Carbon electrodes are rarely used in welding work, but professionals are not yet ready to completely abandon them. One of the oldest methods of joining metal has important advantages over its metal counterparts.

Carbon arc welding is one of the oldest methods of joining metals. It was invented back in 1882. The author of the development was Russian engineer Nikolai Bernardos. Over time, carbon rods gave way to metal rods and today they are used very rarely. However, it is too early to abandon them completely.

Types of carbon electrodes

Among the carbon electrodes on the market, you can find several varieties:

- Round rods with added copper . They are used in various fields and can have a diameter from 3.2 to 19 mm.

- Endless copper plated . Very economical products that can be used for a long time. They require a special machine. Diameter 8 - 25 mm.

- Copper plated flat. They have a square or rectangular cross-section with a diameter of up to 25 mm.

- Semi-circular with the addition of copper. These rods are used most often. On one side they are flat, on the other they are round. This allows you to use them for any task. The diameter can be from 10 to 19 mm.

- Hollow copper-plated. Used for chipping and creating U-grooves. Their diameter can vary from 5 to 13 mm.

Welding principle

There are two welding methods when working with a carbon electrode:

- right, it involves moving the electrode from right to left, and the additive goes right behind it$

- left, in such a situation the rod moves from left to right, and the additive moves in front of it.

Right-hand welding is considered more effective in terms of the use of thermal energy in the welding area. This method is more convenient for welding parts of large thickness. And the speed of the process itself is approximately 20-30% higher. However, in practice, welders give greater preference to left-handed technology.

To summarize, it should be said that most often carbon electrodes are used for welding copper wires; at home, they have found their application in cutting metals. [Total: 2 Average: 1.5/5]

Most popular brands

There are 2 main types of carbon electrodes on the market. These are SK and VDK. They are respectively designed for conventional and air-arc welding.

Arcair electrodes from Esab are most often found on the Russian market. They perform the following work:

- elimination of defects;

- repair of products and structures;

- removal of seams;

- preparatory work;

- removal of excess material;

- trimming excess reinforcement and product fragments.

Welding stainless steel with carbon or graphite electrode

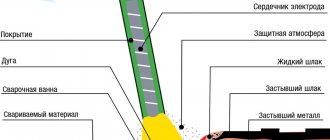

Carbon electrode welding is performed with a direct arc, that is, the arc passes between the metal being welded and the electrode. Welding with carbon electrodes is usually accompanied by evaporation of the electrode itself.

The welding process itself occurs with direct current with straight polarity. Due to the fact that the boiling and melting points of carbon electrodes have a difference of approximately 400 degrees.

When welding with carbon electrodes, the process is carried out without filler material. Sometimes it can be carried out with filler material. You can also carry out welding by first placing filler material in the groove of the edges. Welding without filler material means that an arc melts the edges of the parts of the future product. Welding of metals using the supply of filler material can be performed in the right and left way.

The welding current is selected based on the thickness and type of electrode coating. Also in this case, it is important to take into account the thickness of the sheets or parts being welded. Nowadays, welding with graphite electrodes is quite common, but many professional welders decide to use other electrodes for welding stainless steel.

Still, many people use carbon or graphite electrodes and with their help they can easily correct defects in casting materials or finished products. Many professional welders appreciate this feature, because not every type of electrode can easily correct casting defects or mechanical damage.

If stainless steel is welded overlapping, the quality of welding only improves. Many professional welders weld stainless steel butt to butt. They do this for aesthetic reasons or at the request of the customer. No one should judge someone if that person welds metal in one way or another. Of course, for higher quality and strength of the weld, you need to overlap weld . However, if you are a professional welder, then you can already perform butt-to-butt welding, because only a professional can weld efficiently at such a complex joint of product parts.

Stainless steel is in high demand, so if you want to go from a novice welder to a professional, you should definitely learn how to weld stainless steel. Without such a useful skill, your services will not be in great demand, because stainless steel is used in many industries.

For more comfortable learning, you need to immediately buy high-quality electrodes that will ensure high speed and durability of the product. In order to buy electrodes at competitive prices, you need to go to the “Contacts” page of our website. There you will see links to the websites of our partner manufacturers, which are known for high quality products and the best prices in Russia. Manual Arc Electrodes Broco Electrodes Carbon Steel Electrodes

Air arc gouging of metal. Welding copper contacts

This technology is of secondary relevance to welding, but in welding production it is widely used in serious enterprises that deal with metal structures or foundry production. The invention is called air gouging and it is used to repair welds or castings in cases where they have not passed defect control. The thing is that when welding large thicknesses, when metal penetration reaches 30 mm or more, possible an internal weld defect can be located at a great depth (read the article on methods for flaw detection of welds). Of course, you can get to this defect in different ways, but air-arc gouging is the most effective in this regard: productivity and speed of work increases. The essence of the process is that a powerful electric arc is ignited between the part and the carbon electrode, under its influence the steel melts, while compressed air, which is supplied to the molten bath area, blows out the liquid metal. As a result, defective areas are quickly removed.

