A dowel for concrete is a type of fastening element. Used for insertion into vertical or horizontal cement-based structures. The concrete mass is characterized by high strength, so the fastening must withstand high loads. They are considering special fasteners that look like a self-tapping screw, but have improved characteristics.

What is a concrete dowel?

Such screws are most often used for fastening heavy structures - frames, door jambs, cabinets, shelves, fences, heating radiators and other communications. The screw is held tightly due to the uneven two-start thread and notches along its entire length. This shape ensures reliable fixation even in a concrete wall. On the head of the screw there are notches for countersinking.

The dowel for concrete looks like an elongated self-tapping screw with a thread in the center. On one side there is a head with a hexagonal groove, on the other side there is a sharp end. They are made from carbon steel with a protective galvanized or anodized coating, which provides protection against corrosion and other influences. For screwing, TORX T30 bits are used.

The fasteners can be reused, which is a great advantage for temporary structures. They are chosen for their low price, resistance to moisture and stress, and reliable fixation of objects, regardless of the material.

Benefits of use

The main advantage, compared to other concrete screws, is that it is used without a dowel. Before screwing anything to a concrete wall, beam or partition, you need to drill a hole with a diameter of 6 mm, then screw the dowel into it. The density of concrete does not matter. The screw can be used for dense or cellular concrete. You can screw self-tapping screws into walls made of some types of cellular materials without pre-drilling.

Features of using self-tapping screws

Using such fasteners is quite convenient and simple.

The instructions recommend drilling a hole in advance before screwing a screw into a concrete wall. Before screwing a screw into concrete, you will need:

- Hammer drill, electric drill, screwdriver;

- Drill bit for concrete screwdriver;

Tip: It should be borne in mind that there is no clear answer to the question of whether it is possible to drill concrete with a screwdriver. In this case, work should be carried out very carefully and only as a last resort.

- Regular screwdriver . Its choice depends on the shape of the slot applied to the dowel head. Most often it is cross-shaped or curly, the screwdriver should be of the same type;

- Hammer. Sometimes they are allowed to drive self-tapping screws into the wall. But only in situations where: there is no special tool available for drilling a hole; there will be no significant load on the fastener, for example, it will be intended for attaching a picture.

How to screw in a dowel

Self-tapping screws are used when installing plastic windows, any wooden structures, different profiles, door frames to a concrete or other base.

Before screwing a self-tapping screw into the concrete, a hole is drilled in the wall. It is necessary to take into account that:

- The distance from the edge of the wall should not be less than 60 mm;

- When installing a plastic window, the pitch between fasteners is selected to be a maximum of 60 cm;

- When installing an aluminum or wooden window, the maximum step between elements can be 70 cm.

Further:

- After drilling a hole, it is cleared of dust;

- A dowel of the required size is inserted. It can be plastic or wooden, the main thing is that it can withstand fasteners and be securely fastened to the concrete wall;

- A self-tapping screw is screwed in, as shown in the photo.

Tip: To avoid breaking off the screw, you must screw it in correctly. This should be done carefully, without over-tightening the fasteners. You should avoid fast screwing in, which can lead to overheating of the element head and its destruction.

Types of dowels for concrete

Head shape

- Secret . A flat head that allows you to tighten the screw deep into the structure without leaving a bulge on the surface. The head has cross-shaped slots. There are notches for countersinking.

- Rectangular . They are shaped like a hook. May be rounded.

- Hexagonal . The thread is located inside with a cross-shaped slot. For these types, open-end and ring wrenches are used.

- Hairpin . There is a nut threaded fitting.

The type of head affects the way the dowel is screwed into a concrete wall. A screw with a hook or a pin can only be mounted with a pre-drilled hole. Other types can be screwed directly into the wall.

Coverage type

- Blacked out . Black self-tapping screws with oxidized coating. For use only in rooms with normal humidity. It is not used on the street or in basements.

- Copper-plated . Yellow color. Sensitive to various influences. Used only for indoor work.

