Beton-House.com

Website about concrete: construction, characteristics, design. We combine the experience of professionals and private craftsmen in one place

Types of screws for concrete

A concrete screw or dowel is a cylindrical, elongated part with a head on one side, a thread in the center and a sharp end on the other side. The head of the element can have the form of a hexagon or a cross groove in its center.

For the manufacture of dowels, high-hardness carbon steel is used, which makes the concrete screw quite strong, and the application of a special protective coating protects the elements from corrosion and improves mechanical properties. The article introduces the types of screws and methods of using them on concrete.

Conclusion

Self-tapping screws for concrete – product range

Hardware products used for installation in concrete foundations are classified according to the following criteria:

- according to the shape and pitch of the thread on the screw rod;

- by head configuration;

- by type of protective coating.

It is advisable to use self-tapping screws for concrete in places where other types of fastening cannot be used due to the fragility of the base or the complexity of installation

Based on the shape of the head, it is customary to distinguish the following self-tapping screws for concrete:

- screw with a countersunk head (conical shape with cross-shaped slots);

- products with a hexagonal head (with cross-slots, internal threads, for an open-end or socket wrench);

- stud screws (for a nut, with a threaded drive);

- crocheted screws with round or rectangular heads.

The head configuration affects the mounting principle of the fastener. The studs and hooks are mounted in a pre-drilled hole and filled with sealing material. The rest of the products are fixed without drilling and with drilling - screws with a countersunk, hexagonal head can be used without preparing a mounting hole with a drill, but such installation is acceptable on lightweight concrete.

Based on the properties of the protective coating, fasteners are classified into:

- black screws (with oxidized coating) - used in rooms with a stable normal level of humidity;

- silver – the material is coated with a zinc layer, which allows it to be used everywhere;

- yellow – coated with a copper layer and recommended for indoor installation.

According to the characteristics of the thread, it is customary to distinguish:

- universal fasteners – length 12-220 mm, d 3-6 mm. The rod has a standard helical groove cut into it. The product is mounted into a wall made of light and heavy concrete. In the latter case, a mounting hole is used (for a dowel);

- universal fasteners with herringbone thread - length 12-200 mm, d 3-8 mm. Installation is carried out in prepared mounting holes with a polymer sleeve. The depth of the groove should exceed the length of the screw by 3-5 mm. For work, use an impact driver or a simple screwdriver;

- screws with variable notch (thread) – length 70-200 mm, d5 mm. The dowel is screwed into concrete walls without prior preparation. To screw in the self-tapping screw, you must use a screwdriver.

Location requirements

There are requirements for the location of hardware, for example, markings are necessary in order to screw in the necessary fasteners efficiently and at the required distance. There are the following rules for placing screws:

- from the edge of the product that is attached, it is necessary to retreat a distance equal to twice the length of this fastener;

- the hole in the wall should be slightly larger than the screw;

- the minimum dowel fit for light material is 6 cm, heavy material is 4 cm;

- the distance between the screws is from 12 to 15 cm, depending on the density of the concrete;

- The diameter of the hole is equal to the cross-sectional diameter of the self-tapping screw together with the dowel.

Concrete dowel - technical specifications

Self-tapping screws (without drilling concrete) are made on the basis of hardened steel , which gives the product increased strength. A yellow galvanic zinc coating is applied to the surface. The treatment improves the mechanical characteristics and anti-corrosion properties of fasteners.

The greater the depth of fastening, the higher the load-bearing capacity of the screw. The product is effective in case of pulsating load

Phillips screws are ideal for use with a standard hand screwdriver or power tool. TORX slot, fasteners with loops, convex heads, heads with external threads, hexagon (wrench) are used with the corresponding type of tool.

The thread is cut unevenly. The quality of adhesion of the surface and fasteners is improved by applying special notches. The dowel adheres well to porous substrates and hollow blocks.

Features and types

To mount it on a concrete base, you can use hardware that requires pre-drilling a hole and installing a dowel into it. But another method is also possible - choosing self-tapping screws designed to work with such dense material. They have a pointed end and a screw thread for better adhesion to the base.

Concrete screw - application

Self-tapping screws are effectively used for fastening metal, plastic, wooden door and window frames, fireproof doors, hanging products, lightweight concrete, blocks with voids - that is, for any type of repair and finishing work.

When working with heavy concrete, it is recommended to carry out preliminary preparation of the mounting hole; when working with light concrete, the self-tapping screw is screwed in without preparation.

Drill selection:

- select a drill whose diameter is 2-3 mm less than the d screw;

- the drill is fixed in the chuck of a hammer drill or electric drill;

- if it is intended to use an electric drill in the drilling mode, a universal or special concrete drill can be used;

- if the work involves an impact drill or hammer drill, it is better to use a special drill with grooves on the cylindrical surface of the shank.

Self-tapping screw - how to use fasteners on dense substrates

For installation, a galvanized steel screw for concrete is used - a dowel. How to screw a self-tapping screw into concrete?

