When sawing round timber, boards, beams and sleepers of various sizes are obtained. The resulting amount of lumber is called the output. Manufacturers strive to obtain large quantities of product with a minimum of waste. Proper calculation allows you to obtain the highest yield of lumber from round wood on a band sawmill. This can be done using a log cutting map.

Selection of raw materials

Round timber logging

Not only trunks, but also large branches are processed. Roundwood logs are sorted by size and presence of bark. The trunks that have not been sorted are subsequently used for rough work (making scaffolding, etc.). When accepting raw materials from the supplier, not only the cubic capacity is checked, but also the presence of damage, rot, knots - such materials do not meet the technical specifications. Defects in wood reduce the percentage of finished products at the output, and knots can damage equipment.

Before sawing, trunks are often debarked (bark is removed using a special machine) - this process is optional, but is considered economical:

- due to the absence of stuck pebbles and sand in the bark, the saw is protected from premature wear;

- the quality of the chip material improves;

- some enterprises do not accept slabs from unbarked logs for processing;

- the error in results when sorting wood using electronics is reduced.

Scheme of trunk debarking

Frozen wood - how to saw on a band sawmill?

Many operators, especially those who lack the necessary experience, encounter difficulties when sawing frozen wood with bandsaws. It is especially unpleasant if the wood is not completely frozen, and there are unfrozen areas in the log, i.e. different densities. Meanwhile, the problem is being solved.

And yet, how to saw frozen wood on a band sawmill. Much, when sawing with band saws, depends on the correct selection and preparation of the band saw, much depends on the geometry of the tooth.

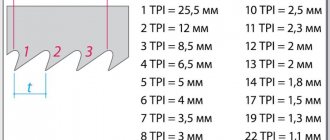

Firstly, saws designed specifically for sawing hard and frozen wood are very effective in this case (for example, Wood-Mizer wood band saws with a 4/32 profile, or saws with a “winter” profile 9/29) Secondly, please note pay attention to the alignment of the tooth. When working with frozen logs, it makes sense to reduce it to 15-18 or even less, to 12-14.

The performance of a band sawmill is usually influenced by an individual combination of various factors, so if this is your first time working with frozen wood, it is advisable to experiment. Using three saws, make three settings: recommended, smaller, and even smaller. Work with all three saws, evaluate the result and then use the optimal layout

Types of wood cutting

Types of wood cutting

First of all, you need to decide on the type of cut - there are several of them. Tangential - the cut goes tangentially to the growth rings, the surface is obtained with patterns in the form of rings and arches. Boards obtained in this way are cheaper, but have high percentages of shrinkage and swelling.

Radial - a cut along the radius, perpendicular to the growth rings, the pattern is uniform, the yield of the board is small, but it is of higher quality and greater strength.

Rustic – carried out at any angle, defects, knots, sapwood, etc. are visible.

Let's start getting acquainted

The band sawmill is a rather complex mechanism consisting of several parts:

- the frame of the sawmill on which all its components are located;

- base for placing the tree in a horizontal position.

In order to start working with this type of sawmill, you first need:

- 1Familiarize yourself with all the main parts of the mechanism and study the principle of their operation.

- Learn how to change the saw and start the device.

- Gain skills in adjusting the position of the tape relative to the horizontal plane. This factor is very important, since the size of the product obtained in the future depends on it.

It is advisable to begin work under the supervision of a person who has extensive experience in performing this procedure.

Cutting methods

For each specific case, a cutting method is selected.

Tumbling is the most economical, almost no waste, high percentage of finished timber. The output is unedged boards and two slabs.

With lumber - first you get a double-edged beam, unedged boards, and two slabs. Then the timber is sawn perpendicular to the cut into edged boards, along the edges two unedged boards and two slabs are obtained.

Methods for cutting wood

Sector - first, the log is sawn into 4–8 sectors, and then each of them into radial or tangential materials. Sometimes several unedged boards are cut in the center.

Break-up-segment - with this type of cutting, two or more unedged boards are cut in the center of the trunk, and edged one-sided boards are sawed from segments on the sides.

Beam-segment - similar to split-segment, only in the middle of the log a two-edged beam is cut, which is then sawn into edged boards. The yield of lumber is high.

Circular - after sawing off one or more unedged boards, the log is rotated 900 and the next boards are sawed off. This method is used when a large log is affected by heart rot in the center. With its help, healthy wood is separated from low-quality wood.

Aggregate - using milling tools and circular saws, along with high-quality lumber, the output is technological chips (instead of slabs and slats). Such complex forest processing allows for rational use of raw materials and labor costs. This results in waste-free production of finished lumber.