In order to accomplish what is planned, you need to have the following in place:

• high power inverter minimum 300A. For large volumes of work, devices up to 1000A are used; • compressor from 400 l/min, capable of delivering a pressure of 6-10 bar. • copper-plated carbon electrodes with a diameter of 4 to 10 mm, designed for current from 150 to 550A

Carbon electrode CARBON

• a holder for gouging, which in welding slang is called “Planer”. it looks like an electrode holder, only the place where the carbon electrode is inserted has a fitting from which compressed air comes out. • a sleeve with a terminal is connected to the planer, inside of which there is a power cable and a hose through which air flows. The terminal is connected to the welder, and the gas hose, respectively, to the compressor.

Recommended equipment: Aurora Pro Stronghold 500, this inverter copes well with the task and a powerful Aurora compressor.

Note. A graphite electrode, among other things, is convenient to use for welding copper cables in places where there are twists during electrical wiring. This method allows you to obtain reliable contacts, without the need to solder them with tin along the entire length of the twist. It is enough to place one point at its end and the melted wires create a monolithic contact that has high strength and durability.

Scope of application

Carbon electrodes are used in the following works:

- Welding.

- Surfacing.

- Removing surface defects.

- Cutting.

- Planing.

Working with carbon electrodes is possible when processing almost all types of materials: steel, cast iron, bronze, non-ferrous metals. Compared to conventional electrodes with a metal rod, the scope of application is wider. The advantage is the reduction in welding process time.

When working with cast iron and bronze, sharpen the end of the electrode at an angle of 65 degrees, and when working with non-ferrous metals - 30 degrees. Carbon welding electrodes operate at direct current. The polarity should be set to straight to avoid overheating of the electrode. At home, you can use a carbon electrode removed from a battery. This is used for small jobs with thin-walled structures.

Carbon electrodes are most often used for air-arc cutting. It involves exposing molten metal to a stream of compressed air. The electrode is clamped in a special holder. This process produces a large release of molten metal, so remember to take precautions and safety measures.

Description of the process and its purpose

Gouging technology involves blowing out molten metal with a jet of compressed air. It is used to remove part of the metal from the surface entirely or in strips, including:

- for removing fragments in welded structures;

- creating grooves and understatements in thick-walled parts;

- cutting out defects;

- samples of poor-quality seams.

When gouging with a carbon electrode, its ability to melt metal with an arc is used. In this case, the graphite itself practically does not burn, only the copper coating melts near the arc. The holder of a special design, the planer, has holes for gas outlet next to the clamp. In addition to the power cable, a hose for compressed air, carbon dioxide or argon is connected to it. The air is pumped by a compressor, gas is supplied from a cylinder.

An electric arc heats and melts the metal, and air blows it out with a strong stream. At the site of the weld pool, a recess is formed in the metal. Electric arc gouging is used to create grooves and grooves in parts and remove defective seams.

Plasma gouging uses gas to simultaneously melt metal and blow it out. The plasma arc instantly heats the metal to its melting point and above. It literally evaporates from the gouging and cutting area.

Plasma gouging is the most productive of all other types of surface processing of parts. In one pass of the cutter, a strip up to 5 mm deep and 8 mm wide is selected.

The disadvantage of this treatment is the release of large amounts of harmful gases. The operation of the equipment is accompanied by loud noise.

The classic method of repairing welded structures and cutting defects is oxy-fuel cutting. The oldest and most productive method is based on the principle of heating using a gas burner. When welding, filler wire is added, which melts along with the edges. For gouging and cutting, it is enough to heat the steel so that it begins to oxidize. The liquid, molten metal is blown out along with the gas.

Oxygen gas cutting is used for cutting thick metal. It burns through a sheet 100–120 mm thick in a matter of seconds and continues to cut it without stopping along a given contour. When manually planing, a strip of 80 mm is selected in one pass. Special machines can remove a 300 mm strip on one cutter in one pass. In mass production, powerful equipment with several burners is used. The limit on the width of metal removal can reach 3000 mm. The maximum depth is limited to 15 mm.

With the development of electric arc and plasma welding, oxygen gas cutting is used to remove profits and accumulators from castings. Cracks, sinks, and sagging are washed out using a planer.

When gouging metal defects in castings, the flame of a gas burner is also used as a control tool for highlighting and eliminating cracks and cavities. In a stream of burning gas, the edges of the cracks heat up faster than the main body of the part and glow in narrow stripes of orange and yellow.

At the beginning of gas gouging, the starting point on the part is heated to red. In this case, the mouthpiece should be positioned at an angle of up to 70⁰, the flame core should touch the surface of the part. After heating the surface of the sheet, the nozzle rises by 15 mm, and after oxygen is released, the angle of inclination decreases depending on the gouging depth. The depth of the groove is also increased by increasing the oxygen pressure.

