The MML 180×300 (MML-1830) table-top screw-cutting lathe is supplied by Metal Master . METAL MASTER is a group of engineering centers in Russia and Germany with contract production certified according to EU standards in Poland, China and Russia. This optimization of resources significantly strengthened the company’s position in the market - high quality equipment was complemented by prices acceptable to the consumer.

More than 10 years ago, the Metal Master company first presented the market with ready-made high-tech solutions for metal processing.

Supplier of the MML-1830 lathe to Russia: Yangzhou Development Import and Export Company, No. 99, West Kaifa Road, Yangzhou, Jiangsu, China .

Metal Master metalworking machines, popular in Russia, are produced under the control of a group of enterprises from Russia and Europe.

The manufacturer of the MML-1830 lathe is the Chinese company Yangzhou Developping Imp. & Exp. Co.,Ltd.

The quality of the European line is guaranteed by the leading Polish manufacturer Sorex and the Swiss company S-Tech, which have research centers in Europe and a network of modern production facilities in Asian countries (China, Vietnam, Taiwan).

Setting the feed and pitch of the thread being cut on an MML 180×300 machine

Information

Metric threads are specified as thread pitch. In the example above, the longitudinal carriage of the caliper moves 1.25 mm per spindle revolution. Inch thread is indicated as the number of complete turns of thread (threads) per inch of length. One inch is 25.4 mm long.

CAREFULLY!

When the lathe is turned on at high speeds and with automatic feed turned on, the longitudinal carriage of the support moves at high speed.

For example, when turning on a lathe with a thread pitch set to 1.25 mm and a spindle speed of 2500 min-1, the speed of movement of the longitudinal carriage of the support will be 52 mm per second.

Thread cutting is always performed at minimum spindle speed.

Cutting speed selection

General consideration: High cutting speeds provide time savings, low cutting speeds provide more cost-effective chips.

Factors affecting cutting speed

Fs = cutting speed [m/min]

t = tool life [min]

The durability of the cutter is the operating time of the cutter in minutes before it becomes necessary to re-sharpen it. It is of great economic importance. When processing the same material, the higher the Fs, the less the t, for example, only a few minutes at Fs = 2000 m/min.

To ensure equal t when processing different materials, different Fs are required. All data in the table below is given for certain constant parameters of the cutting mode (material, tool, etc.). When changing at least one parameter to ensure equal t, Fc must also change.

Cooling the cutting zone

When cutting, the cutting edge of the tool becomes very hot.

Therefore, it is desirable to use cooling of the cutting zone. Cooling the cutting zone with a specially designed coolant system will improve the quality of the cut and significantly extend the life of the tool.

INFORMATION

It is recommended to use a water-soluble, environmentally friendly emulsion as a coolant, which can be handed over to the seller for disposal.

Please note that all used coolant must be collected. Follow the manufacturer's instructions for disposal.

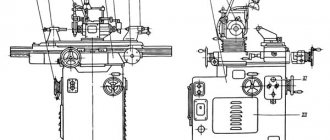

Lathe Metal Master MML 1830V

Metal Master MML 1830V is a table-top screw-cutting lathe with a variator, designed for cutting workpieces made of structural materials (steels, cast irons, non-ferrous alloys), as well as for cutting metric and inch threads.

The main advantage of the lathe: The presence of metal gears with a high service life and increased wear resistance, and the presence of a V-belt will avoid damage to the engine when the load on the spindle is exceeded

The machine is equipped with electronic stepless control of the spindle speed. Data on the number of spindle revolutions is displayed on a digital display on the machine body.

The key on the cross-feed dial mount ensures that the flywheel does not rotate inadvertently and minimizes the risk of changing the size of the part during processing.

The width of the cast iron bed is 100 mm, a record in its class, which significantly increases the rigidity of the machine and affects the processing accuracy.

The machine guides have undergone a scraping procedure, which significantly increases the accuracy of processing on a lathe.

The presence of 6 grease fittings on the lathe support allows you to quickly service and lubricate the support, avoid wear on the guides and enjoy comfortable work and smooth movement of the handle.

Availability of a scale for determining the angle of rotation of the tool holder.

The ability to rotate a thin longitudinal slide allows you to sharpen a cone of a given parameter.

A 100mm quick-release three-jaw chuck is supplied as standard.

The telescopic lead screw chip guard effectively protects the lead screw from wear.

The division price of the cross feed dial is 0.05 mm.

The division price of the fine longitudinal feed dial is 0.02 mm

The division price of the longitudinal feed dial is 0.25 mm

The machine guides have undergone high-frequency hardening (48-52 HRC) and grinding, which helps to increase the level of reliability and accuracy of part processing.

To loosen the tailstock to set the drilling depth and secure long workpieces at centers, the machine is equipped with a quick-release lever.

Tailstock quill reach 60 mm, scale up to 50 mm.

The standard equipment of the machine includes:

- 3-jaw chuck 100 mm.

- 4-position tool holder.