How to increase cutting efficiency

In order for the yield of lumber to be significant, it is necessary to use special measures to increase the efficiency of the process:

- The calculation should be carried out only when using special programs; manually it will have low results, and the percentage of defects will be high.

- The round timber must first be sorted so that processing is carried out correctly.

- For cutting it is necessary to use high quality equipment. Otherwise, the amount of waste will be large, and the quality of the resulting lumber will be low.

- It is best to cut wide lumber first; narrow lumber takes longer to process.

- It is not recommended to take long logs.

- Before work, you should set up the equipment.

The yield of finished lumber may vary. It must be remembered that at the first stage boards are obtained, then they are sorted. As a result, the percentage decreases even more; for example, for deciduous trees it can be only 10-20%.

Necessary tool

Necessary tools for cutting

The choice of tools depends on the quantity of planned finished products, their quality and product sizes. Most often, cutting is performed with a circular saw. At certain stages of production, the use of special machines is required.

The circular saw makes precise cuts in any direction, copes well with any size of log, and is suitable for professional and home use.

A chainsaw is used for home use when it is necessary to prepare a small amount of lumber. It's easier to do more difficult jobs with a chainsaw than to buy expensive equipment. All you need for it is a special attachment, a barrel fastener and cutting guides.

Machines for removing bark. They are quite expensive, but with regular use in an enterprise where large volumes of work are performed, they quickly pay for themselves. They are not required to be used, but are desirable because they can provide a number of economic advantages and conveniences in the production process.

You will also need:

- Disc machine – for obtaining unedged output materials from the forest.

- The band sawmill produces high-quality lumber and a low percentage of waste.

- Frame sawmill does not require a foundation and can be installed directly in logging sites.

- Universal machines are capable of producing high-quality material even from low-grade wood.

At enterprises with mass production, to obtain ultra-precise and high-quality products, entire complexes of modern equipment are installed, and sawing of wood is carried out of any complexity.

The way to prosper your sawing business

Wood is a multi-purpose material. Although wood is abundant in Russia, we still need to be sure that we do not waste this valuable natural resource, both when we turn it into lumber, and when we turn lumber into furniture, houses and other useful things.

Remember: only trees of good size should be felled. Your plans should be to cut as much quality lumber from this tree as possible. You try to do this with as little waste as possible, while at the same time wanting to achieve high value and utility from the product you produce. How to do it?

I would like to share with you the experience I have accumulated over decades. I hope this guide will help you become more profitable and cut your losses as much as possible. Turning our valuable, renewable resource into useful and reliable products that will last for centuries - believe me, you can do it.

Sawing technological map

Sawing technology

To calculate the optimal percentage of obtaining finished lumber from logs, a forest sawing map is drawn up. These calculations can be done independently or using a special computer program. Such information can also be obtained in a regular reference book, which contains information on sawmilling operations.

The cutting map allows you to determine how many finished products will be produced and what percentage of waste will be recycled. From these data, you can determine the final cost of the product. The result may largely depend on the type of forest. There are some measures to increase the percentage of lumber yield.

The percentage of lumber at the output is ready-to-use, useful wood. Waste is the raw material for producing MDF, chipboard, and fiberboard. These volumes will depend on the diameter of the tree, the types of solid wood products being manufactured, and the sawing option.

Introduction

I want to say right away that the article is taken from my new book “ORGANIZATION OF SAWMILLING IN A MODERN ENTERPRISE.” This book provides simply unique information about sawmilling and its organization. You definitely won't find this kind of information anywhere.

At one time, German specialists came to us and taught us how to operate equipment and wood processing technology. The cost of a specialist of this class is 2000 euros per day. I am giving away the updated information, taking into account my personal experience, for free. More details about this book can be found in the “MY BOOKS” section in the top menu.

In addition to relevant and interesting literature, I can provide advice on the selection of sawmill equipment, write a business plan, and organize the technological process. After all, I know firsthand that if the organization is not organized correctly, an enterprise sometimes even has to take on additional sawing lines, and this is simply a colossal expense. More details about my services can be found in the “SERVICES” section.

Percentage of round timber

Accurate calculation of each cubic meter of wood - an expensive natural raw material - is important in every woodworking enterprise. Cubic meters of roundwood are calculated in several ways.

Wood table

By volume of transport. Each type of transport has its own forest cubic capacity calculated and determined. For example, a carriage holds 70.5 cubic meters of round wood. Then there will be 22.5 cubic meters of it in three cars. This method of calculation speeds up the acceptance of raw materials, this is especially important when there is a large amount of incoming cargo. But there is a large error in the calculation results in this way.

