Screw screw conveyor design

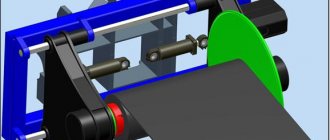

The main unit and working body of the screw conveyor is a screw auger. The second important element is the body, which prevents the transported cargo from falling apart.

The screw conveyor consists of the following parts:

- a receiving compartment in which the transported material accumulates;

- unit body - closed pipe or open half-pipe;

- working auger;

- drive motor that runs on electricity;

- transmission (V-belt or gear);

- outlet pipe section.

Propeller blades are often made from sheet steel. In some cases, cast iron is used to move abrasive substances. The blades are mounted on a central shaft; it is made from a profile pipe. At the ends, the shaft rests on rolling bearings, covered with seals from the penetration of dust and abrasives. If the conveyor is long, intermediate support bearings are installed to protect the shaft from sagging.

The gutter is welded from sheet steel segments. The seams between the segments serve as additional rigid ribs, increasing the geometric stability of the entire structure. A gap of half a centimeter to a centimeter is left between the walls of the vertical screw conveyor pipe and the blades to reduce rotational resistance.

The required pipe sections are placed at the inlet and outlet ends of the pipe. They are equipped with valves.

Advantages of screw conveyors

The screw has become widespread in industry due to a number of advantages that will help speed up and modernize production:

- the closed transport housing allows maintaining high tightness of the system;

- the auger is suitable for hot, dusty and toxic materials;

- on the outside, all moving elements are protected by the housing;

- such a conveyor is more compact and easy to use compared to belt and plate devices;

- it is safer to operate and easier to maintain.

Small and dusty cargo is completely stored inside the housing, which minimizes product losses. Inclined units will help save space, because they require less space with the same length (compared to horizontal conveyors). Screw conveyors consist of separate parts and are connected to each other by flange connections. In this way you can easily change the length of the conveyor. Stainless steel, from which all parts of the units are made, prevents oxidation of the transported product.

The compact dimensions of the mechanisms make them possible to integrate into various types of production.

Working principle of a screw pump

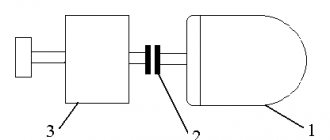

The schematic diagram of a screw pump is shown in the figure.

Auger 3 is installed in a housing (or open tray) and allows liquid to be pumped from reservoir 5 to reservoir 4. The auger is driven by an electric motor 1 with a gearbox 2. Due to frictional forces, the blades entrain liquid particles, moving them along the axis of rotation.

What is an auger?

An auger is a shaft with fixed blades, which are a helical or helical surface. A rotating auger is capable of moving various materials and substances along its axis:

- liquid, including contaminated

- bulk materials

- powdery materials

- pulp

- snow

- cement mortars

- doughy materials

In a pump, the auger is a working element with helicoidal blades that supplies the energy supplied from the drive motor to the fluid flow.

Number of auger passes

The screw can be single-start or multi-start. The number of entries on the auger is determined by the number of escaping turns at the end of the screw.

Increasing the number of passes makes it possible to increase the rigidity of the screw and reduce feed pulsation, but at the same time the distance between the blades decreases, which increases the likelihood of jamming when pumping a mixture with large mechanical inclusions. An auger with three entries is considered optimal.

Advantages of auger pump

- Large flow sections, as a result, the ability to pump contaminated liquids and pulp.

- Ability to work with highly viscous liquids and mixtures.

- Relatively high efficiency - from 60 to 80%.

For this reason, screw pumps are used to pump liquid to a small height. If it is necessary to pump liquid to a height of more than 5 meters, two-stage pumping units are used.

Scope of application of screw conveyors

- Screw conveyors are often used in the food industry, such as bakeries, elevators, flour mills, enterprises that produce various types of cereals, pasta, breakfast cereal mixtures.

- Screw conveyors are used in the production of building materials, construction dry mixtures, in mining and engineering, as well as chemical enterprises. Wherever you need to move sand, sawdust, coal, and other bulk materials.

- In agriculture, these units are necessary for moving material intended for sowing and harvesting grain, transporting dry fertilizers, feed and mixtures for feeding birds and animals.

Classification

As previously noted, there are a variety of types of screws; the scope of application largely depends on the shape and other characteristics. The main features of the classification include the following points:

- Gutter slope.

- Spiral direction.

- Step Variability.

- Shaft diameter.

- Design versions.

All types of products are characterized by their own specific characteristics. Some types of augers are very widespread, others are installed much less frequently. An example is a reverse screw, which has a special direction of turns.

Noria

A bucket belt elevator, or elevator, is a vertically installed closed belt with buckets along its entire length. The buckets continuously move in a circular motion up and down: they pick up loose loads at the bottom, lift them to the top and, turning over the head, pour the contents into the receiving hopper. You can read more about this device in our article on grain elevators.

Norias are installed on the pellet/mixed feed line when it is necessary to deliver the load vertically to a greater height. In most cases, elevators are used to move finished granules from the cooling column to the filling dispenser container.

Features of elevators from ALB Group

- The modular design of elevators from ALB Group allows them to be easily modified to suit the Customer’s conditions.