In the mass production of machines using the oxygen gas method, rough cuts of grooves and grooves are made in large parts for further cutting. They work mainly with low-alloy steels. Carbon and high-alloy steels after oxy-fuel gouging require heat treatment to relieve stress from local heating.

All types of gouging can be done in any position of the part. You just need to be extra careful when working on the ceiling so that molten metal does not drip onto the welder.

The thermal conductivity of carbon and alloy steels is lower than that of simple steels. When heated and sharply cooled, they become heated with a change in the crystal lattice. In this case, internal stresses arise, which can lead to destruction of the part. It is necessary to do normalization or annealing to align the structure and relieve stress.

Process Features

Electrodes made from coal differ from metal ones in that they are infusible. This means that during welding they act as a conductor of electricity, but do not become part of the weld pool.

During operation, the carbon rods heat up to very high temperatures. And if you continue heating, then almost immediately they will go from a molten state to a boiling state (by the way, coal boils at a temperature of 4200 ° C).

Due to the characteristics of the material, only direct electric current of straight polarity can be used in the welding process. Accordingly, the minus (cathode) here should be on the electrode, and the plus (anode) on the metal surface of the product.

When working with carbon electrodes, the welder usually requires filler elements. In this case, welding can be done in two ways:

- from left to right (in this case, the additive is behind the electrode);

- from right to left (there is an additive in front).

Interestingly, when welding from left to right, thermal energy is used more efficiently, and this allows you to increase the speed of work. However, in practice you can often find the “right to left” technology - it is more familiar.

General information about carbon welding

This type of welding is used quite rarely. The structure of the base material is not suitable for welding most metals. However, there are alloys with which it performs well.

These are non-ferrous metals, low-carbon steel or cast iron, the thickness of which does not exceed 3 mm. And also when soldering copper wires.

The key indicator of this material is that it does not melt when exposed to high temperatures. Only melting and evaporation of the copper coating on the surface of the filler material occurs.

Due to this structure, mixing of the filler material with the metal of the part does not occur. This results in minimal rod consumption, and for welders working with consumable type – unusual process characteristics.

Welding metal surfaces when using non-consumable filler materials occurs by mixing the metal of the parts themselves. Under the influence of high temperatures, the edges of the part melt.

Molten metal fills the weld joint, forming a seam web.

If the size of the gap between the parts does not allow the formation of a reliable seam only by mixing the base metals, filler wire is used for the connection.

Advantages and disadvantages

Next, let's talk about the advantages and disadvantages characteristic of graphite electrodes.

Advantages.

- These types of rods are very resistant to current.

- Due to good electrical conductivity, rod wear is minimal.

- Graphite electrodes do not oxidize when working at high temperatures, so they can be used much longer.

- Standard equipment is sufficient.

Flaws.

- They do not have a wide range of applications. For use in certain conditions, you will have to buy tips of different shapes and other materials.

- During use, the amount of carbon in the base metal can be increased.

- It is difficult to use for welding thin joints, since such a rod does not have a diameter of less than 6 mm.

Properties and weldability of aluminum

First of all, you should understand the properties of the metal. When welding aluminum with an electrode, any master will be able to notice that the behavior of the weld pool is noticeably different from steel products. This is due to the high fluidity of the material. In the molten state, aluminum is not viscous, but more like water, so the formation of a seam in this case becomes a physically complex process. For the same reason, it is almost impossible to carry out normal ceiling and vertical welding. Even in a horizontal position, you have to use a reduced current.

It is also worth noting the main enemy of normal weldability - the oxide film. It is constantly formed on aluminum, and the rate of its formation is quite high. It is harmful because it has a melting point almost three times higher than that of aluminum. If it is not removed, then the drops of molten metal will be enveloped by it and will not be able to connect normally, and the seam will be uneven, blurry and will not perform its function properly.

Oxide film when welding aluminum with an electrode

One of the properties of the metal is a high coefficient of expansion, which provides shrinkage that differs from steel. If you do it incorrectly, the part may end up deformed when it starts to cool. To do this, you should make a competent calculation of the consumables so that they adequately fill the joint. Do not forget about temperature deformations, which are often encountered when working with thin sheets. Welding aluminum at home should be carried out taking into account the high electrical and thermal conductivity of the material.

Oxide film when welding aluminum with an electrode

Problems arise mainly in the seams after welding is completed. Often you have to deal with cracks and pores. The metal is subject to the formation of stresses, which can result from the hydrogen present in the weld pool. It gets into the metal and then tries to get out, which is why after some time cracks may appear in the entire seam. If sufficient protection from atmospheric oxygen is not provided, pores may appear on the surface of the connection, so the electrode coating must be dried before use and carefully selected according to the characteristics of the process. Welding of aluminum with a conventional electrode, as well as its alloys of this metal, is carried out in accordance with GOST 14806-80.

Device and characteristics

Carbon electrodes are round or rectangular rods made from electrical coal, which is a mixture of carbon (in the form of coke or anthracite), soot and binders (coal tar or liquid glass). Round ones are made by extrusion and supplied to consumers in the form of rods with a diameter of 4 to 18 mm and a length of 250÷700 mm, and rectangular ones are made by pressing in molds. In addition to GOST standard sizes, special rods of increased thickness (15x15, 20x20, etc.), manufactured according to specifications, are also used.

