This group of mechanisms combines various types of transporting machines in which the movement of materials is carried out by dragging along a chute or pipe. Such a device operates continuously thanks to a closed line of chain or tape on which the scrapers are installed.

Initially, such units were used in coal mines, but subsequently became widespread in many other areas of industry and agriculture. Nowadays, scraper conveyors are used to move so-called bulk cargo: grain, sawdust, coal, sand, etc.

Working principle of a screw conveyor

A conveyor with a screw mechanism operates as follows:

- bulk material enters the storage hopper or directly into the inlet pipe;

- the rotating propeller blades capture portions of the cargo and push it towards the outlet pipe;

- upon reaching the outlet, the load leaves the mechanism through it.

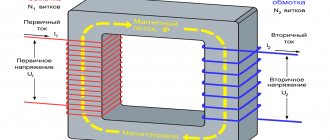

The screw is driven into rotation by a drive device consisting of an electric motor and transmission. On some models designed for work in places where there is no power supply, the conveyor can be equipped with an internal combustion engine. The transmission is a belt drive or gear reducer.

The screw conveyor can be equipped with an electronic control system, the sensors of which monitor the level of the product in the output storage and control the rotation speed of the electric motor and the transport screw, maintaining the level within the specified values.

The conveyor, equipped with a screw mechanism, is designed for long or continuous operation.

Introduction

Integrated mechanization and automation of technological processes, automated control systems based on computers are an important part of technical progress.

A modern mining enterprise is a complex interconnected complex of various production mechanisms, the functioning of which is impossible without the use of modern electric drive control systems. The use of new electric drive systems allows you to increase the productivity of mining machines and mechanisms, reduce capital and operating costs, increase the reliability and efficiency of production processes. The use of new electric drive systems allows you to increase the productivity of mining machines and mechanisms, reduce capital and operating costs, increase the reliability and efficiency of production processes .

Automated electric drive control systems using advances in electronics, converter and microprocessor technology are becoming increasingly used in industry.

We advise you to study - Source of emf. ideal and real sources

This project is devoted to the development of a control system for the electric drive of a conveyor installation using a vector control system, based on frequency conversion of the motor supply voltage, which provides automatic and manual control of the operation of the conveyor installation in normal and emergency modes, protection of the electric drive, automatic setting of the rotation speed of the conveyor installation engine at each moment time, maintaining a given speed with a given accuracy, and also signaling to the dispatcher about violations in the operation of the drive and about the activation of interlocks.

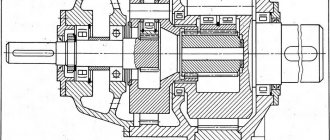

The conveyor drive is designed to transmit the torque of the electric motor to the translational movement of the conveyor belt and consists of an electric motor (1), a gearbox (3) and an elastic coupling connecting them (2).

The operation of the drive is as follows: the switched-on electric motor drives the gearbox through the clutch, on the central shaft of which the drive drum of the conveyor unit is installed.

Application area

Scraper-type conveyors have found very wide application in a wide variety of economic fields.

These are grain processing enterprises, mills, above-silo and under-silage galleries of elevators, feed mills, cereal and oil extraction plants, enterprises processing oilseeds and grain.

Read also: Centerless grinding machine 3m182

In addition, this equipment is used in reception departments of railway and road transport and other enterprises that work with bulk materials that are similar in their physical and mechanical properties to grain.

In short, scraper conveyors are in demand in many areas of both agricultural and industrial production.

Scraper conveyors with high scrapers

There is a scraper conveyor with high elements. The key points of such a mechanism are the following:

In the manufacture of the main structural elements, steel is used, which is capable of withstanding significant mechanical loads. The shape of the gutter can vary significantly, it all depends on the specific application. When creating scrapers, steel is used, the thickness of which is at least 3 mm. In some cases, plastic scrapers are used. Attention is paid to the location of the main elements, since the performance of the device and the load on the drive depend on this. During direct transportation of cargo, the scrapers are located in relation to the main surface at a certain angle.

A similar design is used for transporting various soils. Due to the high scrapers, the productivity of the device is significantly increased.

Conveyor scraper selection criteria

When purchasing chain-type conveyor equipment, you should pay special attention to a number of technical characteristics. One of the most important is performance. This indicator must correspond to the production needs of the enterprise.