- Buckets are made of ST-3 steel, but they can also be made of stainless or galvanized steel.

- A BCNL tape or a food belt with plastic or metal buckets to choose from is installed.

- Optional installation of a tape derailment control device (UKSL).

Types of conveyors

There are several main types of conveyors: belt conveyors, apron conveyors, scraper conveyors, chain conveyors, overhead conveyors, screw conveyors, roller conveyors, inertial conveyors, oscillating conveyors, vibrating conveyors. Let's consider what these types of conveyors are intended for.

Perhaps the most common type of conveyor is the belt conveyor, designed to move bulk, lump and piece goods over both short and long distances. In the design of a belt conveyor, the traction and load-carrying element is a belt moving along stationary roller supports. The belt is tensioned using drive and tension drums. The main advantages of belt conveyors are high reliability and productivity from several tons per hour to several thousand tons per hour.

Plate conveyors are designed to move piece goods (from 0.5 kg to 500 kg or more) and large lumpy goods in a horizontal plane or with a slight slope. The advantage of the apron conveyor is the ability to transport loads with sharp edges and loads heated to high temperatures. Also, plate conveyors are widely used in the food industry.

Scraper conveyors are another type of conveyor designed to move bulk or lumpy cargo along a chute or pipe using moving scrapers. However, the use of scraper conveyors is limited due to the rapid wear of scrapers and chutes, as well as the high energy consumption to overcome the resistance of the material. A type of scraper conveyors are conveyors with submerged scrapers. With such conveyors, the scrapers cover only part of the chute, while the load fills the entire chute or most of it. Such conveyors are most often used to move small bulk goods in horizontal, vertical or inclined directions.

Another extremely common type of conveyor is chain conveyors or, as they are scientifically called, conveyors with carrying and driving chains. Such conveyors do not have a load-carrying body. In such conveyors, loads are installed directly on the chain. Chain conveyors are designed to move heavy, bulky or hot loads. A type of chain conveyor is a trolley conveyor. In such a conveyor, the carts are connected to each other by a traction chain and move along a closed track.

Overhead conveyors are designed to move piece goods, often along a closed route. Among the overhead conveyors there are load-carrying, pulling and pushing ones.

Another extremely common type of conveyor is the screw conveyor. Screw conveyors are designed to move dusty and small-piece cargo in a horizontal or inclined plane with an inclination angle of up to 20 degrees. As in scraper conveyors, the blades and chute of a screw conveyor quickly wear out, the cargo is crushed, and a large amount of energy is spent on its transportation.

Roller conveyors are designed to move piece goods that have a flat, cylindrical or ribbed surface. Rollers can be either driven or non-driven. Conveyors with non-driven rollers (gravity) have a slope of 2-5 degrees; on such conveyors, the load moves under the influence of gravity.

Another type of conveyor that combines two subtypes is inertial conveyors. Inertial conveyors are designed for transporting bulk or small-piece cargo over short distances. The media of inertial conveyors are divided into: swinging conveyors and vibrating conveyors. The former are characterized by large amplitudes and low frequency of oscillations, the latter, on the contrary, by large frequency and small amplitude.

ALPHA ENGINEERING company offers the following types of conveyors:

- chain conveyors;

- plate conveyors;

- belt conveyors;

- conveyors on a modular belt;

- air conveyors;

- roller conveyors;

- conveyors for special applications.

For more than 15 years, our company has been producing reliable and productive conveyors for various industries. Contact our company and we will select for you the type of conveyor that best suits your needs.

Types of Screw Conveyor

It is necessary to design a screw conveyor taking into account its types and purpose.

Screw conveyors are of a closed type (body ─ pipe) and open type (body ─ chute).

In a closed type conveyor, the auger is mounted in a sealed pipe. At the beginning of the line there is a receiving tray, which is equipped with a lid. The hole at the opposite end of the line is a discharge pipe, which is closed with a valve. Such conveyors are waterproof and airtight, have high productivity and speed of product movement. They are used indoors and outdoors for transporting dusty cargo.

Types of cylindrical conveyors (closed type)

The cylindrical screw conveyor is one of the most common. Its tube-shaped body is rigid, and the unit itself is compact and easy to use. It is suitable for almost all industries. Let's pay attention to its features and additional functions:

- Conveyors are straight, with adjustable angle, and vertical.

- Stationary or mobile.

- Housing and screw material ─ stainless or galvanized steel.

- Equipped with dispensers.

- Speed adjustment and reverse rotation of the auger are possible.

An open type conveyor is a chute or half of a pipe within which a screw rotates. The rectangular container can also be an open conveyor body. The mechanism can only be used indoors, as it is not sealed: moisture and dust may enter. It is desirable that the materials being moved are odorless, do not fly apart, and do not create dust during transportation.

Classification of screw conveyors

Screw conveyors differ and are classified according to basic parameters:

- gutter slope

- spiral direction;

- propeller pitch and diameter;

- screw design.

Classification according to the angle of inclination of the gutter. Define horizontal, gently inclined, steeply inclined and vertical conveyors.