Calculation based on the volume of one trunk. If the entire logging consists of timber of the same size, then by counting the volume of one, you can count them all and multiply by the cubic capacity of one. This method is more accurate, but requires a lot of time and the involvement of more workers to accept the cargo.

Automated systems with measuring frames. These measurements provide higher percentages of accuracy than those taken by humans. When logs pass through the measuring frame, all thickening and curvature of the trunk and even knots are taken into account. In this case, you can immediately sort the trunks.

A method of calculation by multiplying the volume by a coefficient. The height, width, and length of the stack are measured and multiplied by a coefficient. This calculation is fast, but with a low percentage of accuracy. It is used when it is necessary to urgently determine the number of cubic meters.

Finished product yield ratio

conclusions

- Log sawing can be a profitable business if done wisely and safely.

- Storing logs in a warehouse should be as short as possible.

- Logs must be protected from drying out at the ends.

- Logs must be cut from the worst edge without compensating for the log's taper, or from the best edge, but taking into account the log's taper.

- Logs need to be turned over on the bed every time a different face of the log promises to produce better quality boards than the one you are currently sawing.

Dependence of the final yield percentage on sawing technology

To increase the yield of finished lumber, it is necessary to optimize the sawing process itself. This is especially true when working with workpieces that have curvature, damage or other flaws:

Wood defects

- First, you need to select and put into production only high-quality wood.

- Then select trunks with damage at the ends (rot, cracks) and trim these places.

- If there is a section of trunk with a rotten core, it must be removed and the remaining wood cut into lumber. They will be shorter, but of better quality.

- The circular cutting method is also suitable for obtaining high-quality boards.

- The yield percentage is higher when sawing timber with a larger diameter.

The yield also depends on the quality of the log, the type of wood, and the equipment used. New high-quality, well-tuned equipment allows you to process trunks with almost no losses.

The efficiency of timber cutting can be increased if special measures are taken in advance. To do this, you need to make accurate calculations using digital programs. If you do this manually, the percentage of output defects will be higher. It should be taken into account in advance that coniferous forest species produce a higher percentage of lumber output. Because their trunks are smooth, large, less susceptible to rotting and therefore almost free of defects. A large volume of deciduous trees is often discarded.

For rational use of wood, it is better to take short logs. But in domestic production, trunks with a length of 4 m or more are usually taken for sawing. Due to their curvature, the output results in a large percentage of rejects.

Deciding on lumber size

The width of the first board when cutting on all four sides of the log is critical.

Good quality limit If the sawyer considers that the first board cut can be classified as good quality, then the minimum width of the sawn timber should be 11+1 cm. Why? Because a board of natural moisture must have a width of at least 11 cm. To take into account further processing of the board (trimming on the sides), it is recommended exactly 11 + 1 cm, and not 11 cm, but still it is not recommended to specially produce a lot of this size, because the quantity Narrow boards per lot are limited.

Determination of variety

Since our company is focused on exporting lumber to the USA, there are five main types of hardwood on their market:

FAS, Select, 1 Common, 2 Common and 3 Common. Let us briefly describe these varieties:

FAS means lumber that is at least 85% clean on 4 sides. Clean means without knots, rot, loose core, cracks, wane, stains or other defects. The clean surface should be extensive both along the length and width of the lumber. The size of the lumber in this case is at least 165 mm. x 2.45 m.

Select is essentially the same as FAS, but one face of such lumber can be like grade 1 Common. The size of the lumber in this case is at least 11 cm x 2.15 m.

1 Common - clean from the worst edge by at least 70%. (no more than 1 knot per 1 meter of length). The size of the lumber in this case is at least 11 cm x 1.85 m.

2 Common - clean from the worst side only 50% (no more than 2 knots per 1 meter of length)

3 Common is lumber that, at its worst, is only 33% pure.

Of course, this is only a general description of sorting. In fact, there are rules issued by the American Hardwood Association (NHLA rules) that explain specific cases in detail.

Currently, US buyers are limited to only two varieties -

Select & btr variety . — a mixture of FAS and Select varieties

and grade 1 Common

The rest of the material, of lower grades, is in demand among European buyers.

Cutting wood

Before choosing a tool, you need to decide on the type of cut, focusing on the annual rings of the log. There are several types:

- radial (along the radius);

- tangential (the cut is parallel to one radius and touches the annual rings);

- the fibers are located parallel to the cutting being performed.