You should also consider power settings. Most models operate on 380 V networks, the power in most cases is at least 1.5 kW. This is taken into account when designing the electrical network at an enterprise and calculating the maximum permissible load on the wiring.

The length of the conveyor is selected individually. Before purchasing, you should take measurements at the site and determine the distance between the loading and unloading points of bulk materials.

Scraper conveyors with submerged scrapers

Scraper conveyors with submersible scrapers have become quite widespread. This is due to the fact that they are characterized by increased productivity due to the use of the entire volume of the gutter. The key features of this version include the following:

- The chute consists of two parts, one is intended for the power stroke, the second for the idle stroke.

- The load is filled into the working chute. At the same time, the installed scrapers are characterized by a certain shape, which can significantly increase productivity.

- It is worth considering that the speed of movement of the chain is much less than the speed of movement of the scrapers. In this case, an increase in speed causes an increase in the difference between the two indicators.

The device in question can be used for horizontal and inclined movement of bulk material. The advantage lies in the ability to create a system with a complex trajectory. The disadvantage is the high rate of wear of the main elements, since transportation is carried out by drawing.

Types of conveyors.

First of all, we need to know what exactly and how far we will move. The type of conveyor directly depends on this. There is a reason why trolleys are used in the mining industry. Using a conveyor would be unjustified.

Belt conveyor.

The principle is very simple. Reinforced textile or rubber tape, depending on your technical process, is stretched on rollers secured to the frame. This entire structure is driven by a motor. The belt crawls, the load moves. The heavier the load, the more powerful the engine used. To prevent the load from falling off the belt, the outer rollers are usually made a little higher. The clutch between the conveyor drive and the belt is not rigid. When a certain load threshold is exceeded, the belt will stop moving. You can complicate the task a little. The end point of the conveyor is higher than the start point. There is nothing simpler: we use tape with ribs. In this case, the cargo will not go anywhere.

Using a conveyor belt you can also move bulk cargo. Thanks to this multiple purpose and low price, the belt conveyor is the most sought after on the market.

Plate conveyor.

The apron conveyor is used if the weight of the load is very high, or other similar loads arise. For example, sometimes people come onto the conveyor belt. And of course, such a conveyor is more resistant to wear.

But bulk cargo is not suitable for moving in this type of conveyor. Maximum small-piece products. This type of conveyor is usually already used with a chain. The chain prevents the drive from slipping.

Chain conveyor.

It is much easier for a conveyor drive to engage with a chain than with a ribbed or even smooth belt. But this imposes some restrictions on the conveyor rollers. Or rather, it is no longer rollers that are used, but sprockets. Moreover, the larger the chain, the more complex the sprockets used.

Any load-bearing organ can be attached to the chain: belt, bucket, scraper...

Scraper conveyor.

A distinctive feature of the scraper conveyor is its “inversion”. In conventional conveyors, the working surface is located on top. This conveyor has it at the bottom. It drags loose or small-piece cargo along a stationary surface with its scrapers. Moreover, the supply of cargo can occur at any point on the conveyor.

Overhead conveyor.

An overhead conveyor is a chain that moves along the ceiling from which loads are suspended.

Typically used in production. The convenience is that there is no limit on the load on the floor near the conveyor as in previous cases.

Roller conveyor.

The structure of the roller conveyor is fundamentally different from other conveyors. There is no work surface here. Essentially it's just a set of videos working synchronously.

I think it’s worth writing about roller tables separately.

Screw conveyor.

And finally, let's look at one of the most ancient types of conveyors - screw. Let's look at the drawing.

Doesn't remind you of anything? Yes Yes! The screw of a conventional meat grinder is an example of a screw conveyor from everyday life.

Of course, this can be applied mainly to bulk cargo. This type of conveyor is characterized by extremely high wear resistance and extremely low price. With some precision of the parts, even liquid can be transported in it.

I can only add one thing. If you are thinking about buying a conveyor belt, then you are a successful person.

Topic: Conveyors

Specifications

The technical characteristics of screw conveyors for transporting materials directly depend on the technology by which they are manufactured:

- by casting into the ground or under high pressure,

- casting with additional processing on a lathe,

- hot deformation also with subsequent processing on a lathe,

- cold flexible

- winding

- welding

To understand the technical features of screw conveyors, let's look at them using the example of machines for casting polymer substances. Regardless of the production method, each drill has a feeding zone, a transition zone and a dosing zone.