The type of auger blades depends on the type of cargo being transported and the performance of the conveyor:

- solid ones are intended for moving bulk (powdery) materials;

- tape ones are suitable for small lumpy materials;

- blades in the form of individual blades are made for transporting materials that are characterized by stickiness and viscosity;

- shaped blades are suitable if it is necessary to mix the material during transportation.

The shape of the screw is selected depending on the type of cargo being transported.

Depending on the type of conveyor and purpose, its blades move materials at a slope (angle of 45°) up to 30 meters, and horizontally at a distance of up to 40-60 meters.

Completed projects

Construction of elevators, grain complexes. Production of elevator equipment.

Installation of screw conveyors

The device should be placed on a level, reliable base to prevent it from falling or being systematically soiled.

A very important stage in preparing the unit for operation is its installation. The installation requirements outlined in the assembly manual must be strictly followed. Such work should be entrusted to qualified assemblers who already have experience in working with under-face mechanisms. Violation of the assembly order, installation dimensions and other errors can lead to the following consequences:

- shocks and vibration when turned on and during operation;

- drop in rotation speed, torque, performance;

- accelerated wear of main parts, frequent repairs;

- reduction in service life.

It is recommended to carry out the assembly and installation of horizontal and vertical screw conveyors in two stages.

The first one is preparatory. within its framework the following operations are performed:

- checking the packaging according to the shipping lists of the manufacturing plant;

- re-preservation of mothballed units and parts;

- initial assembly of large units from individual parts;

- preparation of the installation site, including electrical installation work.

After completing the preparation, you can move on to the main stage, which includes work such as:

- installation of lifting and rigging devices;

- supply of large-unit assemblies to the installation site;

- installation of the unit base;

- installation of other parts with mandatory control of inclination angles and installation dimensions;

- checking the correct assembly, turning the screw manually;

- connecting power supply, setting operating parameters and fine adjustment.

First, a test run is carried out without load. If everything is working normally, the blades do not touch the pipe, no extraneous sounds or impacts are heard, you can test the device under load.

Screw conveyors, screw conveyors.

It is difficult to imagine modern production in which transport and dosing devices would not find a place, which are based on the principle of feeding the product with a rotating spiral screw.

The screw auger has taken a strong place in many industries due to its simple design, compactness and cost-effectiveness. The most popular area is the supply (dosing) of cement and other bulk components of building mixtures. Nowadays augers can be found at all technological stages of cement production, handling and use. Cement augers are a standard design solution for feeding binder from silos into mixing units of concrete plants. It is not surprising that specially designed screw conveyors are now also used to supply concrete.

If we talk about the food industry, then augers can be found in almost all operations of transporting grains, meat, flour, sugar, semi-finished products, additives, up to the selection and disposal of waste. Screws for the food industry are made from stainless steels and technical polymers that do not cause oxidation of the product during transportation. Explosion-proof design allows screw conveyors to be operated in dusty areas.

In the chemical and pharmaceutical industries, screws help transport materials while maintaining a seal and preventing contact with the environment. For dosing chemicals, dispensers are often used, which are also based on the principle of a spiral feed screw.

Special designs of screw feeders are capable of working with materials that have high abrasive properties or have high temperatures during transportation. These design solutions have allowed screws to establish themselves in the most complex and demanding industries: metallurgy, foundries and mining.

Screw manufacturing is a process carried out by a small number of highly specialized companies with many years of experience in the design and manufacture of spiral conveyors. They have an established base of standardized products and additional options that allow them to realize the wishes of any customer. A client who purchases a modern European-made screw conveyor receives a well-thought-out product made from high-quality materials using high-tech equipment and equipped with a durable drive. The technical support service, having a wide range of warehouse items, will select the necessary spare parts and replace wearing parts and assemblies.

We are confident that the range and price we offer will not disappoint the customer who wants to buy a high-quality auger.

| What is your name? (FULL NAME.): * | |

| Company name: * | |

| Your contact phone number: * | |

| Your email address (E-mail): | |

| Note: | |

| * Fields are required | |

Horizontal auger

This type of conveyor consists of a drive (gearbox and electric motor) rotating a screw (the working part of the machine), a drive shaft with turns of the transport screw mounted on it, a chute with a semi-cylindrical bottom, a loading and unloading device.

A bulk load is fed through the holes in the chute cover and slides along the chute when the screw rotates. The joint rotation of the load with the screw is prevented by the force of gravity of the load and its friction against the chute. The chute is unloaded through holes in the bottom equipped with shutters. The auger screw is made with one, two or three threads, with a right or left spiral direction. The surface of the auger screw can be bladed, shaped, belt, solid (used when moving bulk powder, dry fine-grained cargo that is not prone to caking). When moving caking loads, auger screws with a bladed, shaped, or belt surface are used. The auger screw shaft consists of separate sections and can be tubular (fastened together using short connecting rollers inserted at the ends, have less weight) or solid. The screw shaft of the auger lies in the end bearings (fixed in the end walls of the chute) and intermediate bearings (suspended from above on transverse strips mounted on the chute). One of the end bearings is made thrust and installed on the side where the load begins to move. The intermediate bearings have a small diameter and length, as well as a reliable seal to avoid contamination by cargo particles.