Carbon electrodes are much cheaper and stronger than graphite electrodes. But the resistivity of electrical coal is several times higher than that of graphite. Therefore, to improve the electrical characteristics of carbon rods, their surface is coated with copper.

As an example, the table shows the main parameters of round copper-plated carbon electrodes of the VDK brand with a length of 305 mm.

| Diameter (mm) | Operating current (A) | Metal Removal (g/cm) | Groove (width/depth) (mm) | Cutting thickness (mm) |

| 4 | 150÷200 | 10 | 6÷8/3÷4 | 7 |

| 6 | 300÷350 | 18 | 9÷11/4÷6 | 9 |

| 8 | 400÷500 | 33 | 1÷13/6÷9 | 11 |

| 10 | 500÷550 | 49 | 13÷15/8÷12 | 13 |

A prerequisite for using these products is to perform work only with straight polarity. When turned back on, the arc is very unstable, the quality of the weld due to carburization of the metal is low, the operating temperature of the carbon rod is much higher, which increases the rate of its evaporation.

Advantages

- Welding aluminum with a consumable electrode is the simplest and most affordable option that can be used by almost any welder, since it requires a minimum set of equipment;

- The preparatory procedures go quite quickly, and after work it doesn’t take much time to return everything to its original form;

- The consumables used here as electrodes are very accessible, widespread and have a relatively low cost;

- The cost of welding is much lower than when using other methods;

- The master does not need extensive experience in using other equipment, since everything happens according to the most standard scheme.

Flaws

- The quality of the connection suffers greatly due to the insufficient protection of the weld pool provided by the electrode coating;

- Selecting electrodes can become a serious problem if it is not known which metal alloy is being worked with;

- It is required to use flux as an additional consumable;

- The high speed of electric welding makes it difficult to form a seam normally.

Electrode welding methods

The technology of welding aluminum with electrodes involves the use of several different methods, which are most often found in the private and industrial sphere.

Welding with conventional coated consumable electrodes. A standard welding transformer is used here, which is also used for welding other metals. In this case, the welding technology is no different from steel seams, but the result may not be of the highest quality, since a number of problems arise due to poor aluminum welding.

Welding aluminum with a non-consumable electrode. Here the problem with the selection of filler material no longer exists, since the bath is formed from the metal of the workpiece itself, but for this, the parts themselves must have a thickness of at least 3 mm and be butt welded. There are already some nuances to the work here, since it is necessary to ensure protection of the weld pool.

Welding aluminum with a carbon electrode using gas. In this case, in addition to the infusible electrode, a protective gas is used, which is supplied from a special burner. This can be welding aluminum without argon, for example, with acetylene or propane and other gases, since everything depends on their availability at the master’s disposal.

Selecting an electrode and brand of aluminum welding electrodes

OZANA-1 – used for welding parts and structures made of technical aluminum in its pure form. We work with such brands as A0, A1, A2, A3.

Electrode OZANA-1

OZANA-2 – used for welding casting defects and surfacing work on parts made of silicon aluminum alloys. Work is carried out with such brands as AL4, AL9 and AL11.

Electrode OZANA-2

OK 96.10 - this type refers to an alkali-salt coating, which is well suited for welding technical aluminum. When choosing a welding mode for them, the voltage should be reduced, since the melting rate of these products is approximately three times higher than that of steel ones.

Electrode OK96.10

OK 96.20 - an alkali-salt coating is used here, which is well suited for welding rolled metal from various metal alloys, in particular aluminum with manganese or magnesium. The electrode itself uses an aluminum-manganese alloy rod. Before use, the electrodes must be heated to 150-300 degrees Celsius, which is due to the high hygroscopicity of the coating.

Electrode OK96.20

"Important!

In almost all cases, welding is carried out in lower positions, with only a few exceptions when this is possible in a vertical position with limitations.”

Preparing metal for welding

Before welding itself, a preparatory procedure should be carried out that will help improve the quality of the connection. It begins with cleaning the metal surface mechanically. A metal brush or sandpaper should be used to remove the layer of dirt, oil and other deposits, including oxidative film, which will interfere with welding. After this, you can treat the edges of the parts with a solvent such as acetone, which will help remove any remaining items after mechanical cleaning. If the part is too thick, it may require bevelling. It is necessary for thicknesses of 4 mm and above.

Instructions

- Pre-processing of parts is carried out as described above;

- After this, flux is applied to the surface of the workpieces to be welded at the welding points;

- The electrodes are heated;

- The metal also sometimes needs to be heated, especially if it is thick, in order to melt the flux and evaporate the moisture;

- You can start welding;

- Allow to cool, gradually heating the seam with a burner flame;

- Check the quality of the connection.

"Important!

Do not forget that due to the high melting rate of the electrode, the speed of aluminum welding increases.”