- Food area. As soon as the polymer enters the screw mechanism, it ends up in this area, which is responsible for receiving and transporting solid materials. In order for the polymer to move as quickly as possible, its friction coefficient at the base of the mechanism must be lower than the friction coefficient at the cylinder walls.

- The transition zone, or compression zone, is the area of the drill where the polymer substance begins to melt. Closer to the base, the area thins out a little, allowing the polymer to stick to the cylinders and eventually completely melt.

- Dosing area. At this section of the drill, the melting of the polymer material is completed.

Scraper conveyor - MiningWiki - mining encyclopedia

Material from MiningWiki - the free mining encyclopedia

Scraper Conveyor

- (English

flight conveyor

) a continuous transport device in which the movement of bulk cargo is carried out along a stationary chute - a pan with the help of scrapers attached to one or more traction chains and immersed in a layer of bulk cargo.

Characteristics of scraper conveyors

- side height—from 100mm

- thickness of the delivered formation—up to 0.8 m

- the angle of incidence of the delivered formation is up to 25º

- length of accumulating workings—50 m or more

https://youtube.com/watch?v=x5aWNXJ1kk8%3F

- becoming

- chain

- scrapers

- gutters

- drive station

- end head

Classification of scraper conveyors

- underground scraper conveyors (for coal and ore mines)

- general purpose scraper conveyors (for the surface of mines and processing plants)

- special scraper conveyors (used in mining transport machines)

according to the nature of the functions performed

- delivery scraper conveyors (transport only)

- modular scraper conveyors (work in conjunction with other extraction units, in addition to transportation they have other functions)

- brake scraper conveyors (coal descent through workings with a large angle of inclination)

by type of drive

- Electrically driven scraper conveyors

- pneumatically driven scraper conveyors

- hydraulically driven scraper conveyors

by type of traction chain

- Scraper conveyors with rollers and bushing chain

- scraper conveyors with collapsible chain

- scraper conveyors with round link chain

by location of the working branch

- scraper conveyors with upper working branch

- scraper conveyors with a lower working branch

- scraper conveyors with two working branches

according to the method of moving the structure

- collapsible scraper conveyors (CP)

- mobile scraper conveyors (SP)

Some safety aspects of working on scraper conveyors

A typical injury for a miner, when he remains fingerless, is associated with work, or rather with a violation of safety regulations when working on scraper conveyors. Tightening the chain of the S-53 conveyor with drive shocks and attempting to insert a chain finger while moving when there is slack leads to traumatic amputation of the phalanx or the entire finger. Do not do that! Don't rely on your dexterity.

Today, a conveyor such as a scraper conveyor is used in various fields of activity. Most often, such equipment is used where the movement of bulk and small-piece cargo is required. Thus, the most common use of this type of conveyor is in chemical production, coal production, agriculture, construction and many other industrial areas where the movement of bulk and small-sized cargo is often required.

Classification[]

According to the area of application, design and parameters, underground belt conveyors are divided into five groups.

- for transport workings adjacent to longwalls with an inclination angle from -3 to +6°.

- for horizontal and slightly inclined workings.

- for slopes up to 18°.

- for Bremsbergs with angles up to 16°.

- for inclined shafts and main slopes with an angle from 3 to 18°.

Quarry belt conveyors (by design) are divided into face, dump, transfer and stationary main ones. In addition, they are an integral part of some quarry units as part of rotary and chain excavators, spoilers, transport and dump bridges, and loaders. Sections of face and dump belt conveyors are mounted on a rail and sleeper grid (the frame is allowed to bend during transverse movement as the face moves). A loading trolley with a receiving funnel and a feeder moves along the rails of the face belt conveyor, and a double-drum unloading trolley moves along the rails of the dump belt conveyor. The rail is also used for gripping by a tractor mover when moving the conveyor transversely. The transfer belt conveyor is installed on trolleys and moves along a rail track in the longitudinal direction. The stationary belt conveyors are assembled on the ground, concrete path or beds, and the drive and tensioning device are mounted on the foundation. In ore quarries, when loading hard rocks with a single-bucket excavator and secondary crushing (mobile crusher) at the face, stationary and mobile type belt conveyors are used for in-pit transportation and lifting (flow technology), and when crushing in a stationary crusher, stationary type belt conveyors are used for lifting (cyclic -flow technology).

