be provided;

- For safe operation of the machine, especially with an electric drive, protection should be used on the moving parts of the mechanism.

With the right approach, rollers made at home are in no way inferior to industrial machines.