Screw feeder

Main article: Screw feeder

Essentially, the feeder is a motor, coupling and gearbox, which is engaged with the working body directly through a gear drive.

How does a screw conveyor work?

Let's look at the design of a screw conveyor, its operating principle and basic parameters. The design of the conveyor body consists of a chute, which is equipped with loading sections. Inside the housing there is a screw (auger) - the main working element. It is rotated by an electric motor. The auger blades grab the load and move it along a line to the outlet pipes. The conveyor screw is a pipe to which the blades are welded.

Operating principle and design of the screw conveyor

The operation of screw conveyors is based on an axial driving force. The screw of the screw conveyor rotates in a closed, stationary chute using an electric motor with a gearbox and two couplings. It is supported by suspension supports: end and intermediate. The body (gutter) consists of sections made of sheet steel. Its thickness varies from 2mm to 6mm depending on the type and purpose of the structure. For sealing, all sections are connected to each other by flanges with bolts and gaskets.

The operation of a horizontal screw conveyor consists of three stages:

- feeding bulk material into the loading hole;

- gradual movement of the load into the unloading hole as the screw rotates;

- unloading.

The conveyor screw slides along the chute and the material moves forward. Sliding bearings are used as supports for the auger. The end thrust bearing absorbs the longitudinal force.

A loading device is used to place the transported material inside the conveyor. This is a hatch in the gutter cover with an inlet pipe that provides a tight seal. The unloading device is the hole in the conveyor chute.

Technical characteristics of the screw conveyor

For each customer, the type of screw conveyor is individually selected according to specific technical characteristics:

- productivity, m3/h;

- screw diameter, mm;

- screw pitch, mm;

- propeller blade thickness, mm;

- screw type;

- maximum transportation length, m, etc.

The layout of the future conveyor and its elements are designed based on the initial data: characteristics of the transported cargo, height and angle of inclination. Also, to select the right type of screw conveyor, you should take into account the direction of movement of the load, the performance of the equipment, and the method of loading materials. The type of conveyor determines how the material is moved: downhill or horizontally. Depending on the type of load and the accepted diameter of the screw, its rotation frequency (rpm) is determined.

Methodology for calculating main indicators

To manufacture screw conveyors, it is necessary to perform a significant amount of design and technological preparation. It includes the production of product drawings, the construction of its kinematic diagram, and the research of engineers.

To calculate a screw conveyor, it is very important to understand the important parameters. This may include:

- Spiral pitch t. depends on specific gravity? of the transported substance, with increasing density the step has to be reduced.

- Shaft rotation speed n. For light loads, the bottom can reach 120 rpm; for dense and viscous loads, the speed must be reduced to 30 rpm.

- Screw diameter d. also decreases with increasing specific gravity and viscosity.

- The gutter filling criterion ?, depending on the density of the material, can range from 15 to 40%.

- C - correction for the elevation angle, for horizontal devices C = 1, for vertical screw conveyors the value is taken from the tables;

The productivity of the screw mechanism is calculated using the formula:

Motor power sufficient for good operation of the conveyor with a given performance capacity is set:

- mass of the shaft with blades;

- weight of the load in the pipe;

- linear speed of movement;

- a number of correction factors for friction.

The entire power is set taking into account the efficiency of the gearbox and with the addition of the standard power reserve required to start a conveyor filled with cargo.

A screw conveyor is a device that transports materials through a chute using a rotating screw.

A screw (screw) conveyor consists of a stationary chute, the lower part of which has the shape of a half-cylinder, closed at the top with a lid. A screw, the lower part of the turns of which is immersed in the transported load, rotates and moves it along the chute. The screw rests on end and intermediate supports. The screw rotates from the drive. The cargo is fed into the casing through the loading hatch. The cargo is unloaded through a special device.

Screw conveyors can move loads not only horizontally, but also along inclined and vertical chutes. Screw conveyors are used for transporting bulk or small-piece cargo that is not compressed into a dense mass and does not lose its quality with minor crushing and abrasion, as well as for transporting dusty, hot or slightly damp cargo. Since the trough of screw conveyors is relatively easy to seal, they also transport chemically hazardous cargo.

In light industry, such conveyors transport crushed tanning agents, dry lime, chemicals, production waste, and also serve for mixing components (in the production of natural and artificial leather).

Advantages and disadvantages

Advantages of screw conveyors : compactness and simplicity of design, complete safety of dusty cargo, low cost, ease of maintenance and the absence of external moving parts.

Disadvantages: high power consumption, short transportation length, partial crushing of the cargo, increased wear of the chute and screw, which is explained by the constant mixing of the cargo. Wear is especially intense when transporting abrasive loads.

Essential elements

The screw is the most important and responsible element of the conveyor, as it receives the force from the drive and transmits movement to the transported load.

Screws can be of several types: solid, tape, bladed and shaped.

The most common are solid screws, which are assembled from sections stamped from sheet steel 2...5 mm thick and welded to a hollow shaft made of pipe. Since a screw conveyor can be up to 50 m long, the screws must be supported at several points. To do this, after 2...3 m the helical line is interrupted and intermediate axles resting on bearings are installed between the screw sections. Solid screws are used when transporting dry, powdery, fine-grained and medium-sized materials that do not have the ability to cake.

