Definition and Application of Pipe Bender

Profile pipe – rolled metal in the form of a hollow pipe product with any cross-section. The only exception is round steel. The most popular pipes are those with rectangular and square cross-sections. Such rolled metal can withstand significant loads due to the presence of hard corners.

Construction is one of the areas where profile pipes are widely used. It is used during the construction of small architectural forms and large objects. In this case, not only products with rectilinear geometry are used. During the work, specialists have to bend straight pipes with a profile section at different angles at a construction site or in a factory, or even twist it into a spiral. Professionals do not use handicraft devices for such operations. They use a special mechanism - a profile pipe bender. It is also called a profile bender. It simplifies the process and allows, with minimal time, to achieve the desired shape of initially straight rolled metal.

Roll forming device Source prostanki.com

Bending a tubular product with a cross-section of a rectangular, square or other shape other than a circle is an alternative to cutting solid metal products into separate fragments, from which a single structure of the desired configuration is subsequently made by welding. The use of a profile bender allows you to immediately create curved blanks from corrugated pipes without violating their original integrity.

Manufacturers produce a wide range of roll forming equipment for pipes made of various materials, with almost any cross-section, diameter and wall thickness. It is used to create:

- small greenhouses and entire complexes;

- elements for stairs;

- free-standing sheds and those attached to the house;

- gazebos;

- frame buildings with arched elements;

- fences and barriers with curved parts;

- street furniture;

- designs for house benches, sports and children's playgrounds.

Arched element of a greenhouse made from corrugated pipe Source ad-cd.net

To bend the required profile, specialists use appropriate attachments in each specific case. They are usually included with pipe bending equipment. Devices can also be equipped with them.

Bending process

To set up a roll forming machine, regardless of quantity, 2-3 profiles are usually required. Wall thickness, shelf life of the aluminum profile, the state of its delivery and the geometric characteristics of the profile - all these indicators affect the possibility of bending the profile with a particular radius and the subsequent quality of the arc. The minimum radius also depends on the profile width. For a quality system profile with a width of 45 to 50 mm, a minimum radius of 150 to 175 mm can be achieved. The rollers must slide freely along the profile flanges, otherwise the profile may curl; this fact is taken into account when installing the clamp. The surface of the rollers must be clean to avoid scoring and scratches on the profile being processed. Due to the fact that the profile blank is coated with oil, along with the lubricant, dust and grains of sand fall on the walls of the rollers, which scratch the surface of the profile. Also, during bending of an unpainted profile, particles of aluminum oxide can be torn off by the force of friction from the cladding layer of aluminum (a thin layer of pure aluminum), which are smeared over the deformed surface and scratch the walls of the profile and rollers. Therefore, during the bending process, periodically wipe the rollers with a clean rag and remove accumulated dirt from them. The main indicator of the quality of a bent profile is the preservation of a constant cross-section, the absence of metal corrugations on the inner edge of the profile, the parallelism of the front walls of the profile, undeformed grooves for installing glazing beads and seals.

Classification of bending equipment

A modern profile pipe bender can have different designs. Professional craftsmen engaged in the manufacture of products and structures from profiled assortments can use the following devices in their work:

- portable and stationary equipment;

- devices with different types of drive (electric, manual, hydraulic devices);

- machines that differ from each other in the way they influence the workpiece.

The assortment, which has undergone profiling during the manufacturing process, can be bent by rolling, winding or rolling. The latter method is also called rolling.

Run-in

This method of influence involves clamping one end of the pipe. The required bend is given to it using a stationary template. The tubular product is rolled around a stationary part using pressure rollers.

Rectangular bar rolling machine Source wp.com

Winding

In pipe bending equipment that operates on the winding principle, the workpiece is pressed against a template roller. During the bending process, the pipe is wound around a moving part. The tubular product is pulled between a template that performs rotational movements and a special thrust element that acts on the workpiece at the starting point of bending.

See also: Catalog of companies that specialize in the design and installation of metal structures

Rolling

A bend of the required radius is created when using a device whose design contains three shafts. Of these, two are support rollers. The third element is the central shaft. The bending radius of the profile depends on its spatial position. The rolling bending device is a more versatile equipment than devices operating on the principle of winding and rolling. After all, the bending radius of the workpiece directly depends on the installed template.

