Scope and purpose

Today, this is one of the most promising types of transport, which is practically indispensable for large cargo flows. In addition, a belt conveyor is an essential part of any heavy or light production. It is used in metallurgy, for transporting bulk materials, in the food industry, medicine and so on. The operating principle and device are practically the same in all cases. Differences may lie in the type of belt, its load capacity and flexibility, as well as drive power. In most cases, this type of conveyor makes it possible to partially automate production and reduce the amount of manual labor. Taking this into account, the transported vehicles in question are subject to strict requirements. Much of this relates to the strength, performance and interchangeability of the worn belt. The units are capable of operating in a temperature range from -50 to +45, which is determined by the technical characteristics of the supporting body.

Operation and design of a belt conveyor

The belt is the working part of the conveyor; it is pre-tensioned and connected. It is driven by friction between the belt and the drive drum. Moreover, the determining factor is the friction force due to which the load-carrying and traction body moves. To avoid deflection of the belt along the length of the conveyor, roller supports are installed, on which it rests during movement. As you can see, the device of the unit is quite simple. An interesting point is the speed of replacing worn out tape. This is done as follows: during the operation of the conveyor, at the junction point, the load-carrying organ is steamed and a new tape is attached to it, by riveting or vulcanization. After the drive drum has completed a full cycle, the other end is secured. This approach is good because there is practically no equipment downtime during operation, since installation is carried out in a few minutes, although much depends on the type of traction element. Brushes are installed to clean the belt, and centering rollers are used to avoid skewing. The design of the belt conveyor is such that the unit can be used in many industries. Now let's move on.

Benefits of using a belt conveyor

Let's look at the main advantages that this unit has. The main advantage of a belt conveyor is that it can be used to transport goods over a very long distance. In some cases, the length of the load-carrying organ can reach 3-5 kilometers. No other pipeline can be this long. This is due to the heavy weight, complex design and, most importantly, the high cost of the equipment. In the case of a belt conveyor there are no problems. Another undeniable advantage is high performance. Sometimes the speed can reach 6-10 m/s, with a belt width of 2.4-3.0 meters. In this case, productivity can exceed 20-30 thousand tons per hour. In addition, the belt conveyor is a universal transport line. This is due to the fact that a wide variety of loads can be moved. Another important advantage is the ability to move loads in an inclined position. As the angle and duration of the conveyor increases, its speed decreases.

Scraper conveyor

The scraper belt conveyor is similar in principle to a roller conveyor. This type of transporting devices speeds up the movement of cargo due to limiting scrapers, which have different shapes: round, trapezoidal, rectangular.

The standard version from ALB Group is a belt with rectangular scrapers and a corrugated side. It receives the hot pellets just coming out of the granulator and transfers the pellets to the cooling column

. The conveyor mechanics allow you to carefully transport the load without crushing it.

Usually the device is made according to customer requirements: with European polyurethane tape or Russian BKNL tape with metal scrapers; with open or closed housing. Productivity varies from 3 to 6 tons per hour.

Disadvantages of belt conveyors

It is worth saying that there are also significant drawbacks that limit the scope of application of transport devices of this type. The main disadvantage is the high price of the tape and rollers. In most cases, the traction and load-carrying body costs approximately 30% of the total cost of the installation, which is not a small amount. Although here a lot depends on the purpose, as well as technical characteristics (material, number of layers, etc.). Another disadvantage is that the conveyor belt drum moves the belt using friction. This limits the lift angle so it cannot exceed 20 degrees. In addition, it is quite problematic to move dusty loads, which during movement can partially evaporate and crumble. It is difficult to work at temperatures that are too low, as well as at temperatures that are too high. Thermal exposure will change the characteristics of the flexible tape and also lead to destruction.

Operation of Belt Conveyors

As noted above, the LC can operate at high speeds. This makes the belt conveyor more productive compared to other conveying units. The main feature of operation is that it is possible to create complex routes. For example, you can make a complex route with bends, horizontal and inclined sections. Even under difficult operating conditions (temperature changes, high dust levels, etc.), the belt conveyor ensures reliable operation without failures. In most cases, with proper maintenance, you can clearly predict the period of failure of the traction element. This allows you to operate the device without downtime. To date, a huge number of drives have been developed that ensure the operation of the LC. As the length increases, several motors are installed to ensure normal operation. When one drive exits, the second one will work. In this case, although productivity will decrease, there will be no downtime.

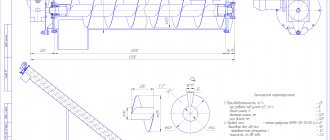

Noria

A bucket belt elevator, or elevator, is a vertically installed closed belt with buckets along its entire length. The buckets continuously move in a circular motion up and down: they pick up loose loads at the bottom, lift them to the top and, turning over the head, pour the contents into the receiving hopper. You can read more about this device in our article on grain elevators.

Norias are installed on the pellet/mixed feed line when it is necessary to deliver the load vertically to a greater height. In most cases, elevators are used to move finished granules from a cooling column into a filling dispenser container.