To make everything go more accurately, you should watch the video welding aluminum with an electrode.

Welding mode

The carbon electrode for welding falls into the category of infusible electrodes, which distinguishes it from other metal rods. Thus, when carrying out welding work with such a product, you can use only direct current of direct polarity. This means that the minus is connected to the electrode, and the plus to the metal workpiece.

In certain situations, welding requires the use of a filler element. For example, when flanging thin metal workpieces. This procedure will be more profitable and simpler. There is a large selection of additives on the market that are used in this type of welding. For example, if you are working with copper, it is better to give preference to bronze filler material.

You should also pay attention to the parameters of the cross-section of the filler wire or plate. If it is larger, then there is a risk that the seam will not be welded through. If the cross-section is insufficient, on the contrary, you can burn it out.

Advice! When choosing copper-plated carbon electrodes for welding, select the filler material based on the thickness of the workpieces being joined.

Do-it-yourself welding with a graphite rod

When making miniature homemade products, sometimes it is necessary to weld thin-walled parts that a conventional welding machine simply burns through. In this case, you can use a car or motorcycle battery to weld the workpieces. This solution is also suitable for connecting twisted electrical wires in junction boxes.

Accessories:

- battery 12V;

- crocodile clips – 3 pcs.;

- powerful copper wires, preferably up to 1 m long – 2 pcs.;

- R20 battery (used will do).

Assembling the welding machine

A graphite rod from an R20 battery will be used as a welding electrode in this homemade product. It is easily removed after cutting its body in a circle.

Clamps are attached to the ends of the wires stripped of insulation. There are 2 crocodiles on one cable, and one clip and a graphite rod on the second.

There is no need to use long wires during assembly. The battery power is too small to overcome their resistance. The shorter the cable, the better.

A wire with two clamps is connected to the negative terminal of the battery. The cable crocodile with a rod is placed on the positive terminal.

How to use

Before welding begins, the free crocodile from the negative terminal of the battery is clamped onto one of the workpieces. It will perform the function of mass. The rod will act as an electrode. Its end is briefly touched to the suture site.

The electrode gets hot, so it is better to hold it with pliers. The graphite becomes hot and begins to melt the thin metal. To avoid burning the part, the electrode should be moved slowly along the joint line of the workpieces, sometimes interrupting.

In the first seconds, the graphite smokes heavily until the remaining electrolyte from the battery burns out.

You can weld with a seam or do spot welding. In the latter case, it is worth pre-drilling holes in the upper part to be connected. This device is also suitable for soldering. It can be used to heat a part and then apply solder to it.

Welding with a battery wears out the battery, so you should not get carried away with this method. It is important to keep the electrode closed for no more than a few seconds at a time.

Under the stress of welding, the battery becomes hot and may rupture. The signal for this will be the noise of electrolyte boiling emanating from it. The larger the battery, the larger and thicker the workpieces can be welded.

Typically the battery charge is sufficient to operate for several minutes.

Autonomous welding from batteries with your own hands!

The welding machine uses a fairly low (tens of volts) voltage and high current to create an arc, which actually melts the metal.

What if you use for this purpose not mains voltage with a bulky transformer, but... batteries? Unexpected, right? But nothing is impossible here.

Conventional batteries provide almost the same voltage that is needed for welding, only lower - 12 Volts.

Theoretically, you can get an arc from one 12-volt battery, but it will be so short that cooking with it is a hassle. For reliable and convenient operation, you will need three 12 Volt lead batteries, which in total will give 36 Volts.

It is best to take car ones - their current is enough even for thick electrodes (4 mm), but you can also use batteries from uninterruptible power supplies or motorcycle ones.

In this case, you will have to limit yourself to thin electrodes (no thicker than 2 mm), and the welding itself will take more time.

Scheme

The scheme is simple, but pay attention to the following subtleties:

- all connections must be very good, since at low voltage heating and losses increase greatly due to poor contact (it is best to use conductive paste);

- The cross-section of the wires between the batteries and from the batteries to the terminals should not be less than 16 square meters. mm (better - 25 square), of course, only copper will do;

- it is not the minus that is connected to the part (that is, the ground clamp), but the plus - accordingly, the minus is connected to the electrode, and welding must be done with “blue” electrodes (for example, MP-3S);

- if the electrode is stuck, try to tear it off, since long-term operation in short circuit mode is harmful to batteries - they do not have built-in protection (see also below);

- to protect the batteries from overheating in the event of a strong “sticking”, connect a short piece of wire of 2.5 squares between the batteries, preferably on a screw terminal, so that it can be easily changed: if there is a strong overload, it will burn out and prevent the batteries from overheating.

conclusions

Of course, this “welding machine” is not as convenient as a regular one; in the end, the batteries will run out and will have to be charged. But if you need to cook infrequently and away from 220 Volt outlets, this solution has a right to life.

Welding copper wires with a graphite electrode

In modern wire joining, carbon electrodes are increasingly being used to weld the ends of copper wires. This method replaces the outdated method of soldering copper strands. This does not require the use of solder or flux.