- Galvanized . Silver color. Can be used indoors and outdoors. They do not collapse or deform.

The dowel is used where other fastening is impossible: the base is too fragile, or installation causes certain difficulties.

Fastener selection

Before screwing a screw into a concrete wall, you must correctly select the fastening element itself and the diameter of the drill.

In appearance, the anchor self-tapping screw for concrete is practically no different from simple screws. But there are some special characteristics that products suitable for DIY installation in concrete surfaces must have.

These include:

- The screw for concrete dowel must be made of high quality steel;

- Cap type and head shape. This depends on the tool you plan to use when screwing in the hardware. For example, cross and star slots are suitable for screwdrivers and screwdrivers. Such caps are convenient to use when it is necessary to exert great effort when screwing a self-tapping screw into a concrete wall;

- The end of the dowel must be sharp;

- The screws must have an anti-corrosion coating, otherwise they will quickly rust, which will cause corrosion to spread to the reinforcing frame, if present in the wall.

Can I drill into a concrete wall with a screwdriver or electric drill? In fact, you shouldn't ruin your instrument.

Find a hammer drill and don’t worry, but as a last resort, choose the right drill, taking into account the following criteria:

- The diameter of the tool should be 2-3 mm less than the cross-section of the hardware;

- It is allowed to use a universal drill bit for an electric drill;

- Product cost. The highest prices are for frame and wedge type anchors. It makes sense to purchase them if the part will be subject to a fairly large load. In other cases, it is enough to buy inexpensive self-tapping screws used for concrete surfaces;

- When using an impact tool, it is worth purchasing a special drill with grooves on the cylindrical part of the shank.

- Before screwing a screw into a concrete wall, you must first calculate the load for which the fastening element will be designed. To do this, you can use the table below:

The main sizes of screws that can be bought in stores

The diameter of the dowel always remains the same - 75 mm. The length of the working part varies - from 52 to 202 mm in increments of 20 mm, except for the 30 mm gap between 150 and 180 mm. Pins are sold in boxes of 20, 100 and 200 pieces. On some construction sites you can order from 1000 pieces. There is no price difference between screws with different coatings. The cost depends only on the length of the working part.

Drill for a dowel for concrete: is it necessary?

Before screwing the mount into the concrete wall, you must drill a hole. To do this, use a drill with a diameter of 6 mm. The width and length of the hole should be 15-20% smaller than the dowel itself. If you use an electric drill in drilling mode, then a universal or special concrete drill will do.

When using an impact drill or hammer drill, a drill is used that has grooves located on a cylindrical surface. For expanded clay concrete, foam or aerated concrete, there is no need to drill a preliminary hole. This is done in order to create full contact between the screw and the concrete.

Requirements for the location of self-tapping screws for concrete

Before using screws, you need to mark the fasteners:

- they retreat from the edge of the structure to a distance of at least twice the length of the anchor;

- the depth of the hole must be greater than the length of the self-tapping screw by the value of one of its diameters;

- the minimum recommended dowel insertion depth for lightweight concrete is 60 mm; for heavy ones - 40 mm;

- distance between anchors - 120 mm for porous, 150 mm - for dense materials;

- The diameter of the hole must correspond to the cross-section of the dowel.

The fasteners are positioned so as not to cause the formation of cold bridges.

How to screw a dowel into concrete

- Before installing the structure, it is necessary to calculate the load. This is quite easy to do, since the diameter of the screws is standard. Lightweight items such as wall shelves can be mounted on 72mm long dowels. For heavy and bulky objects, the screw is selected individually.

- Before drilling, it is necessary to clean the wall surface. Future fastenings are marked on the surface. Before marking, you need to make sure that it does not fall into the passage of fittings or wiring. There should be no more than 60 centimeters between the fastening points; when installing windows, the step should be no more than 70 centimeters. 5-6 centimeters retreat from the edge of the wall.

