The development of the timber industry, improvement of equipment and technology makes it possible to process natural resources in large quantities. Therefore, the issue of integrated use of wood processing residues arises especially acutely at both small and large sawmills. This is due not only to fire safety, but also to problems of resource conservation.

Processing and harvesting of timber is most often accompanied by the generation of large amounts of wood waste. Lumps of trimmings, tailings and underside boards - all this is stored in the forest or at production sites as substandard material. A competent forestry manager must think about selling such products in order to obtain additional profit, and therefore uses a croaker machine.

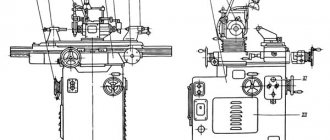

Features and purpose of equipment

A log side processing line, or slab line, is a secondary processing process for timber products. This is necessary to avoid the loss of valuable types of wood, because during primary processing, the quality material forms only 65% of the total volume of processed resources. The remaining 35% is production waste.

A machine for processing substandard waste - slabs, logs, sawn-off edges - consists of several main parts:

- Bed. It is a static frame that carries the load from the equipment of the slab-rib sawmill. Typically, to ensure the stability of the structure, no special preparation of the base or foundation is required.

- Feeder. It evenly presses the surface being processed against the machine body and has an adjustment depending on the thickness of the material being processed. The supply of raw materials occurs mechanically using upper rollers, which are fixedly mounted on the body of the croaker machine.

- The cutting system is represented by circular saws, which are located vertically in relation to the device. The average disc diameter is up to 500 mm.

- The roller chain allows you to create a straight cutting direction. The mechanism is equipped with special scrapers to remove chips and sawdust formed during the processing of the product.

- The control center is located on the frame body in the form of a cabinet, which contains electrical equipment and control buttons.

Recycling of raw materials using a croaker machine increases the final yield of industrial wood, which is used in industry. In addition, recycling waste from the sawmill industry using this woodworking device allows us to solve the problem of storing slabs and other large wood scraps.

Croaker-edging machine

| > |

The croaker-edging machine is designed for processing sawmill waste remaining after cutting round timber. Using the machine, the slab is sawed into edged lumber in one pass.

Distinctive features of the machine:

Specifications:

| Options | Value standard version | Value by ind. to order (additional option *) |

| Dimensions of the resulting material at the outlet: | ||

| width, mm | up to 150 | more than 150* |

| thickness, mm | up to 50 | over 50* |

| minimum length, mm | 2000 | 2000 |

| maximum length, mm | not limited | not limited |

| Diameter of vertical saws, mm | 500 | 560 or more* |

| Number of vertical saws, pcs. (saws are not included with the machine) | 2 | 2 |

| Max. distance between vert. saws, mm | 150 | more than 150* |

| Diameter of horizontal saws, mm | 500 | more than 500* |

| Number of horizontal saws, pcs. (saws are not included in the machine package) | 1 | 2* |

| Diameter of saw shafts, mm | 50 | 50 |

| Adjusting the distance between vertical saws | spacers | from the handle* |

| Electric motor for vertical saws, pcs./kW | 1 / 11 | 2 / 5.5 (or 2 / 7.5)* |

| Electric motor for horizontal saw, pcs./kW | 1 / 11 | 1 / more than 11* |

| Saw blade rotation speed, rpm. | 3000 | 3000 |

| Material feed speed, m/min. | 6 : 9 | stepless* |

| Dimensions: length x width x height, m | 3 x 0.85 x 1.5 | 3 x 0.85 x 1.5 |

We also bring to your attention a croaker-edging machine in a different version.

Video of the machine in operation:

Types of slab machines

It is advisable to select the necessary equipment for a croaker machine based on the timber for which it will be used. When selecting equipment, you should indicate the parameters of the slab available in production:

- overall or overall dimensions;

- dimensions for wood excluding bark;

- shape - flat or expanding;

- wood type;

- the presence of defects, defects or damage.

These properties together determine whether the raw material belongs to commercial or firewood material. Industrial wood has larger dimensions and sufficient strength characteristics. There are no defects on such samples, so they are used for the manufacture of building materials and structures. Small pieces of wood that are chipped or cracked are usually used to make fuel chips or firewood.