The task of welding is the same as with soldering - it is to ensure reliable and durable contact between two or even several wires, since this cannot be achieved with a conventional connection.

Over time, a film will certainly appear on the surface of copper due to oxidation. After the welding process, the junction of the cores is welded differently than during soldering; soldering occurs only at the tip.

However, even such formed contact at an increased load prevents overheating of the welded cable cores.

Graphite electrode for welding

Due to its technical characteristics, the graphite electrode is easy to cut , consumes more slowly, and does not crack during welding.

As practice shows, welding of wire cores is carried out in distribution boxes. The boxes are located quite high, so you will need to use portable welding equipment for welding.

Industrial devices are used for these purposes, the use of which is advisable in a professional sense. If possible, you can assemble the welding machine yourself. However, for most people, inverter-type devices, which are presented in a large assortment in stores, are perfect. They are compact, mobile, lightweight and also have the ability to adjust the welding current you need.

Types of electrodes for welding copper wire cores

When welding copper conductors, appropriate electrodes . We have already mentioned carbon electrodes. There is also a graphite type of electrodes. Battery rods, brushes of commutator motors and similar products made of graphite can be used as an electrode in household use.

Graphite rods are a good replacement for purchased electrodes, with the only exception that they do not have copper plating, but this can be solved by improving the holder.

To do this, it will be necessary to use an alligator clip, both for the electrode and for the ground connection. They will not be as bulky as standard ones, so it will be more convenient for you to work in switchboards.

Of course, you will need to take care of additional insulation of the handles.

Composition and technical characteristics

The main component of coal rods is coal coke. In addition to it, the composition contains metal powder, which gives the electrode strength and a resin that connects all components. The diameter of such electrodes can be different - from 1.5 mm to 300 mm.

In addition to size and cross-section, carbon electrodes have other parameters:

- The current strength that is supplied to the electrode. It depends on the material and equipment you are working with.

- Shapes and sizes of grooves . They depend on the end of the rod and its dimensions. The most popular are large electrodes, which can be used to work with massive parts.

- The thickness of the cut depends on the current power. But here you need to carefully ensure that the product withstands and does not melt.

Varieties and their properties

A carbon electrode is a consumable material made from hard coal. It contains additives that determine the characteristics of the welding rod. To ensure that the composition holds its shape and can be used in work, resin is added to the mixture.

Carbon electrodes are suitable for working with all metals, from refractory to materials with a low specific gravity and a large number of pores. The diameter of the rods varies over a wide range of values - from 1.5 to 25 mm. They are also very different in length. The shortest electrode is only 25 mm in length, and the longest is 300 mm. Consumables of such long length are in demand for welding seams in hard-to-reach places. The electrodes also differ in shape. They are round, rectangular, hollow or semicircular.

For work, specialists most often use round and semicircular ones, which are the optimal choice for forming a welded joint of a standard configuration. Rectangular ones are an ideal option when you need to eliminate flaws on a metal surface. Using hollow electrodes, you can create a U-shaped groove at the junction.

In addition to the usual ones, welders also have copper-plated carbon electrodes in their arsenal. They are used to impart strength to the welded joint and create a copper coating on the joint surface in the form of sputtering. The remaining performance indicators of these consumables are no different from the usual ones.

Carbon electrodes in home workshops

Copper wire welding diagram.

To work with them in a makeshift manner, a traditional electric arc welding machine is quite suitable. One of the advantageous aspects is a very modest current strength for creating an electric arc due to low thermal conductivity: 3 - 5 A is enough.

An electric carbon arc can be extended to a length of up to 50 mm; it is very easy and comfortable to guide along the future seam due to the slow evaporation of the electrode during welding and the absence of a sticking effect.

Learn welding with carbon electrodes using examples of connecting wires, metal workpieces with thin edges, etc. – a wonderful opportunity to master all skills quickly and efficiently.

Important advice: this type of welding should only be done indoors. The fact is that the arc in such technologies can go out at the slightest breath of wind, not to mention gas flows, magnetic fields and other environmental factors.

It is best to sharpen the electrode at both ends: in this case, you will not need to waste extra time rearranging the consumables in the holder. In addition, the risk of consumable overheating during welding will be reduced.

And with sharpened ends, the holder can rotate 180° when one end overheats, so that the other end can continue working. This will also allow you to save on consumables.

Sometimes non-consumable carbon electrodes are used for welding copper busbars in transformers at substations. Copper wires are also welded, but this is mainly in small artisanal workshops.

The best option for filler materials is bronze alloy rods. They come with different diameters, which must be selected based on the thickness of the metal workpieces being connected, which is used in calculations using a special formula.

Another type of work in which squares are used is cutting metals.

Do-it-yourself welding of copper wires with a graphite electrode - instructions

Several copper wires can be connected in different ways.

Welding occupies a special place among them, since it is one of the best methods in terms of reliability. The connection obtained in this way is durable, has good electrical conductivity, meets the maximum safety requirements and lasts for many years.