The depth of the drilled hole should be slightly greater than the length of the dowel. If the hole is not deep enough, a metal pin can be used to achieve the desired depth. During installation, deviations from the drilling axis are unacceptable; the drill must be held strictly perpendicular to the wall. The hole is cleaned of dust using a cleaning rod or a construction vacuum cleaner.- In the absence of a tool, simply use a drill to drill a preliminary hole. He is driven into the wall with a hammer. After several blows, turn and hammer again until a hole of the required size is obtained.

- When screwing the dowel into concrete, it is not recommended to use a screwdriver. Since the screw itself is quite fragile, it may not withstand excessive tightening and the heat generated during operation of the power tool. For installation use a simple screwdriver. If you have problems with screwing, it is better to take a hammer. When screwing a screw into a wall made of porous concrete, the installation must be done carefully.

Wall mount

For concrete, the screw selected is short enough, since the recommended depth for inserting hardware into such structures is 45 mm. For comparison, the holes in a brick wall are deeper - up to 55 mm. For cellular concrete, a depth of up to 75 mm is recommended. The less durable the material, the larger the fastener should be. Screws are placed using the same principle. If the structure of the material is loose, then holes are made in the wall into the structure as far apart as possible.

When studying the question of how to use such fasteners, it is necessary to assess the condition of the structures. Strength is ensured if the wall does not collapse. Concrete should not crumble; if there are cracks, the reliability of the structure is reduced. In this case, the use of the largest dowel will not provide the required result.

When work begins, determine the area for installing the first screw. For example, it is necessary to deviate from the corner by at least 60 mm. If you break this rule, the strength of the fastening will decrease. Under the influence of significant load, the structure will begin to collapse. This will lead to the collapse of the element, which was fixed with a screw in the concrete.

Recommendations for using the dowel:

- work is carried out according to a pre-drawn up project;

- markings are made on the structure;

- prepare the holes, and it is necessary to ensure that the cement does not crumble, and there should be no chips;

- if the material is porous, it is impossible to put pressure on the tool when inserting a screw into the concrete mass, since there is a risk of damaging the structure, as a result the screws will not hold, the structure will deform over time or immediately as soon as increased pressure is applied to the fastener .

During the work process, there are many nuances that should be taken into account.

Installation begins with preparing the tool. You will need a screwdriver, drill or screwdriver, concrete screws, hammer drill, and a container filled with water.

Instructions for performing the work:

- To prevent chipping, you need to clean the surface. If the structure has defects, you can level it using cement compounds and plaster.

- The load on the fastener is determined. Based on this, drills of the required length are selected.

- Work begins after marking the site.

- Concrete is a dense, durable material. The tool will get hot when drilling. To cool it, water is used. An alternative option is oil.

- If it is not possible to drill the concrete to the required depth, use a hammer. You need to hit the head with the screw several times. However, this method is used when the fasteners will not be subject to significant load.

Is it possible to fasten heavy structures

Concrete dowels are used when working with structures made of different materials. It is used for metal, plastic or wooden products. It is also used to attach aluminum and plastic windows to concrete walls and beams. The notches on the working surface of the screw prevent any unscrewing.

Dowels are used to secure aluminum profiles, door frames, roofs, stairs, awnings, fences, and fireproof doors. When choosing the length of the working part, it should be taken into account that a screw measuring 7.5x72 mm can withstand a structure of 10 kilograms. To secure a structure weighing more than 100 kilograms, it is necessary to use a dowel of at least 152 mm. The load-bearing capacity of the self-tapping screw depends on the length of the working part. The material from which it is made allows it to be used in home renovation, construction and industry.

For concrete, the dowel is the most reliable fastening. Its low price and ease of use will be an excellent assistant in construction and repair. A minimum of tools for installation and various types of screws will simplify repairs and make the fastening reliable and strong.

The first concrete screws, also called dowels, appeared at a time when only wooden structures were built. Today, dowels are often used to fasten window frames or other wooden structures to massive concrete structures. This fastening element is very easy to use, but very reliable, and therefore it is widely used in construction circles. If you need to attach some kind of structure to concrete, you must use just such hardware. It has great strength, reliability and durability, and therefore builders love to use it.