The main calculation of a belt conveyor is to determine the width of the belt, its maximum tension and engine power according to the required conveyor performance, length and angle of inclination of the installation. The productivity of a belt conveyor depends mainly on the width of the belt and its speed.

In the mining industry, when lifting coarsely crushed ore from quarries, the productivity of belt conveyors is usually up to 6000 t/h, the belt width is 1600 and 2000 mm, the power of the drive motors is from 1200 to 3000 kW. The length of the conveyor belt in one station ranges from several meters to 10-15 thousand meters. Factors limiting the use of belt conveyors: the permitted size and weight of pieces contained in the bulk cargo being moved depending on the width of the belt, the angle of inclination of the belt conveyor, which (with the exception of special types) for most cargo does not exceed 16-18°. The highest productivity of a belt conveyor (achieved in lignite open-pit mines in Germany with a belt width of 3000 mm and a speed of 6-7 m/s) 30 thousand t/h, the longest conveyor line length (in the phosphate ore transport system in Western Sahara from the quarry to the ocean port ) 100 km, the maximum power of the electric motors of the drive power units is 2000 kW and the total drive power is 12,000 kW. The speed of the belt is 7-8 m/s, and in some cases (on the transport-dump bridge in Germany) 10 m/s. The use of automation ensures smooth start-up of the belt conveyor, the ability to regulate the speed of the belt depending on the size of the incoming cargo flow, automatic monitoring (ultrasonic) of the condition of the roller supports, the integrity of the belt, weighing and recording the amount of cargo moved on the belt, etc.

Modern belt conveyors are distinguished by low maintenance complexity, high operational reliability and occupational safety. The expansion of the volume and scope of application of belt conveyors is associated with further improvement of the design and technological characteristics of installations. The use of intermediate drives for belt conveyors has begun, making it possible to increase the length of the staves and thereby reduce the number of intermediate overloads (or completely eliminate them), reduce the turnover of the belt and increase its service life. Improvement of loading devices, roller supports and support structures of stands, as well as the creation of new special types of belt conveyors (belt-trolley) makes it possible to increase the lumpiness of rock loads moved by conveyors. The use of belts made of frost-resistant rubber, special types of lubricants and new structural materials for drive gears expands the scope of application of belt conveyors to the Far North.

Device of belt conveyors

The designs of conveyors differ significantly depending on their purpose, but in fact they all consist of the following significant parts and assemblies:

- supporting frame;

- motor;

- driving drum;

- tension drum;

- support rollers;

- ribbon;

- control system and auxiliary devices.

The supporting frame is fixed on a fixed or movable base; it serves as the basis of the entire structure. Support rollers are fixed on it, along which the conveyor belt is rolled. It is driven by a driving (or drive) drum. A motor is placed next to it or even on one shaft, driving the entire mechanism. The rotational moment can be transmitted to the drum and from a remote energy source using belt, chain or other transmissions. But such a scheme is used less and less often; it is easier and more effective to place a motor that runs on electricity directly on the frame. the second drum is called the tension drum; it rotates on a shaft, which can move along the frame and creates tension on the belt.

When working with bulk cargo, the conveyor is equipped with sides that prevent it from crumbling.

The design of the belt varies depending on the nature of the goods being transported. To work with bulk materials, ribs are often installed, transverse or at an angle. The ribs are made along with this with tape, then they are called grooved. Corrugation can also be triangular, straight, trapezoidal.

Some items are more often moved on smooth conveyors. The tapes are made from rubberized fabric, specialized wear-resistant plastics, and iron segments.

The working principle of the conveyor belt is very simple:

- the tension drum ensures the tension of the flax and its adhesion to the drive drum;

- the drive drum sets the belt in motion;

- the load is placed or poured onto the working branch at the beginning of the belt;

- it rides on it to the drum and there it is poured into a hopper, removed by workers or machinery, or fed to the next conveyor.

Conveyor productivity is determined by most factors, including:

- motor power;

- belt speed;

- conveyor width;

- slope angle.

Productivity also depends on the nature of the transported material.

Construction of chain conveyors

The main components, or sections, included in the design of the device are as follows:

- Driven. This is the frame on which the drive shaft and drive gear are mounted. The drive is also located here - an electric motor and a gear-type reducer that transmits torque to the drive shaft.