Among the cutting methods, the one that is most suitable for a particular case is selected:

- Waddle. Sawing wood in this way is carried out for deciduous trees with a small trunk thickness, and is considered the simplest processing. Output: unedged elements and slabs.

- If you have another forest processing machine, then it is possible to cut up to 65% of the material to produce edged boards of equal width. First, the double-edged timber and boards on the sides are cut, and then a certain amount of edged lumber is obtained from the timber.

- More specific methods are sector and segment sawing. The number of elements in the first method varies from 4 to 8, and depends on the thickness of the trunk. After dividing, elements are cut from each sector along a tangential or radial line. The second method begins with the timber coming out of the central part, and boards are cut from the side segments in a tangential direction.

- For individual cutting of wood, the circular method is suitable. It is based on turning the log along the longitudinal line by 90° after each sawn board. This allows you to monitor the quality of the wood and promptly remove affected areas of the trunk.

Manual work: using a chainsaw

For home cutting of several trunks, it is not advisable to purchase a tool whose cost is several times higher than the price of finished products. If you have the necessary skill, then it is more efficient and cheaper to do all the necessary work with a conventional chainsaw or chain equipment powered by electricity. Of course, such work requires much more physical effort and time, but the cost of the issue is significantly reduced.

Working on a garden plot requires pruning fruit trees, and it also becomes possible to additionally produce material for outbuildings without resorting to the services of specialists, so any thrifty owner will prefer to buy a chainsaw. Most often, coniferous wood is harvested for the home, and this tool does an excellent job of cutting it. Thanks to straight trunks, it is easier to mark cutting lines, which increases the speed of work. Professionals, by the way, most often use a chainsaw, since it is more powerful than an electric one and can be used anywhere, regardless of whether there are power sources at the cutting or cutting site.

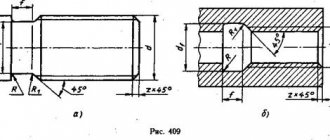

To use a chainsaw to cut logs, you will need a device such as a saw attachment, as well as cutting guides and base-trunk fasteners. The frame-shaped attachment is attached to the tool so that it remains possible to adjust the distance between the chain and the frame itself. This is done to make it possible to produce finished lumber of different thicknesses. For the role of a guide, you can take either a profile of the required length, or a flat wooden plank with sufficient rigidity. A special chain is selected for the tool, designed to cut the trunk lengthwise. Its difference from the others lies in the teeth sharpened at a certain angle.

Before you start work, you need to not only prepare all the necessary tools. Regardless of whether a woodworking machine or a manual device is intended for processing the trunk, the first thing you need to do is familiarize yourself with the cutting map. This is done in order to minimize the percentage of waste and increase the yield of useful products.

The first thing you need to worry about when cutting longitudinally is the uniform density of the finished boards. To do this, a competent sawyer directs the tool from the east side of the log to the west, or in the opposite direction. This is explained by the higher density of round timber in its northern part than in the southern part.

Next, use a chainsaw to remove the slab from both sides so as to obtain a double-edged beam. It, in turn, is sawed in accordance with the cutting pattern chosen at the beginning of the work. The solution is an unedged board. If there is a certain percentage of defects in the trunk, then a circular cut is possible with the trunk turning at a right angle or 180°.

Volume of waste after sawing

In order for the finished board to come out with a high percentage, everything must be prepared correctly, the work must be carried out only in accordance with the technology. Roundwood of coniferous and deciduous species produces different yields. In the latter case, the volume is smaller, even if special additional equipment is used. Needles are considered more convenient for sawing, since their trunk is straight and the log has a larger diameter.

Coniferous forest is not so susceptible to rotting, so there is less waste. For hardwood, 2 cutting technologies are usually used:

- using a band sawmill on Z75, Z63;

- into collapse, when a half-beam is cut out in the core of the material and passed through a multi-saw machine.

The volume of a band sawmill is 40-50%. When using technology for collapse, the yield is different, it can be increased up to 70%, but the costs of such work are higher. If you cut round timber, the length of which is 3 m, you can see that the percentage of scrap is quite large, and the remaining material requires processing. This applies to the bulk with boards 22x105(110, 115)x3000 mm. There are many options for such a marriage. For example, it could be a wormhole, which is no longer suitable for most jobs.

After sorting, the volume of hardwood material, which belongs to grade 0-2, will be only 20-30% of the amount obtained after sawing. This means that of the total mass of harvested round timber, the yield of normal boards will be only 10-20%. The remaining materials are mainly used for firewood. For coniferous round timber, the yield will be different, but attention must be paid to what average values of the resulting volume are observed.