The helical surface of the band screws is a narrow spiral strip, between the inner edge of which and the shaft there is a gap that allows the load to roll back over the turn, which promotes mixing. Such screws are used when moving lumpy or sticky material and when raking up residues on conveyors operating without a casing. Band screws operating in a casing, due to the significant gap between the band strip and the shaft, cannot create large loads if the space between the groove and the intermediate bearing becomes clogged with sticky material or pieces of cargo.

The disadvantage of band screws is that they need to be manufactured to a larger diameter than the diameter of a solid screw to achieve a given performance.

Bladed propellers consist of blades arranged along a helix. Such screws loosen, mix and move the load.

Shaped screws have cutouts on the outer edge of the screw surface. They are used to move caking materials or combine transport and technological operations (mixing, crushing, wetting, etc.).

To transport abrasive loads, screws made of cast iron sections are used, the bleached surface of which is highly resistant to wear.

Screw pitch = (0.5…1)d, where d is the diameter of the screw.

The lighter the material, the larger the step. The speed of rotation of the screw depends on the abrasive properties, the type of cargo being transported and the diameter of the screw; the smaller the density of the material and the diameter of the screw, the greater it is. For heavy materials, the rotation speed is usually about 50 rpm, and for light materials - up to 150.

The chute of a screw conveyor (conveyor) is made of sheet iron with a thickness of 2...8 mm. The lower part of the gutter has the shape of a half-cylinder, turning into two straight vertical walls. Suspension bearings are mounted on the groove, supporting the middle part of the screw. The chute is closed with a lid, which is made airtight when transporting harmful substances. The cover has holes for loading hatches, hatches for inspection of bearings, screws and the inside of the chute. There are openings for unloading hatches on the bottom of the chute.

The gutter is assembled from a section up to 3 m long, and after the same distance it rests on racks. The width of the groove and the diameter of its lower cylindrical part are 5...10 mm larger than the diameter of the screw. To increase the rigidity of the gutter, it is edged with ribs (corners).

In modern designs of screw conveyors , as a rule, rolling bearings are replaced, which, while protecting their internal cavity from dust and dirt, ensure long-term performance and simplify maintenance and lubrication. The head bearing must absorb the radial load and longitudinal force from the screw, for which a thrust ball bearing and a tapered roller bearing are installed in its design.

The middle hanger bearings must have a minimum width and height so as not to obstruct the passage of the load through the chute. They must be protected from contamination, since they are located inside the chute in close proximity to the transported cargo - a source of dust. To avoid noticeable shaft deflection in conveyors with a small diameter screw (=200...300 mm), the distance between the bearings is taken to be 2...2.5 m, and in conveyors with a large diameter screw - 2.5...3 m.

The tail bearing only supports radial load. It is in better working conditions than the head and middle bearings.

The screw conveyor drive consists of an electric motor and a gearbox, connected both to each other and to the conveyor shaft by elastic and equalizing couplings. The drive is mounted on a frame; the head bearing is usually located on the discharge end of the conveyor so that the screw works in tension rather than compression.

Screw conveyors are loaded using transport units or from bins through transfer pipes.

Conveyors may have several discharge openings covered by flat valves or gates.

Transport pipes

Conveying pipes are a type of screw conveyor . Transport pipes are used to move bulk materials that are not subject to crushing; they are especially suitable for moving cargo while simultaneously performing any technological operation (drying, roasting, cooling, washing, mixing, etc.).

In the leather industry, various conveying pipes are used for liquid treatment of leather.

Transport pipes have a relatively simple and reliable design and ensure the tightness of the transportation process. However, they have large mass and size, as well as high energy consumption. Pipes are horizontal or inclined cylinders supported by two or more pairs of rollers. The pipe is driven into rotation by an open gear transmission connected to the installation drive.

Inside the pipe there can be a one-, two- or three-way helical surface (helix), welded to the cylindrical part of the pipe. The height of the spiral crest in the transport pipe = (0.2…0.3).

There are also pipe designs that do not have an internal helical surface.

When the pipe rotates, the load deviates slightly from the central position in the direction of its rotation and falls down and forward along the resulting inclined plane. In transport pipes with an internal helical surface, the load moves for each revolution a distance equal to the pitch of the spiral. The pitch of the helical spiral is usually taken equal to 1/2d, and the fill factor of the pipe section is taken into account, taking into account the decrease in productivity when the pipe is located with an upward slope.

Screw conveyors for piece goods

Screw conveyors for piece goods are an open helical surface, along the depressions of which, as it rotates, the transported cargo moves.

Conveyors are divided into two types: single-screw overhead for light loads and double-screw floor-mounted for heavy loads.

Single-screw conveyors for transmitting light piece goods over short distances (2...4 m) horizontally consist of an electric motor with a built-in gearbox (geared motor), a coupling connecting the output shaft of the gearbox with a screw, the end of which rests on the tail bearing.

The screw is usually made from a pipe with a diameter of about 100 mm, to the surface of which screw turns of round wire with a diameter of 8...10 mm are welded. The conveyor is mounted on a metal structure, which is suspended from the ceiling or mounted on the floor.