- Tension. This is the end of the frame opposite to the leading one. The driven VAZ and gear are fixed in a special spring-loaded bracket. Its distance from the drive shaft is adjusted using a worm drive. The further the driven shaft moves away from the drive shaft, the higher the chain tension.

- Intermediate. It is a frame section between the drive and tension sections. If the conveyor is long enough, passive support shafts with chain-supporting gears can be installed on it. This avoids chain sagging. The number of support shafts is determined during engineering calculations and construction of the conveyor drawing. In scraper type devices there is no need for support shafts.

- Working body. It's the chain itself. Its links can be forged, welded or assembled, like a bicycle chain. On scraper chain conveyors, shields perpendicular to it are attached to the chain, which, moving through the mass of the product, carry it along with them.

For conveyors operating in hot shops, special steel grades are used; electrical equipment, gearboxes and shaft bearings must also be selected in a heat-resistant design.

The load on a chain conveyor can be placed either from above the working branch, on platforms, containers, etc., or from below - on hooks or magnetic hangers.

Kinds

Currently, several types of screw conveyors are produced, differing in functional features and performance properties. In addition, when classifying drills, the following parameters are taken into account:

- gutter slope,

- spiral direction,

- screw design,

- step variability,

- screw diameter,

- compression ratio,

- type of cargo transported.

Depending on which direction the chute is inclined, the auger can be horizontal, vertical, gently inclined or steeply inclined. According to the design of the propeller, it can be solid, bladed, strip or shaped, and according to the number of power zones - 1, 2 and 3-zone.

When choosing a screw conveyor, most people focus on only one parameter – purpose. According to this parameter, the auger can be:

- dosing,

- mixing,

- barrier

Machines with a dosing screw mechanism are used in the polymer processing process. Their main advantage is their improved design and high performance.

Mixing-type mechanisms are indispensable for thorough mixing of materials, polyethylene production and PVC processing. They differ from the previous type of screws by the presence of a mixing section and high rotation speed.

Barrier screw machines are used for enhanced compression and melting of materials. Their design includes a mixing section, which increases productivity.

Advantages

As noted above, a scraper conveyor can be widely used in various industries, where the production process is associated with the need to constantly move various bulk materials in large volumes. Compared to other types of vehicles, they have several important advantages. First of all, in this case, one should remember the high productivity, because such a device (depending on the modification) is capable of moving up to 300 tons of cargo over a short distance in an hour. The next advantage of the unit is the reliability of its design. Provided you follow the instruction manual and take proper care, it will last a very long time. The vehicle is ready to function uninterruptedly, regardless of the temperature and humidity of the environment, as well as the terrain where it is mounted. There is no need to talk about any significant disadvantages of this type of device.

Distinctive features of conveyors

Scraper conveyors are characterized by a fairly large number of different features. At the same time, the performance of a scraper conveyor can vary over a fairly wide range, it all depends on the type of installed motor and drive. Distinctive features of the design in question include the following:

- The mechanism can be used exclusively for transporting bulk materials that are not subject to wear. It is worth considering that transportation is carried out by drawing.

- The speed of material movement is relatively low. This is due to the fact that when drawing, friction occurs, due to which the speed indicator decreases.

- The weight of the device can be quite high. This is due to the fact that it consists of a fairly large number of different elements that are made of metal. Too much weight makes it difficult to transport and install the structure, since it requires a special base.

- The modern design of the device in question may involve moving the load in a straight line or at an angle. This determines how the mount looks. In some cases, it is possible to adjust the angle of inclination.

The key feature of a scraper conveyor is that it can move a fairly large volume of bulk cargo. At the same time, the likelihood of the load falling out of the device is reduced, since there are special restrictive sides.

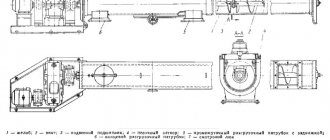

Design and principle of operation

The design of the scraper conveyor is quite simple. In itself, it is a rectangular box, inside of which a chain with scrapers moves in a closed circle (cargo is transported in them from the loading point to the unloading point). It should be noted that, regardless of the type of vehicle and its scope of use, the use of closed metal boxes is provided. The drive is usually mounted on a separate frame. It is mandatory to have guides in the design, the purpose of which is to level out excessive tension in the chain and counteract its sagging.