- The center is stubborn.

- Protective guard for the cartridge.

- Chip tray.

- Set of replacement guitar gears.

- Tool box with tools

TOOL BOX CONTENTS (Fig. 1)

- 2 screwdrivers

- 3 double-sided wrenches 8-10 mm, 12-14 mm, 17-19 mm

- 1 key for three-jaw chuck

- 2 fuses

- 1 x MT2 thrust center

- 1 x MT3 thrust center

- 1 oiler

- 3 return cams

- 1 roll sleeve

- 1 cross slide handle

- 6 hex keys 2.5mm, 3mm, 4mm, 5mm, 6mm, 8mm

- 7 replaceable gears 33T, 35T, 40T,42T 50T, 52T, 60T

Equipment prices

Depending on the company where you buy the machine, the price may vary. But on average, the cost of such equipment in Russia is around 50-60 thousand rubles.

If the equipment costs much less than these figures, then you should think about whether it is a fake or defective. If you buy a used machine secondhand, you can buy it 2 times less than the cost of a new one.

It is important that the small metal lathe Metal Master MML 1830 V is not only easy to use, but also inexpensive. At the same time, the quality of the equipment allows it to serve for a long time without repair.

Any home craftsman will be happy with such a machine. Small dimensions and convenient technical characteristics allow you to perform all standard metal turning operations in a home workshop or small workshop.

DESCRIPTION METALMASTER MML 1830 V

This model is exported by the Metal Master organization, which produces metalworking equipment of European quality from Russia, the USA and Europe.

A special advantage of the company is the reliability and durability of the equipment at reasonable prices. Area of use: desktop. Suitable for longitudinal and transverse turning.

Classification: universal.

Warranty: 12 months.

The differences between the MML 1830 V and its competitors are its electronic visual control, thanks to which you can check the number of spindle rotations, ease of settings, since the machine is equipped with a quick-release lever, and safe operation. The transparent shield prevents the possible escape of production waste. The presence of a frequency device for an asynchronous motor provides stepless control of the spindle speed. And the layout of the machine allows you to create a turning finish with class “H” accuracy.

This model is useful for making holes, turning parts and threads. Its power is 600 W, spindle rotation is 150-2500 rpm, the maximum processing diameter is 180 mm, and the wide bed width is 100 mm. increases the accuracy of turning workpieces.

CHARACTERISTICS OF METALMASTER MML 1830 V

| Input electrical characteristics | |

| Voltage | 220 V |

| Power | 600 W |

| Technical data | |

| Height of centers | 90 mm |

| Chuck diameter | 100 mm |

| Maximum processing diameter | 180 mm |

| Distance between centers | 300 mm |

| Bed width | 100 mm |

| 1 speed. Spindle speed | 150 - 1500 rpm |

| 2 speed. Spindle speed | 300 - 2500 rpm |

| Spindle inner taper | MK 3 |

| Through hole diameter of three jaw lathe chuck | 21 mm |

| Moving the upper caliper slide | 60 mm |

| Moving the cross slide of the caliper | 75 mm |

| Tailstock quill inner cone | MK 2 |

| Moving the tailstock quill | 60 mm |

| Automatic longitudinal feed | 0.1-0.2 mm/rev |

| Range of cut metric threads | 0.5 - 3 mm/rev |

| Range of cut inch threads | 8 - 44 threads/inch] |

| Difference in heights of the supporting surface of the tool holder and the center line | 10 mm |

| Maximum cutter holder section | 10 mm |

| Dimensions | 740x390x370 mm |

| Weight | 60 / 75 kg |

Reviews and Reviews

You can read more text reviews in the comments to this page. Respect other people's opinions when responding to existing comments and share your reviews about the machines on the site pages. By doing so, you help other visitors make an informed choice. You can omit your name and email, then the commentator will be identified as Anonymous. All comments are moderated. Thanks for your feedback!

The machine is gorgeous, I have the same one. I work on it a lot, I’m very pleased. Precision and quality suitable for desktop home use. What I didn't like about it: the engine. Ideally, install the motor and replace the control board, it will pull perfectly at the bottom, and this is at least a plus for cutting threads. The standard engine works great and is comfortable to work with at speeds from 600-800

Dmitry 11/13/2019

Rate this model:

Model rating: 3.8 / 5. Number of ratings: 20

Features, purpose and scope of application of a desktop metal cutting machine

Tabletop machine Metal Master MML 1830 V is designed for processing parts up to 30 cm in length and up to 18 cm in diameter. Features of this device:

- automatic mode of longitudinal feed drive;

- the handle to turn on the automatic mode is located on the apron of the machine;

- the main movement drive consists of an electric motor and two belt drives - gear and V-belt;

- low noise level due to high-quality belts;

- Spindle rotation speed ranges occur due to the transfer of the belt on the belt pulleys in accordance with the instructions on the diagram on the side of the machine.

Designed for use at home and for small turning works in small workshops. It is characterized by durability and low level of breakdowns.