- November 21, 2020

- Cars

- Petr Kuznetsov

They say that in Russia there are no roads, but only directions. Sometimes there are not even directions - all around are fields, swamps and impassable mud. You have to figure out the direction yourself. Often, a car gets stuck in the mud, and this applies not only to simple cars, but also to quite serious SUVs - from the Ulyanovsk “goat” to the SUVs used in the NATO army. It's good if there is a winch. What if she’s not there or even she doesn’t help? Don’t leave the “iron horse” to the mercy of fate. But there is one device - a hi-jack, also known as a rack and pinion jack. Not only can he lift your car for a tire change or a detailed inspection. This hi-jack can also be used as a winch.

But not by itself, but with the help of special devices. Such hi-jack kits (they are called Off Road Kits) are sold on specialized Internet sites.

You can also assemble it yourself, it won't be difficult. Some car enthusiasts complain that when used as a hi-jack winch, the main chain cannot withstand it. However, if your goal is not to constantly drive the car deeper into the mud on purpose, and then pull it out of there, but only pull it out, and as rarely as possible, then you can get by with a magazine device.

With hi-jack and...

A manual winch made from a rack jack is a simple device. This device consists of:

- main circuit;

- connecting links;

- chain shorteners;

- shaklov;

- textile sling.

If your task is to participate in competitions, then you can assemble the kit yourself in order to use a hi-jack instead of a winch. It is advisable to buy a chain not even in a fastening store, but in companies that sell rigging products. Its working load should be 4-5 tons. The working load of hooks and shucks is from 1.5 tons.

Cast iron or steel?

Pretty simple, right? But the trick is that the composition of cast iron or steel for the manufacture of the device is strictly regulated. There are no secrets in its composition, but it is the successful proportion of material elements presented in the table that allows the jack to withstand high loads and serve for a very long time.

Read also: What to cook for your child for dinner

The Hi-Lift company produces several modifications of jacks, differing in the length of the perforated rail and the material from which the main structural elements are made. Roughly speaking, you can buy two types of Hi-Lift Jack - black and bright red. The difference is that the black hi-jack has a support shoe, a lifting mechanism. and the handle are made of stamped steel, and for red devices everything is cast from cast iron of a special composition.

Give me a foothold!

Archimedes also said that if he is given a fulcrum, he will move the Earth. To use a hi-jack instead of a winch, you need to attach it to some kind of mount on the ground. In the field, this is most often a tree trunk, although it could also be a stone, a slab, or a concrete block that somehow got in your way.

If there are no trees, stumps or stones, a spare tire will come to the rescue. It can be attached to uneven terrain (for example, in a hole or on a mound with old roots), and best of all, on some bushes (of course, not listed in the Red Book). The main thing is that the structure can withstand the weight of the car and the thrust of the hi-jack. The spare wheel is put on these bushes with the holes in the disk - and the replacement tree is ready.

Operating principle

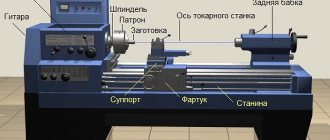

The operation of a rack jack is based on the gradual movement of the load between small and large platforms mounted on the rack. The pressure is transmitted using a connecting rod.

So, at the beginning of lifting the load, the handle is positioned strictly vertically, and the entire load is applied to a large platform. When the lever is lowered, the connecting rod begins to rest against a small platform, which in turn transfers the lifting load to the upper stop until the pin occupies the next hole in the rack. At this moment, the pressure on the small area stops. Then the handle rises again, and with it the lower stop (exactly one hole). This is what one lifting cycle looks like.

It's not just a ship that needs an anchor

Don’t forget about securing the car itself in place so that it doesn’t fall back when using the hi-jack as a winch, and making the path forward easier, or rather to where you are going to pull it. To do this, if possible, you should place boards, branches, bricks (without piercing or cutting fragments) under the wheels. This needs to be done both when starting to hi-jack and after you have pulled the car out a little. The support is placed under the rear wheels. It is also possible under the front ones, if it does not further interfere with movement when starting off. All manipulations will make it much easier for you to use the hi-jack as a winch. These procedures must be carried out not only at the beginning of the process, but also as it progresses - depending on the situation. In addition, when running a hi-jack, there are often cases when the car is pulled not forward, but up and sideways or even backwards. Then the emphasis of the machine must be adjusted according to the situation.