Sooner or later, you will have to make repairs in an apartment or private house, and you can’t do it without reliable hardware. That’s why it’s so important to understand all the nuances of working with such a building element.

How to choose the right dowel

When you plan to purchase concrete screws, the application (intended purpose) of such fasteners is one of the criteria. This is due to the fact that the parameters are determined by the material and the type of thread of the hardware.

Criterias of choice:

- the type of structure, the material from which it is made, while considering different screws that differ in properties, type of coating, for example, to fix heavy structures of more than 100 kg, products with a length of 150 cm are used;

- choose products according to the type of head: protruding, hidden;

- The type of slot also plays a role, and you need to choose the right tool;

- a type of thread, which determines the method of installing hardware (with dowels, in a finished hole, etc.);

- operating conditions, some types of fasteners are negatively affected by moisture.

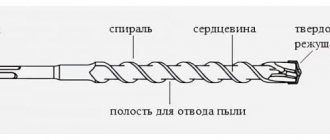

Device

The dowel is made of durable steel and then covered with various technological coatings. This is necessary to give the screw a protective function. Passaging is done with yellow or white metal, and it should be noted that there is absolutely no difference in properties. The head of the screw is always flat, it is very easy to hide it in the structure. The bottom has the shape of a cone or notch, and therefore the hardware will not jump out. All these qualities allow you to screw in hardware without fear that the surface of the product will crack.

Easy installation of the screw can be done with a regular screwdriver, because the hardware is equipped with a cross-shaped notch. If you look at the thread, it will become obvious that it is uneven and has notches that are located along the entire length of the rod. These features allow for good adhesion to the concrete surface, which is why it will be possible to carry out high-quality work even in a porous base.

A concrete screw has a thread with a frequent pitch, and therefore it can be used very reliably for attaching an object to a concrete wall.

Correct Application

Dowels are very often used when installing wooden structures, PVC windows, aluminum profiles, wooden frames to concrete structures, brick or other walls. Before you start screwing in the screw, you need to drill a hole in the brick using a special drill.

When carrying out such work, you need to take into account some nuances:

- You should retreat 5 or 6 cm from the edge.

- If there is a need to install a PVC window, then the distance between the fasteners should be 60 cm.

- If you need to install wooden or aluminum windows, then the maximum distance between the fasteners is 70 cm, and from the corner of the frame to the racks - 10 cm.

After the marking has been made, you need to start screwing in the dowel. It must be secured very carefully. If the wall is made of porous or hollow material, then do not apply pressure when twisting. In this case, you only need to use screwing movements. It must be remembered that a dowel with a variable thread will never be combined with a dowel .

Wall mount

There is nothing difficult about attaching a screw to the wall. Before starting, you just need to do the preparatory work using certain tools:

- drill;

- perforator;

- screwdriver or screwdriver;

- fastening material.

- Before starting work, it is always necessary to thoroughly clean the surface.

- Afterwards we carry out the correct marking of future holes. They will be different for each type of work.

- When the marks are applied to the surface, you can start drilling. The length of the hole must correspond to the prepared fastening material.

- It is necessary to remember that the drill will become very hot, and therefore you should periodically moisten it in oil or water.

- If the depth needs to be increased, a pin should be used. By turning it inside, you can achieve the optimal length.

- The dowel will be screwed into the hole through the prepared structure, which is pre-fixed.

- The notches on the screw allow you to firmly secure the surface. The screw is quite brittle. If you over-tighten or heat the rod too much, it will break. That is why it is better to very carefully use a screwdriver to screw the dowel into the concrete. Screwing will be done at high speeds. The rod gets very hot and the hole expands. Therefore, the screw may become loose and fall out. That is why it is better to use a regular screwdriver, which must be selected according to the drawings printed on the head of the product. There is a curly or cross-shaped form.