Thus, a machine for processing existing slabs in production is selected based on the characteristics of the processed timber waste. Several types of this device are widely used in production:

- GR series rib-slab machine. Equipped with a two-saw or three-saw row of discs arranged in series. Allows you to cut three-edged timber or unprocessed slabs, but has low production capacity. Standard models have several waste feed speed modes and a thickness adjustment function. The disadvantage of this device is the inability to produce edged boards. Therefore, it is necessary to use an edge trimmer in tandem with it.

- Horizontal or belt machine for processing slabs. It is a set of mechanisms that simultaneously saw and advance the workpiece. The cutting device on such machines is presented in the form of an extended steel strip with teeth or cutters. Cutting raw materials can be done without setup, which speeds up and unifies work in production. This increases the volume of processed raw materials, while reducing the time spent on auxiliary operations. It is advisable to use it in large sawmills, where it is necessary to debark logs, logs, ore stands and pulpwood using combi-lines for processing slabs.

Modern representatives of slab machines make it possible to utilize a large amount of wood waste in one approach and save natural resources. These devices have high productivity due to the high feed rate of raw materials. For convenience, many croaker machines are equipped with a system for removing sawdust and chips, as well as laser cut direction indicators.

They are of particular interest to owners of sawmills, as they have a short payback period and generate profit due to the high demand for secondary wood processing products.

Types of units

The slab-rib machine is divided into types depending on the equipment with sawing devices. The presence of 1 saw in the equipment design makes it possible to process the slab board for the production of edged and unedged lumber. In a multi-saw unit, the material is separated to produce a larger range of wood products. The saws in the device are installed in horizontal and vertical positions.

Various modifications of croaker machines are united by ease of operation and operational reliability. Designs can have a different number of wood feeding speeds, be equipped with a riving knife to prevent clamping of saws and a device for processing waste resulting from sawing. The mechanisms use closed bearings, which are protected from clogging and do not require preventive maintenance throughout the entire period of use.

Slab processing process

The technological sequence of work on slab processing is a series of sequential operations:

- The raw materials for cutting are pre-cleaned from dirt and sorted by overall dimensions. It is also checked for the presence of foreign objects that could get into the stacks during storage and transportation.

- Log trims, tailings and other raw materials are stored on the feeder manually or using a loading machine.

- The material is oriented on the tape in accordance with the set dimensions. The croaker sawmill is adjustable in width if necessary.

- Processed raw materials and waste are fed to a roller table after the division unit and undergo final sorting.

It is worth paying attention to the storage of finished products. It must be carried out under a protective canopy - an awning. Products must be stacked in stacks with adequate ventilation. This will avoid rotting, warping and cracks associated with shrinkage.

To turn slabs into wooden boards that can be used for containers or formwork, the raw material must be reprocessed using a slab and rib processing machine. The result is an unedged board that requires further finishing in a four-saw edger.

It is important to set the required overall dimensions of the mechanism and the location of the cutting discs, according to the parameters of the container blanks.

At home, cabinetmakers make decorative elements or exclusive furniture from recycled wood waste. Untreated coniferous wood looks especially impressive in the interior. This trend, associated with the use of sawmill waste, is gaining popularity. This does not require large-scale production facilities in the form of belt slab machines. However, dexterity and ability to handle wood, tools and paints are required.

The croaker machine is an affordable and effective way of recycling sawmill waste, the use of which is advisable in large-scale production conditions. This will minimize the costs associated with transporting and storing wood trimmings. Horizontal or rib-and-slab sawmills installed in production transform raw materials into cladding, construction or packaging products that are in demand. A well-structured process for processing such raw materials will become a profitable business.

Uses and Benefits of Machine Tools

The GR 500 slab-rib machine will be a valuable acquisition for any enterprise. Such equipment performs several functions at once:

- Fast and efficient recycling of slab boards. The top and side edges are cut off from it, the result is an edged board of the correct geometric shape.

- Processing of all kinds of scraps that remain after the production of lumber. The resulting slats can be used as raw materials in the production of parquet, laminated veneer lumber, and various furniture components.

- Preparation of edged boards from three-edged timber. The rib and slab machine GR 500 can be used as a 3rd row machine.

Installing equipment minimizes waste and increases wood processing efficiency. As a result, the harm caused to the environment is reduced and production becomes as environmentally friendly as possible.