Rolling pipe bending device in a compact housing Source kovkapro.com

Experts select a factory pipe bender for professional pipes depending on the required bending radius of the workpiece. At the same time, they must take into account the cross-section and wall thickness of the tubular product.

The procedure for bending a profile pipe on homemade machines

It is unlikely that you will be able to obtain the required bending radius in one go - too much force is required for this. It is impossible to create it manually. Receive the required bend in several passes:

- First, the rollers are aligned so as to obtain a slight bend, the pipe is rolled in one direction, then removed from the rolls, unfolded and inserted on the other side. It is necessary to unfold in order to obtain an evenly curved pipe.

- With the same position of the rollers, it is pulled several times until the curvature is no longer added.

- If the required bending radius is not achieved, change the position of the roller and repeat the steps again.

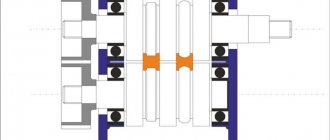

Rolling pipe bender with electric drive

The change in bending radius is achieved gradually, otherwise you won’t be able to make an arc from a profile pipe on a homemade pipe bender. What to do if you need to repeat the same bend? Make a graduation - note to what height the roller moved, how many times it was rolled in each position. When repeated, the differences, if any, will be insignificant.

The difficulty of bending lies in the fact that there is no scale and it is difficult to obtain the intended bending radius without experience. Sooner or later you will get it, but you can spoil a lot of material in the process.

Manual profile benders

Devices for bending hollow metal of any cross-section, which operate solely using muscular force, are manual pipe benders. These are mobile devices. They are small in size and weight.

Professionals use this type of roll forming devices to produce the required products at the installation site. One of the most common machines is a profile bender with three template rollers. It is around them that the workpiece moves when bending work is performed directly at the customer’s site. Using a manual profile bender, a craftsman can produce the required parts at any time. The machine also allows you to adjust their curvature at the installation site.

After inserting a straight profile pipe into the device, a product bent at the desired angle comes out of a manual pipe bending device. In this case, the bend can be whatever you want.

Manual roll benders Source equipnet.ru

Specialists use a manual pipe bender for square pipes and hollow rectangular products, as well as for bending strips, squares, round pipes, rods, and angles. The device has a simple design. It contains no electronic components. To use it, you do not need to perform complex preliminary settings. In this case, the workpiece is bent with high precision in accordance with a predetermined radius.

Other advantages of the roll forming machine include:

- high degree of safety during the processes performed;

- no need to connect to the electrical network;

- easy transportation;

- large area of application.

A manual roll forming machine is a reliable device. It is made from high quality steel, including alloy grades. This manufacturing material provides high strength to the mechanism.

Roller shafts for pipe benders are made in different sizes. Their design allows you to carefully bend corrugated pipes. In this case, it does not require much effort, regardless of the material of the workpiece, which can be steel, aluminum and copper.

Pipe bending roller shafts Source ufaprom.ru

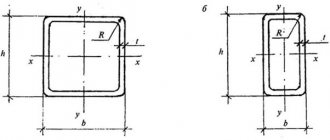

Drawing of a typical machine

Now you can find many designs of manual profile benders, which can be made from simple parts with your own hands and without special skills. One of the simplest drawings of a profile bending machine allows radial bending of pipes and rectangular profiles. The need for just such a bend of the material arises most often.

Drawings of a homemade profile bender

The operating principle of such homemade equipment is based on the use of three rollers - two support rollers and the main working one. It is this working roller that will deform the pipe during the operation of homemade equipment.

The main working shaft must have a small free play, which will be limited by the parameters of the guides. For the manufacture of such structural elements the following are used:

- steel plates up to 8 millimeters thick;

- one large plate;

- steel corner 30 cm long - 4 such elements are needed;

- auxiliary rollers.

Auxiliary rollers are attached to the large plate using bolts, and corners are attached using a welding machine, which will act as guides.

To increase the strength and reliability of the base, two steel corners should be welded to its bottom. To strengthen the guides, a metal plate with a hole is attached to them on top using a welding machine. Its diameter must exceed the cross-section of the screw, which will exert the main load on the working shaft of a hand-made manual profile bender.

After completing the installation of the guide rollers, the bending machine will be ready for work, and you can use it to shape pipes and rectangular profiles into any configuration with your own hands.

Hydraulic roll forming machines

Hydraulic roll bending mechanisms allow efficient bending of pipe assortments with complex profiles. When using such equipment, the specialist makes minimal physical effort, because the main actions are performed by the hydraulic system.