The load is hung on a screw in special conveyors or on hangers. When it rotates, the loads fall into the groove of the thread and begin to move at the speed of a helix.

To avoid swinging and falling loads, the speed should not exceed 0.3 m/s.

Conveyor productivity, pcs./hour, is limited by the distance between the loads and the difficulty of manually hanging the loads.

Twin screw conveyor

The twin-screw conveyor is designed for transporting piece goods (jute and paper bags with cargo, barrels, boxes, bales in matting or tarpaulin, etc.). A twin-screw conveyor consists of two parallel pipes located at a distance of 200...300 mm from each other, with helical surfaces (ribs), with one pipe having left-hand and the other right-hand direction of turns. Piece loads move along the conveyor when the screw surfaces rotate. The lateral forces that appear when the screw rotates cancel each other out, do not interfere with the movement of the load and cannot throw it off.

A twin-screw conveyor with a length of 15...30 m consists of a section 2.5...3 m long. Each section rests on racks in which bearings are located. The sections are connected by spatial hinges, which allow them to rotate relative to each other by 15 in the horizontal or vertical plane.

The pipes are driven into rotation by an electric motor, which is mounted together with gears on a portable frame and located at one end of the conveyor.

Screw conveyors for piece goods have limited use due to rapid wear of containers (bags, bales, etc.), low productivity and high movement resistance.

Similar

Occupational Health and Safety

In order to avoid malfunctions of equipment and accidents that could damage the safety of property values and the health of personnel, it is necessary to strictly follow the requirements of safety regulations when working with screw-type conveyors:

- constantly check the qualifications of personnel authorized to work on auger equipment;

- equip the mechanism with a fence that prevents access of strangers to the work area;

- when using inclined screw conveyors, its entire projection area must be fenced;

- use personal protective equipment, protective gloves, a respirator (when working with dusty materials), protective glasses, durable special protective clothing and shoes;

- when moving dusty materials, it is necessary to constantly monitor the quality of sealing of all pipe joints in order to prevent the formation of an explosive suspension; moreover, exhaust ventilation must be working in the room;

It is absolutely prohibited to carry out service and repair work without turning off the power to the device.

A screw conveyor is... What is a screw conveyor?

Screw conveyor (a. screw conveyor; n. Schneckeforderer; f. convoyeur a vis, vis transporteuse, couloir helicoidal; i. transportadora de tornillo sin fin, transportador helicoidal, transportador de espiral) - a type of conveyor whose operating principle is based on moving bulk cargo with a rotating auger (screw) along a horizontal or inclined closed chute. Sh. k. - a type of transport. continuous machines. The first attempts to use augers to transport bulk cargo date back to the 16th and 17th centuries. Sh.k. with spiral blades began to be used in industry. conditions in the USA in 1887. Scope of modern. Sh.k. - transportation over short distances of dust- and gas-forming, as well as hot bulk cargoes for enrichment. f-kah. Sh. k. are often performed both transp. and technol. functions - simultaneous movement and mixing of bulk cargo. Sh. k. are also used as feeders in pneumatic and hydraulic loading devices. and other transport installations. Screw conveyor: 1 - electric motor; 2 - gearbox; 3 - gutter; 4 — outboard bearing; 5 - auger; 6 — loading pipe; 7 — unloading pipe. Sh. k. (Fig.) consists of a fixed closed chute, inside of which there is an auger supported by hanging bearings. The load entering through the loading pipe is moved forward by the rotating auger blades along the axis of the chute. Unloading is carried out through a special branch pipes (can be installed at any point along the length of the conveyor). The auger blades are usually made solid (for transporting powder and granular light-bulk cargoes), less often - tape-shaped (for small pieces) and in the form of blades separately mounted on the shaft (for caking cargoes). Screw diameter 100-600 mm, rotation speed 10-50 min-1. The Sh. K. gutter is collected from the dep. sections long 2000-4000 mm and closed with removable lids. Sections of the auger shaft corresponding in length to the sections of the chute are connected using couplings or journals supported by intermediate bearings. The head bearing is designed as a thrust bearing to absorb axial loads. The total length of the roller is up to 60 m, productivity is up to 150 t/h. Advantages of Sh. K.: simplicity of design and small size, low cost, transportation of goods in closed chutes with insignificant. dust formation, safety in operation and maintenance. Disadvantages: high energy consumption, rapid wear of the auger and chute, crumbling and abrasion of the transported cargo. Yu. S. Pukhov. Mountain encyclopedia. - M.: Soviet Encyclopedia. Edited by E. A. Kozlovsky. 1984-1991.