Features of elevators from ALB Group

:

- The modular design of elevators from ALB Group allows them to be easily modified to suit the Customer’s conditions.

- Buckets are made of ST-3 steel, but they can also be made of stainless or galvanized steel.

- A BCNL tape or a food belt with plastic or metal buckets to choose from is installed.

- Optional installation of a tape derailment control device (UKSL).

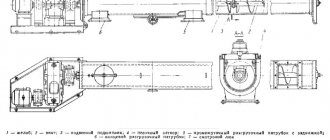

Device and design of the tension and drive station

The belt conveyor drive consists of a motor, a gearbox and several couplings. In places of bending, roller or deflecting batteries are installed, creating a smooth transition. The entire structure, together with the drive, is mounted on a foundation that must be laid first. The drive station consists of a drive, as well as a loading box, and the part where the tensioning device and loading funnel are located is called the tensioning station. Between these two stations there is the middle part of the conveyor; it is made of several linear sections. The latter consist of identical linear sections connected to each other by bolts. Now let's talk about what types of conveyor belts there are and what their fundamental differences are. There are several interesting points here.

DIY belt conveyor drawings

One of the main goals of business is saving on costs. How can you save money on purchasing a conveyor belt? Can you do it yourself? Let's calculate how much it will cost to make a conveyor with your own hands. Let's look at an example of manufacturing a grooved belt conveyor 5 meters long and 500 mm wide in Nizhny Novgorod. What does a conveyor belt consist of?

Belt conveyor frame (2 bent profiles 5 m long), including hardware (let them be 3 kg). Conveyor roller supports (6 pcs) and conveyor support rollers (4 pcs). Drive and tension stations of the belt conveyor (including drive and tension drums). Conveyor belt 11 m long and connecting lock. Geared motor (let it be NMRV 063, 0.75 kW, 380V), 380V starter and 2 meters of VVG 4x1.5 cable. Now let's calculate the cost of materials and components for the conveyor belt.

The situation with roller supports is not simple - to manufacture the load-bearing support of a belt conveyor, at least 2 rollers are required, consisting of a pipe, a bearing axle and a bearing insert. To fix the axle in the roller support bracket, it is possible to use a screw fastening, which requires turning, or the use of a hexagon. In addition, there is no structural steel on the metal rolling market in Nizhny Novgorod; in order to buy it, you need to make a lot of effort. As for the frame of the roller support, its production requires 4 bent brackets, cut using laser cutting and a piece of rectangular pipe. If we add up the cost of all materials, the roller bearings will cost approximately 21,000 rubles. The cost of the material for the deflector rollers will be 4,000 rubles.

The conveyor frame can be made from either a channel or a bent profile, but in any case, you are unlikely to spend less than 9,000 rubles on its manufacture. In addition, the conveyor needs to be assembled and painted (operations cost 3,000 rubles). The cost of hardware will be approximately 1000 rubles.

Now all that remains is to add up all the numbers. What do we see? The resulting cost of materials and components for the manufacture of a grooved belt conveyor will be 113,000 rubles. It was possible to add to this figure the time costs for production, the work itself, delivery, etc. But is it worth it?

It’s easier to order this belt conveyor (LZh 5000/500) from us for 107 thousand rubles or seek advice on choosing suitable conveyor equipment.

Source

Classification of belt conveyors

There are some signs according to which these devices can be divided into several groups:

- by area of application: there are general purpose, special and underground (transportation of people, rolling, and also mobile);

- according to the shape of the route: simple (with a straight section), complex (with an inclined broken route), as well as curvilinear or spatial (bending in the plane of the load-carrying body);

- in the direction of movement of the load: lifting and lowering;

- according to the shape of the belt and the placement of the load: there are flat and grooved belts in various modifications;

- by the angle of inclination of the route: horizontal, inclined, steeply inclined (angle more than 22 degrees) and vertical.

It is worth understanding that, in addition to this, the belt conveyor scheme involves the use of various traction and load-carrying organs. Tapes can be rubber-fabric, rubber-rope, wire, or steel. The type of tape is selected based on the conditions under which it will work. For example, steel traction elements are used to work at high temperatures (up to 850 degrees), just like wire ones, which can transport loads at an operating temperature of 1100 degrees Celsius.

How to make a conveyor belt with your own hands

The idea of creating a conveyor belt with your own hands

- a completely realizable idea that can be operational and effective, but under one condition: you need to know the features of this type of conveyors, their vulnerabilities and the subtleties of setting operating modes. As it turns out, the most difficult processes are the processes of debugging speeds and features of the belt profile.

Mine conveyors

Separately, a few words need to be said about transport devices operating underground. It is noteworthy that the layout of this type of belt conveyor is somewhat different. The degree of reliability increases several times. This is due to the fact that the load-carrying body is used to transport people, as well as heavy piece goods, and all this is done in cramped conditions. The drive, for example, has two tension drums, which makes the device not only more powerful, but also ensures sufficient reliability.