A bending device with hydraulics for corrugated pipes is a more advanced mechanism than a manual profile bender. The equipment is equipped with wolves for horizontal and vertical rolling of workpieces. This allows you to bend the rolled product in several directions at various required angles and required radii in one operation.

A standard machine with hydraulics for bending profile pipes is equipped with 3 rollers. One of them is pressure rollers, and the other two are drive rollers. For their manufacture, manufacturers use durable alloy steel. For this reason, rollers rarely have to be replaced with new rollers. If necessary, they can be easily removed from the hydraulic machine, which allows for quick service work.

We make a hydraulic pipe bender

Let's consider the diagram of a machine with a hydraulic drive, where bending occurs due to pressing a profile pipe in the center with a punch fixed on a rising rod. As a result of close contact of the workpiece, supported by two stationary rollers, with the movable punch, the latter takes on its outline.

This type of machine is called a crossbow machine due to the similarity of the outline of the punch with the shape of a crossbow. Its main parts are the base (1), hydraulic jack (2), punch (3) and fasteners in the form of bolts. The layout of machine components is carried out according to the sketch

To mark the working surface, lay a vertical axis and, at the distance indicated in the drawing from the edge and axis, mark the location of the lower holes. Then mark the location of the upper holes, retreating the required distance from the edge. Connect the center of these holes with a straight line and lay equal segments on it.

The axes of the intermediate holes will be located at the intersection of the marks made with the inclined axis. Holes on the working surface are needed to be able to adjust the bending radius of the profile workpiece. Since the working surface consists of two mirror-like parts, the second one is marked in the same way.

The height of the machine is determined by the parameters of the jack and the distance indicated in the drawing by the symbol “a”. To bend a profile pipe 15 mm wide, this gap when the jack is not in use should be approximately 20 mm.

In this design, the force transmitted by the punch is concentrated in its upper part. As a result of this effect, the outer radius of the pipe is subject to tension, which can cause thinning of the wall, and in some cases, rupture. Therefore, this machine is not recommended for deforming thin-walled workpieces.

Video description

See the video for operating features of a hydraulic pipe bender.

Hydraulic profile benders are also equipped with three grooves, but they allow you to work with pipes of a larger cross-section. Its maximum dimensions can be 60*30 mm. Moreover, most models are capable of bending square pipes with a maximum cross-sectional size of 40*40 mm. A hydraulic machine for bending profiled pipes also allows you to bend rods, strips and round pipes.

The presence of an engine braking device increases the ease of use of pipe bending equipment with hydraulics. It allows you to stop the machine if adjustments need to be made. After this, the process can be continued further using the same workpiece. In addition, machines of this type are variable units. In other words, the devices can be manual, semi-automatic and fully automatic devices for bending corrugated steel pipes.

What is the problem with profile bending?

Rolled metal with a rectangular cross-section is easy to work with, and the workpieces can be joined at different angles. Difficulties arise when there is a need to give the design parts a curved shape. This is due to the fact that a tensile force acts on the outer wall of the product, and the inner side is subjected to compression.

Attempts to bend a profile pipe without a pipe bender are associated with the following problems:

- The appearance of cracks in the material. If the wall thickness is small, then metal rupture is possible.

- Crinkling of sides. A similar effect occurs when excessive pressure is applied while passing workpieces through bending fixtures.

- The appearance of internal folds. The greater the height of the product profile and the smaller the straightening radius, the greater the likelihood of such a defect occurring.

- Section break. Occurs when sudden force is applied to the workpiece.

- Changing the section configuration. If the technology is violated, the planes, the longitudinal axis are displaced, and the part is bent in the form of a spiral.

- Reduced metal strength. Such a flaw is a consequence of overheating and, as a result, a violation of the crystalline structure of iron.

It is not difficult to avoid such complications. It is enough to approach the matter competently and thoughtfully.

Electric profile benders

Manufacturers also equip equipment for bending corrugated pipes with an electric drive. This machine for a profile pipe is a professional device that allows you to bend the workpiece as accurately as possible in accordance with the given dimensions. Electric profile bending machines are used by specialized companies for the serial production of bent parts of metal structures. Its customizable rollers are designed for bending metal products, which can be made from various steel, copper, aluminum alloys and so on.