For welding wires, a graphite electrode is used, which has several undeniable advantages.

Inverter welding machine

The inverter device has clear advantages over other devices:

- Small-sized parameters;

- Light weight;

- Adjustment of current parameters;

- The presence of a portable belt (it is convenient to carry out work on a stepladder, in a junction box);

- A stable arc that ignites at low currents;

- Quality of welded joints;

- Less energy consumption without changing the voltage of the household electrical network.

In addition, welding is carried out using transformer devices, devices, stations, devices made independently (if you have certain skills).

The ease of operation of the do-it-yourself electric arc spot welding machine has made it the most widespread. Main parameters of this equipment:

- Electric arc current;

- The mains voltage that forms an arc;

- Type of electric current (alternating, direct).

Welding technology

Welding work must be carried out using a protective mask, glasses, gloves, and special clothing. There is a possibility of getting burned by hot metal and “catching bunnies.”

Welding of copper wires at home with an inverter is carried out using graphite and carbon electrodes. You can replace the electrodes with the carbon rod of a used battery.

Approximate welding current range:

- 2 cores, cross section of each 1.5 mm² - 70 A;

- 3 cores, cross section of each 1.5 mm² – 80-90 A;

- 2-3 cores, cross-section 2.5 mm² – 80-100 A;

- 3-4 cores, cross-section 2.5 mm² – 100-120 A.

The copper used in the manufacture of electrical wires is of different composition and quality, which determines the welding mode used. Indicators of the optimally selected mode: the electrode does not stick to the welded area, the arc is stable. This combination can be maintained if you have experience in welding.

- The insulating sheath of the copper cable is removed (7-10 cm);

- Stranded wires are twisted;

- The twisted copper wires are trimmed to form an even cut. The remaining twist length is 5 cm;

- A copper clamping mechanism for removing excess heat is placed on the twist, and grounding (“ground”) is connected;

- The twist section is brought to the electrode;

- Welding work is carried out until a molten copper ball appears at the end of the wires, 1-2 seconds is enough;

- After welding of the copper strands stops so that the insulating material remains intact;

- The cooled ends of the wiring must be insulated (insulating tape, heat-shrink tubing).

In addition, it is necessary to promptly change the copper welding tip, which holds the electrode during welding. The main function is to supply electric current to the electrode rod.

Its condition determines the quality of the weld: the hole inside the tip should tightly hold the rod, but it quickly loses its properties during the welding process.

The copper welding tip wears out and most often requires replacement.

Electrodes for welding wires

The choice of the appropriate type of electrode determines the quality of the work done. It is necessary to select welding tools that optimally meet the parameters of the upcoming process. The general classification of these tools used in the welding process includes electrodes for:

- Alloy steel;

- High-alloy steel with non-standard parameters;

- Metal surfacing (applying a metal alloy or metal to the surface of an object by fusion welding);

- Non-ferrous metals;

- Structural steel;

- Cast iron.

The electrode coating defines the following typology:

- A – acid coating (oxide of iron, silicon, manganese);

- B – basic coating that allows welding with direct current of alternating polarity. Contains calcium carbonate, calcium fluoride;

- C – cellulose spraying creates gas protection during welding (flour, compounds of organic origin);

- R – rutile (rutile, organic, mineral components) provides a low percentage of metal splashing and gas protection.

Electrodes for welding wires:

- Coal – electrical coal;

- Graphite – crystalline carbon.

Popular brands

Among domestically produced electrodes, the most popular are the following:

- EG - graphitized, made from petroleum coke with the addition of coal tar pitch. Withstands operating current density up to 25 A/cm2. Equipped with nipples, it is used in electric furnaces for smelting ore and for welding metals in various combinations, for example, nichrome-copper welding.

- EGS - instead of an oil streamer, a needle streamer is used. Such products are used in electric furnaces in steel mills and metal refining plants.

- EGPs are additionally impregnated with pitch. It is used in electric arc cutting installations and foundries.

- EGSP - products based on needle coke, with enhanced impregnation with pitch. They are used to weld non-ferrous metals, as well as in melting furnaces for various purposes.

Graphite electrodes for welding

Composition – graphite, a carbon substance of dark gray color with a metallic sheen. The soft material makes it easy to cut elements. Graphite electrodes for welding show better results compared to carbon electrodes.

- The graphite electrode remains intact during the welding process;

- The cost is lower than coal;

- Suitable for inverter welding machines equipped with current regulation;

- The connection of wires by welding a graphite rod is durable and reliable;

- Welding with a graphite electrode ensures the metal's resistance to oxidation.

- Low consumption during welding due to the high melting point (four times higher than copper);

- When welding wires with a graphite electrode, it is possible to replace it with improvised graphite products (graphite rod, brushes of commutator motors, battery rods);

- The absence of copper plating of graphite substitutes is solved by using an alligator clip for the electrode instead of standard holders, and an alligator clip is also used to connect the mass.