The sequence of actions is as follows:

- a hole is drilled on the surface. The depth is selected based on the length of the product - it is taken with a margin of several mm. This is necessary to collect concrete dust that is formed when screwing in a self-tapping screw;

- when working, it is necessary to avoid deviations from the drilling axis, otherwise a diameter error will occur and the hardware will not hold;

- debris is removed from the resulting hole;

- the part to be fixed is installed in place before the screw is screwed in;

- The screw is screwed in using a screwdriver or a screwdriver at very low speeds.

If preliminary preparation is necessary, the hole is cleaned by moving the drill back and forth

If you don’t have any tools, you can use an old drill of the required size and a hammer. The drill is placed perpendicular to the surface, 2-3 blows are applied to it, the drill is turned and the blow is struck again. This continues until a hole of the required length is produced.

How to screw in a self-tapping screw without drilling, video

When working with lightweight concrete - expanded clay concrete, gas concrete, foam concrete, preliminary preparation of the hole is not allowed . To create full contact with the base, self-tapping screws for concrete are used without drilling the concrete.

The master can use another method of fixation - a screw with a dowel. The body of the seal is made of polyethylene, polypropylene or nylon and is divided into equal parts by longitudinal slots. As the material is twisted, it becomes wedged, ensuring full contact.

For this type of fastener, hole preparation is necessary. The drill should be selected in accordance with the thickness of the seal, slightly greater than its length . The seal should fit easily into the prepared hole, but provide a tight fit. The product is screwed with an electric or manual tool through the attached part.

Into metal

As for screwing the self-tapping screw into metal, only metal fasteners are used here. The twisting method depends on the thickness of the workpiece. If it is thin sheet metal, then you can often tighten it without much effort using a screwdriver or screwdriver. Moreover, there are different types of screws. Some have a small drill with sharpened teeth on the tip, as shown in the picture.

A self-tapping screw with a drill with sharpened teeth.

But as practice shows, not all such self-tapping screws can be screwed into metal, this is explained by the weak sharpening of the drill. So, a screwdriver is used to tighten them. You should not gain high speed, otherwise the screw may overheat and quickly become dull. Such fasteners can be used for metal up to 7 mm thick.

If the metal is too thick, then the best option would be to pre-drill a hole with a drill/drill, and then screw the fasteners into it. This method is not associated with any problems.

When making a hole, remember that its diameter should be smaller than that of a self-tapping screw. When the hole is ready, it can be lubricated with machine oil. This will allow you to tighten the screw without much difficulty.

The metal screw used should be made of solid steel, which is harder than the product.

reference Information

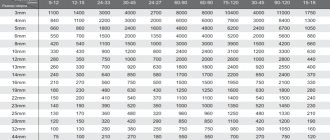

To calculate the load, it is recommended to familiarize yourself with the tabular data:

| Load, kg | Fastener size |

| Until 1.00 | 3*16 |

| Until 5.00 | 3*20 |

| Until 10.00 | 4*30 |

| Until 20.00 | 4*70 |

| Until 30.00 | 5*50 |

| Until 50.00 | 6*60 |

| Until 75.00 | 8*80 |

| Up to 100.0 | 10*100 |

Standard dimensions of self-tapping screws for concrete with pre-drilling are indicated in the table data:

| Concrete screw - dimensions | |||||||

| D internal, mm | 7.5*182 | 7.5*152 | 7.5*132 | 7.5*112 | 7.5*92 | 7.5*72 | 7.5*52 |

| 7.35-7.65 | |||||||

| D outer, mm | 6.30-6.70 | ||||||

| Thread pitch, mm | 2.55-2.75 | ||||||

| D heads, mm | 10.82-11.80 | ||||||

| Head height, mm | 2.80-3.20 | ||||||

| Slot type and depth, mm | TORX 2.30-2.70 | ||||||

| Length, mm | 180*184 | 150*154 | 130*134 | 110*114 | 90*94 | 70*74 | 50*54 |

| Tightening torque, kN*m | 20.00 | ||||||

| Min. pulling force, KN | 2.50 | ||||||

| Drill D, mm | 6.00 | ||||||

When working with a drill, it heats up, which requires regular wetting with water.

Anchoring and drilling depth:

| Material | Min anchoring depth, mm | Min drilling depth in wall structure, mm |

| Lightweight concrete | 60.00 | 75.00 |

| Heavy concrete | 30.00 | 48.00 |

How to attach?

The work plan for fixing self-tapping screws into concrete requires preparing the following tools and materials:

To perform this manipulation, you must have a screwdriver.

- drill;

- concrete drills of the appropriate diameter;

- screwdriver and suitable bit or attachment;

- hammer;

- screwdriver;

- dowels and screws for concrete (small and large).

All these tools will allow you to securely screw the mount not only into concrete, but also into brick or wood. When leveling a concrete floor under laminate or parquet, anchor screws for plywood are chosen 3 times longer than the thickness of the sheet. Some craftsmen recommend lubricating it with glue or machine oil before driving a screw into concrete. For better fastening, it is recommended to use a dowel plug.