- Auger drilling

- Shokshinskoye field

See what “Screw conveyor” is in other dictionaries:

- screw conveyor - sraigtinis konvejeris statusas T sritis automatika atitikmenys: engl. Archimedean screw; helical conveyor; helical screw conveyor; helicoid conveyor; screw conveyer; screw conveyor; spiral conveyor vok. Archimedesche Schraube, f; Förderschnecke,… … Automatikos terminų žodynas

- screw [screw] conveyor - auger - [https://slovarionline.ru/anglo russkiy slovar neftegazovoy promyishlennosti/] Topics oil and gas industry Synonyms auger EN screw conveyer ... Technical Translator's Guide

- Conveyor - This term has other meanings, see Conveyor (meanings). Not to be confused with Conveyor Manufacturing. Belt conveyor Conveyor (from ... Wikipedia

- Screw conveyor (screw conveyor) - a screw conveyor is a stationary transport device, the working part of which is a screw (screw), which imparts forward movement to the material. Screw conveyors are used for transporting dusty,... ...Encyclopedia of terms, definitions and explanations of building materials

- Screw Conveyor - This term has other meanings, see Auger. A screw conveyor (or screw conveyor, auger) is a transporting device for bulk, small-piece, dusty, powdery materials. The principle of operation of a screw conveyor... ... Wikipedia

- screw conveyor - sraigtinis konvejeris statusas T sritis automatika atitikmenys: engl. Archimedean screw; helical conveyor; helical screw conveyor; helicoid conveyor; screw conveyer; screw conveyor; spiral conveyor vok. Archimedesche Schraube, f; Förderschnecke,… … Automatikos terminų žodynas

- Auger (screw conveyor) - An auger (or screw conveyor) is a transport device for bulk, small-piece, dusty, powdery materials. Augers are used in enterprises producing building materials, in the feed mill, flour milling and chemical industries... ... Wikipedia

- CONVEYORS are mechanical continuous vehicles for moving various goods over short distances. Conveyors of various types are used in all industries for loading, unloading and transporting materials during the production process ... Collier's Encyclopedia

- feed shop - A - layout of the technological equipment of the KOPK 15 feed shop in standard premises; B - diagram (sectional view) of the main feed mixing production line: 1 - feeder tray for silage or haylage; 2, 3, 11, 13, 14, 15 -... ... Agriculture. Large encyclopedic dictionary

- KORMOTSEKH - in the village. X. enterprise, is intended for the preparation of wet multicomponent feed mixtures immediately before feeding them to women. K. object of the feeding area; equipment of its in-line technologies. lines are adapted for blocking with unloading ... Agricultural encyclopedic dictionary

dic.academic.ru

Screw Conveyors

It is not easy to make helical screw conveyors on your own, since this requires the necessary calculations. It is necessary to take into account that there is an inclined or tape version. The production properties include the following:

- To begin with, there is a designation of what qualities the conveyor should have.

- The second step is to calculate the most appropriate indicators.

- After determining the key parameters, the necessary equipment is selected.

The assembly procedure requires specific tools, such as a welding machine and angle grinders. This is due to the fact that it is necessary to work with metal

Much attention is paid to connecting the electric motor

Essential elements

The mechanism under consideration for transporting bulk materials consists of a fairly large number of different elements. The screw conveyor scheme is characterized by the following features:

- As previously noted, screw conveyors move bulk materials. That is why an important design element can be called a screw or auger. It receives force from the drive and transmits force to the material itself. There are quite a large number of different versions of augers: shaped, solid, belt, bladed and others. The performance characteristics of the device largely depend on the shape.

- Solid screws, which are assembled by connecting sections, have become quite widespread. Sheets with a thickness of 2-5 mm are used as the main material. The basis is a hollow shaft.

- The robust screw shaft can withstand a very high degree of impact. That is why it is made up to 50 meters long. However, the required operating conditions can only be ensured by fastening at several points.

- The gutter is represented by a body, which is often made using a metal sheet 2-8 mm thick. As previously noted, the lower part resembles the shape of a half-cylinder. The main parameter can be called the capacity of the structure.

- On the end sides there are special holes intended for installing bearings.

- The gutter is closed with a lid, thereby ensuring the required degree of tightness.

- The main part of the structure can be assembled from several separate sections. The width of the cylindrical part can vary from 5 to 10 meters. The rigidity of the structure can be significantly increased by placing a large number of stiffeners.

- Bearings can also be located in the middle part, which increases the degree of screw fixation. Tail bearings are designed to support radial loads only.

- The drive of a screw conveyor is represented by a combination of a fairly large number of different elements that are designed to change the parameters of rotation and its transmission. The main element is an electric motor, which is connected to a gearbox or a system of pulleys and gears. In most cases, the drive is responsible for reducing the number of revolutions and increasing the transmitted force.

The dimensions of the screw conveyor window are selected depending on what substance will be transported.

Device and design

Modern manufacturers offer many different models of screw conveyors. They all differ in design features and appearance. But the operating principle is the same in all devices. The basis of the mechanism is a spiral type screw, which during operation carries out rotating movements. Thanks to such rotations, the loaded material moves from the starting point to the unloading point.

The unit starts after the electric motor starts. The screw conveyor mechanism itself is equipped with a drive shaft and gearbox. It is these elements that are responsible for transmitting traction forces. The efficiency and speed of movement directly depends on the design features of the screw (variability of pitch, diameter and type). There are shaped, solid, band and bladed propellers.

To equip an enterprise with such equipment, it is necessary to contact specialized companies that design and sell equipment of this type. Experienced specialists will help you choose a specific type of unit, as well as advise on additional questions.