- If the screw cannot be screwed in, then you should use a hammer. But this should be done only if the structure will not bear a large load.

Types of hardware

Professionals classify this hardware according to several main characteristics, not counting its size.

The main feature is the type of head. There are models with countersunk hex or rectangular heads. The first option has cross or conical splines. Hexagonal elements have internal threads or slots that are intended for open-end or ring wrenches. Rectangular models are made with a rounded head, which is why technical hinges can be attached to them.

On the market and in stores you can find a wide variety of hardware, which are made from various materials. If you study this topic, you can understand that only the external technological coatings that perform a protective function differ. There are galvanized, copper-plated or darkened screw models.

They also differ in terms of use. Galvanized models can be used indoors as well as outdoors. Copper dowel does not like external influences, and therefore there is no reason to install it outside. Blackened mestizo is protected in the worst way of all, and therefore it is better to use it in places where moisture will not get in.

Briefly about the main thing

Self-tapping screws for concrete are universal. With their help, you can attach interior items, household appliances, communications, finishing materials to the concrete surface both outside and inside. Externally, they have the shape of a screw and differ in a number of parameters:

- Material.

- Type of protective coating.

- The shape of the head part.

- Type of thread.

When choosing for specific application conditions, it is necessary to correctly calculate the load, take into account corrosion factors, as well as how the fasteners will be combined with the finishing design and what its final cost will be. During installation, a number of rules must be observed, including safety regulations.

Ratings 0

Characteristics

Dowels have several important parameters that you need to know when using:

- The outer section can be from 7.35 to 7.65 mm.

- The thread pitch is selected from 2.5 to 2.75 mm.

- The outer diameter ranges from 6.3 to 6.7 mm.

- Internal section - from 5.15 to 5.45 mm.

- The diameter of the cap is from 10.82 to 11.82 mm.

- The head height ranges from 2.8 to 3.2 mm.

- The screws have 30 Torx slots.

- Depth varies from 2.3 to 2.7 mm.

- The length of the screws can range from 50 to 184 mm.

- The diameter of the drill used should be 6 mm.

Part parameters

When choosing screws for concrete, their sizes must be selected according to the applied load.

- when fastening a cabinet that weighs five kilograms, you can use a screw with dimensions of 3 x 25 mm, where 3 is the diameter of the rod, 25 is its length;

- for fastening an object weighing 100 kg, it is better to take the self-tapping screw dimensions 10 x 160 mm;

- The sizes of screws, depending on their type, can be found in the table:

| Concrete dowel | Diameters, mm | Length, mm | Weight of 1 piece, gr. |

| Black | 7,5 | 52; 72; 92; 112; 132; 152; 182; 202 | From 10 to 36.2 |

| White | 2,5; 3; 3,5 | 10; 12; 13; 16; 20; 25; 30; 40; 45 | From 0.3 to 1.6 |

| Yellow | 2,5; 3; 3,5 | 10; 12; 13; 16; 20; 25; 30; 40; 45 | From 0.3 to 1.9 |

Price

The cost of the product will depend on the length, as well as coating parameters. For example, a copper-plated product will cost a little more than a darkened one, and you will have to pay more for 150 mm hardware than for 70 mm. But in any case, purchasing such screws will not cause much damage to your wallet, since the dowel is not too expensive, and not too many of these products are needed for construction work. Therefore, you can go to the first hardware store you come across and choose exactly the hardware that is suitable for a specific situation.

Safety precautions at work

To avoid unpleasant injuries, you must always follow basic safety rules to protect your body from harm.

When working, you must strictly follow several instructions:

- Under no circumstances should you start drilling without safety glasses, as a piece of concrete may break off and get into your eye. If this happens, you should immediately wash the damaged area with water and ask someone in the house to carry out a thorough inspection and remove all foreign bodies. If after a few hours the pain still bothers you, then you should seek help from a specialist.

- The drill cannot be operated with gloves on, as it can get screwed onto the rotating drill. This can seriously damage your fingers.