High-quality steel is used in the manufacture of electric pipe benders. Rolling rollers are made from it. They are highly wear resistant. Therefore, they do not have to be replaced frequently with new parts.

Electric pipe benders for corrugated pipes are not mobile devices. They are stationary equipment. For their operation, a constant connection to the electrical network is required. Such machines are installed in production shops and forging plants.

Type of designs

The machine for bending aluminum profiles of sliding wardrobes and cornices is divided into several types. Yes, they are:

- Electric. Often the unit is large. Therefore, it is most often used for industrial purposes. Small home installations are no less popular. This is explained by the fact that they are used to process workpieces with a small cross-section. It is used to perform high precision bending.

- Hydraulic. Used for rolling metal products on an industrial scale. It is often used in the construction of pipelines.

- Manual. Widely used at home. They are often made by hand. The disadvantage is its simple design and low functionality. A manual machine is used for bending aluminum profiles of small-section wardrobes and cornices.

Manual aluminum profile bending machine

Electrical model of the machine

Horizontal version of the profile bending machine

Despite some disadvantages, manual installations are the most acceptable option for use at home.

Therefore, it is worth taking a closer look at how to make such equipment at home.

Video description

The operation of an electric stationary profile bender is shown in the following video:

One of the main advantages of electric profile benders is the minimum physical effort of the master, even when performing a large amount of work. The only exception may be the installation of workpieces and the acceptance of curved parts.

Electrically driven pipe benders make it possible to produce bent metal products of high quality. Manufacturers produce models in which the bending angle is adjusted manually or using special programs. The second version of the equipment is equipped with a remote or built-in display. It is designed to monitor ongoing operations on an electric profile bending machine.

Making a lever pipe bender

At home, you can make a lever-type pipe bender for rolling professional pipes, which can easily cope with a variety of bending radii of the product.

In this case, you should adhere to the following recommendations of experienced specialists:

- the structure is mainly made of metal, but wood can also be used for this purpose;

- the pressure and central rollers must be made of metal, since they form the basis of the future machine;

- give the holder a U-shape;

- when choosing the size of the machine, take into account the cross-section of the pipes you plan to work with: the larger it is, the more significant the load on the products should be, which means that the machine itself must be large;

- the axis under the central roller must be fixed to the base as securely as possible, but without pinching that prevents the rotation of this holder;

- on the other side of the roller, install a lever of a certain length on the holder: the shorter the lever, the more difficult it will be to perform the operation;

Video description

The following video will help you get acquainted with the operation of a stationary profile bender with a remote display:

The maximum and minimum dimensions of a pipe bender with an electric drive depend on the capabilities of the equipment, whether it is equipped with additional functions, and the number of rollers. The performance of the electric profile bender is affected by the power of the installed motor. This characteristic can be 0.7-2.2 kW. The power of the electric motor is selected depending on the production tasks. A set of attachments is usually supplied with the equipment. They allow you to work with different profiles. Their number can always be increased.

The most powerful and productive profile bending machine is CNC equipment. This is already an industrial machine that allows you to work with a wide variety of metal profiles. With its help, three-dimensional bending of rolled products is carried out. Blanks can be made from different metals, including aluminum, stainless steel, copper, bronze.

CNC machine equipment for bending corrugated pipes is controlled mainly by a servo drive. This is the most popular option, the effectiveness of which has been tested in practice.

Stationary CNC pipe bending machine Source jcee.cz

Principle of operation

The operating principle of the device is based on the fact that the workpiece is rolled, resulting in bends. Before starting work, it is necessary to ground the equipment. This is especially true for structures equipped with an electric drive.

Before use, the rollers and workpiece are wiped with a dry cloth, and the installation itself is started and idles for half an hour. If any deviations occur during the running process, the equipment is stopped and appropriate adjustment work is performed. If this is provided for by the design features, then the rollers are adjusted.

At the initial stage, the profile is clamped between the shafts, after which it is rolled. The radius of curvature is adjusted by lowering and raising the operating shaft.

Briefly about the main thing

A modern bending machine for profiled pipes is a compact, portable or stationary equipment that allows you to bend rolled metal pipes with square, rectangular and other cross-sections. It is used by large and small manufacturing enterprises that produce metal structures from corrugated pipes. Manufacturers produce equipment with manual, hydraulic and electric drive. Profile benders are also classified according to the method of influencing the metal workpiece. Pipe benders can carry out rolling, winding or rolling of profiled metal products.

Ratings 0