Which to choose

When purchasing, first of all, you need to decide on the brand and dimensions of the device. Which one to choose? There are many manufacturers of rack jacks. But if you want to purchase a truly high-quality and reliable tool, then you will not find a better jack from the American company Hi Lift. This company has been producing rack and pinion jacks for over a hundred years, and their products are used by the most avid Jeepers.

Hi-Jacks are available in only two colors - black and red. They are made of high-strength cast iron and have several steel parts. Such jacks are considered the standard of reliability and quality. They cost, of course, a little more than models from other manufacturers, but they fully justify their price. At least modifications longer than 150 centimeters do not bend, unlike tools from Chinese manufacturers. By the name of the model you can determine its length. Thus, the Hi-Lift Jack HL-485 has a length of 48.5 inches (120 centimeters), and the HL-605 has a length of 60.5 inches (150 centimeters). These are the models that are most popular among off-road enthusiasts.

Important: When buying a jack, think about how you will transport it, because a one and a half meter tool will not fit into every trunk. Therefore, most likely, you will have to equip your car with a special external mount.

With a swift jack

Assemble the device as indicated in the instructions. Then attach it with a sling to a tree and a chain to the car. It is possible and vice versa, if there is a possibility of rigid fixation. Make sure that the structure is taut and does not sag. This applies to both the sling and the chain. And start using the lever, as when jacking up. The rack moves, and behind it the car returns to active life. It’s very good if a friend sits behind the wheel, works the accelerator pedal, and does it wisely. If you have comrades pushing your iron horse from behind, that’s also good, but in the mud there is usually no such opportunity, and you must not forget where you are pushing the car. Act according to the situation.

The main characteristics of a rack jack that you should pay attention to when choosing

When purchasing or independently manufacturing rack-and-pinion automotive structures, you need to pay attention to the main characteristics that a high-quality tool must meet.

The following qualities influence the efficiency and safety of work:

- Load capacity - in the instructions for the jack it is indicated in tons.

- Compliance of the support platform with established standards. The platform must be stable and not shake during work. Therefore, when purchasing, you need to pay attention to ensure that the shape of the base is correct.

- An important parameter when choosing is the pick-up height. This element can be of different shapes, but the indicator does not affect the quality of work.

- Also, special attention is paid to the lifting height. This is the difference between the distance from the pick-up to the support platform.

- The force required to lift a load. It depends on the maximum permissible weight. This parameter is different for different types of mechanisms.

Important!

The quality of operation of the mechanism will be influenced by the strength of fixation of the support platform.

Leading device characteristics

Why are additional chains needed?

When you pull the car out of the mud captivity, it travels a certain distance by inertia, moreover, than the distance by which you moved the rack. The chain sags, and the shorteners fasten it with hooks along the sagging area, and the tension returns. In this case, it is desirable to have not one such shortener, but several. Or, for example, you moved the car approximately the length of the rack, but this is not enough. What should I do? Secure the car firmly to the rear and put the handbrake on. Then, carefully and according to all the rules, as written in the instructions for using this device as a jack, return the hi-jack lever to its original position. It is extremely important to use all safety precautions, and first of all, do not place your head and other parts of the body along the path of movement of the handle. Shorten the chain, remove the handbrake from the car, and start working again.

Scheme of work

If you want to buy a rack jack for your own needs or to use it at your service station, then first you need to decide on their varieties - there are only two of them.

- Serrated. They have a handle and gears that are driven by it.

- Lever. Such models lift and lower loads using pressure applied to the lever of the device.

Rack and pinion jacks are also divided into manual and electric - and they can be gear or lever. With hand-held tools, everything is simple - they are used mainly by ordinary motorists, who do not need it very often. The electric drive, in turn, will be useful in specialized workshops when it is necessary to lift as quickly as possible and with minimal effort.

Hi-jack vs winch

The best option, of course, is the one when you have all the necessary auto devices, while they take up little space, and are also cheap and reliable. For obvious reasons, this is unattainable.

A hi-jack is not a winch or even an ordinary jack in the full sense of the word. In fact, this is a universal thing for jeepers and just people who drive off-road. It serves as a kind of lifesaver for them. That is, he can jack up, and successfully, but only by the wheel or by the power threshold. It can also work with a hand winch, pulling it out of almost any mud, but according to a rather complex and branched algorithm. At the same time, it can work in both modes in any puddle. The winch, it would seem, is easier to operate, but, firstly, it is rare that any will withstand Russian mud, and secondly, dissolving a manual winch under a load is quite a complicated matter.