Cost of products

A concrete dowel screw is a popular type of fastener. It is used in the installation of doors, windows, plumbing and electrical equipment. Prices for self-tapping screws for concrete are almost the same in all regions of the country. For a package of concrete screws, the price will range from 250 to 550 rubles/100 pcs.

Using concrete screws without drilling or with preliminary preparation in accordance with all installation rules, you can achieve reliable fixation.

How simply and reliably screws on concrete are screwed without drilling is clear from the video:

How to choose?

Stainless steel products are suitable for fixing window frames.

Such a wide range of self-tapping screws for aerated concrete and ordinary concrete allows you to select fastenings for any type of building materials and loads. The main criteria for choosing a product are the size and material from which the fasteners are made. The following types of metal are distinguished:

- Carbon steel. The disadvantage of such raw materials is their poor corrosion resistance. Therefore, products are galvanized or coated with a copper layer. Self-tapping screws for sandwich panels for concrete and metal are most often made from this material. Can be used to secure skirting boards.

- Stainless steel screws. This metal can be used in any conditions. This is due to its high resistance to corrosion. Strength and price depend on the concentration of expensive nickel in stainless steel. They look aesthetically pleasing and are convenient to work with to secure window and door frames. With its help, roofing work is carried out.

- Brass. It is called the most durable material, which is why the price of such screws is quite high. The anchor is resistant to salts and acids. The high elasticity of the alloy does not withstand large mechanical loads.

Products from companies such as Harpoon, Hilti, Koelner, Fisher, and Leroy are widely popular.

View "GOST 9012-59" or

Device

The dowel is made of durable steel and then covered with various technological coatings. This is necessary to give the screw a protective function. Passaging is done with yellow or white metal, and it should be noted that there is absolutely no difference in properties. The head of the screw is always flat, it is very easy to hide it in the structure. The bottom has the shape of a cone or notch, and therefore the hardware will not jump out. All these qualities allow you to screw in hardware without fear that the surface of the product will crack.

Easy installation of the screw can be done with a regular screwdriver, because the hardware is equipped with a cross-shaped notch. If you look at the thread, it will become obvious that it is uneven and has notches that are located along the entire length of the rod. These features allow for good adhesion to the concrete surface, which is why it will be possible to carry out high-quality work even in a porous base.

A concrete screw has a thread with a frequent pitch, and therefore it can be used very reliably for attaching an object to a concrete wall.

Types of fasteners

Concrete dowels are manufactured in accordance with GOST 1146–80. There are 2 main types:

- MMS-I. With hexagonal base, with press washer, galvanized.

- MMS-S. Cylindrical base with a diameter of 17 mm, hole for a torx key, electro-galvanized.

The MMS-I bushing nut anchor is used for installation of utility lines located inside buildings. Their galvanized steel threaded edges cut into the material, making them fit tightly and cannot turn. Self-tapping screws do not disturb the layers of material, so they can be mounted close to the surface. To install, you need to drill a hole to the required depth and screw in the dowel. This type of screws is used in the installation of utilities.

The second type is characterized by both easy installation by hand and with a power tool. Can be dismantled and reused. Main applications of MMS-S screws:

The MMS-S dowel has found its application in fastening stair railings or formwork.

- supports and columns;

- metal structures;

- stair railings;

- formwork

In addition to the main types, there are others, for example, the FRS-S concrete screw for medium loads, it is used for fastening door and window blocks made of wood, plastic and aluminum to a layer of concrete, as well as for hidden installation without the use of dowels. It has a double-start self-tapping thread and high corrosion resistance.

Safety precautions at work

To avoid unpleasant injuries, you must always follow basic safety rules to protect your body from harm.

When working, you must strictly follow several instructions:

- Under no circumstances should you start drilling without safety glasses, as a piece of concrete may break off and get into your eye. If this happens, you should immediately wash the damaged area with water and ask someone in the house to carry out a thorough inspection and remove all foreign bodies. If after a few hours the pain still bothers you, then you should seek help from a specialist.

- The drill cannot be operated with gloves on, as it can get screwed onto the rotating drill. This can seriously damage your fingers.

- Do not try to change the drill immediately after drilling, as it will be very hot. This can cause you to get seriously burned. First, cool the drill in water.

- Keep children away from the appliances. If the baby is running nearby, then all tools that are connected to the electrical network should be placed at such a distance that the child cannot reach them. Also, remove all cutting and piercing objects away.

Follow these simple safety rules and your work will only be a pleasure.

Thus, from a constructive point of view , a screw, which is used for fastening to concrete, is a rod with a thread that can be high, or alternately become low or high. The dowel also has a countersunk head, the inner side of which is equipped with a notch. Typically, these types of fasteners are used for screwing plastic and wooden windows, door frames to some kind of solid base. When working, it is always necessary to first qualitatively drill holes to the required depth, and then you can screw in the dowel, which will fit tightly into the part. All fastenings can be made independently.