- Do not try to change the drill immediately after drilling, as it will be very hot. This can cause you to get seriously burned. First, cool the drill in water.

- Keep children away from the appliances. If the baby is running nearby, then all tools that are connected to the electrical network should be placed at such a distance that the child cannot reach them. Also, remove all cutting and piercing objects away.

Follow these simple safety rules and your work will only be a pleasure.

Thus, from a constructive point of view , a screw, which is used for fastening to concrete, is a rod with a thread that can be high, or alternately become low or high. The dowel also has a countersunk head, the inner side of which is equipped with a notch. Typically, these types of fasteners are used for screwing plastic and wooden windows, door frames to some kind of solid base. When working, it is always necessary to first qualitatively drill holes to the required depth, and then you can screw in the dowel, which will fit tightly into the part. All fastenings can be made independently.

What is a concrete dowel and what does it look like?

A bolt is a shaped nail of round or square cross-section with a thread, without a pronounced point at the end with a hexagonal head, which can be screwed into concrete. The screw is made of galvanized steel, which guarantees its maximum service life even in wet environments. The unevenness of the thread ensures reliable fixation of the dowel screw in the concrete surface. The fastener is also suitable for bricks (solid with a void volume of less than 13% of its volume, and hollow with more than 14%). Dimensions range from 7 to 200 mm, its diameter is 3-6 mm. The metal tip allows the hardware not to “lick off” when screwed into a brick. For concrete, dowels are made from the following materials:

- alloy of iron and carbon;

- stainless steel.

What is it and where is it used

It is a regular self-tapping screw with a reinforced shaft and a hex head that can be screwed into concrete.

In addition to small items, you can use them to strengthen:

- door frames;

- frames;

- fencing;

- pipelines;

- heating radiators.

Below we will look in more detail at the types of such fasteners, as well as how to use concrete dowels correctly.

Hardware for concrete

Hardware products used for installation in concrete surfaces are usually classified according to the following criteria:

Types of dowel heads

The shape of the head directly affects the installation of the self-tapping screw. For example, screws in the form of hooks and studs are allowed to be installed only in a hole that has been pre-drilled and with a dowel. Other self-tapping screws for concrete are screwed in without drilling or with it.

Copper-plated screws for interior work

For example, screws with a hexagonal or countersunk head are screwed in without drilling a mounting hole. However, not every concrete is suitable for such installation.

Screw with variable thread and serrations along the entire length of the rod

Advice: cellular concrete is the best, but reinforced concrete is not suitable for this installation method.

The price of self-tapping screws depends on the scope of their application, the shape and pitch of the thread, and the length of the hardware also affects it. With a herringbone pattern, products will cost less than dowels and universal ones, and a screw 12 mm long will cost less than 200 mm, since less material and working time will be spent on it

Characteristics of self-tapping screws

The appearance of the screw indicates the use of a specific alloy. The silver color is associated with the use of zinc; this electroplating is used both on the outside and on the inside of the structure, and is considered universal. Yellow zinc is used on elements to a limited extent; such self-tapping screws are suitable exclusively for indoor work, most often for aerated concrete. It is made of carbon steel with a countersunk head with a Torx slot, double threads and a sharp tip (FRS-S). Black colored fasteners, which are achieved by chemical oxidation, are considered quite durable, but are used only inside a building with a normal percentage of humidity. Anchor heads for concrete are:

Screws with a torx head with an asterisk allow you to achieve the tightest possible fit of the fastener to the product.

- with cross slot;

- rectangular;

- with hook;

- with a torx head under an asterisk;

- hexagonal;

- spire-shaped.

Conclusion

From the article you learned that concrete is considered one of the most practical materials for placing various elements on its surface. To do this, metal products are used in the form of self-tapping screws, anchors and, of course, dowels, which differ from others in the ability to screw a ceiling or floor into a wall without prior preparation of a mounting hole.

The latter has different head shapes and is used for external and internal work. The video in this article will help you find additional information on this topic.