A simple jack is more versatile and can lift a car without any additional equipment. But he often becomes helpless on country roads or the lack thereof. A hi-jack with a special platform (instead you can use a reliable support like a board or brick) can help in this regard as well. Moreover, if one of your friends has a winch, then even the process of winching with this device can be greatly simplified when the car is additionally pulled out with a hi-jack.

In addition, this device is very unpretentious. After it has been removed from the mud, the hi-jack only needs to be rinsed with water. Additional lubrication may even harm it. It's best to spray it with a little WD-40.

Caring for a rack and pinion lift

As mentioned above, the rack and pinion lift does not require special care. After completing the work, you can wipe off the dirt or rinse it in a nearby puddle so as not to get the trunk too dirty.

Many people are accustomed to taking proper care of such devices, so they maintain their longevity by thoroughly cleaning and lubricating them with machine oil. Oil will only cause harm to a rack and pinion jack, as it attracts excess dust and dirt. Of course, the lift can jam due to debris getting inside the rack. To operate the device, simply pour water over it so that the internal parts can be cleaned.

It is recommended to store hi-jacks on the side of the rails, since the long base will not allow the device to be placed in a different position. In addition, in this position the lift will not interfere with the placement of additional fog lights on the roof rack. It is not advisable to store the jack inside the passenger compartment, as it will contaminate it, not to mention causing difficulties when removing the device.

A little about security

In conclusion of this story, I would like to say that in no case should we forget that the HiJack is one of the most traumatic off-road equipment and when working with it, it is necessary to strictly observe the safety rules and regulations. Somehow, it is necessary to work with it in thick gloves, it is forbidden to keep your hands, head and other parts of the body between the rack and the jack handle while lifting or lowering, and you also need to remember that after lifting is completed, the jack handle must be positioned vertically (parallel to the plane of the rack ).

That's all, good luck to you and your car off-road!

Application area

A rack and pinion jack is a multifunctional device, because a vehicle can be lifted in four ways. In addition, the device can replace a winch, clamp and even a press. Let's consider all the options for using the tool in more detail.

Lifting the machine by the power parts

Place the jack on a solid surface before lifting the machine.

Jacking up a car by reinforced protruding elements such as sills and bumpers is, of course, the most obvious way to use a rack and pinion “comrade”. So, you can get the vehicle out of a deep and muddy rut or lift the front of the car, thereby simplifying the winch’s task.

Wheel lift

If your car is not equipped with reinforced structures, then a special accessory called Lift Mate, which is often included with the lift, will help you pull it out of any substance. This device is put on the “beak” of the lift and clings to the wheel rim with hooks hanging on rag slings. After this, the ascent is performed.

Special slings are used to lift the car by the wheel.

Helpful Hint: If the Lift Mate was not originally included with the jack, it can be purchased separately. In this case, you should give preference to accessories with rubberized hooks.

Jacking up the bumper

The device is suitable for almost all metal bumpers, under which it is impossible to install a jack “beak”

There are situations when to replace a damaged wheel you need to lift the car by the bumper. But what to do if the latter is not able to withstand the weight of the car. In this case, another additional device will help you out - Bumper Lift. This device is a chain sling with an attachment to the “beak” of the jack and one powerful hook that can be used to grab the power elements under the bumper (frame, axles, etc.).

Helpful Hint: When purchasing a Bumper Lift, pay attention to its maximum load capacity.

Jack as a winch replacement

As noted earlier, the operation of rack and pinion tools is not limited to lifting vehicles and other heavy loads. Hi Jack can also be used as a hand winch. Sometimes, in order to free your “iron horse” from snow or mud captivity, you need to move it less than half a meter. And the capabilities of a rack and pinion jack are quite enough to solve such problems. Moreover, the lift can be placed in the most convenient place, in front or behind the car, and then push or pull the car in the desired direction.

Load capacity

When deciding which jack to choose, it is worth considering one of the main parameters - load capacity. Each model is designed for a certain weight, exceeding which is undesirable.

When choosing a jack for an ordinary class C passenger car weighing no more than 1200 kg, take the equipment’s load capacity at 1500-2000 kg. For a small car weighing up to a ton, a device with a carrying capacity of 1.2-1.5 tons is not recommended. It is not recommended to take a larger “reserve” - it is unlikely to be useful for such a car, and the cost will increase noticeably (and the dimensions will be larger).

Large vehicles (classes D, E and F, SUVs, trucks) require models designed to carry more weight. For a large passenger car, sedan, hatchback or crossover, the weight of which reaches 2 tons, choose a jack for 2.5-4 tons. For freight transport, equipment designed for 10-30 tons is selected, taking into account the weight of the vehicle itself and the cargo transported in the body.