- Do-it-yourself welding of wires in a junction box with these clamps is more convenient due to their smaller dimensions.

Production process

Both natural coal extracted from deposits and artificially produced graphite are used as raw materials for production . Various resins serve as binders. Production is divided into the following technological stages:

- extrusion of rod-shaped blanks at high temperature and pressure;

- final forming and cooling;

- thread cutting;

- copper plating

To produce products for a specific purpose, small amounts of metal additives are added to the material.

Carbon electrodes for welding copper wires

- The melting point is 3800⁰ C, the boiling point is 4200⁰ C, so the melting process is invisible, evaporation is recorded;

- Welding work with a carbon electrode is carried out with straight polarity;

- The welding process with a carbon electrode is accompanied by the influence of external factors (wind, gas flow);

- The efficiency of the welding arc is lower;

- Scope of application: welding work on thin sheet metal, non-ferrous alloys, correction of defects in metal casting;

- Methods of welding work: without filler material, feeding the filler into the arc, laying the filler metal on the seam;

- The most common method is melting the edge of the elements being welded (non-additive);

- The magnitude of the welding current is determined by the thickness of the metal and the type of connection;

- When warming up, carbon electrodes for welding copper wires are quickly consumed;

- Creates a high-temperature welding arc (even at low current).

Recommendations

Useful tips that will help you weld wires with your own hands efficiently:

- Do-it-yourself use of non-copper-plated graphite rods for copper wires in welding work. Burning out the corner of the electrode will lead to a decrease in resistance and prolonged contact, which will deteriorate the quality of the electrical wiring connection.

- The formation of the required shape of the copper solder ball is facilitated by the preliminary preparation of the graphite rod: a recess is made inside the end.

- Using an alternative to factory rods (waste batteries, trolleybus current collectors, etc.).

- The use of a protective mask, glasses, gloves, and special clothing is mandatory.

- Welding of twists is checked by applying maximum voltage to the network. Lack of heating is an indicator of a high-quality connection.

- Soldering or welding copper wires is better than simple twisting, terminal connections, and clamps.

- The correct choice of electrode rod and welding mode determines the quality of the result and the reliability of the weld.

- Using an inverter machine is advisable in everyday life, with frequent welding work for wires on your own.

Read also: Photos of welding inverter boards

Before carrying out work on connecting the cores of electrical cables, it is necessary to determine how to do it, what is best to choose for this particular situation. The correct choice greatly contributes to the successful result of the work done: the quality of the connection, the flow of current, the reliability of electrical wiring during peak load on the network.

You should not trust twisting electrical wires as a connection method. This is a rather unreliable option. Terminal and crimping mechanisms increase reliability, but are inferior in quality to soldering and welded connections.

In order to connect two wires, several techniques are used. This can be twisting, soldering or welding of various wires. The last technique is one of the most successful and frequently used. It helps to achieve long service life of electrical wiring.

It is mainly made from a copper composition rather than aluminum, which is not suitable for these purposes. Welding occurs using direct and alternating current, at a voltage of 12-36 V. Directly for the process, we recommend using an inverter welding machine.

Copper wire welding technology

There is one technique that always leads the welder to the best result. As mentioned earlier, the best device for welding is an inverter. Then they take hold of the wire. It is freed from insulation and excess shell and twisted. When cutting wires, the ends should remain the same length and at the same level, and the twist should be at least 50 mm in length.

Next, a heat repellent copper clamp is installed and the welding machine is connected. The charcoal pencil (or rather its end) is brought closer to the finished twist. When welding, the pencil must be clamped in the holder.

Welding of strands is considered complete once a small molten ball of copper has formed. In order for the insulation to remain intact, you must not overdo it, but devote no more than 1-2 seconds to each twist. When welding of copper wires is stopped, ordinary electrical tape or a similar version is used to insulate the frozen part.

Step by step process

Let's describe the whole process step by step:

- Remove the insulation on the wires;

- We make twists;

- Add mass;

- Turn on the welding inverter;

- We bring the electrode to the twist until an arc forms;

- Contact duration is 1-2 seconds;

- We proceed to the next twist (if there is one), after the finished one has cooled;

- We insulate using heat-shrinkable tubing or electrical tape.

The device should be selected with the ability to adjust the current, the strength of which should be 30-90 amperes. The electrode used is carbon containing copper.

Production Standards

Requirements for production technology and quality are formulated in GOST 4426-62 . It describes the chemical composition of the product, manufacturing methods, their design and the following typical cross-sectional shapes:

Carbon gouging

Gouging is the removal of a narrow surface layer using carbon arc welding. The word itself originates from the verb “to plan,” since this process is somewhat similar to the processing of grooves on a planing machine. Gouging technology is based on heating the metal with an electric arc to boiling temperature, followed by blowing it out of the weld pool with a narrowly directed air flow. Gouging is carried out to depths of up to tens of millimeters, and its productivity, depending on the thickness of the carbon electrode and the current strength, is measured in grams of metal removed per centimeter of groove.