Types of fasteners

Concrete dowels are manufactured in accordance with GOST 1146–80. There are 2 main types:

- MMS-I. With hexagonal base, with press washer, galvanized.

- MMS-S. Cylindrical base with a diameter of 17 mm, hole for a torx key, electro-galvanized.

The MMS-I bushing nut anchor is used for installation of utility lines located inside buildings. Their galvanized steel threaded edges cut into the material, making them fit tightly and cannot turn. Self-tapping screws do not disturb the layers of material, so they can be mounted close to the surface. To install, you need to drill a hole to the required depth and screw in the dowel. This type of screws is used in the installation of utilities.

The second type is characterized by both easy installation by hand and with a power tool. Can be dismantled and reused. Main applications of MMS-S screws:

The MMS-S dowel has found its application in fastening stair railings or formwork.

- supports and columns;

- metal structures;

- stair railings;

- formwork

In addition to the main types, there are others, for example, the FRS-S concrete screw for medium loads, it is used for fastening door and window blocks made of wood, plastic and aluminum to a layer of concrete, as well as for hidden installation without the use of dowels. It has a double-start self-tapping thread and high corrosion resistance.

Using a screw anchor

Self-tapping screws come with an intermediate length relative to the 2 main ones - 9-18 cm and from different materials. They are selected by length for each specific purpose for installing fasteners. If you are installing a lightweight and not bulky structure, for example, a bookshelf, choose a 7 cm dowel. When fixing frames for windows or doors, take screws that can withstand the load, respectively, use a longer self-tapping screw. It is better to make a landing opening in heavy concrete using a drill with a diameter 2-3 mm less than the d screw.

If the weight of the fastening element exceeds 100 kilograms, it is necessary to use self-tapping screws from 15 cm, since the speed of screwing into the wall depends on the length of the screw. Pins are used for all types of repair and finishing work for fastening metal and plastic elements, hanging products on light and heavy concrete, and bricks with voids.

Builders note the main advantage of the dowel over other anchors - the load immediately after installation.

Features of choosing fasteners

The main criterion for choosing a dowel for concrete is the ability of the fixing element to withstand the expected load. According to experts, for a small-sized and lightweight structure, such as a bookshelf, a screw 70 mm long is suitable. To secure a window frame or door in the opening, you will need longer dowels. Thus, a structure weighing a total of about 100 kg requires the use of screws whose length is at least 150 mm.

An important point when choosing a fastener is the step with which the element is mounted in the general installation system of one object. The distance between the screws should be about 70-100 mm. This distance is reduced or increased, depending on the structural features of the object connected to the concrete base.

When choosing fasteners for concrete, be sure to take into account operating conditions. It’s one thing to use a dowel in a room with a high level of humidity (bathroom, sanitary unit), and another thing to use in a room with dry air, so special attention is paid to the protective coating of the fasteners.

Rules for using concrete screws

The correct sequence of actions during installation:

- Determine the required installation parameters when applying the product.

- Transfer the resulting installation dimensions onto the plane.

- Drill a hole with a margin of a couple of mm, taking into account the concrete dust that collects when screwing.

- Remove any residue from the hole.

- Install the element in place of fixation.

- Use a screwdriver or screwdriver to insert the self-tapping screw into the plane.

Due to the cross-shaped notch, you can use a screwdriver for installation. Screws with dowels and the hardware itself with herringbone threads are inserted if large loads are expected. A dowel with a variable thread does not require the use of a dowel. You can install parts or products after tightening them by placing them on the head of a cylindrical screw.

«>

Correct use

Using screws, you can attach wooden structures to concrete.

Pins are used for fastening wooden and aluminum structures to a concrete (brick) base. Using screws is convenient and easy. If there is a dowel in a pre-drilled hole, the dowel can withstand a large load. If there is no load on the fastening material, you can do without a dowel. The folk method will help prevent loosening in the second case. Place pieces of matches into the hole made. They will seal the position of the fastener and prevent it from loosening.

Return to contents