The basic operating principle of a device such as a scraper conveyor is based on continuous drawing of the product and is associated with the creation of traction force due to a flexible chain. When the motor rotates, the belt pulls special plates or buckets, clinging to the teeth of the sprocket. The product is loaded through bins, the location of which during operation the user can choose independently. As for unloading, a permanently open hole is provided for it, located in the drive section.

Selecting the type of gearbox for the conveyor

Using the peculiarities of the relative position of the primary and secondary shafts in different types of gearboxes, it is possible to achieve the most ergonomic layout of all conveyor or conveyor mechanisms, thereby ensuring not only ease of maintenance, but also workplace safety.

Advantages of the most common types of gearboxes due to design features:

- Cylindrical (with straight or oblique teeth) allows you to install the motor parallel to the axis of the conveyor drive drum.

- Conical is perfect for conveyors where the motor must be installed parallel to the conveyor (perpendicular to the axis of the drive drum).

- The worm, like the bevel, transmits torque at an angle of 90˚, but allows the axis of rotation of the secondary shaft to be shifted significantly higher than the primary one.

Operating principle and main components of a scraper conveyor

The scraper conveyor is a reliable device designed for the continuous movement of powdery, lump and granular bulk cargo.

Among its advantages are:

- possibility of unloading at different points using several outlet valves;

- smaller (in comparison with a belt conveyor) area required for its installation;

- closed design, which makes it dust-, gas- and waterproof.

Such conveyors are used by enterprises of the agro-industrial complex, metallurgical industry, coal industry, etc.

Operating principle of a scraper conveyor

During the product transport process, only one part of the constantly rotating chain is always involved. Along its entire length, at equal distances from each other, scrapers are placed. They push the load towards the tension station, move it along the bottom of the chute and push it out to the place where the material is unloaded. The web then returns to the top through the drive station.

If the scraper conveyor is horizontal, the product layer may exceed the height of the scrapers. This will not prevent the lower and upper layers from forming a single flow, the maximum possible height of which depends on the factors listed below.

- Product density. If the density is high, then the friction between the layers of material will be insignificant and transportation will be faster.

- External friction. This factor depends not only on the properties of the load, but also on the quality of the walls of the gutter.

- Internal friction. The smaller the product particles, the lower this figure.

Consequently, the speed of movement of the material will be lower near the walls of the trench (due to additional contact with them) and higher in the center of the flow. If a vertical scraper conveyor or elevator is used, the weight of the product must also be taken into account.

Main components of a scraper conveyor

The main components of the structure include: a chute, a drive station, a tension station, a complex of scrapers, a stand, and traction chains.

The gutter consists of a bottom, a cover and two side walls. The chain moves in the upper part, and the load moves in the lower part. As a rule, in vertical or inclined conveyor models, a partition is installed between the chain webs. It prevents the downward part from sagging under the pressure of the mass of the contents. The drive station consists of a sprocket (it sets the blade in motion) and two shafts with bearings. The tension station also has a sprocket and rotates due to the movement of the reverse branch of the web. The tensioning device may consist of automatic compression springs or a lead screw. In the first case, a travel switch is additionally used. The scrapers are mounted on traction chains. They immerse the material and move it at a speed of approximately 1 m/s, located at an equal distance from each other. The stave is connected to the tension and drive sections. It is an intermediate sector with a closed traction mechanism located inside. The traction chains of the horizontal conveyor apply pressure only to the lower part of the structure

Therefore, it is important that the links have flat scrapers and move the contents ahead of them along the entire length of the structure. The speed of transportation and its quality depend on this

MHM Ukraine LLC (Odessa) is the official representative of 3BHungaria in Ukraine. At your service: individual selection of equipment, delivery, installation supervision, warranty and post-warranty service.

Advantages of the unit

- Possibility of mixing several components of a substance during transportation. This technology is actively used in light industry.

- The quality of the body allows the conveyor to be used for transporting wet and hot loads without damaging the surface. In addition, the auger can be sealed and used to move hazardous substances.

- The integrity of the material, which is not pressed or caked during movement.

- Unlike belt conveyors, screw models can move contents in both horizontal and vertical directions.

MHM Ukraine LLC (Odessa) is the official representative of 3BHungaria in Ukraine. We provide services for individual selection of the device, its configuration and configuration in accordance with the features of the production process, we provide supervision of installation and commissioning of equipment, warranty and post-warranty service.