Screw conveyor or screw conveyor: operating features

Even those who are sure that they have no idea what a screw conveyor is are mistaken. Its second name is a screw conveyor, and the principle of operation resembles the operation of a meat grinder. This is where the analogy ends. This is a reliable mechanism, easy to operate and maintain. Thanks to this device, the issue of transporting raw materials at enterprises from the construction and chemical industries to the cereal and fat-and-oil industries has been resolved.

The relatively low cost has made screw conveyors very popular. In order to increase its service life, you need to know the design features, its strengths and weaknesses. Let's talk about them.

Screw conveyor: diagram, classification, features

A screw conveyor is a device for transporting goods. Its working mechanism is a screw. As a result of its rotation (at an angle or horizontally), flour, sand, sawdust, rocks, and chemical materials are moved.

The first conveyors with spiral blades began to be used in industry at the end of the 19th century in the USA. At the same time, references to moving goods using an auger date back to the 16-17th century.

The apparatus is designed to meet the needs of production. However, the basic structure of all conveyors is similar. This is a stationary closed chute, inside of which there is an auger (screw) secured by hanging bearings. It is driven by a motor (usually powered by an electrical network).

To put it simply, the principle of operation of the conveyor looks like this.

Cargo → loading pipe → conveyor chute → auger rotating from the drive → outlet pipe.

Screw conveyors differ in the type of chute inclination.

There are:

- horizontal;

- vertical;

- inclined (up to 45 degrees).

The efficiency of transportation depends on the design of the propeller, its diameter, the direction of the spiral (right or left-handed) and the pitch. Productivity is calculated using the formula. The type of auger is selected according to the type of cargo.

- With a continuous surface. Used when moving dry, fine-grained and powdery products that are not prone to caking.

- With tape, blade and shaped. For moving compacted loads. Paddle and shaped are also used for mixing them.

The lighter the material being moved, the larger the pitch of the screw in the conveyor.

Recommendations for operating the screw conveyor

In order for the operation of the equipment to subsequently bring the expected economic effect, you need to correctly draw up the technical specifications for its production.

Barion LLC designers will take into account all the subtleties of using the conveyor, make correct calculations, and select the optimal material for its manufacture. Most often, stainless or carbon steel is used for screws.

The customer of the equipment approves the technical specifications for the production of the conveyor and the drawing attached to it. Coordinates with the manufacturer the terms of delivery and installation of equipment.

The choice in favor of a screw conveyor is obvious if you know its advantages:

- small sizes;

- simple design;

- tightness when transporting small cargo;

- affordable price;

- ease of maintenance;

- no moving parts outside.

Although these units also have disadvantages, knowing and taking them into account, you can extend the service life of the screw conveyor.

- Significant power consumption;

- short working surface length;

- partial crushing of cargo;

- rapid wear of the auger and the chute itself (especially when transporting abrasive loads).

It is equally important not to neglect scheduled and preventive maintenance of units. To extend the life of conveyors, the most wearable elements are treated with anti-corrosion and anti-static coatings.

Equipment maintenance is trusted to professionals.

barion-ua.com

Varieties

There are different types of screw . They are of a closed type (pipe) or open type (gutter), and can also differ in their length or pipe diameter. They differ in the way the screw rotates, stationary and movable in the direction of rotation, low-speed and high-speed. To correctly select the right type of screw conveyor, you should take into account what materials will need to be moved, the direction, the productivity of the equipment, the distance over which it is planned to move the materials and what will serve as the receiving tray, how the materials will be loaded.

With the help of inclined units, you can save space; compared to horizontal screw conveyors with the same length, inclined conveyors take up much less space. Mobile screw conveyors have a collapsible design, they can be disassembled and transported to another place of work. All parts of the screw unit consist of separate parts, all these parts are connected to each other by flange connections. This allows you to change the length of the conveyor. The use of screw conveyors made of stainless steel in the food industry eliminates the possibility of oxidation of food products.

Closed conveyor

- A closed-type screw unit consists of a sealed pipe in which a screw is mounted. This auger rotates using an electric motor. Such augers can be solid, shaped or belt, it all depends on the type of blades. The blades determine the performance of the conveyor and the type of material to be moved by this equipment. At the end of the device, in its upper part, there is a receiving tray into which bulk materials are thrown. For safety reasons, such a tray must be equipped with a lid. Below at the other end of the conveyor there is another hole, this is the unloading pipe, and it is equipped with a valve. Holes that serve for filling bulk materials can be located at any distance of the conveyor pipe.

- Enclosed screw conveyors are waterproof as well as airtight and are therefore well suited for transporting dusty materials. They can be used both indoors and outdoors. Such equipment has high productivity and speed of movement of materials. The downside is the complexity of maintenance and repair work, because all the main mechanisms are hidden in the pipe.

Open screw conveyor

An open-type screw conveyor consists of a chute or half a pipe; a screw rotates inside the structure. There are also models of open conveyors in the form of a rectangular container. The screw blades of open conveyors, like closed ones, can be solid, shaped or belt; the screw is also driven by an electric motor. Such a conveyor is primarily suitable for indoor use in order to prevent the penetration of moisture, dust or debris into the materials being moved.

Using an open conveyor, it is recommended to move materials that are odorless and will not fly away or create dust during transportation. Unlike closed conveyors, open ones are easy to repair and maintain; all working parts are in a visible place.